Log in

Search

Latest topics

» Retail price mark-up.. how much is enough?by Ken Cook Today at 2:54 pm

» Did you spot the Cox engine in this NASA research video?

by Ken Cook Today at 2:45 pm

» Happy 77th birthday Andrew!

by Admin Today at 12:34 pm

» Roger Harris revisited

by getback Today at 12:30 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 10:34 am

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 8:15 am

» TEE DEE Having issues

by balogh Today at 7:42 am

» Cox films/videos...

by Coxfledgling Today at 4:46 am

» My N-1R build log

by roddie Today at 12:32 am

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

Cox Engine of The Month

My first Little Satan build

Page 1 of 3

Page 1 of 3 • 1, 2, 3

My first Little Satan build

My first Little Satan build

Hi Everyone

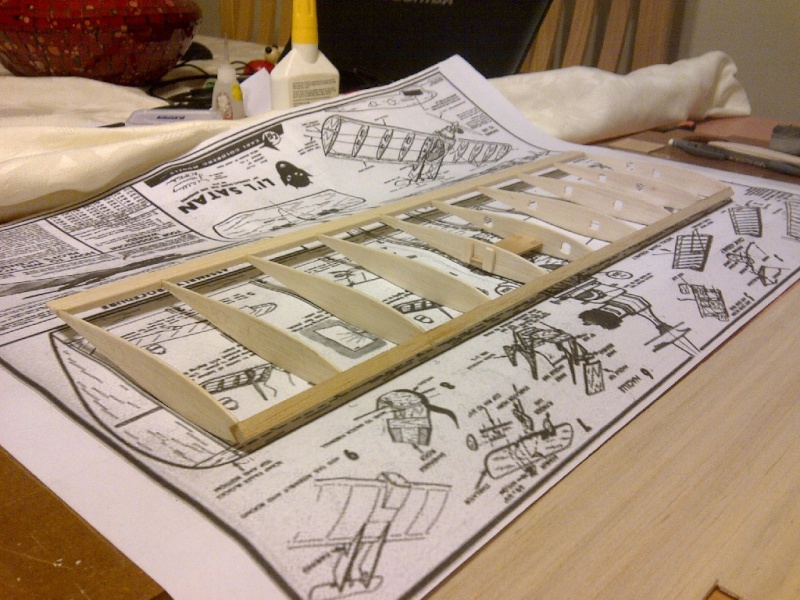

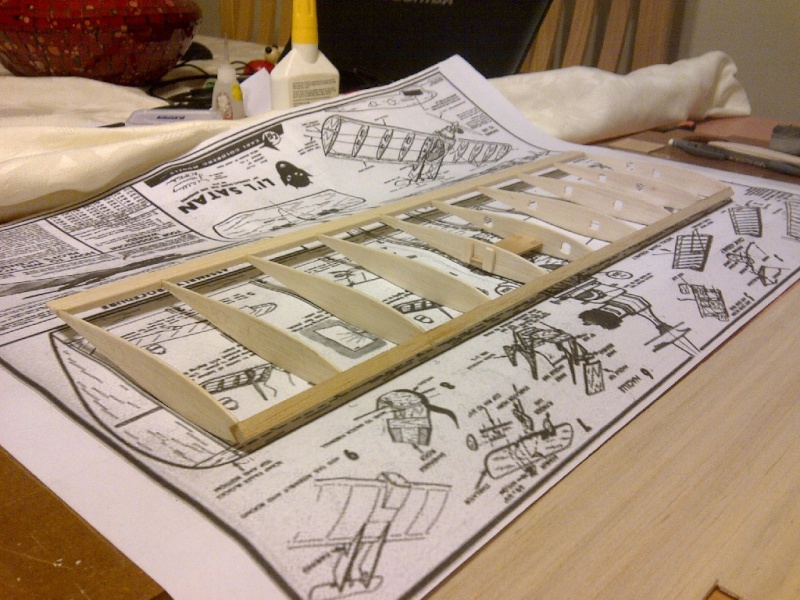

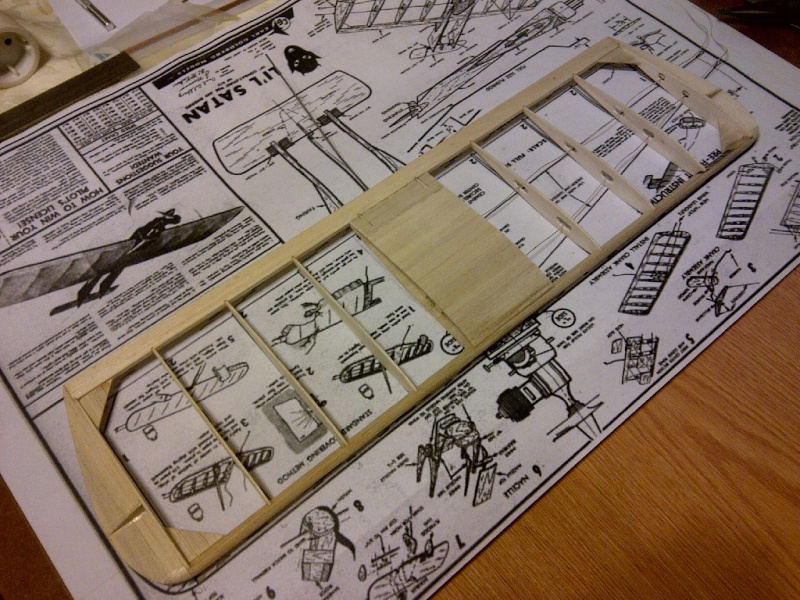

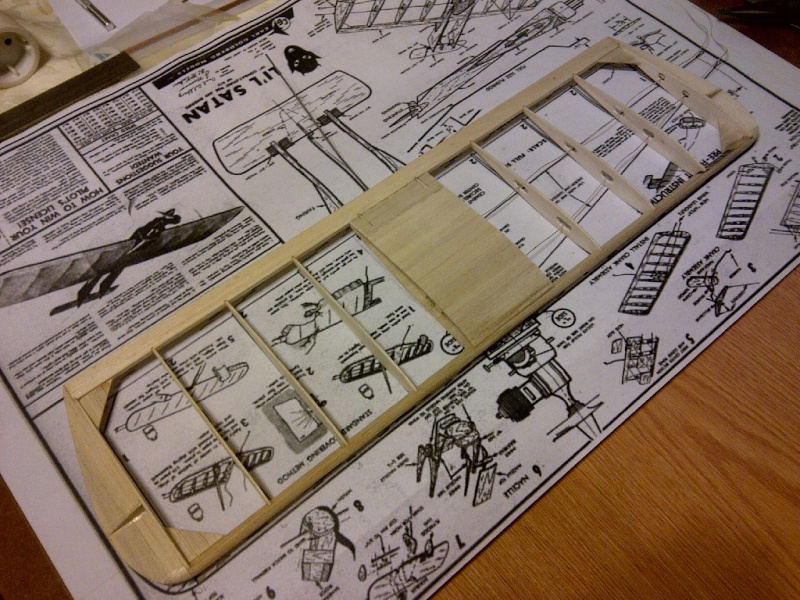

I have started a little Satan build. After seeing how much fun you guys have had with them. I am scratch building from the old Goldberg kit plan.

This is how it started a few nights ago:

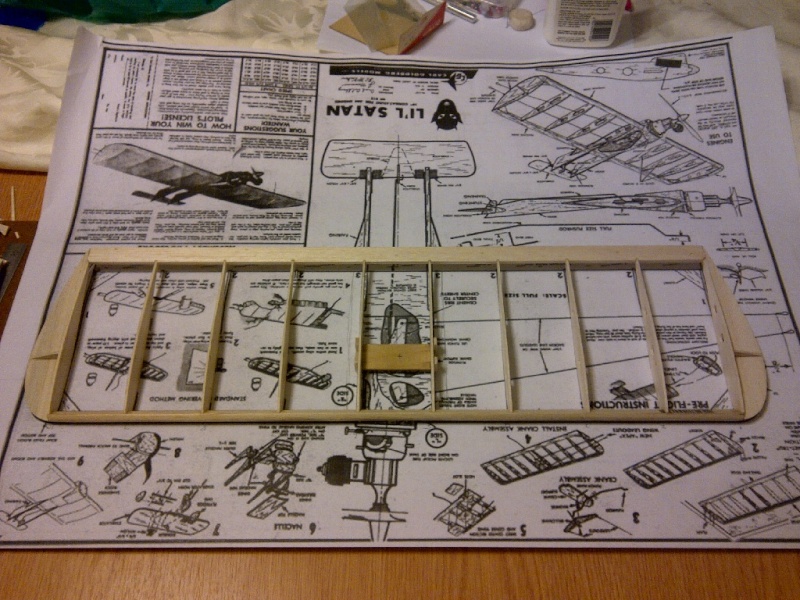

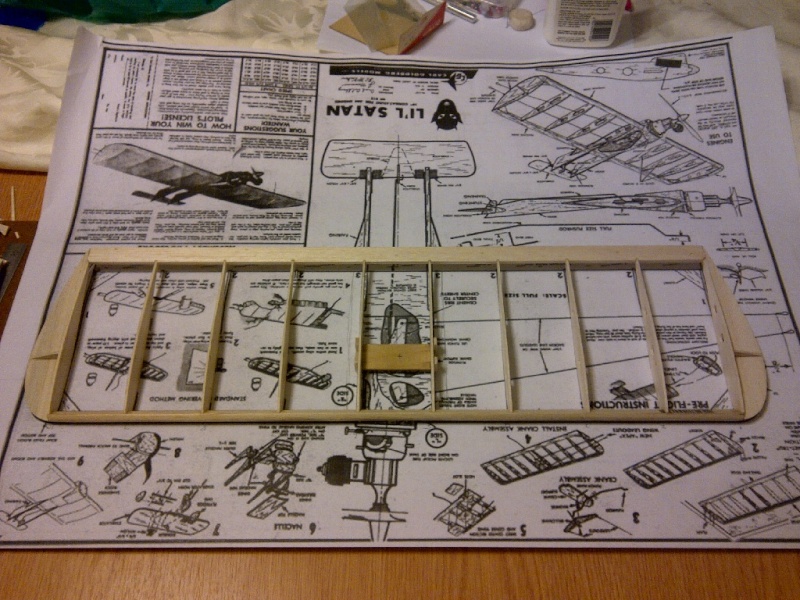

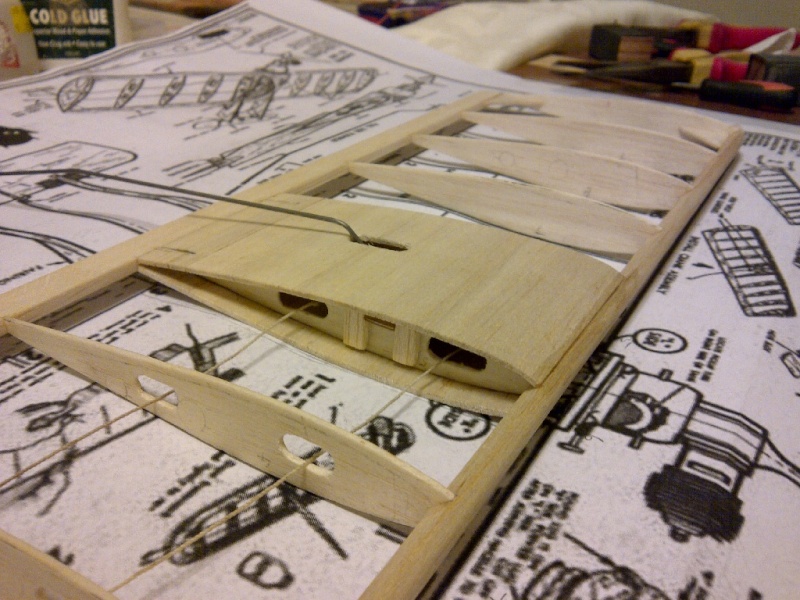

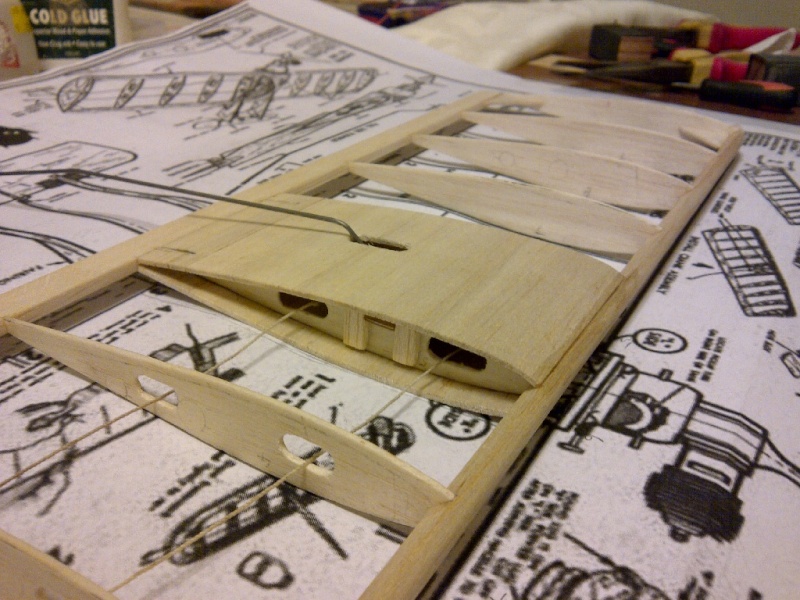

Then it went to this:

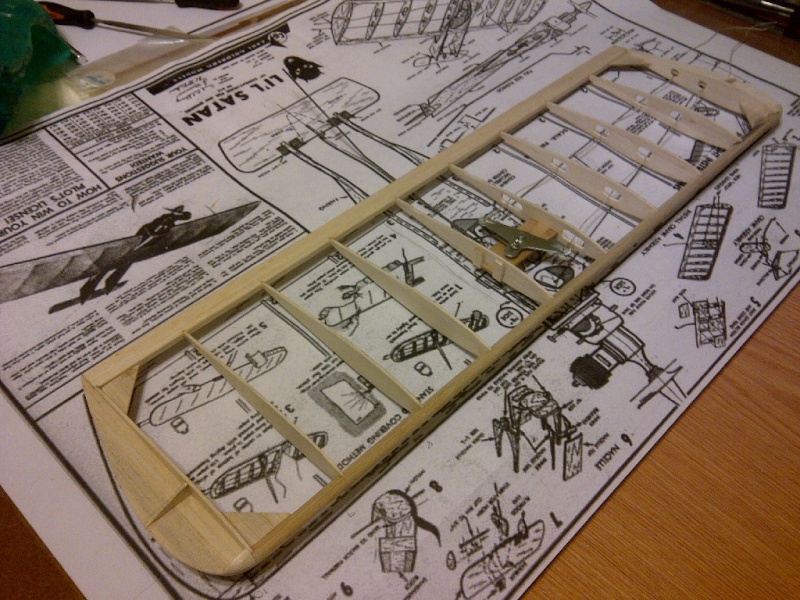

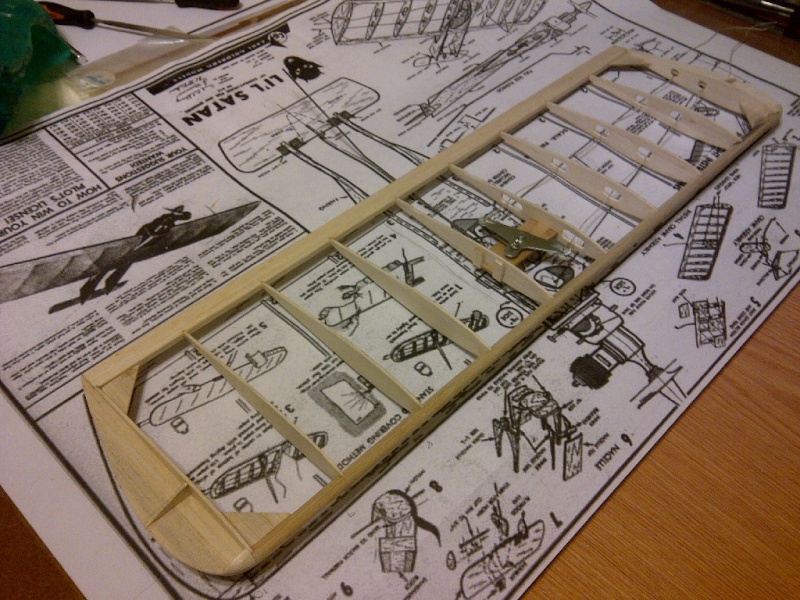

Now it is at this stage:

I will appreciate your comments and suggestions.

What tip weight should I add?

I cannot get from the plan what Balsa to use for the Elevator. Could someone please help me with what thickness balsa I should use?

Should I reinforce the nacelle around the joint of the firewall as indicated on the plan? Is this necessary?

I see that the firewall on the outer wing side is basically onto the leading endge. Thus the engine back plate on the right side will be very close to the leading edge. Any comments on this?

Theo

I have started a little Satan build. After seeing how much fun you guys have had with them. I am scratch building from the old Goldberg kit plan.

This is how it started a few nights ago:

Then it went to this:

Now it is at this stage:

I will appreciate your comments and suggestions.

What tip weight should I add?

I cannot get from the plan what Balsa to use for the Elevator. Could someone please help me with what thickness balsa I should use?

Should I reinforce the nacelle around the joint of the firewall as indicated on the plan? Is this necessary?

I see that the firewall on the outer wing side is basically onto the leading endge. Thus the engine back plate on the right side will be very close to the leading edge. Any comments on this?

Theo

Theo Kleynhans- Gold Member

- Posts : 196

Join date : 2013-12-30

Age : 43

Location : South Africa

Re: My first Little Satan build

Re: My first Little Satan build

Theo,

Nice job on the build, that's a fun airplane. I've built a few little satans. They are how I taught myself inverted flight.

I think I used 1/4oz tip weight but I can't be sure. I use 1" fiberglass tape applied with thinned epoxy to wrap from the top of the nacelle across the firewall to the bottom. This is a very important step, don't leave it out. The outboard nacelle is shorter so the engine points out and keeps the lines tight. I would use hard 1/8 balsa for the elevator.

What engine do you plan on using?

Jim

Nice job on the build, that's a fun airplane. I've built a few little satans. They are how I taught myself inverted flight.

I think I used 1/4oz tip weight but I can't be sure. I use 1" fiberglass tape applied with thinned epoxy to wrap from the top of the nacelle across the firewall to the bottom. This is a very important step, don't leave it out. The outboard nacelle is shorter so the engine points out and keeps the lines tight. I would use hard 1/8 balsa for the elevator.

What engine do you plan on using?

Jim

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 57

Location : Colorado

Re: My first Little Satan build

Re: My first Little Satan build

Thank you for the info Jim.

I will ensure to do the fiberglass strengthening.

Yes I hope mine will also be a great plane and fun to fly.

I am going to use a Black Widow for now. I also have a Norvel that I am busy running in. Maybe I will try it with the Norvel later on.

Do I also use the fiberglass tape on the hinges on the elevator?

Theo

I will ensure to do the fiberglass strengthening.

Yes I hope mine will also be a great plane and fun to fly.

I am going to use a Black Widow for now. I also have a Norvel that I am busy running in. Maybe I will try it with the Norvel later on.

Do I also use the fiberglass tape on the hinges on the elevator?

Theo

Theo Kleynhans- Gold Member

- Posts : 196

Join date : 2013-12-30

Age : 43

Location : South Africa

Re: My first Little Satan build

Re: My first Little Satan build

You can do Theo. On my JR Satan, I cut a 90° groove in the elevator's leading edge to locate the hinge. I then epoxied the hinge with 2h époxy to the elevator. Also try to use 1 continuous wire for both hinges.

This is only 1 way of doing it.

Lieven

This is only 1 way of doing it.

Lieven

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: My first Little Satan build

Re: My first Little Satan build

Hi Theo

My very old Li'l Satan plans said to use a sewing pin as a hinge on each side held in place with either epoxy and fabric or fiberglass tape. And mine came loose. Luckily it came loose two flights after I flew the Traveling prop. The plans I sent to you were a new Brodak version. A continuous hinge made from very thin music wire is a good idea. It's easy to make it tail heavy and difficult to add nose weight, so 3/64" wire, max. Personally, I think 1/8" balsa is too thick for the tiny Li'l Satan. My stab is hard 1/16" balsa with a ply doubler to support the control horn.

The plans I sent to you were a new Brodak version. A continuous hinge made from very thin music wire is a good idea. It's easy to make it tail heavy and difficult to add nose weight, so 3/64" wire, max. Personally, I think 1/8" balsa is too thick for the tiny Li'l Satan. My stab is hard 1/16" balsa with a ply doubler to support the control horn.

When I re-made my tail feathers the other day, I got overly fancy. The CF tube is not necessary as long as the hinge pin moves freely. My pin is locked and the tube pivots on the wire. My tube is wire wrapped and epoxied to the stab. I made my cutout reliefs too large, and plan to fill them with some scrap balsa.

Rusty

My very old Li'l Satan plans said to use a sewing pin as a hinge on each side held in place with either epoxy and fabric or fiberglass tape. And mine came loose. Luckily it came loose two flights after I flew the Traveling prop.

When I re-made my tail feathers the other day, I got overly fancy. The CF tube is not necessary as long as the hinge pin moves freely. My pin is locked and the tube pivots on the wire. My tube is wire wrapped and epoxied to the stab. I made my cutout reliefs too large, and plan to fill them with some scrap balsa.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My first Little Satan build

Re: My first Little Satan build

Nice looking plane, Theo. Your build is going great. I keep thinking about a Little Satan also, but my mind keeps going off in odd directions when I sit down to print out plans. Can't wait to see how yours turns out.

The Thinker Mark

The Thinker Mark

batjac- Diamond Member

Posts : 2375

Join date : 2013-05-22

Age : 61

Location : Broken Arrow, OK, USA

Re: My first Little Satan build

Re: My first Little Satan build

Theo, is that Dacron line your using for leadout material on a aluminum bellcrank? That could be very short lived. I highly suggest using either .015" braided wire or solid music wire like 1/64" for that purpose. Personally I prefer braided due to it not kinking and binding. It's much more forgiving over the solids not to mention smoother. Ken

Ken Cook- Top Poster

- Posts : 5644

Join date : 2012-03-27

Location : pennsylvania

Re: My first Little Satan build

Re: My first Little Satan build

Good catch, I missed that.Ken Cook wrote: Theo, is that Dacron line your using for leadout material on a aluminum bellcrank? Ken

Thanks for not mentioning the old greasy dacron hanging from the end of my wing. It's on a nylon crank, but as I found last week, there's no reasonable amount of surgery possible to change it once it's all sealed up.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My first Little Satan build

Re: My first Little Satan build

Rusty,RknRusty wrote:Good catch, I missed that.Ken Cook wrote: Theo, is that Dacron line your using for leadout material on a aluminum bellcrank? Ken

Thanks for not mentioning the old greasy dacron hanging from the end of my wing. It's on a nylon crank, but as I found last week, there's no reasonable amount of surgery possible to change it once it's all sealed up.

Rusty

this is what the easiest reasonable surgery looks like!

Theo,

This is why you reinforce the nacelle with fiberglass. I can't tell you how many times this plane had flown straight into the ground. Tail booms are easily replaced and the nacelle stays in one piece.

Jim

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 57

Location : Colorado

Re: My first Little Satan build

Re: My first Little Satan build

Ha! Yeah, that's one way to get to the bellcrank. I'll reinforce what Jim says, glass the nacelle. Here are some pictures of my construction a few years ago. It's solid as a rock.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My first Little Satan build

Re: My first Little Satan build

Do both you and Jim have Brodak versions?

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: My first Little Satan build

Re: My first Little Satan build

Mine is from a pair of hand cut kits I bought on eBay a couple years ago. I have a 1/2a elliptical combat wing from the same seller I need to build.Cribbs74 wrote:Do both you and Jim have Brodak versions?

Jim

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 57

Location : Colorado

Re: My first Little Satan build

Re: My first Little Satan build

Mine is a Goldberg original. And I have a new Brodak Li'l Satan in the box. I want to build a couple of 1/2As later this Summer including that one and a Stuntman23 with a solid airfoil.

Rusty

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My first Little Satan build

Re: My first Little Satan build

Yeah your guys Bellcranks are in the right spot. If I knew then what I know now I would have corrected that.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: My first Little Satan build

Re: My first Little Satan build

Thanks Guys for all the assistance and nice words.

Lieven, Thank you for showing me how you do the elevator.

Rusty, Thanks for showing me what you did regarding the elevator and the necalle. I have never used epoxy before. Hope it is not difficult to use.

Mark, maybe when I am done and you see it finished, you could start your own.

Ken, thanks for letting me know with regards to the dacron leadouts. Unfortunately I already closed the middle section last night. I hope it will not fail. Dammit, why did I not see the post before I closed the middle section. It will be very difficult to open it up again I guess. What do you propose? Can I leave it?

This is the wing as it stands:

Any comments regarding the epoxy to use and how to apply it?

Theo

Lieven, Thank you for showing me how you do the elevator.

Rusty, Thanks for showing me what you did regarding the elevator and the necalle. I have never used epoxy before. Hope it is not difficult to use.

Mark, maybe when I am done and you see it finished, you could start your own.

Ken, thanks for letting me know with regards to the dacron leadouts. Unfortunately I already closed the middle section last night. I hope it will not fail. Dammit, why did I not see the post before I closed the middle section. It will be very difficult to open it up again I guess. What do you propose? Can I leave it?

This is the wing as it stands:

Any comments regarding the epoxy to use and how to apply it?

Theo

Theo Kleynhans- Gold Member

- Posts : 196

Join date : 2013-12-30

Age : 43

Location : South Africa

Re: My first Little Satan build

Re: My first Little Satan build

Theo,

As the saying goes "An ounce of prevention is worth a pound of cure"

At this stage of the game it's easier to do it now. I am not sure what glue you used to adhere the sheeting, but if CA they make debonder. If something else like Sigment or Ambroid type glue some denatured alcohol might work(might)

In either case you can slowly separate the sheeting on one side if you work slow with a hobby knife cutting and prying along the joint.

As far as epoxy is concerned it's usually two part and is mixed together and applied with a spreader or whatever is handy. A little goes a long way! If you apply too much it can be removed with alcohol if it is still curing. I would apply Epoxy to the Bell crank mount once you have the sheeting removed.

Epoxy is usually found at hobby stores and is sold as 5, 15 or 30 min. That refers to the time it takes to hard set. Rule of thumb is the longer it takes to set the better the adhesion.

Ron

As the saying goes "An ounce of prevention is worth a pound of cure"

At this stage of the game it's easier to do it now. I am not sure what glue you used to adhere the sheeting, but if CA they make debonder. If something else like Sigment or Ambroid type glue some denatured alcohol might work(might)

In either case you can slowly separate the sheeting on one side if you work slow with a hobby knife cutting and prying along the joint.

As far as epoxy is concerned it's usually two part and is mixed together and applied with a spreader or whatever is handy. A little goes a long way! If you apply too much it can be removed with alcohol if it is still curing. I would apply Epoxy to the Bell crank mount once you have the sheeting removed.

Epoxy is usually found at hobby stores and is sold as 5, 15 or 30 min. That refers to the time it takes to hard set. Rule of thumb is the longer it takes to set the better the adhesion.

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: My first Little Satan build

Re: My first Little Satan build

Theo,

Why don't you cut 2 10 to 12 mm holes, 1 above each bellcrank end. That will allow you to cut the knot. Then you could feed the braided wire through the hole and make the loop long enough to make the knot outside the covered part. It will be a bit of a fiddle but it could work. You can plug the holes again with a round piece of balsa or directly by iron on covering. What do you think?

Lieven

Why don't you cut 2 10 to 12 mm holes, 1 above each bellcrank end. That will allow you to cut the knot. Then you could feed the braided wire through the hole and make the loop long enough to make the knot outside the covered part. It will be a bit of a fiddle but it could work. You can plug the holes again with a round piece of balsa or directly by iron on covering. What do you think?

Lieven

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: My first Little Satan build

Re: My first Little Satan build

Hi Theo, Your build looks great! sorry about the bell-crank dilemma... Like Ron said; better to fix it "now".. than to constantly worry about when your lead-out will break. I've always used "solids".. but I could've made the same mistake. There's so much valuable information you'll get from fellow modelers here.. and this is just one more thing I never knew could happen.

Epoxy is something you'll always want to have in your assortment of adhesives. As Ron also said; it is a two-part adhesive, and needs to be mixed in order to work. Be sure to thoroughly mix together equal parts of resin and hardener.. and only mix enough to do the job at hand. Once mixed; it has a "pot-life".. and if your using the 5-minute type, you need to work FAST!

As with anything model-building related; "preparation is everything". Assure adequate ventilation and protect your work surface with wax paper or plastic wrap, (snug-fitting vinyl surgical gloves keep your fingers clean.. and the oils from your skin off the model) Devise a clamping method beforehand.. make sure your joints fit well, have some cotton swabs/tissues on hand to smooth-out/remove blobs of excess glue that may seep out or spill. A great tool for spreading mixed epoxy is a Plumber's "flux-brush" with it's bristles cut short with scissors (to approx. 3/8" or shorter)

This allows you to brush-on the glue and spread it evenly. An un-noticed epoxy glue-blob once hardened; requires trimming-off with a blade.. which can risk breaking delicate construction. I save the flexible plastic lids from food containers for a palette to mix epoxy on and can be reused many times. Set it aside when finished.. and later when the glue has set; it will easily peel off the lid.

Epoxy is something you'll always want to have in your assortment of adhesives. As Ron also said; it is a two-part adhesive, and needs to be mixed in order to work. Be sure to thoroughly mix together equal parts of resin and hardener.. and only mix enough to do the job at hand. Once mixed; it has a "pot-life".. and if your using the 5-minute type, you need to work FAST!

As with anything model-building related; "preparation is everything". Assure adequate ventilation and protect your work surface with wax paper or plastic wrap, (snug-fitting vinyl surgical gloves keep your fingers clean.. and the oils from your skin off the model) Devise a clamping method beforehand.. make sure your joints fit well, have some cotton swabs/tissues on hand to smooth-out/remove blobs of excess glue that may seep out or spill. A great tool for spreading mixed epoxy is a Plumber's "flux-brush" with it's bristles cut short with scissors (to approx. 3/8" or shorter)

This allows you to brush-on the glue and spread it evenly. An un-noticed epoxy glue-blob once hardened; requires trimming-off with a blade.. which can risk breaking delicate construction. I save the flexible plastic lids from food containers for a palette to mix epoxy on and can be reused many times. Set it aside when finished.. and later when the glue has set; it will easily peel off the lid.

Re: My first Little Satan build

Re: My first Little Satan build

Another nice build coming along.

Where on the plan did you get the profile to cut the ribs from?

Where on the plan did you get the profile to cut the ribs from?

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: My first Little Satan build

Re: My first Little Satan build

The simplest way to get into sheeting is to use a straight edge and cut with your knife on a sharp bevel. Don't have your knife at a 90 deg angle to your work. Keep it at a good 35 deg-40 deg angle. Pull out the piece and do what you have to do. The pieces will go right back in and can be glued . There's no need for anything under it using this method. Ken

Ken Cook- Top Poster

- Posts : 5644

Join date : 2012-03-27

Location : pennsylvania

Re: My first Little Satan build

Re: My first Little Satan build

Absolutely, I agree. It's the neatest, easiest, and strongest way. No need for micro-surgery.Ken Cook wrote: The simplest way to get into sheeting is to use a straight edge and cut with your knife on a sharp bevel. Don't have your knife at a 90 deg angle to your work. Keep it at a good 35 deg-40 deg angle. Pull out the piece and do what you have to do. The pieces will go right back in and can be glued . There's no need for anything under it using this method. Ken

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: My first Little Satan build

Re: My first Little Satan build

I would also suggest that you use nuts behind your firewall if you haven't already. I personally use 2-56 blind nuts for this purpose. I epoxy them into the ply. This stops oil migration and also keeps wood screws from tearing out of the wood. Ken

Ken Cook- Top Poster

- Posts : 5644

Join date : 2012-03-27

Location : pennsylvania

Re: My first Little Satan build

Re: My first Little Satan build

Couldn't agree more. I tried blind nuts once and now I can't imagine building a 1/2a without them.Ken Cook wrote:I would also suggest that you use nuts behind your firewall if you haven't already. I personally use 2-56 blind nuts for this purpose. I epoxy them into the ply. This stops oil migration and also keeps wood screws from tearing out of the wood. Ken

Jim

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 57

Location : Colorado

Its all right now

Its all right now

Theo I know it hurts to cut that pretty but is the best way to keep it is to do it now read , figure and just figure out what you need to do , step by step as you rebuild it to change it to make it right these guys know there stuff and can be over whelming , been there and have had to correct a few of my mistakes (did not know no better ). Learning is a good thing you have a good learning ability , skill going there just needs shaping  Getback

Getback

getback- Top Poster

Posts : 10443

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: My first Little Satan build

Re: My first Little Satan build

Guys, thank you for all the comments and recommendations regarding the changing of the leadouts and how to get back in the centre area.

I was staring at the wing and thinking for quite some time last night before starting. I actually did not have to cut anything to get them changed. I changed them through the leadout holes in the middle rib. It took a lot of patience, frustrations and long nose pliers, but at the end I got them changed without cutting any wood. I am so glad about that one.

Roddie, thank you for the info on the epoxy. I got some 30min epoxy. We will see how that will turn out.

ian1954, I got the rib template at the bottom left of the plan. You do need to create your own one for the middle sheeted section. I just used the original template and cut away the thinkness of the sheeting for the centre ones.

Ken, thanks for letting me know regarding the blind nuts. Do anyone have a picture to share so I can see how this looks when it is finished in the plywood whith the epoxy? I just want to make sure I do it the right way.

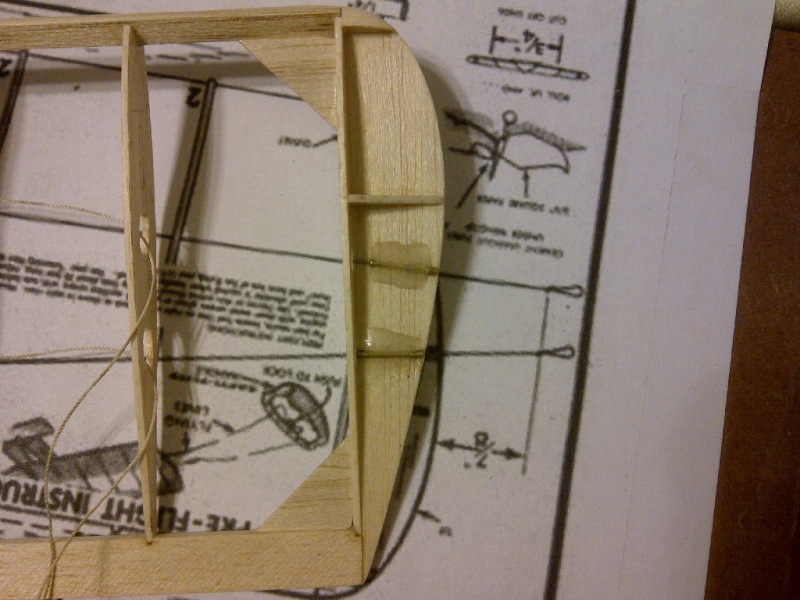

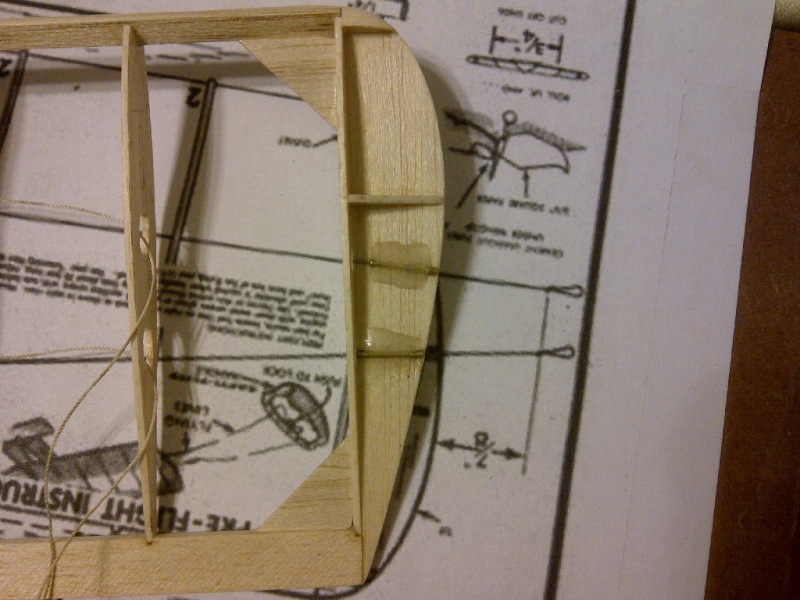

I cut all the rest of the parts last night and started with the necalle.

This is where I am at the moment:

Now I need to finish the necalle and do the blind nuts.

Then I will start the booms and elevator. Regarding this, do I first fix the booms to the wing and then do the elevator portion?

Thanks again Guys

Theo

I was staring at the wing and thinking for quite some time last night before starting. I actually did not have to cut anything to get them changed. I changed them through the leadout holes in the middle rib. It took a lot of patience, frustrations and long nose pliers, but at the end I got them changed without cutting any wood. I am so glad about that one.

Roddie, thank you for the info on the epoxy. I got some 30min epoxy. We will see how that will turn out.

ian1954, I got the rib template at the bottom left of the plan. You do need to create your own one for the middle sheeted section. I just used the original template and cut away the thinkness of the sheeting for the centre ones.

Ken, thanks for letting me know regarding the blind nuts. Do anyone have a picture to share so I can see how this looks when it is finished in the plywood whith the epoxy? I just want to make sure I do it the right way.

I cut all the rest of the parts last night and started with the necalle.

This is where I am at the moment:

Now I need to finish the necalle and do the blind nuts.

Then I will start the booms and elevator. Regarding this, do I first fix the booms to the wing and then do the elevator portion?

Thanks again Guys

Theo

Theo Kleynhans- Gold Member

- Posts : 196

Join date : 2013-12-30

Age : 43

Location : South Africa

Page 1 of 3 • 1, 2, 3

Similar topics

Similar topics» Super Satan build

» Lil' Satan build.

» Yet another Lil' Satan build...

» I put a Tee Dee on my Lil' Satan

» Another Li'l Satan build (Finished)

» Lil' Satan build.

» Yet another Lil' Satan build...

» I put a Tee Dee on my Lil' Satan

» Another Li'l Satan build (Finished)

Page 1 of 3

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules