Log in

Search

Latest topics

» Cox films/videos...by Coxfledgling Today at 4:46 am

» Purchased the last of any bult engines from Ken Enya

by Coxfledgling Today at 4:18 am

» My N-1R build log

by roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

Cox Engine of The Month

I need help

Page 1 of 1

I need help

I need help

Question #1=Can anyone tell me how to determine where the cg is on a plane with 33'' wing, 4'' chord and 25.750'' fuselage?

Question #2= How do you determine thrust angles on a engine, my plane will have above said dimensions and fuselage width of 1.125"

Question #3= How should I go about determining control throws and control surface sizes

thanks

Question #2= How do you determine thrust angles on a engine, my plane will have above said dimensions and fuselage width of 1.125"

Question #3= How should I go about determining control throws and control surface sizes

thanks

mitchg95- Diamond Member

- Posts : 2103

Join date : 2011-12-19

Age : 29

Location : Geneva, mn, USA

Re: I need help

Re: I need help

Mitch,

High wing, low wing? Power? All up weight? Can you shoot a quick picture? Should be easy enough to get in the ballpark.

High wing, low wing? Power? All up weight? Can you shoot a quick picture? Should be easy enough to get in the ballpark.

GUS THE I.A.- Gold Member

- Posts : 359

Join date : 2012-08-15

Location : Wichita, Kansas

Re: I need help

Re: I need help

mid wing design, kind of basing it off of a guillows "flying machine" rubber glider.

not sure on all up weight yet. So far the elevator and wings that I have made up are 2.8oz

wing is 1/4" balsa and elevator is 3/16"

not sure on all up weight yet. So far the elevator and wings that I have made up are 2.8oz

wing is 1/4" balsa and elevator is 3/16"

mitchg95- Diamond Member

- Posts : 2103

Join date : 2011-12-19

Age : 29

Location : Geneva, mn, USA

Re: I need help

Re: I need help

A Tee Dee engine, and others with the similar mounting, use the bottom surface of the mounting lugs as centerline, fore and aft. A Bee-type engine, you kind of "eyeball" , on the prop shaft, unless you have REAL dimensions. If you swing a large prop-slowly- trying for torque, you might add-in some right thrust, provided you rotate the propeller in the conventional direction. A degree or two. Rule of thumb on my scratch-built planes- R/C - is 25% to about 1/3rd of the chord, aft of the L.E. for the CG.

Hmmm, what else? Incidence is a biggie, too! I like to start with everything at 0-0-0, then add angles and stuff to correct weird flight tendencies.

Hmmm, what else? Incidence is a biggie, too! I like to start with everything at 0-0-0, then add angles and stuff to correct weird flight tendencies.

GUS THE I.A.- Gold Member

- Posts : 359

Join date : 2012-08-15

Location : Wichita, Kansas

re: wing CG

re: wing CG

mitchg95 wrote:Question #1=Can anyone tell me how to determine where the cg is on a plane with 33'' wing, 4'' chord and 25.750'' fuselage?

Question #2= How do you determine thrust angles on a engine, my plane will have above said dimensions and fuselage width of 1.125"

Question #3= How should I go about determining control throws and control surface sizes

thanks

typical CG for the plane is 20 to 30% of the wing cord back from the leading edge of the wing. the 20 to 30% is typical and the final number depends on what you do with the plane. stunt, glide, etc. I would lean to 20% of 4inchs or .8inch from the leading edge of a fully loaded plane, engine, landing gear, and all hardware.

if the plane is RC the best way to determine CG is to take the plane up to a safe altitude, 75 to 100 feet. trim the plane for neutral, or flat flight, then MOMENTARILY put the plane into a dive AND release the controls. the plane should

that's the way I remember it. these rules can be used for control line if you are real good at knowing where your control handle neutral point is.

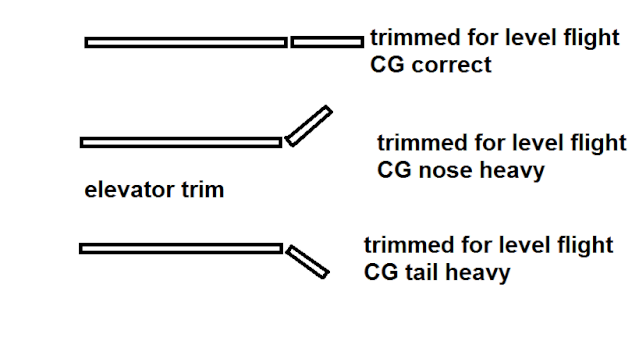

edit 6-21-13 9:10p.m. - after thinking about this subject last night I believe I have the end results backwards. if the plane is trimmed for straight flight and the CG is correct, when it is placed into a dive it will continue in the dive if the CG is correct. see pic later.

if the plane is nose heavy the plane will have to be trimmed with a bit of up elevator for level flight resulting in a pullout when the plane is placed into a dive. again see pic later.

if the plane is tail heavy the plane will have to be trimmed with a bit of down elevator for level flight resulting in a steeper dive when the RC controls are released. see pic below.

hope this helps.

that's my 2 cents.

happydad

happydad

Last edited by happydad on Fri Jun 21, 2013 11:38 pm; edited 1 time in total (Reason for editing : to correct text/answer to correct CG question)

happydad- Rest In Peace

- Posts : 1592

Join date : 2012-05-28

Age : 79

Location : Escondido, CA

Re: I need help

Re: I need help

thanks HD that helps a bunch, i will have to print that out and post it to my poster board so i will always remember that tip

mitchg95- Diamond Member

- Posts : 2103

Join date : 2011-12-19

Age : 29

Location : Geneva, mn, USA

Re: I need help

Re: I need help

its going to be rc, and will be a sport model

mitchg95- Diamond Member

- Posts : 2103

Join date : 2011-12-19

Age : 29

Location : Geneva, mn, USA

Re: I need help

Re: I need help

#1 - Assuming a constant chord wing, look at the end of the wing to see the airfoil shape. It is generally assumed that the c.g. is at the thickest point of the wing. Most general airfoils used on our planes fall somewhere around 1/3 of the chord back from the leading edge. This is for simple Clark Y or USA35B type airfoils. I usually mark the wing on both sides of the fuselage at 25% and 33%, then make sure it balances between these points for the first flights. Gliding or idle throttle flight will tell you which way you need to move the c.g. from there.

#2 - Width isn't that big a deal. It's the wing position that counts. With a high wing or shoulder wing you need down thrust. The higher the wing above the centerline (assuming the prop is on the centerline), and the thicker the wing, the more down thrust you need. A low wing plane generally doesn't use down thrust. For a high wing trainer type plan, use 3-5 degrees down thrust for a start. Since you say a mid-wing design, I'll assume the wing is generally in-line with the prop, so I'd go 0 myself, or maybe 1-2 degrees if it's more of a shoulder wing plane or if you're doing rudder and elevator only. Right thrust is more determined by the engine you're using, weight of the plane, and whether it's a speed plane or a slower trainer that flies more on the wing than the prop. I'd go maybe 2-3 degrees by what you've described.

#3 - Since it doesn't sound like you'll be doing much aerobatics, I'd size the rudder at 30% of total fin area (Total combined Fin area, rudder area, and area beneath the two.), elevator also at 30% of the total horizontal stabilizer area. Ailerons should be about 12-15% of the total wing area, whether you use strip ailerons or barn door ailerons. As for throws, I've always used TLAR, then decrease (normally) or increase after the first couple of flights.

These are the general rules I used to use in designing planes in the 80's and early 90's, and they all flew pretty good. I doubt that small plane aerodynamics have changed much in the last 20 years. Just start easy and make changes after getting a feel from the test flights.

The Scholarly Mark

#2 - Width isn't that big a deal. It's the wing position that counts. With a high wing or shoulder wing you need down thrust. The higher the wing above the centerline (assuming the prop is on the centerline), and the thicker the wing, the more down thrust you need. A low wing plane generally doesn't use down thrust. For a high wing trainer type plan, use 3-5 degrees down thrust for a start. Since you say a mid-wing design, I'll assume the wing is generally in-line with the prop, so I'd go 0 myself, or maybe 1-2 degrees if it's more of a shoulder wing plane or if you're doing rudder and elevator only. Right thrust is more determined by the engine you're using, weight of the plane, and whether it's a speed plane or a slower trainer that flies more on the wing than the prop. I'd go maybe 2-3 degrees by what you've described.

#3 - Since it doesn't sound like you'll be doing much aerobatics, I'd size the rudder at 30% of total fin area (Total combined Fin area, rudder area, and area beneath the two.), elevator also at 30% of the total horizontal stabilizer area. Ailerons should be about 12-15% of the total wing area, whether you use strip ailerons or barn door ailerons. As for throws, I've always used TLAR, then decrease (normally) or increase after the first couple of flights.

These are the general rules I used to use in designing planes in the 80's and early 90's, and they all flew pretty good. I doubt that small plane aerodynamics have changed much in the last 20 years. Just start easy and make changes after getting a feel from the test flights.

The Scholarly Mark

batjac- Diamond Member

Posts : 2375

Join date : 2013-05-22

Age : 61

Location : Broken Arrow, OK, USA

Re: I need help

Re: I need help

Thanks Mark, It does have a constant chord, i might sand an airfoil into the sheeted wings but i am not sure yet. I might do ailerons and elevator with throttle, ill right down the thrust recomendations that you gave

mitchg95- Diamond Member

- Posts : 2103

Join date : 2011-12-19

Age : 29

Location : Geneva, mn, USA

Re: I need help

Re: I need help

I have a table in one of my modelling books that summarizes the CG location issue.

Two main factors are:

1. Ratio of wing area to stab area - the bigger the ratio the more aft the CG

2. Ratio of mean wing chord to the stab lever length (defined as distance between geometrical center of the stab and the theoretical CG) - the bigger the ratio the more forward the CG.

I can make a scan and send it to you, if you want.

Two main factors are:

1. Ratio of wing area to stab area - the bigger the ratio the more aft the CG

2. Ratio of mean wing chord to the stab lever length (defined as distance between geometrical center of the stab and the theoretical CG) - the bigger the ratio the more forward the CG.

I can make a scan and send it to you, if you want.

dirk gently- Gold Member

- Posts : 430

Join date : 2012-02-03

Age : 42

Location : Poznań

Re: I need help

Re: I need help

dirk gently wrote:I have a table in one of my modelling books that summarizes the CG location issue.

Two main factors are:

1. Ratio of wing area to stab area - the bigger the ratio the more aft the CG

2. Ratio of mean wing chord to the stab lever length (defined as distance between geometrical center of the stab and the theoretical CG) - the bigger the ratio the more forward the CG.

I can make a scan and send it to you, if you want.

that would be great if you could scan it, it would be a real big help

mitchg95- Diamond Member

- Posts : 2103

Join date : 2011-12-19

Age : 29

Location : Geneva, mn, USA

Re: I need help

Re: I need help

https://2img.net/r/ihimizer/img824/4065/nu7l.jpg

SH - horizontal stab surface

S - wing surface

LH - distance between geometrical center of the stab and the geometrical surface of the wing

lśr - mean wing chord

The percentages in the table are percentages of the mean wing chord.

SH - horizontal stab surface

S - wing surface

LH - distance between geometrical center of the stab and the geometrical surface of the wing

lśr - mean wing chord

The percentages in the table are percentages of the mean wing chord.

dirk gently- Gold Member

- Posts : 430

Join date : 2012-02-03

Age : 42

Location : Poznań

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules