Log in

Search

Latest topics

» Cox films/videos...by Coxfledgling Today at 4:46 am

» Purchased the last of any bult engines from Ken Enya

by Coxfledgling Today at 4:18 am

» My N-1R build log

by roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

Cox Engine of The Month

Frog Aerobat

Page 1 of 2

Page 1 of 2 • 1, 2

Frog Aerobat

Frog Aerobat

There I was - quietly building a Frog Aerobat - a vintage kit. I had been watching the "Windy" videos and taking my time with the wings - sanding, shaping to get the neatest fit to the precut fuselage sides possible.

I made templates from the fuselage sides to assist and finally

Not perfect but one of my best attempts.

I made templates from the fuselage sides to assist and finally

Not perfect but one of my best attempts.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Frog Aerobat

Re: Frog Aerobat

I had built the wings first, following the brief instructions, and realised that the pushrod had to be fitted before the centre sheeting.

Also the flaps, I prepared but .........

Then I moved to the fuselage and realised that if I built it - the wings would not slide in. The pushrod would be in the way and the control horns for the flaps.

Also the flaps, I prepared but .........

Then I moved to the fuselage and realised that if I built it - the wings would not slide in. The pushrod would be in the way and the control horns for the flaps.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Frog Aerobat

Re: Frog Aerobat

I have now worked out that I will have to build the formers to the engine bearers first, Make sure that everything is square. Then - attach one fuselage side. Place the flap and slide the wing in. Then fit the other flap through the other fuselage side and slide them both over the wing.

Then attach the hinges.

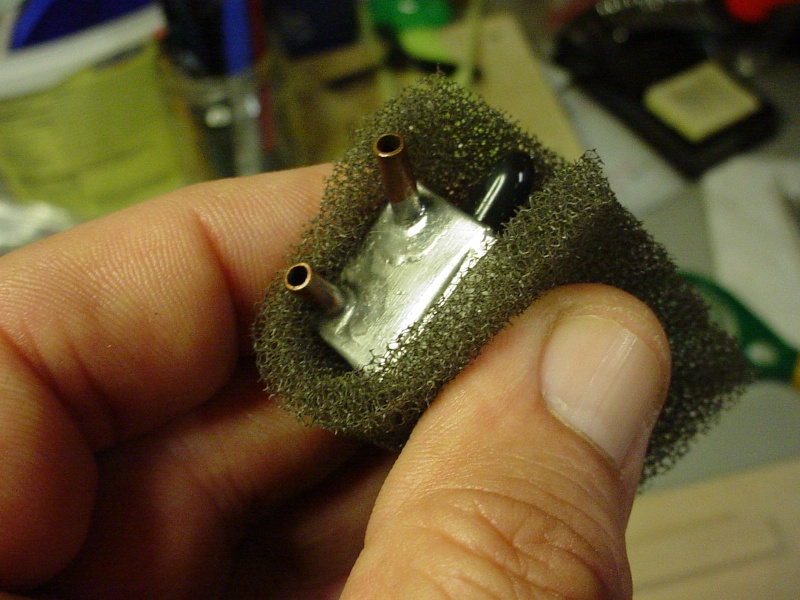

Anyway, this picture is for Roddie. Not neat but I timed this tank construction. 6 mins 46 secs from marking out to finishing. Only two blisters!

Then attach the hinges.

Anyway, this picture is for Roddie. Not neat but I timed this tank construction. 6 mins 46 secs from marking out to finishing. Only two blisters!

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Frog Aerobat

Re: Frog Aerobat

I had to just resign myself to learn to love working around problems like your wing installation. This looks interesting. I'll have to get back to it when I am not on my phone.

Rusty

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Frog Aerobat

Re: Frog Aerobat

Ian, a very common solution to the fuse installation is to cut out the belly of the fuse. There's no need to have it slide from the tip to the center sheeting. You could install the pushrod and flap assembly and then hook the fuse onto the wing so to speak. Glue the belly section back on just back up the joint using some 1/64" ply. I go as far to glass the joints prior to painting or covering. Ken

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: Frog Aerobat

Re: Frog Aerobat

Ken Cook wrote: Ian, a very common solution to the fuse installation is to cut out the belly of the fuse. There's no need to have it slide from the tip to the center sheeting. You could install the pushrod and flap assembly and then hook the fuse onto the wing so to speak. Glue the belly section back on just back up the joint using some 1/64" ply. I go as far to glass the joints prior to painting or covering. Ken

Thanks Ken. I saw this in the Windy videos and wondered why he'd done it. After seeing your post I went back and reviewed.

At first I thought he had made them detachable - which I thought was a good idea for transporting larger models. Do it in RC all the time! The videos can be a little confusing - they are not in an easily followed order and so I got a bit mixed up at times.

It is food for thought. On this model it would definitely have to be bottom entry as you suggest. Top entry would allow for a detachable wing but, in this instance, the engine bearer would be in the way.

We lives and learns!

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Frog Aerobat

Re: Frog Aerobat

One of the drawbacks of building fuselages rather than profile is that the tank is usually inaccessible. I have leaned this the hard way.

On a profile fuselage, you can adjust the position within reason but it is always best to recreate the engine and tank position and test before committing to burying the tank in the fuselage.

Recreate everything. Side mounted engine, tank position, length of fuel line ........ then knock something together that you can waggle about.

See if anything starves the engine, see how long the engine runs for.

Set the engine up as close as you can before mounting in the plane. It is a lot easier to fiddle using an open jig instead of a cowled engine.

On a profile fuselage, you can adjust the position within reason but it is always best to recreate the engine and tank position and test before committing to burying the tank in the fuselage.

Recreate everything. Side mounted engine, tank position, length of fuel line ........ then knock something together that you can waggle about.

See if anything starves the engine, see how long the engine runs for.

Set the engine up as close as you can before mounting in the plane. It is a lot easier to fiddle using an open jig instead of a cowled engine.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Frog Aerobat

Re: Frog Aerobat

Ian,

Nice setup and great build.

I see one flaw in your plan. Even though you have everything setup before installation, you may find it's a whole different ball game once you fly the plane.

If at all possible make a hatch to make the tank accessible. The only way to test for tank height or tank faults is to fly the plane.

At first when just flying level it may run fine, but once inverted or doing eights or overhead stuff you may find the tank position to be incorrect or that the tank itself has issues.

I have only had one tank that worked right out of the box and that was the one Ken Cook went through for me. All others have needed attention from time to time. A hatch is the only way to go.

You could even have a hatch underneath the fuse so it looks cleaner.

Ron

Nice setup and great build.

I see one flaw in your plan. Even though you have everything setup before installation, you may find it's a whole different ball game once you fly the plane.

If at all possible make a hatch to make the tank accessible. The only way to test for tank height or tank faults is to fly the plane.

At first when just flying level it may run fine, but once inverted or doing eights or overhead stuff you may find the tank position to be incorrect or that the tank itself has issues.

I have only had one tank that worked right out of the box and that was the one Ken Cook went through for me. All others have needed attention from time to time. A hatch is the only way to go.

You could even have a hatch underneath the fuse so it looks cleaner.

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Frog Aerobat

Re: Frog Aerobat

ian1954 wrote:

Anyway, this picture is for Roddie. Not neat but I timed this tank construction. 6 mins 46 secs from marking out to finishing. Only two blisters!

Holy crap!!! Were you listening to Barbara Streisand's "Minute Waltz" or something?

This is polyurethane filter media made for "window" type air conditioners.

... and this is a newer type of "shelf-liner" that's sold in rolls.

I don't know how fuel-proof the shelf-liner is... but the filter media is polyurethane and I've used it without any problems with breaking down. Hopefully your tank wont leak.. but don't forget to fuel-proof that entire tank-bay before you seal it up; including the inside of the hatch panel.. (it's easy to forget that piece, where it's not on the model yet..)

Re: Frog Aerobat

Re: Frog Aerobat

That is very good advice and "building in" a tank is a risk which is why I do so much testing.

I remove the board from the workmate with the engine running - with a diesel I don't even bother using the workmate - and really put it through the motions.

I use tanks all the time for testing and running engines. (Just running engines can be boring and so testing tanks as well makes it more interesting!)

The tank you see in the rig is as per the plan supplied with the kit. It was supplied as a sheet of "coated" steel. I had not come across this material before - it had a matt grey finish - but it was easy and true to bend and the solder flowed beautifully.

Unfortunately, there is no provision for a hatch in this fuselage - the tank sits tight between the engine bearer top and bottom - it would also not be possible to alter the height even if there was tank access.

The only thing that I can't test easily is the "centrifugal effect" - the whole essence behind the wedge shape. For this, I keep everything "level" and when the engine coughs I do a spin with up and down motions to see if it comes back to life.

I make many tanks and, more recently, have been exploring "uniflo" rather than just taking it for granted. The tank in the KK Radian is uniflo (that is another story - caused me alot of frustration because of my stupidity (or was it a memory issue?)).

I build tanks for a couple of vintage combat flyers (they, like me, are vintage as well as the models) in the north of England but these, although simple tanks, are difficult to build. They send me a cross section of the wing and I make the tank to fit inside and match the profile of the wing. The wedge is at the back of the tank but rounded. The filler and the overflow pipe are at the peak of the profile and the feed pipe bottom front exit to the far rear corner. I don't understand how this works when they are battling overhead as the tank fails my tests! Pointing my test rig downwards results in an engine cut. I modifed one for a baffle and it only gained a few seconds.

What I have found is that commercial tanks are not always good quality. I have to say that I have not had one that leaks but have taken several apart and found - filler and overflow pipes that do not penetrate far enough, feed pipes that stop short, feed pipes that are blocked - up against the tank back, cut narrowing inlet, solder restricting uptake.............. I do have some vintage brass tanks that are superb!

I have just seen Roddies post. I will be using soft rubber strip. Not wrapped around the tank but strips between the bearers and the tank and thin strips at the sides fron and rear.

I will be fuel proofing with epoxy during the build - still haven't worked out the assenbbly order yet! Mulling over Ken's suggestion of cutting open the belly of the fuselage.

I remove the board from the workmate with the engine running - with a diesel I don't even bother using the workmate - and really put it through the motions.

I use tanks all the time for testing and running engines. (Just running engines can be boring and so testing tanks as well makes it more interesting!)

The tank you see in the rig is as per the plan supplied with the kit. It was supplied as a sheet of "coated" steel. I had not come across this material before - it had a matt grey finish - but it was easy and true to bend and the solder flowed beautifully.

Unfortunately, there is no provision for a hatch in this fuselage - the tank sits tight between the engine bearer top and bottom - it would also not be possible to alter the height even if there was tank access.

The only thing that I can't test easily is the "centrifugal effect" - the whole essence behind the wedge shape. For this, I keep everything "level" and when the engine coughs I do a spin with up and down motions to see if it comes back to life.

I make many tanks and, more recently, have been exploring "uniflo" rather than just taking it for granted. The tank in the KK Radian is uniflo (that is another story - caused me alot of frustration because of my stupidity (or was it a memory issue?)).

I build tanks for a couple of vintage combat flyers (they, like me, are vintage as well as the models) in the north of England but these, although simple tanks, are difficult to build. They send me a cross section of the wing and I make the tank to fit inside and match the profile of the wing. The wedge is at the back of the tank but rounded. The filler and the overflow pipe are at the peak of the profile and the feed pipe bottom front exit to the far rear corner. I don't understand how this works when they are battling overhead as the tank fails my tests! Pointing my test rig downwards results in an engine cut. I modifed one for a baffle and it only gained a few seconds.

What I have found is that commercial tanks are not always good quality. I have to say that I have not had one that leaks but have taken several apart and found - filler and overflow pipes that do not penetrate far enough, feed pipes that stop short, feed pipes that are blocked - up against the tank back, cut narrowing inlet, solder restricting uptake.............. I do have some vintage brass tanks that are superb!

I have just seen Roddies post. I will be using soft rubber strip. Not wrapped around the tank but strips between the bearers and the tank and thin strips at the sides fron and rear.

I will be fuel proofing with epoxy during the build - still haven't worked out the assenbbly order yet! Mulling over Ken's suggestion of cutting open the belly of the fuselage.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Frog Aerobat

Re: Frog Aerobat

Ian, looking at your engine crutch I would like to make a suggestion. You could cut out the F-1 firewall between your engine bearers and slide the tank in from the front. You could also re plumb your tank having all pipes forward. This would allow for easy install. Make your opening slightly larger, you can add balsa or paper shims under the tank to adjust height if needed. Running a engine on a test stand vs on the plane is something you can't really replicate. One factor that hasn't been mentioned is vibration. If vibrations are present, uniflow will not work period. While Roddie has mentioned isolating the tank with foam, and this helps, it may or may not be needed. Adding a spritz of Armor -All to the fuel works wonders although not a cure all it does indeed work well. I've been switiching most of my hard tanks to plastic. That's another animal and a art in itself, but they work well allowing you to see inside. I use Sullivan Flex-tanks. They're clear not opaque like the regular versions they sell. They also can be molded into shape. Ken

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: Frog Aerobat

Re: Frog Aerobat

Thanks Ken - another good suggestion.

The Flex tanks look a good idea. Adjusting shape with a heat gun!

http://www.sullivanproducts.com/FuelTanksMainContent.htm

There is a store in the UK that sells them

http://www.hobbystores.co.uk/default.asp?WPG=HOB_HomePage1&PageNumber=1&s=c:0,c:080,c:080-100,b:Sullivan

The Flex tanks look a good idea. Adjusting shape with a heat gun!

http://www.sullivanproducts.com/FuelTanksMainContent.htm

There is a store in the UK that sells them

http://www.hobbystores.co.uk/default.asp?WPG=HOB_HomePage1&PageNumber=1&s=c:0,c:080,c:080-100,b:Sullivan

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Frog Aerobat

Re: Frog Aerobat

I have stalled a bit on this build and only making slow progress. I also got sidetracked by the "Rocking Donkey" and a few other models.

I decided that seeing as I hadn't used "hinge" hinges before I would try them on this. However, I tried them on the "Rocking Donkey" and found cutting the recess with a knife tedious and prone to error. There were three hinges on that, The Aerobat needs eight for the ailerons!

After watching yet another "Windy" video I saw him make and use a little sanding tool for fitting hinges.

I quickly made one and eight recesses were completed very neatly in just a few minutes.

I decided that seeing as I hadn't used "hinge" hinges before I would try them on this. However, I tried them on the "Rocking Donkey" and found cutting the recess with a knife tedious and prone to error. There were three hinges on that, The Aerobat needs eight for the ailerons!

After watching yet another "Windy" video I saw him make and use a little sanding tool for fitting hinges.

I quickly made one and eight recesses were completed very neatly in just a few minutes.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Frog Aerobat

Re: Frog Aerobat

That is a great little tool. You have to get the measurements just right. When I was hinging my elevator the other day, I spent a minute talking myself out of making one and 45 minutes fiddling with an emery board. Luckily they came out nicely, but next time I'm making the tool. I need some sticky backed sandpaper.

Rusty

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Frog Aerobat

Re: Frog Aerobat

No need for sticky back stuff. I just used CA - the "tool" is from "scrap" balsa. The paper will last a long time.

It was all cut and CA 'd together in a couple of minutes.

It was all cut and CA 'd together in a couple of minutes.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Frog Aerobat

Re: Frog Aerobat

Maybe I should watch the Windy video's.

Good stuff Ian

Good stuff Ian

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Frog Aerobat

Re: Frog Aerobat

Nice build Ian. You mentioned "not perfect", but as far as I can see, it looks really good.

GallopingGhostler- Top Poster

Posts : 5724

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Frog Aerobat

Re: Frog Aerobat

It continues

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Frog Aerobat

Re: Frog Aerobat

Good work Ian!!!

Can't wait to see it completed.

Can't wait to see it completed.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Frog Aerobat

Re: Frog Aerobat

Ready for a bit of sanding.

I don't like snading. I am clumsy and seem to create more dings and gouges during the process!

I don't like snading. I am clumsy and seem to create more dings and gouges during the process!

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Frog Aerobat

Re: Frog Aerobat

ian1954 wrote:Ready for a bit of sanding.

I don't like sanding. I am clumsy and seem to create more dings and gouges during the process!

I can agree with you there. At first I get that inflated feeling of control over the wood, the quiet voices of angels singing approval(or at least Jimi Hendrix), shaping its beauty to my own desi... crack...ah crap, busted a rib. Better put it on the table to... whap damn banged it against the mag lamp, and on and on. I finally got my LE shaped last night and dry fit it into the fuse. I better give those ribs a once-over and patch the nicks and chips. Ten times worse if using contest balsa.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Frog Aerobat

Re: Frog Aerobat

Looking sweet Ian , I'll bet that baby will fly some circles ! What is the power for that bird ? .....I go wit you and Rusty on the sanding , seems I end up doing more damage than good But most defiantly find the weak areas

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Frog Aerobat

Re: Frog Aerobat

RknRusty wrote:ian1954 wrote:Ready for a bit of sanding.

I don't like sanding. I am clumsy and seem to create more dings and gouges during the process!

I can agree with you there. At first I get that inflated feeling of control over the wood, the quiet voices of angels singing approval(or at least Jimi Hendrix), shaping its beauty to my own desi... crack...ah crap, busted a rib. Better put it on the table to... whap damn banged it against the mag lamp, and on and on. I finally got my LE shaped last night and dry fit it into the fuse. I better give those ribs a once-over and patch the nicks and chips. Ten times worse if using contest balsa.

Rusty

It REALLY pays to have sanding-tools handy before starting a modeling project. Making your own is time-consuming.. but well-worth it when you realize the time spent on sanding.. and "how well" the sanding job turned out. One of the easiest ways to attach sandpaper to a block or form, is to use double-sided tape. Make sure the tape-strips don't overlap though. For wood, I usually make 3 identically shaped forms (dowels of the same diameter, sticks of the same size, angle-stock etc.) and face them with coarse, medium and fine papers. PVC pipe couplers in different sizes make great radius-sanding tools, where a wooden dowel size would be too big and heavy. Emery-cloth, which comes in rolls is cheap.. and great for attaching to a long length of aluminum angle or extrusion for shaping leading-edges. Two such tools can be mounted "face to face" and clamped at a "V"-angle of your choice, for making very quick and accurate long tapers. This makes short work of making your own flap and trailing-edge stock. I think that Windy U. mentioned in one of his build videos; buying a sanding belt and cutting it at it's seam.. and adhering it to a piece of 1/2" safety-glass... another excellent tool to have handy.. and will last for a lifetime of balsa sanding.

Re: Frog Aerobat

Re: Frog Aerobat

Ian it looks fantatstic! Home stretch!

I like the wing tips, hollowed block tips look the best.

I like the wing tips, hollowed block tips look the best.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Frog Aerobat

Re: Frog Aerobat

I wish it was the home straight! Me and finishing form a slow process that often lacks motivation.

I use all sorts of sanding tools but still manage to grip too tight, bash the model on something or other while handling it, apply too much pressure, get carried away sanding .......... It now has two dings in the leading edge of the wing that need filling!

I will probably be powering it with an OS "15" motor. Still to be decided - alot depends on balance as I approach completion.

I use all sorts of sanding tools but still manage to grip too tight, bash the model on something or other while handling it, apply too much pressure, get carried away sanding .......... It now has two dings in the leading edge of the wing that need filling!

I will probably be powering it with an OS "15" motor. Still to be decided - alot depends on balance as I approach completion.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Page 1 of 2 • 1, 2

Similar topics

Similar topics» Cessna 150 Aerobat

» For Sale-Cox E-Z Flyer Aerobat 150 Control Line RTF

» Frog 349 BB CL

» An army of Frog 80s

» Venom Frog

» For Sale-Cox E-Z Flyer Aerobat 150 Control Line RTF

» Frog 349 BB CL

» An army of Frog 80s

» Venom Frog

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules