Log in

Search

Latest topics

» Cox films/videos...by Coxfledgling Today at 4:46 am

» Purchased the last of any bult engines from Ken Enya

by Coxfledgling Today at 4:18 am

» My N-1R build log

by roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

Cox Engine of The Month

.018" Phenolic sheet stock

Page 1 of 1

.018" Phenolic sheet stock

.018" Phenolic sheet stock

I have access to a lot of this scrap stock where I work. It occurred to me that it may be useful for my models. It has a rough side and a smooth side.. and is very strong, light and pliable. It seems comparable to 1/64" plywood.. which is .015" thick. I want to try to make a small air-foiled wing using it; by cutting a sheet and forming half chord-wise.. with a spar that doubles as a bellcrank mount. It can be formed into a very small radius without splitting or kinking. The airfoil would be established by the spar and fuse cut-out. The T/E could be secured with thin double-sided film-tape. Two internal ribs at the tips only; would provide for a lead-out arrangement for control-line.

Stay tuned... I will report on progress soon.

Stay tuned... I will report on progress soon.

Re: .018" Phenolic sheet stock

Re: .018" Phenolic sheet stock

I am tuned in.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: .018" Phenolic sheet stock

Re: .018" Phenolic sheet stock

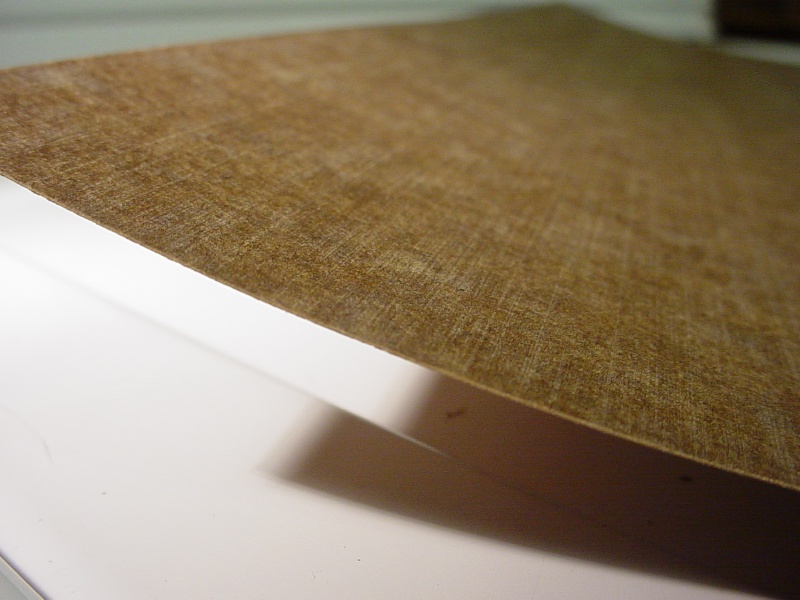

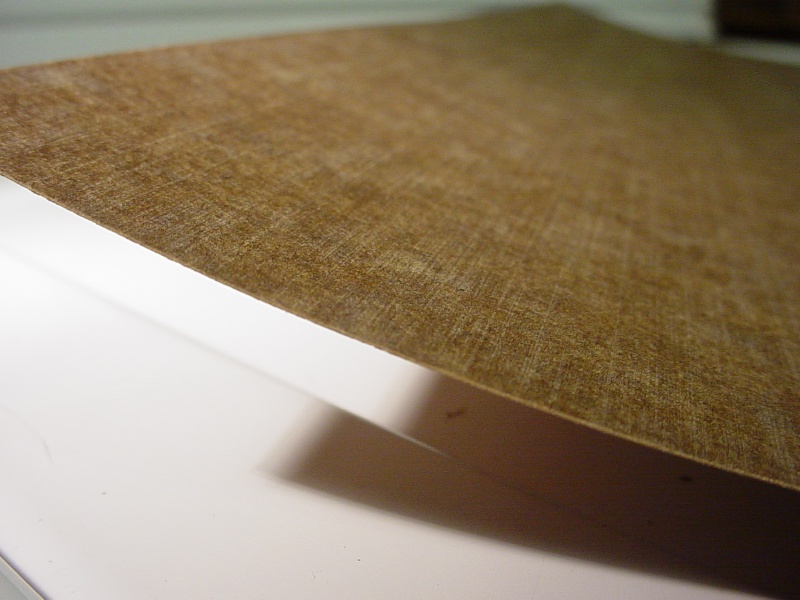

Not really any progress yet.. but I wanted to show some pics of this material.. and share some more design thoughts.

It's quite flexible.. and should be strong enough "alone".. to form a leading edge.

We use this material at work to "skin" gondola frames for paint. It is .018" (.46mm) in thickness and one side is of paint-grade smoothness.

This experiment is in building a small (22" span-110 sq.) monocoque fully symmetrical constant-chord wing.. and I will begin with building a full-span spar, which will adhere to the phenolic sheet and establish the thickness of the airfoil. The spar will be slotted for a bell-crank and pivot pin and will utilize only 3 ribs; a "central" rib for support inside the profile-fuse wing cut-out.. and tip-ribs, with the inboard one containing an adjustable lead-out guide. The outboard end of the spar will have a plastic tube for a weight-box, secured to the backside of the spar and threaded internally at the exposed end for a shortened nylon screw/cap.

For an idea of the weight.. this rolled sheet measures 317 sq. in. (22.25 x 14.25)

That's 3.2 oz. and shows the "smooth" side of the sheet. Since it will require approx. 250 sq. in. to skin a 110 sq. in wing.. I'll have to design the spar as light as possible. It's only function(s) will be to provide a bell-crank mount, establish the thickness of the airfoil and provide an attachment point for the 3 ribs used. Once secured; the phenolic skin should provide all of the strength in this monocoque design. The trailing edge skins will extend 1/2" rearward of the ribs.. and be joined either with thin d/s tape or CA glue. A conventional slot for the pushrod will be cut in the skin.

I figure that if this experiment fails.. (excess weight.. warping.. problems with skin adhesion etc.) I'm not out a whole lot other than my time invested.

It's quite flexible.. and should be strong enough "alone".. to form a leading edge.

We use this material at work to "skin" gondola frames for paint. It is .018" (.46mm) in thickness and one side is of paint-grade smoothness.

This experiment is in building a small (22" span-110 sq.) monocoque fully symmetrical constant-chord wing.. and I will begin with building a full-span spar, which will adhere to the phenolic sheet and establish the thickness of the airfoil. The spar will be slotted for a bell-crank and pivot pin and will utilize only 3 ribs; a "central" rib for support inside the profile-fuse wing cut-out.. and tip-ribs, with the inboard one containing an adjustable lead-out guide. The outboard end of the spar will have a plastic tube for a weight-box, secured to the backside of the spar and threaded internally at the exposed end for a shortened nylon screw/cap.

For an idea of the weight.. this rolled sheet measures 317 sq. in. (22.25 x 14.25)

That's 3.2 oz. and shows the "smooth" side of the sheet. Since it will require approx. 250 sq. in. to skin a 110 sq. in wing.. I'll have to design the spar as light as possible. It's only function(s) will be to provide a bell-crank mount, establish the thickness of the airfoil and provide an attachment point for the 3 ribs used. Once secured; the phenolic skin should provide all of the strength in this monocoque design. The trailing edge skins will extend 1/2" rearward of the ribs.. and be joined either with thin d/s tape or CA glue. A conventional slot for the pushrod will be cut in the skin.

I figure that if this experiment fails.. (excess weight.. warping.. problems with skin adhesion etc.) I'm not out a whole lot other than my time invested.

Re: .018" Phenolic sheet stock

Re: .018" Phenolic sheet stock

I am interested in acquiring some of this material

Do you have enough to slip two or three sheets in large envelope to me

I use a lot of 1/64 ply for elevator doubler and other structural strength on combat planes

Of course I would compensate you appropriatly

Do you have enough to slip two or three sheets in large envelope to me

I use a lot of 1/64 ply for elevator doubler and other structural strength on combat planes

Of course I would compensate you appropriatly

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: .018" Phenolic sheet stock

Re: .018" Phenolic sheet stock

fredvon4 wrote:I am interested in acquiring some of this material

Do you have enough to slip two or three sheets in large envelope to me

I use a lot of 1/64 ply for elevator doubler and other structural strength on combat planes

Of course I would compensate you appropriatly

PM sent

Similar topics

Similar topics» OK Cub Sticker Sheet

» Need Cox Sea Bee instruction sheet

» Cox QRC instruction sheet

» COX RR1 operation instruction sheet

» Sheet Balsa Fighter

» Need Cox Sea Bee instruction sheet

» Cox QRC instruction sheet

» COX RR1 operation instruction sheet

» Sheet Balsa Fighter

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules