Log in

Search

Latest topics

» Roger Harris revisitedby rsv1cox Today at 3:44 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Today at 2:54 pm

» Did you spot the Cox engine in this NASA research video?

by Ken Cook Today at 2:45 pm

» Happy 77th birthday Andrew!

by Admin Today at 12:34 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 10:34 am

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 8:15 am

» TEE DEE Having issues

by balogh Today at 7:42 am

» Cox films/videos...

by Coxfledgling Today at 4:46 am

» My N-1R build log

by roddie Today at 12:32 am

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

Cox Engine of The Month

My first Little Satan build

Page 2 of 3

Page 2 of 3 •  1, 2, 3

1, 2, 3

Re: My first Little Satan build

Re: My first Little Satan build

I would build the whole tail assembly before gluing it to the wing, This will better assure proper alignment in all directions. Notice that's how I did it in my pictures in the Traveling engine thread. Oh yeah, I need to send that thing off to Matthew.

I can't find any pictures of blind nut(T-nut) installation. The package may have info on drill bit size and a simple picture. I'll look again later.

Rusty

I can't find any pictures of blind nut(T-nut) installation. The package may have info on drill bit size and a simple picture. I'll look again later.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My first Little Satan build

Re: My first Little Satan build

Theo, your a true natural at this. Your leadouts look great. You will appreciate how smooth they work. Nicely done. In regards to the elevator installation, I would first fit the booms to the wing ( Dry fit only) . Assembling the elevator accurately to the booms would be next.Slide the assembly onto the sheeted portion of the wing taking care that the booms are parallel and square to the wing. I generally tape the elevator in the neutral position and sight from the rear of the wing to check to see if the elevator is aligned with the trailing edge. If need be sand or add a shim to one of the booms to align the elevator. Your eyeball is a great tool. When satisfied all can be glued on. My initial wing was covered first with silkspan and I glued everything on later. If your using iron on covering it could be covered first and then carefully remove the covering. I don't recommend scoring the covering with a #11 blade though. If you do so keep the knife blade upside down so that your not cutting into the sheeting but rather the covering. Ken

Ken Cook- Top Poster

- Posts : 5644

Join date : 2012-03-27

Location : pennsylvania

Re: My first Little Satan build

Re: My first Little Satan build

Thanks Rusty and Ken.

I am enjoying this build.

I will connect the elevator onto the booms and then align everything dry before starting the glue. Do you also use fibreglass and epoxy over the piano wire in the elevator to keep it there?

Can this wire just go through the ply on the boom? Will the ply wear out at this point?

Theo

I am enjoying this build.

I will connect the elevator onto the booms and then align everything dry before starting the glue. Do you also use fibreglass and epoxy over the piano wire in the elevator to keep it there?

Can this wire just go through the ply on the boom? Will the ply wear out at this point?

Theo

Theo Kleynhans- Gold Member

- Posts : 196

Join date : 2013-12-30

Age : 43

Location : South Africa

Re: My first Little Satan build

Re: My first Little Satan build

Theo, If the hole in the horn will wear out, depends on how intensive your plane will be used. What you can do is epoxy some tin can foil inside the hole. I did that both on the horn and in the tail boom holes for the elevator hinge on my JR Satan. To give you an idea of the size, the pushrod is 2 mm diameter

Lieven

Lieven

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: My first Little Satan build

Re: My first Little Satan build

Anytime I use pins or music wire dowels for elevators I always wrap with lightweight glass cloth and epoxy. If memory serves me correctly, the Lil Satan used T-pins for wire hinges with the heads clipped off. The ply boom should be just fine even without a bushing. These types of planes don't always have a long lifespan. Not saying it won't or couldn't, it's just been in my experience that hangar rash is truly expedited with wings. Ken

Ken Cook- Top Poster

- Posts : 5644

Join date : 2012-03-27

Location : pennsylvania

Re: My first Little Satan build

Re: My first Little Satan build

The music wire can go through the ply hinges on the boom. I put an L bend in one end, and on the other end I wrapped some copper wire with epoxy as a retainer. Click the enlarge link, and look at the picture. You can't see the L bend, but look closely on the far right side, just outside the boom and you can see my epoxied wire wrap on the tip end of the hinge wire.Theo Kleynhans wrote:Thanks Rusty and Ken.

I am enjoying this build.

I will connect the elevator onto the booms and then align everything dry before starting the glue. Do you also use fibreglass and epoxy over the piano wire in the elevator to keep it there?

Can this wire just go through the ply on the boom? Will the ply wear out at this point?

Theo

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My first Little Satan build

Re: My first Little Satan build

Thank you all for the comments

Lieven, that is some really delicate gluing needed. Will have to try it some time.

Ken. Thanks for the info. I have used one piece of Piano wire all the way through. I will then epoxy it in place as you recommended.

Rusty. Thank you for the detailed view of yours. I have done mine a little differently. But I hope it will be good enough.

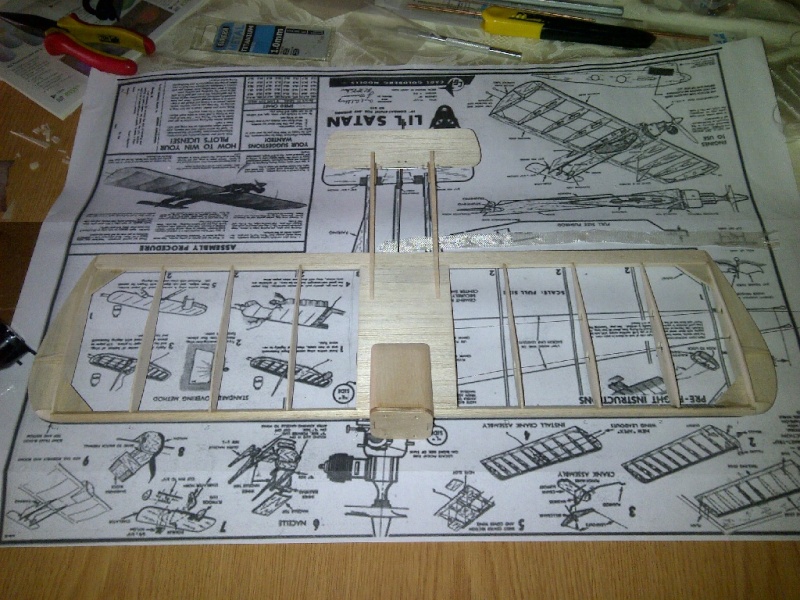

Here is where I am on the build at this stage:

Now I need to epoxy the music wire into the elevator.

Do I use the fibreglass with epoxy only on the necalle and the elevator where the music wire goes?

I saw that Rusty also added some fibreglass on the wing sheeting where the necalle come onto. Is this how it should be done?

Thanks guys.

Theo

Lieven, that is some really delicate gluing needed. Will have to try it some time.

Ken. Thanks for the info. I have used one piece of Piano wire all the way through. I will then epoxy it in place as you recommended.

Rusty. Thank you for the detailed view of yours. I have done mine a little differently. But I hope it will be good enough.

Here is where I am on the build at this stage:

Now I need to epoxy the music wire into the elevator.

Do I use the fibreglass with epoxy only on the necalle and the elevator where the music wire goes?

I saw that Rusty also added some fibreglass on the wing sheeting where the necalle come onto. Is this how it should be done?

Thanks guys.

Theo

Theo Kleynhans- Gold Member

- Posts : 196

Join date : 2013-12-30

Age : 43

Location : South Africa

Re: My first Little Satan build

Re: My first Little Satan build

Hi TheoTheo Kleynhans wrote:

I saw that Rusty also added some fibreglass on the wing sheeting where the necalle come onto. Is this how it should be done?

Thanks guys.

Theo

The plans didn't say to put those strips on the center sheeting, but I thought it seemed like a good idea both for strength and to help with the adhesion of the nacelle. My nacelle is wrapped like the old Goldberg plans illustrated. After wrapping it, I tacked it in place with tiny dots of CA at the corners and where the ends overlap to hold it in shape, then spread it with epoxy, being careful to spread it and mash it through the weave so that the fabric is fully saturated. And I painted the whole firewall face with epoxy too. It's the ultimate fuel proofing. After the nacelle was attached, I then painted the whole nacelle with epoxy.

Make sure you make some test mixes to get your hardness right. The last thing you want it for a major job to set up only to still be gummy and tacky. With the brands I buy, I always have to add a small amount of extra hardener.

On the elevator, you can either use some epoxied fiberglass cloth or other non-stretchy fabric, or a few wraps of dacron line stitched through tiny pre-drilled holes. The latter would be my preference. Rather than Dacron flying line you may be able to see on mine where I used thin copper wire for this at each end of my CF hinge tube.

Did you use 1/16" balsa for the stabilator? It looks thicker in the picture. If you went thicker, be as light as possible with the paint because a tail heavy Li'l Satan is hard to correct, and impossible to fly. It's difficult to find any place up front to add nose weight. Some hard 1/16" is plenty for this model and the primer and paint along with your balsa doubler will stiffen it adequately. Of all the tail parts I've broken, my 1/16" stab and doubler have never cracked, only the booms. After adding the balsa doubler, I saturated the doubler with extra thin CA to harden it.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My first Little Satan build

Re: My first Little Satan build

Thank you for all the valuable info Rusty.

I actually ended up using 3/32". Then I used a ply doubler. Do you think this will be too heavy?

I can make one from 1/16" balsa and use 1/16" balsa for the doubler as well to test the strength. 1/16" just sounded a bit thin. But like you say, the paint and doubler will stiffen it up quite nicely. I will cut one and see how it is. Quick and easy to do.

I will have to do a test or two with the epoxy before I do it on the plane. I have never used epoxy before.

I will use some dacron line and stitch the music wire to the elevator.

Theo

I actually ended up using 3/32". Then I used a ply doubler. Do you think this will be too heavy?

I can make one from 1/16" balsa and use 1/16" balsa for the doubler as well to test the strength. 1/16" just sounded a bit thin. But like you say, the paint and doubler will stiffen it up quite nicely. I will cut one and see how it is. Quick and easy to do.

I will have to do a test or two with the epoxy before I do it on the plane. I have never used epoxy before.

I will use some dacron line and stitch the music wire to the elevator.

Theo

Theo Kleynhans- Gold Member

- Posts : 196

Join date : 2013-12-30

Age : 43

Location : South Africa

Re: My first Little Satan build

Re: My first Little Satan build

Theo, my 3 pound stunt plane uses 3/32 balsa on the stab. I think 1/16 will be better. And a balsa doubler, hardened with thon CA. Use the nylon plate that comes with the control horn or similar on top to support the load and not crush the wood.Theo Kleynhans wrote:Thank you for all the valuable info Rusty.

I actually ended up using 3/32". Then I used a ply doubler. Do you think this will be too heavy?

I can make one from 1/16" balsa and use 1/16" balsa for the doubler as well to test the strength. 1/16" just sounded a bit thin. But like you say, the paint and doubler will stiffen it up quite nicely. I will cut one and see how it is. Quick and easy to do.

I will have to do a test or two with the epoxy before I do it on the plane. I have never used epoxy before.

I will use some dacron line and stitch the music wire to the elevator.

Theo

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My first Little Satan build

Re: My first Little Satan build

Thank you Rusty

I have made a new one. I use 1/16" for the elevator and the doubler.

This is it:

This is how my finished necalle looks:

Now I need to do the fibreglass on the necalle and also fix the music wire to the elevator.

Also I now can do the covering on the wing. Then I will cut away the areas where the necalle and booms need to go.

Theo

I have made a new one. I use 1/16" for the elevator and the doubler.

This is it:

This is how my finished necalle looks:

Now I need to do the fibreglass on the necalle and also fix the music wire to the elevator.

Also I now can do the covering on the wing. Then I will cut away the areas where the necalle and booms need to go.

Theo

Theo Kleynhans- Gold Member

- Posts : 196

Join date : 2013-12-30

Age : 43

Location : South Africa

Re: My first Little Satan build

Re: My first Little Satan build

Perfect! You'have a really good touch with building, Theo. That looks great.

I would soak that doubler with very thin CA to harden it..

If you can get some of these 2-56 blind nuts and put them into the back of the firewall, you can mount your engine with hex head machine screws rather than wood screws.

http://www.ebay.com/itm/Great-Planes-Blind-Nuts-2-56-4-GPMQ3320-/400716314764?pt=Model_Kit_US&hash=item5d4c8db88c

All you do is drill a 1/8" hole(or what the directions on the package say), dab some epoxy onto the face of the blind nbt, then pull it into place with a screw and washer. When the glue hardens you have permanent threaded inserts for mounting your engine. That helps a lot to prevent fuel and oil penetration. It also extends the useful life of the firewall.

When I retro fitted mine to the Tee Dee aluminum backplate mount, I made a 1/8 birch ply plate with the nuts installed, and attached it with a wide strip of fiberglass that covered the whole face of the new firewall, wrapping back onto the old one.

Rusty

I would soak that doubler with very thin CA to harden it..

If you can get some of these 2-56 blind nuts and put them into the back of the firewall, you can mount your engine with hex head machine screws rather than wood screws.

http://www.ebay.com/itm/Great-Planes-Blind-Nuts-2-56-4-GPMQ3320-/400716314764?pt=Model_Kit_US&hash=item5d4c8db88c

All you do is drill a 1/8" hole(or what the directions on the package say), dab some epoxy onto the face of the blind nbt, then pull it into place with a screw and washer. When the glue hardens you have permanent threaded inserts for mounting your engine. That helps a lot to prevent fuel and oil penetration. It also extends the useful life of the firewall.

When I retro fitted mine to the Tee Dee aluminum backplate mount, I made a 1/8 birch ply plate with the nuts installed, and attached it with a wide strip of fiberglass that covered the whole face of the new firewall, wrapping back onto the old one.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My first Little Satan build

Re: My first Little Satan build

For such a purpose I prefer socket-head screws. Much easier to secure than slot-head fastener.

SD

SD

SuperDave- Rest In Peace

- Posts : 3552

Join date : 2011-08-13

Location : Washington (state)

Re: My first Little Satan build

Re: My first Little Satan build

SuperDave wrote:For such a purpose I prefer socket-head screws. Much easier to secure than slot-head fastener.

SD

ABSOLUTELY !!!!!!!!!!!!!!

Kim- Top Poster

Posts : 8625

Join date : 2011-09-06

Location : South East Missouri

Re: My first Little Satan build

Re: My first Little Satan build

Dave's back! Kim's back!

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My first Little Satan build

Re: My first Little Satan build

Thank you for the info guys. I really appreciate it.

Can someone please show me the difference between a "socket-head screw" and a "slot-head fastener"?

Rusty, thank you for that. I installed the blind nuts last night. It was easy at the end.

I played with some epoxy last night to test before I do the necalle strengthening. It was not that easy to use for me. But I could get it on the wood as a thin layer at the end. Will try and do the necalle strengthening tonight or tomorrow.

Theo

Can someone please show me the difference between a "socket-head screw" and a "slot-head fastener"?

Rusty, thank you for that. I installed the blind nuts last night. It was easy at the end.

I played with some epoxy last night to test before I do the necalle strengthening. It was not that easy to use for me. But I could get it on the wood as a thin layer at the end. Will try and do the necalle strengthening tonight or tomorrow.

Theo

Theo Kleynhans- Gold Member

- Posts : 196

Join date : 2013-12-30

Age : 43

Location : South Africa

Re: My first Little Satan build

Re: My first Little Satan build

A socket head screw requires an Allen wrench to fit into the head of the screw, which is six-sided inside.

The slot screw is just a straight groove, from one side of the screw head, to the other.

Phillips head screws look like a "plus" sign. Sorry no pics.

The slot screw is just a straight groove, from one side of the screw head, to the other.

Phillips head screws look like a "plus" sign. Sorry no pics.

GUS THE I.A.- Gold Member

- Posts : 359

Join date : 2012-08-15

Location : Wichita, Kansas

Re: My first Little Satan build

Re: My first Little Satan build

Thank you for the clarification Gus. I now know what it is.

I am using Socket head screws, so that is perfect then.

Theo

I am using Socket head screws, so that is perfect then.

Theo

Theo Kleynhans- Gold Member

- Posts : 196

Join date : 2013-12-30

Age : 43

Location : South Africa

Re: My first Little Satan build

Re: My first Little Satan build

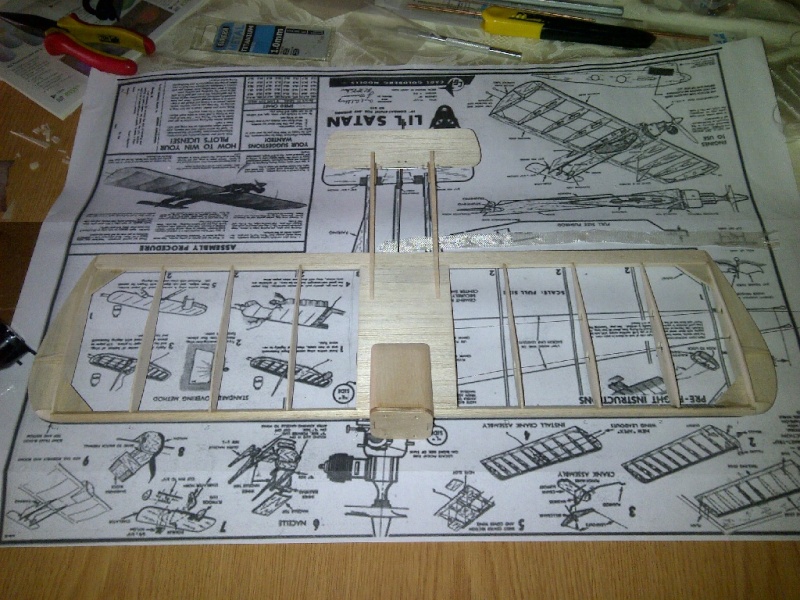

Hi Guys

I have done the blind nuts and fixed the elevator to the booms.

I now only need to do the strengthening on the necalle and cover the wing.

Then I can put the plane together and paint.

What do you guys think?

Theo

I have done the blind nuts and fixed the elevator to the booms.

I now only need to do the strengthening on the necalle and cover the wing.

Then I can put the plane together and paint.

What do you guys think?

Theo

Theo Kleynhans- Gold Member

- Posts : 196

Join date : 2013-12-30

Age : 43

Location : South Africa

Re: My first Little Satan build

Re: My first Little Satan build

I think that's one fine Li'l Satan.

Be sure and balance it exactly as the plan says. A balance point that's even 1/8" too far aft can cause a great deal of unwanted excitement on your maiden flight. When I balance my small planes, I usually press a fingernail dent into the wingtips so I can easily feel for it when I pick it up to test the balance.

If I recall correctly, you are new to working with epoxy. How do you like it so far? 30 minute is my main epoxy. I like 60 minute too but it's getting hard to find in stores. 5 minute is great for really small quick jobs, but I spend so much time being thorough about mixing, I almost leave no work time. Where super strength and metal are involved, JB Weld(regular) is the stuff of choice.

Rusty

Be sure and balance it exactly as the plan says. A balance point that's even 1/8" too far aft can cause a great deal of unwanted excitement on your maiden flight. When I balance my small planes, I usually press a fingernail dent into the wingtips so I can easily feel for it when I pick it up to test the balance.

If I recall correctly, you are new to working with epoxy. How do you like it so far? 30 minute is my main epoxy. I like 60 minute too but it's getting hard to find in stores. 5 minute is great for really small quick jobs, but I spend so much time being thorough about mixing, I almost leave no work time. Where super strength and metal are involved, JB Weld(regular) is the stuff of choice.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My first Little Satan build

Re: My first Little Satan build

Theo, I had only seen photos of "finished" Lil' Satans.. and never knew how they were built. When you started this build and posted photos with questions on construction.. It started to really interest me. Some very important details were discussed.. and you've followed the advice of others who have built and flown the model.

You had mentioned having a little trouble with the epoxy glue. Was it the way it handles? It can be messy stuff.. and we can tell by your photos, that you're a very neat builder! I had mentioned being prepared before you use/mix it... and another very useful tool for applying the glue is a round wooden toothpick. Scoop up some glue on the tip and when you pull up from the mixing palette.. "twirl" the toothpick to break the strand of "drool".. and keep twirling while moving toward your target. This can help stop a drip along the way. This would have been my tool of choice for spreading glue around those blind-nuts inside the engine nacelle. I don't use the "quick-setting" epoxy, for the same reasons as Rusty.. if epoxies are not thoroughly mixed.. you can end up with a sticky mess that does not cure properly.

You're doing a beautiful job of building! Thanks for sharing it with us!

You had mentioned having a little trouble with the epoxy glue. Was it the way it handles? It can be messy stuff.. and we can tell by your photos, that you're a very neat builder! I had mentioned being prepared before you use/mix it... and another very useful tool for applying the glue is a round wooden toothpick. Scoop up some glue on the tip and when you pull up from the mixing palette.. "twirl" the toothpick to break the strand of "drool".. and keep twirling while moving toward your target. This can help stop a drip along the way. This would have been my tool of choice for spreading glue around those blind-nuts inside the engine nacelle. I don't use the "quick-setting" epoxy, for the same reasons as Rusty.. if epoxies are not thoroughly mixed.. you can end up with a sticky mess that does not cure properly.

You're doing a beautiful job of building! Thanks for sharing it with us!

Re: My first Little Satan build

Re: My first Little Satan build

I found it very difficult to assemble the tank per the Goldberg drawings and have the pickup work correctly. I actually gave up on it and just put the needle valve on the opposing side allowing for more room within the tank for the pickup to loop back around. The vent pipes really get in the ay of assembly. Ken

Ken Cook- Top Poster

- Posts : 5644

Join date : 2012-03-27

Location : pennsylvania

Re: My first Little Satan build

Re: My first Little Satan build

Thank you Guys.

Hi Rusty. Thank you, I just hope I can do the finishing justice. I will be using iron on covering.

I put everything together last night just to test the balance point and check the weight. The balance point is way forward. It is in front of the leading edge at this stage. The plane only weighs 45 grams without the engine as it is. I think that is really light. Will see what the end weight will be. What should the model end weight be? With or without the engine.

Rusty and Roddie:

I used 30minute epoxy. When I did the tests with the epoxy, yes it handled a bit difficult. But I strengthened the necalle last night with the fibreglass and it worked quite well. I used a steel rod to apply it. It was much easier than with the testing I did. I did it exactly as you mentioned here Roddie. Thanks for the tips. Will see today how it looks.

I am enjoying the build Roddie. As you say, I have really received some excellent comments and TIPS. Thank you to everyone.

Ken, I agree with you. That is extremely difficult. I will be using a black widow, and I will be installing it straight up as normal. You can see what I will do in the picture below.

Here is what it looked like last night when I wanted to see it together:

I installed the tip weight last night. 7 grams. That is approximately 1/4 ounce. I glued it on the bottom of the tip.

Rusty, I see that you did not install the fairings on the booms. But on all the others that I have seen they have them. Why did you not use them?

Theo

Hi Rusty. Thank you, I just hope I can do the finishing justice. I will be using iron on covering.

I put everything together last night just to test the balance point and check the weight. The balance point is way forward. It is in front of the leading edge at this stage. The plane only weighs 45 grams without the engine as it is. I think that is really light. Will see what the end weight will be. What should the model end weight be? With or without the engine.

Rusty and Roddie:

I used 30minute epoxy. When I did the tests with the epoxy, yes it handled a bit difficult. But I strengthened the necalle last night with the fibreglass and it worked quite well. I used a steel rod to apply it. It was much easier than with the testing I did. I did it exactly as you mentioned here Roddie. Thanks for the tips. Will see today how it looks.

I am enjoying the build Roddie. As you say, I have really received some excellent comments and TIPS. Thank you to everyone.

Ken, I agree with you. That is extremely difficult. I will be using a black widow, and I will be installing it straight up as normal. You can see what I will do in the picture below.

Here is what it looked like last night when I wanted to see it together:

I installed the tip weight last night. 7 grams. That is approximately 1/4 ounce. I glued it on the bottom of the tip.

Rusty, I see that you did not install the fairings on the booms. But on all the others that I have seen they have them. Why did you not use them?

Theo

Theo Kleynhans- Gold Member

- Posts : 196

Join date : 2013-12-30

Age : 43

Location : South Africa

Re: My first Little Satan build

Re: My first Little Satan build

Because I forgot to put the fairings on. I did add them this time when I built a new tail end. They should be installed..

Don't worry about the balance before finishing. It doesn't even resemble what it will be like with paint on it.

Rusty

Don't worry about the balance before finishing. It doesn't even resemble what it will be like with paint on it.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My first Little Satan build

Re: My first Little Satan build

Theo, does your nacelle fit square on? They're usually designed to be angled to the outboard side. No big deal, you can still add thrust offset. When I glued mine on, it slipped in the clamp and ended up straight, so I had to use offset shims.

Rusty

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Page 2 of 3 •  1, 2, 3

1, 2, 3

Similar topics

Similar topics» Super Satan build

» Lil' Satan build.

» Yet another Lil' Satan build...

» I put a Tee Dee on my Lil' Satan

» Another Li'l Satan build (Finished)

» Lil' Satan build.

» Yet another Lil' Satan build...

» I put a Tee Dee on my Lil' Satan

» Another Li'l Satan build (Finished)

Page 2 of 3

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules