Log in

Search

Latest topics

» Retail price mark-up.. how much is enough?by Ken Cook Today at 5:08 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 4:34 pm

» Happy 77th birthday Andrew!

by rdw777 Today at 4:04 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 2:15 pm

» TEE DEE Having issues

by balogh Today at 1:42 pm

» Cox films/videos...

by Coxfledgling Today at 10:46 am

» My N-1R build log

by roddie Today at 6:32 am

» Landing-gear tips

by roddie Today at 12:17 am

» Roger Harris revisited

by TD ABUSER Yesterday at 8:13 pm

» My latest doodle...

by roddie Yesterday at 4:43 pm

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 7:13 pm

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 3:24 pm

Cox Engine of The Month

CEF speed contest Design Discussions

Page 19 of 40

Page 19 of 40 •  1 ... 11 ... 18, 19, 20 ... 29 ... 40

1 ... 11 ... 18, 19, 20 ... 29 ... 40

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

That's right, Roddie! I'm here because it IS fun, and I get to see other people's ideas, and share mine. The cometition is just an incentive to promote involvement! The fellowship of model airplanes is a basis for community. (except ARFs) Oops, how did that slip out? If you don't build, you can STILL fly! There.

GUS THE I.A.- Gold Member

- Posts : 359

Join date : 2012-08-15

Location : Wichita, Kansas

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

Lieven, looking good! Can't wait to see the finished Caudron. I built a rubber powered one in peanut scale years who and it was a great flyer.

Mike, that model is going to be cool, can't wait to see it fly.

Gus, the level of detail on your models is amazing. Let's see some video if that Corsair in the air.

Thanks to everyone involved for the high level of participation, can't wait for the flight videos to start coming in.

Jim

Mike, that model is going to be cool, can't wait to see it fly.

Gus, the level of detail on your models is amazing. Let's see some video if that Corsair in the air.

Thanks to everyone involved for the high level of participation, can't wait for the flight videos to start coming in.

Jim

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 57

Location : Colorado

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

Yeah, this whole worldwide postal comp thing is really good. Its fantastic to see the models and having shared ideas and goals. It realy does give the internet purpose. I'm looking forward to the final photo gallery and and the posted times. The Corsair has set the bench mark very high though

Cheers Mike

Cheers Mike

ebeneezer- Gold Member

- Posts : 282

Join date : 2012-05-22

Age : 66

Location : Banbury Oxfordshire England

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

I'm WAY behind with the Rare Bear... I did a lot of little odds and ends this weekend. Little odds and ends add up to a LOT of time!

This is one of many custom .040" aluminum bell-cranks I made in 3 sizes on a CNC router years ago. I'm finally getting to use one of the smallest ones. The bearing is acrylic and was also routered. Lead-outs are .031" music-wire.

I still haven't soldered my tank(s) yet.. but I'm hoping that this setup will help with the task.

This is one of many custom .040" aluminum bell-cranks I made in 3 sizes on a CNC router years ago. I'm finally getting to use one of the smallest ones. The bearing is acrylic and was also routered. Lead-outs are .031" music-wire.

I still haven't soldered my tank(s) yet.. but I'm hoping that this setup will help with the task.

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

Those leadouts look great. Every time I do solid leadouts they turn out looking like crap.

Jim

Jim

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 57

Location : Colorado

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

Yeah Man!

I'll second what Jim said. Those solids look great!

Ron

I'll second what Jim said. Those solids look great!

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

I am seeing some fine pieces of miniature metal work here. Be careful with the crocodile clips on the helping hands - they are not very strong!

I have bust a few "helping hands" including the magnifying glass (it overbalances easily). I have melted a crocodile clip but ............. they are so useful, I keep buying another one!

I have bust a few "helping hands" including the magnifying glass (it overbalances easily). I have melted a crocodile clip but ............. they are so useful, I keep buying another one!

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

Crocodile clip! That's what alligator clips are called on the other side of the swamp?  That's what I'm gonna call them from now on. I forget which is which, but gators and crocs have oppositely hinged jaws.

That's what I'm gonna call them from now on. I forget which is which, but gators and crocs have oppositely hinged jaws.

Seriously nice equipment being built. My first thought, back on page 1 was, piece o' cake, I can win this thing! Not so much now. You guys are on the game.

Rusty

That's what I'm gonna call them from now on. I forget which is which, but gators and crocs have oppositely hinged jaws.

That's what I'm gonna call them from now on. I forget which is which, but gators and crocs have oppositely hinged jaws.Seriously nice equipment being built. My first thought, back on page 1 was, piece o' cake, I can win this thing! Not so much now. You guys are on the game.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-11

Age : 68

Location : South Carolina, USA

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

Cribbs74 wrote:Yeah Man!

I'll second what Jim said. Those solids look great!

Ron

Thanks guys.. It had been quite a while since I'd made any. As I mentioned; this set is .031" dia. music-wire... a little "over-kill", but the only other choice on hand was .015"... too small for this app. in my opinion.

Not sure if this will help.. but I use 2 tools to bend the wire; The three 90 degree bends are made using needle-nose pliers; starting at a little over an inch from the wire's end. This leaves a "tang" to be coil-wound, and should be perpendicular to the long wire and ON TOP OF/OVER IT. I'm right-handed... so I position the wire so that the "work" is to the left, with the "tang" facing away from me and "over" the long wire. I then use a small locking-pliers in my left hand, to hold the last "bend" tight while I "wind" the coil with my right hand, using the needle-nose pliers. The .031" wire is the toughest to wind, I'll admit. If you have some .025" wire (I didn't...) it's much easier to wind. (having a bell-crank flopping around doesn't make things any easier either.. it gets attached after the 2nd.. and before the last 90 degree bend)

Make sure before you form both ends of your lead-out... that you "thread" whatever you're using for guides on FIRST.

If you forget.. it will make you rather upset!

Roddie

EDIT: this photo shows .025" music-wire that I formed for a tail-hook for my pin-stooge. The hook "floats" on the tail-gear strut and stows under the fuse for when photos are taken. Most of my airplanes have a stooge hook of some kind.. and it's usually the means for "hanging" them on a wall... in the "Hangar"!

Last edited by roddie on Tue Jan 21, 2014 1:04 am; edited 1 time in total

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

ian1954 wrote:I am seeing some fine pieces of miniature metal work here. Be careful with the crocodile clips on the helping hands - they are not very strong!

I have bust a few "helping hands" including the magnifying glass (it overbalances easily). I have melted a crocodile clip but ............. they are so useful, I keep buying another one!

Hi Ian, I'm not sure you noticed in the photo.. but I made "soft-jaws" for the Crocodile clips on my "helping-hands" fixture. I made them by cutting pieces 1/4" x 3/4" of bicycle tire "inner-tube" rubber... and facing one side with thin-film double-sided tape to "stick" to the jaws.

I try to protect all my lenses-magnifiers/reader/safety-glasses etc. by storing them in clear plastic bags until ready for use.

The "purely... and undeniably... OCD Roddie"

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

So much effort for soft jaws... medium silicone fuel line is so much easier and it is heat resistant.

Phil

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

pkrankow wrote:So much effort for soft jaws... medium silicone fuel line is so much easier and it is heat resistant.

Phil

but Phil... medium Silicone fuel line has a wall thickness of .060"... and it's expensive/precious! My inner-tube "flat-pad" material with film-tape measures .050" thick.. (with the adhesives' liner...) That works out to + .020" more of a bite with the Crocodile clip...

The "purely... and undeniably... OCD Roddie"

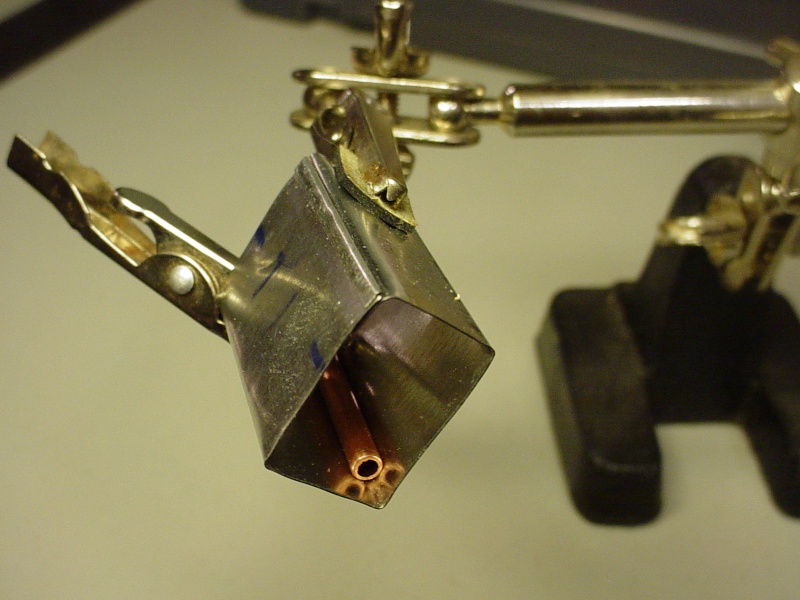

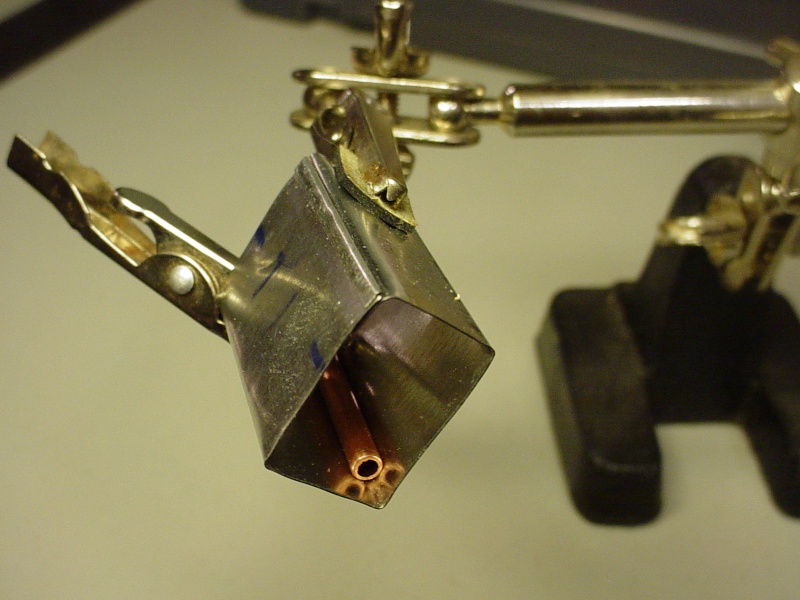

F8F-2 tank work

F8F-2 tank work

I finally got the nerve to start soldering the 1st of 4 tanks to test. Another lesson in patience... I used a 40w. iron with a long pointed tip, .022" dia. 62/36/2 Silver bearing solder and "Ruby-Fluid" paste flux. All that's left with this one is to solder the rear cap on, solvent-flush and leak test. I couldn't have done this work without a lighted magnifier... and it took me a good part of 5 hours... but that was with screwing around with different methods/fixturing etc. The other tanks should be easier.. and take a lot less time.

This is a uni-flow vent arrangement with a fill-tube that gets capped during running.

Roddie

This is a uni-flow vent arrangement with a fill-tube that gets capped during running.

Roddie

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

You got a good hot flow on the outside joints. Those look perfect.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-11

Age : 68

Location : South Carolina, USA

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

RknRusty wrote:You got a good hot flow on the outside joints. Those look perfect.

Thanks Rusty.. It definitely took some time. I had thoughts on testing the tanks on a short "RTP" tethered dolly, to see how they flow. It would be simple to build, and I would imagine a 10 ft. tether would produce higher "G's" than would be encountered on the 42 ft. lines we'll be using for the contest. It might help to see if shims are needed.

Roddie

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

The first few tanks always take a while - soldering them up isn't as easy as it looks! These look very neat.

I would be surprised if skin, hot solder, metal and the iron didn't make acquaintence at some time. This is 3D soldering and manipulating everything for a continuous run isn't always simple.

Solder in one hand, iron/torch in the other - I usually manage to burn my lip! I often use my teeth to pull solder from the reel or bend the end .... often forget it is hot!

Nice work - the metal work on those tanks is very neat.

I would be surprised if skin, hot solder, metal and the iron didn't make acquaintence at some time. This is 3D soldering and manipulating everything for a continuous run isn't always simple.

Solder in one hand, iron/torch in the other - I usually manage to burn my lip! I often use my teeth to pull solder from the reel or bend the end .... often forget it is hot!

Nice work - the metal work on those tanks is very neat.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

F8F-2 tank work

F8F-2 tank work

ian1954 wrote:The first few tanks always take a while - soldering them up isn't as easy as it looks! These look very neat.

I would be surprised if skin, hot solder, metal and the iron didn't make acquaintence at some time. This is 3D soldering and manipulating everything for a continuous run isn't always simple.

Solder in one hand, iron/torch in the other - I usually manage to burn my lip! I often use my teeth to pull solder from the reel or bend the end .... often forget it is hot!

Nice work - the metal work on those tanks is very neat.

Thanks much Ian, I "did" use the helping-hands fixture for a couple operations... particularly the "angled" uni-flow tube where it sits atop the pick-up tube at the rear.

I soldered the body-seam 1st.. followed by the front cap (it's definitely worth taking the extra time to dry-fit all the panels; tight and square)...

I cut a balsa gage-block to fit inside the rear body while standing on end to set the depth of the feed tube, while soldering it into the front cap. This worked ok... but I had to take care that the pick-up was also positioned tight into the lower rear corner.

I will try a "crocodile" clip... held by sm. locking pliers; to hold the tube in position next time.

Last edited by roddie on Fri Jan 24, 2014 11:53 pm; edited 1 time in total

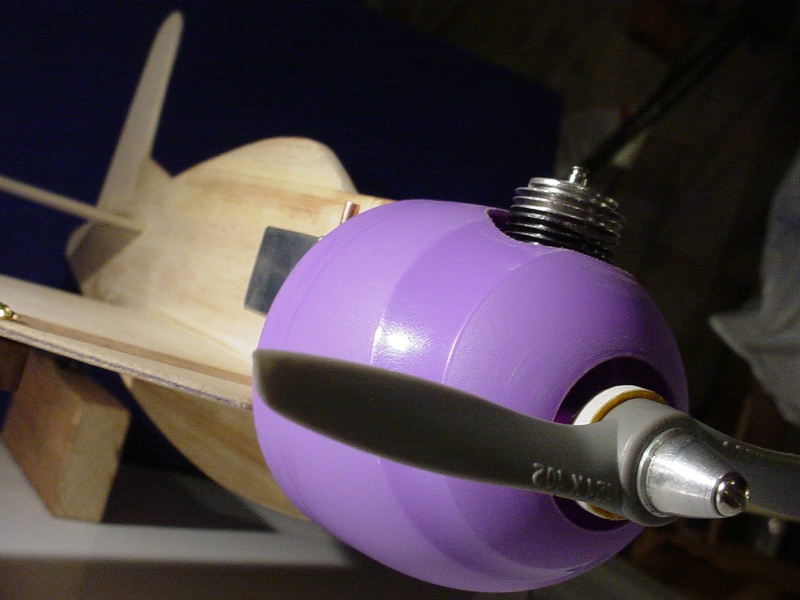

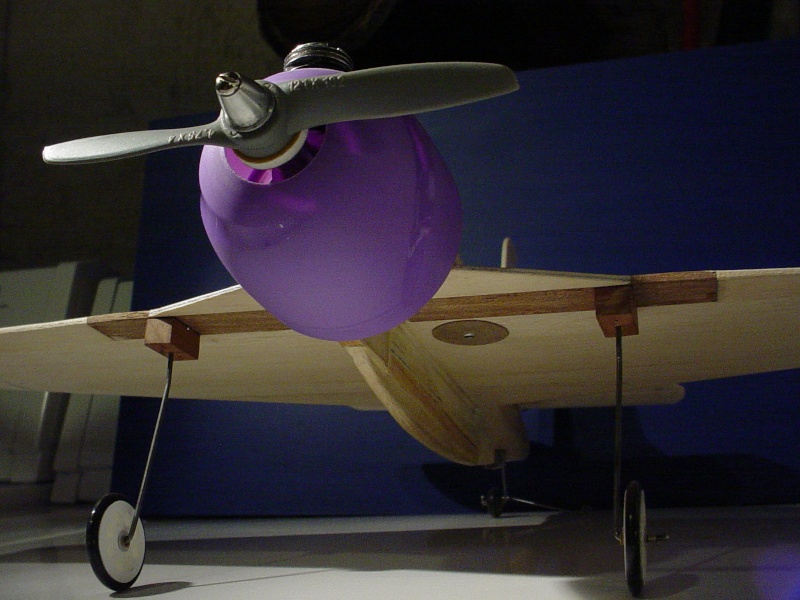

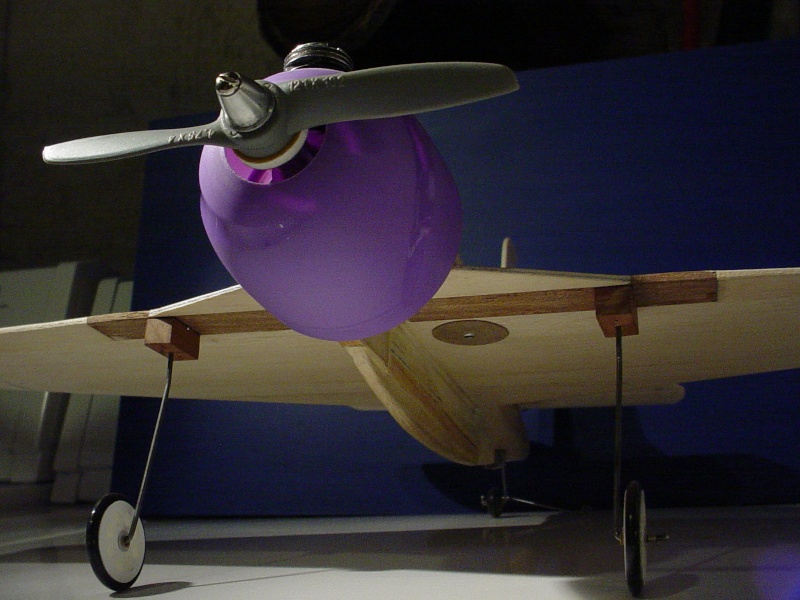

Roddie's F8F-2 "Rare-Bear"

Roddie's F8F-2 "Rare-Bear"

Without paint, controls and tank.. weight is just shy of 5 ounces. The plane is quite nose-heavy right now.. but has perfect longitudinal balance... not that it matters too much. It's sitting on the scale with spinner balancing in a small steel bushing.

sorry... can't seem to save correctly rotated pic...

I need a painting environment... my wife gets terrible migraines from anything solvent-based that's in the air... and "get this"... "She want's to help with painting the model"... and we live in a VERY small house. My workshop is less than 100 sq. ft. and it's freezing outside. For all the countless hours I have in this plane.. I have to let her paint something... she is an artist though...

My workshop is less than 100 sq. ft. and it's freezing outside. For all the countless hours I have in this plane.. I have to let her paint something... she is an artist though...

Roddie

Roddie

sorry... can't seem to save correctly rotated pic...

I need a painting environment... my wife gets terrible migraines from anything solvent-based that's in the air... and "get this"... "She want's to help with painting the model"... and we live in a VERY small house.

My workshop is less than 100 sq. ft. and it's freezing outside. For all the countless hours I have in this plane.. I have to let her paint something... she is an artist though...

My workshop is less than 100 sq. ft. and it's freezing outside. For all the countless hours I have in this plane.. I have to let her paint something... she is an artist though... Roddie

Roddie

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

Very nice, neat and meticulous workmanship. Tank and plane.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

You guys are putting my efforts to shame. Great modelling Roddie, as for the fuel tank great job. I consider myself a bit of a metal basher, but your fuel tank is fantastic. I'll keep mine hidden on the blind side of the model when I take some pics.

Cheers Mike

Cheers Mike

ebeneezer- Gold Member

- Posts : 282

Join date : 2012-05-22

Age : 66

Location : Banbury Oxfordshire England

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

When it comes to craftsmanship and detail work I think Roddie and Gus are going to put us all to shame.

Jim

Jim

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 57

Location : Colorado

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

Good work Roddie, very precise and clean.

I am struggling making a cowl at the moment. It should end up with something like this:

I am struggling making a cowl at the moment. It should end up with something like this:

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

OVERLORD wrote:Good work Roddie, very precise and clean.

I am struggling making a cowl at the moment. It should end up with something like this:

Thats a great looking Racer, Do you have the name of it?

Thanks, RK Flyer

RK Flyer- Gold Member

- Posts : 274

Join date : 2013-07-16

Location : Somerset, Kentucky

Page 19 of 40 •  1 ... 11 ... 18, 19, 20 ... 29 ... 40

1 ... 11 ... 18, 19, 20 ... 29 ... 40

Similar topics

Similar topics» CEF speed contest Design Discussions (2014)

» CEF T-Shirt Design Contest

» *VOTE* CEF T-Shirt Design Contest

» Cox Engine Forum Speed Contest 2018!!!

» Speed Contest

» CEF T-Shirt Design Contest

» *VOTE* CEF T-Shirt Design Contest

» Cox Engine Forum Speed Contest 2018!!!

» Speed Contest

Page 19 of 40

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules