Log in

Search

Latest topics

» My N-1R build logby roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Fri Nov 22, 2024 11:32 am

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

Cox Engine of The Month

"Old School" Stitched Hinges

Page 1 of 2

Page 1 of 2 • 1, 2

"Old School" Stitched Hinges

"Old School" Stitched Hinges

I do love stitched hinges. They can easily outlast the life of the plane, but require a bit more "manipulation". I add mine after the plane and it's surfaces are totally painted and finished. If you don't like their appearance, they can be "hidden in plain sight" by painting black boxes over them.

Once the plane is finished, scotch tape the two surfaces together as they will be in use. Mark three holes on either side of the hinge line, and drill them through with a small bit (1/16th or less), or you can just push the needle through. Using a sewing needle, threaded with carpet thread, sew them together using a figure 8 pattern, gently drawing out the slack as you go. The needle should go through the hinge line and into the opposite side on each pass, never going straight across the top or bottom.

I always put one set of hinges right next to the control horn to help it move the surface squarely.

Once the individual hinge is finished, CAREFULLY place a drop of CA at each spot where the thread goes through the surface...NOT getting any in the hinge line. Some glue will wick down the thread to the hinge line, but will usually break loose easily and get better with use. Finish all the hinges, then carefully pull the tape off. Work the controls gently to break loose any glue that's made it to the hinge line.

When done properly, the hinges will work easily, with NO slop in any direction, and can go to 90 degrees deflection if you decide to have a "Crazy Moment" !!

Whew! That's it...hope it wasn't a total bore!

Once the plane is finished, scotch tape the two surfaces together as they will be in use. Mark three holes on either side of the hinge line, and drill them through with a small bit (1/16th or less), or you can just push the needle through. Using a sewing needle, threaded with carpet thread, sew them together using a figure 8 pattern, gently drawing out the slack as you go. The needle should go through the hinge line and into the opposite side on each pass, never going straight across the top or bottom.

I always put one set of hinges right next to the control horn to help it move the surface squarely.

Once the individual hinge is finished, CAREFULLY place a drop of CA at each spot where the thread goes through the surface...NOT getting any in the hinge line. Some glue will wick down the thread to the hinge line, but will usually break loose easily and get better with use. Finish all the hinges, then carefully pull the tape off. Work the controls gently to break loose any glue that's made it to the hinge line.

When done properly, the hinges will work easily, with NO slop in any direction, and can go to 90 degrees deflection if you decide to have a "Crazy Moment" !!

Whew! That's it...hope it wasn't a total bore!

Kim- Top Poster

Posts : 8625

Join date : 2011-09-06

Location : South East Missouri

Re: "Old School" Stitched Hinges

Re: "Old School" Stitched Hinges

To add a footnote to Kim's post:

The most commonly thread used is carpet thread available a your local crafts store like JoAnn Fabrics. (The nylon thread is fuel proof and does not rot)

The most commonly thread used is carpet thread available a your local crafts store like JoAnn Fabrics. (The nylon thread is fuel proof and does not rot)

SuperDave- Rest In Peace

- Posts : 3552

Join date : 2011-08-13

Location : Washington (state)

Re: "Old School" Stitched Hinges

Re: "Old School" Stitched Hinges

you can try something more high performance like Dyneema Ultra-high-molecular-weight polyethyleneSuperDave wrote:To add a footnote to Kim's post:

The most commonly thread used is carpet thread available a your local crafts store like JoAnn Fabrics.

I use a Dyneema line for a Tree throwline Strongest stuff on earth its 1/8 thick and breaking strength 600 lb and its splice-able

It's Available in threads Although i think its probably overkill Will last 4 ever Probably

Kevlar

Kevlar

I have many of miles thread on a BAS* and will happily send 10 feet to any member if you send a SSAE.

You must be careful with this thread as it will cut your hand bad if you think you have the nads to break it

I got it while working ALSE for the Army

Don’t worry; some other old curmudgeon will explain ALSE in a little bit

Kim? Dave?

NSN 8310-00-988-1300

16Oz Z Twist

Size F Class 1 Polyester Thread

Used for repair on NOMEX and Kevlar flight gear

*Big A-- Spool

You must be careful with this thread as it will cut your hand bad if you think you have the nads to break it

I got it while working ALSE for the Army

Don’t worry; some other old curmudgeon will explain ALSE in a little bit

Kim? Dave?

NSN 8310-00-988-1300

16Oz Z Twist

Size F Class 1 Polyester Thread

Used for repair on NOMEX and Kevlar flight gear

*Big A-- Spool

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: "Old School" Stitched Hinges

Re: "Old School" Stitched Hinges

ALSE = Aviation Life Support Equipment

SuperDave- Rest In Peace

- Posts : 3552

Join date : 2011-08-13

Location : Washington (state)

Re: "Old School" Stitched Hinges

Re: "Old School" Stitched Hinges

please post address I will send a SASEfredvon4 wrote:I have many of miles thread on a BAS* and will happily send 10 feet to any member if you send a SSAE.

You must be careful with this thread as it will cut your hand bad if you think you have the nads to break it

I got it while working ALSE for the Army

Don’t worry; some other old curmudgeon will explain ALSE in a little bit

Kim? Dave?

NSN 8310-00-988-1300

16Oz Z Twist

Size F Class 1 Polyester Thread

Used for repair on NOMEX and Kevlar flight gear

*Big A-- Spool

cur·mudg·eon/kərˈməjən/

Noun: A bad-tempered or surly person.

Synonyms: [bleep] - miser - skinflint - tightwad

Is curmudgeon derogatory or can it be used in light hearted play?

Re: "Old School" Stitched Hinges

Re: "Old School" Stitched Hinges

re: crumudgeon

Among contemporaries it's playfull. Across generations it's derogatory.

BTW: It's ETC rather than ECT. (etcetera from the Latin)

et·cet·era

noun

\et-ˈse-tə-rə, -ˈse-trə also it-, ÷ek-, ÷ik-\

Definition of ETCETERA

1

: a number of unspecified additional persons or things

2

plural : unspecified additional items : odds and ends

Among contemporaries it's playfull. Across generations it's derogatory.

BTW: It's ETC rather than ECT. (etcetera from the Latin)

et·cet·era

noun

\et-ˈse-tə-rə, -ˈse-trə also it-, ÷ek-, ÷ik-\

Definition of ETCETERA

1

: a number of unspecified additional persons or things

2

plural : unspecified additional items : odds and ends

Last edited by SuperDave on Wed Mar 14, 2012 5:33 pm; edited 1 time in total

SuperDave- Rest In Peace

- Posts : 3552

Join date : 2011-08-13

Location : Washington (state)

Re: "Old School" Stitched Hinges

Re: "Old School" Stitched Hinges

Signature should have address now

Write free hinge thread on outside of envelope

Write free hinge thread on outside of envelope

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: "Old School" Stitched Hinges

Re: "Old School" Stitched Hinges

I have to knock this out tonight and I have a couple questions.

I was told to do stitched hinges by Larry Renger so figured I would listen.

Is the figure eight loop continuous? Or do I cut and restart at each hole?

How many holes should I drill? Should they be offset?

Thanks for any help anyone can provide.

Ron

I was told to do stitched hinges by Larry Renger so figured I would listen.

Is the figure eight loop continuous? Or do I cut and restart at each hole?

How many holes should I drill? Should they be offset?

Thanks for any help anyone can provide.

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: "Old School" Stitched Hinges

Re: "Old School" Stitched Hinges

Ron, unwaxed dental floss works exceptionally well and is very strong. The loops should be continuous. This is rather difficult initially to figure out the length so use a long enough piece when starting. Dental floss is cheap and plentiful. Don't use CA to fix the knot. It will wick through the floss or thread and make the material hard which will fail. When done, I use drops of white glue on a toothpick over each hole placing just a dot to seal them. Ambroid or Duco could also be substituted if speed of dry time is desired. I generally use 5 holes evenly spaced in about a 7/8" - 1" wide pattern. I choose my width based on the size of the stab as I don't want it to look like too much. I use very small drill bits and I make a template using a piece of ply and this keeps the holes lined up and the symmetry correct. Use a pin through the holes and prick the stab and elevator to mark it. Don't use household thread as it won't last. Ken

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: "Old School" Stitched Hinges

Re: "Old School" Stitched Hinges

Thanks Ken,

One more question. How many times do I pass through?

One more question. How many times do I pass through?

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: "Old School" Stitched Hinges

Re: "Old School" Stitched Hinges

I usually start and finish at the same end of my hole group, and my holes line up. I sew down and back, being careful to pass the needle through the proper space on the return.

If your holes are offset you start and end and different ends of the hole group. You can make one part have 1 fewer hole, so say 5 on the plane and 4 on the elevator. Start on the long row, stop on the long row, at the opposite end.

The row of holes should be approximately the thickness of the stock from the edge. If you get too far from the edge on thin material it looks bad, and loosens some at the deflection limits. If you are too near the edge on thick material the hinge will bind at extremes of deflection.

The edges should be round, but this is surprisingly unimportant for the hinge. It is more important for the controls to function smoothly.

Avoid thin CA. Testors or thick CA work ok and tend to not wick.

Phil

If your holes are offset you start and end and different ends of the hole group. You can make one part have 1 fewer hole, so say 5 on the plane and 4 on the elevator. Start on the long row, stop on the long row, at the opposite end.

The row of holes should be approximately the thickness of the stock from the edge. If you get too far from the edge on thin material it looks bad, and loosens some at the deflection limits. If you are too near the edge on thick material the hinge will bind at extremes of deflection.

The edges should be round, but this is surprisingly unimportant for the hinge. It is more important for the controls to function smoothly.

Avoid thin CA. Testors or thick CA work ok and tend to not wick.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: "Old School" Stitched Hinges

Re: "Old School" Stitched Hinges

Cool Phil, I might not have floss, will Dacron work guys?

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: "Old School" Stitched Hinges

Re: "Old School" Stitched Hinges

Dacron, nylon, polyester good

cotton, wool, bad

I have used poly-cotton thread and it holds up for quite a while, but does start pulling apart after a while, a few dozen flights...

Phil

cotton, wool, bad

I have used poly-cotton thread and it holds up for quite a while, but does start pulling apart after a while, a few dozen flights...

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: "Old School" Stitched Hinges

Re: "Old School" Stitched Hinges

Good stuff thanks gentlemen. Guess I had better get busy!

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: "Old School" Stitched Hinges

Re: "Old School" Stitched Hinges

I used dacron on the shoestring elevator and it was great, almost no gap in the hinge line. But lately a gap has developed so I used shipping tape to seal it on the underside. I think if I had pulled off a length and pulled it to stretch before I used it, maybe this wouldn't have happened. If you use dacron I would suggest trying this. Also the right needles help. I bought a pack of large needles at WalMart that work well.

I saw where Larry over at SH said to anchor the thread in the first hole with CA, but I just knot it and dot it with a epoxy on a toothpick. And like Ken said, dot each hole with some wood glue when you're finished sewing. He showed me a bunch of different stitch patterns for different types of hinges. That thread is around here somewhere. It might be one of mine.

I saw where Larry over at SH said to anchor the thread in the first hole with CA, but I just knot it and dot it with a epoxy on a toothpick. And like Ken said, dot each hole with some wood glue when you're finished sewing. He showed me a bunch of different stitch patterns for different types of hinges. That thread is around here somewhere. It might be one of mine.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: "Old School" Stitched Hinges

Re: "Old School" Stitched Hinges

My wife sews so needles were no problem.

No CA got it........

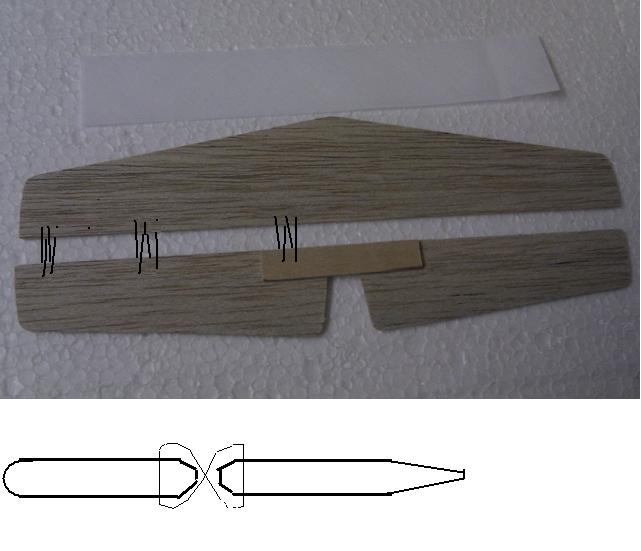

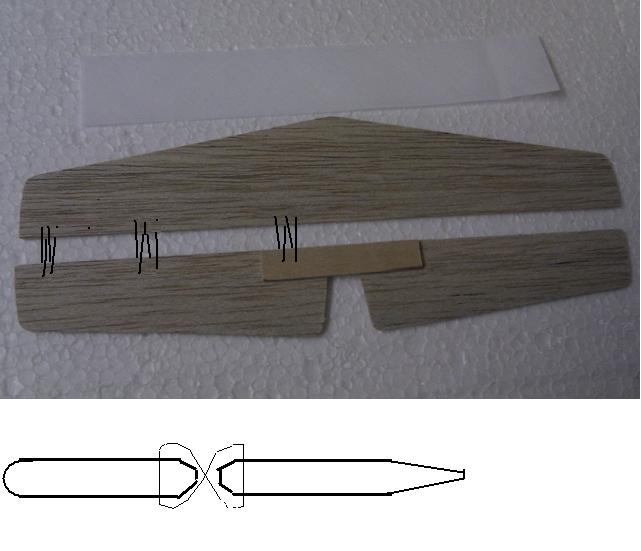

Here is my first attempt.

No CA got it........

Here is my first attempt.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: "Old School" Stitched Hinges

Re: "Old School" Stitched Hinges

I like the hinges - as well as the plane. I am surprised, though, not to see little red blotches on that nice white wing!

Me and needles don't get on and it usually ends up as a finger pricking session!

Are you going to continue the checker on to the flap now it is attached?

Me and needles don't get on and it usually ends up as a finger pricking session!

Are you going to continue the checker on to the flap now it is attached?

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: "Old School" Stitched Hinges

Re: "Old School" Stitched Hinges

The covering for my Super Clown was almost $40 so I decided just a swatch will do this time around!

I will be extending it, if I can find some more that is. I only pricked myself once!

Ron

I will be extending it, if I can find some more that is. I only pricked myself once!

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: "Old School" Stitched Hinges

Re: "Old School" Stitched Hinges

Your hinges look good. And you'll get better at it every time you do it.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: "Old School" Stitched Hinges

Re: "Old School" Stitched Hinges

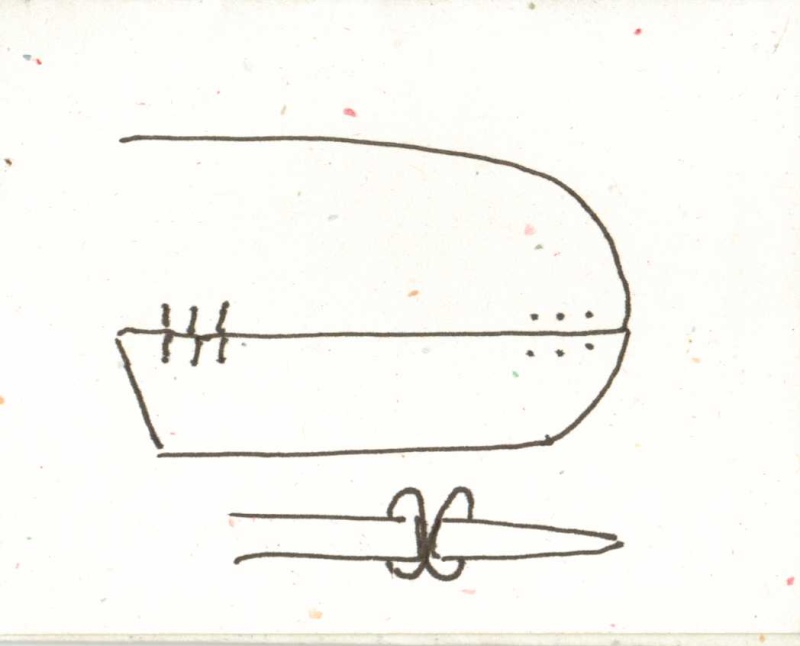

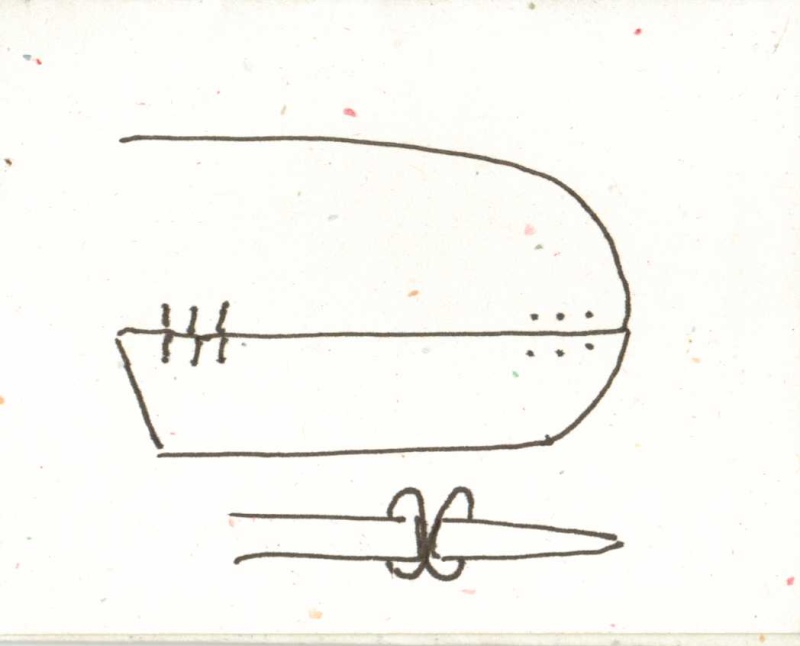

I do them slightly different than has been shown, though the figure eight path is the same. Two holes on each side will work fine for a 1/2A, though I used 4 on the beginners ringmaster.

Four hole pattern

12

34

Thread passes through hole in this order: 1,4,2,3,1

Notice hole one is listed twice, this is because the two ends are tied together. I have a way of doing this s that leaves the knot inside hole 1. Not sure how to explain that in words.

Eight hole pattern:

1234

5678

Thread path:1,6,3,8,4,7,2,5,1

I claim three advantages for my way:

1) You tie the two ends of the thread together instead of trusting a stopper knot or glue.

2) for a given hole spacing, the lacing angle is doubled, which helps keep surface from moving sideways.

3) The holes are aligned on both sides instead of staggered as is needed in the more common way. I find this easier to lay out.

I came up with this because I was unsure how to do it, so I looked at how my shoes were laced. Because of the figure eights, th hinge shows alternating V's instead of X's like shoe laces do. Note that most Europeans lace thier shoes differently, so the preceding will make no sense to them.

Four hole pattern

12

34

Thread passes through hole in this order: 1,4,2,3,1

Notice hole one is listed twice, this is because the two ends are tied together. I have a way of doing this s that leaves the knot inside hole 1. Not sure how to explain that in words.

Eight hole pattern:

1234

5678

Thread path:1,6,3,8,4,7,2,5,1

I claim three advantages for my way:

1) You tie the two ends of the thread together instead of trusting a stopper knot or glue.

2) for a given hole spacing, the lacing angle is doubled, which helps keep surface from moving sideways.

3) The holes are aligned on both sides instead of staggered as is needed in the more common way. I find this easier to lay out.

I came up with this because I was unsure how to do it, so I looked at how my shoes were laced. Because of the figure eights, th hinge shows alternating V's instead of X's like shoe laces do. Note that most Europeans lace thier shoes differently, so the preceding will make no sense to them.

kevbo- Silver Member

- Posts : 91

Join date : 2013-03-05

Re: "Old School" Stitched Hinges

Re: "Old School" Stitched Hinges

Interesting! Have a picture of one?

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: "Old School" Stitched Hinges

Re: "Old School" Stitched Hinges

I commented about having the holes spaced from the edge similar to the thickness of the material or the hinge would loosen up and mis-align. Well, I have a toolbox that I put a stitched hinge onto when the original hinges broke. It has my drywall kit in it and was stepped on when I was doing handyman stuff, underemployed, fresh out of college, and unable to afford a replacement box.

Generous amount of material for strength.

It doesn't automatically align when the lid is closed.

The thickness of the box is much less than the hole spacing from the edge.

With a little care the lid closes properly, latches and is sturdy.

Now this is in the extreme. Similarly if you go to the extreme the other way by having the holes much closer to the edge than the material thickness then the hinge binds. It probably is impossible to get this to happen on 1/2a size parts, but is possible on larger scale airframes that using a different type of hinge is probably more appropriate in the first place.

Generous amount of material for strength.

It doesn't automatically align when the lid is closed.

The thickness of the box is much less than the hole spacing from the edge.

With a little care the lid closes properly, latches and is sturdy.

Now this is in the extreme. Similarly if you go to the extreme the other way by having the holes much closer to the edge than the material thickness then the hinge binds. It probably is impossible to get this to happen on 1/2a size parts, but is possible on larger scale airframes that using a different type of hinge is probably more appropriate in the first place.

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: "Old School" Stitched Hinges

Re: "Old School" Stitched Hinges

Here is the photo I have. Not very clear due to being doped over. Note that the holes are well back from edge, but due to "skip one hole" lacing pattern, there is still plenty of angle to keep elevator aligned.

kevbo- Silver Member

- Posts : 91

Join date : 2013-03-05

Re: "Old School" Stitched Hinges

Re: "Old School" Stitched Hinges

Looks good. You would think the elevator would stay aligned no matter the distance from the hinge point. As long as the tension is equal that is.

Thanks for posting the picture!

Ron

Thanks for posting the picture!

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Page 1 of 2 • 1, 2

Similar topics

Similar topics» Stitched Hinges, "Z" Hinges, and Other Old School / New School Tips

» The Refried Bean Build-It flies

» A Quick and Dirty CA Hinge Installation

» Another proposed design by Roddie

» Tyvek hinges??

» The Refried Bean Build-It flies

» A Quick and Dirty CA Hinge Installation

» Another proposed design by Roddie

» Tyvek hinges??

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules