Log in

Search

Latest topics

» Happy 77th birthday Andrew!by rdw777 Today at 10:04 am

» Tee Dee .020 combat model

by rdw777 Today at 10:02 am

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 8:15 am

» TEE DEE Having issues

by balogh Today at 7:42 am

» Retail price mark-up.. how much is enough?

by rsv1cox Today at 7:36 am

» Cox films/videos...

by Coxfledgling Today at 4:46 am

» My N-1R build log

by roddie Today at 12:32 am

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

Cox Engine of The Month

Musings on balsa vs. coroplast.

Page 1 of 2

Page 1 of 2 • 1, 2

Musings on balsa vs. coroplast.

Musings on balsa vs. coroplast.

The availability and cost of balsa is making coroplast more of a viable alternative. I know coroplast planes are not new, just about everyone’s built and flonw one or more. I’m just thinking about how to expand on the planes currently out there. The most recent that I’ve done is the Man-Win Trainer I made a couple of week ago. I’ve seen lots of coroplast planes over the years, but they are almost uniformly plain looking, if not outright ugly. The best looking ones I’ve seen are Goozgog’s PT-19 coroplast trainers, three of which I’ve built. A few Baby Ringmasters looked pretty good as well.

But why, for the most part, are they consistently ugly? I always thought it was because coroplast is heavier than balsa and it’s not worth the time to make a nice looking plane if it’s going to be a rock. If it weren’t for the weight, there are so many sheet wing planes out there that look so much better. Look at all the planes by Dick Sarpolus. How about the Skyray or Deweybird from SIG? Or the hundreds of other slab wings designed over time for sheet balsa published in the various magazines?

Well, I got to wondering just how much heavier is Coroplast versus 1/8” balsa sheet that seems to be the norm for 1/2A planes? So a few minutes ago I pulled out my scale, a sheet of medium 1/8”balsa, and a 20”x24” sheet of white coroplast. I realize that there are different weights of balsa, but around here you take what you can get, so the medium available to me it is. Measuring the sheet of 1/8” balsa gave a weight of 0.399 gm/in². The coroplast came out to 0.392 gm/in². The coroplast is lighter?!? I re-measured three times, but this is what my digital kitchen scale shows.

Yes, coroplast doesn’t have the same stiffness as balsa and needs stiffeners through the flutes. But it doesn’t need the finishing methods that balsa needs. No grain fillers, no fuel proofing, no paint or Monokote. Yes, colors are limited. Vinyl sheet or decals can solve this if more decoration than base colors are desired. Also, coroplast should be more prang resistant.

But what about cost? The last 3”x36” sheet of 1/8” balsa cost me $4.99, and the last sheet of 24”x20” coroplast cost me $7.99. That’s 4.6 cents/in² for the balsa and 1.7 cents/in² for the coroplast. The coroplast is much cheaper when not just the base price is considered, but also including the price of finishing materials for the balsa. I haven’t checked Amazon for coroplast prices.

Even though I really need to not build any more planes right now, I’m very tempted to build some comparison planes. I’m thinking a Sarpolus Flip and a Netezband/Testors Ambush. I have these on the shelf that I can use to compare weight and flight characteristics between balsa versions and coroplast versions. And maybe a WingMaster to experiment with flaps.

Also, my normal method of hinging coroplast is the simple method of cutting off one side of a flute to leave one surface as the hinge. I’ve also seen the tail surfaces cut so that the stab and elevator interconnect with a rod through both to make a hinge. But I’m wondering how well a thread hinge would work…

Yes, balsa flies better. But why not see how far we can take the cheaper and more available coroplast for Cox engines? Maybe I should also take a look at a couple of the S.P.A.D. websites also. Who knows what we can learn from them for, say, .35 sized planes?

The Reanimator Mark

But why, for the most part, are they consistently ugly? I always thought it was because coroplast is heavier than balsa and it’s not worth the time to make a nice looking plane if it’s going to be a rock. If it weren’t for the weight, there are so many sheet wing planes out there that look so much better. Look at all the planes by Dick Sarpolus. How about the Skyray or Deweybird from SIG? Or the hundreds of other slab wings designed over time for sheet balsa published in the various magazines?

Well, I got to wondering just how much heavier is Coroplast versus 1/8” balsa sheet that seems to be the norm for 1/2A planes? So a few minutes ago I pulled out my scale, a sheet of medium 1/8”balsa, and a 20”x24” sheet of white coroplast. I realize that there are different weights of balsa, but around here you take what you can get, so the medium available to me it is. Measuring the sheet of 1/8” balsa gave a weight of 0.399 gm/in². The coroplast came out to 0.392 gm/in². The coroplast is lighter?!? I re-measured three times, but this is what my digital kitchen scale shows.

Yes, coroplast doesn’t have the same stiffness as balsa and needs stiffeners through the flutes. But it doesn’t need the finishing methods that balsa needs. No grain fillers, no fuel proofing, no paint or Monokote. Yes, colors are limited. Vinyl sheet or decals can solve this if more decoration than base colors are desired. Also, coroplast should be more prang resistant.

But what about cost? The last 3”x36” sheet of 1/8” balsa cost me $4.99, and the last sheet of 24”x20” coroplast cost me $7.99. That’s 4.6 cents/in² for the balsa and 1.7 cents/in² for the coroplast. The coroplast is much cheaper when not just the base price is considered, but also including the price of finishing materials for the balsa. I haven’t checked Amazon for coroplast prices.

Even though I really need to not build any more planes right now, I’m very tempted to build some comparison planes. I’m thinking a Sarpolus Flip and a Netezband/Testors Ambush. I have these on the shelf that I can use to compare weight and flight characteristics between balsa versions and coroplast versions. And maybe a WingMaster to experiment with flaps.

Also, my normal method of hinging coroplast is the simple method of cutting off one side of a flute to leave one surface as the hinge. I’ve also seen the tail surfaces cut so that the stab and elevator interconnect with a rod through both to make a hinge. But I’m wondering how well a thread hinge would work…

Yes, balsa flies better. But why not see how far we can take the cheaper and more available coroplast for Cox engines? Maybe I should also take a look at a couple of the S.P.A.D. websites also. Who knows what we can learn from them for, say, .35 sized planes?

The Reanimator Mark

batjac- Diamond Member

Posts : 2375

Join date : 2013-05-22

Age : 61

Location : Broken Arrow, OK, USA

Re: Musings on balsa vs. coroplast.

Re: Musings on balsa vs. coroplast.

Mark, I myself am not a fan of that material. We use it at work to protect floors. The job I'm on currently probably has purchased 2 thousand 4x8 sheets of it. All of it is going to be in a landfill by the end of this job. So much for a green push. We can only get deliveries on certain days to conserve trucking trips to the job to cut down on pollution but it's ok to fill up the earth. That's just this job. It cuts great in one direction with a utility knife but it can put you in a hospital going across the flutes or trying to cut a radius. Obviously, not model related but I personally am not a fan of it.

What I have seen and this was in Flying Models was this older gentleman who makes cardboard control line planes. These were .35-60 size models entirely of cardboard. They were truly amazing. Sometimes he incorporated balsa into it but it was very little, usually just a wing tip or additional stiffening areas. He was getting a cardboard which I've never seen before. It had white paper on one side and brown on the other.

Just did a search and found some information http://www.feltondesignanddata.com/

His methods were truly remarkable and he did have a website showing all of it. He would use a thinned polyurethane mix of poly and paint thinner to fuel proof and stiffen the surfaces. I would be quite certain water base would be acceptable as well until the final went on. He utilized a double roller screen tool for replacing window screens which would crease the cardboard on the back without cutting it to roll into shapes. All models were glued with white and yellow glue. Sometimes he would silkspan using the thinned white glue method to hide seams. Truly a neat repurpose.

What I have seen and this was in Flying Models was this older gentleman who makes cardboard control line planes. These were .35-60 size models entirely of cardboard. They were truly amazing. Sometimes he incorporated balsa into it but it was very little, usually just a wing tip or additional stiffening areas. He was getting a cardboard which I've never seen before. It had white paper on one side and brown on the other.

Just did a search and found some information http://www.feltondesignanddata.com/

His methods were truly remarkable and he did have a website showing all of it. He would use a thinned polyurethane mix of poly and paint thinner to fuel proof and stiffen the surfaces. I would be quite certain water base would be acceptable as well until the final went on. He utilized a double roller screen tool for replacing window screens which would crease the cardboard on the back without cutting it to roll into shapes. All models were glued with white and yellow glue. Sometimes he would silkspan using the thinned white glue method to hide seams. Truly a neat repurpose.

Ken Cook- Top Poster

- Posts : 5641

Join date : 2012-03-27

Location : pennsylvania

Re: Musings on balsa vs. coroplast.

Re: Musings on balsa vs. coroplast.

That is just amazing Ken! I think I'm going to experiment with cardboard soon!

Michpatriot- Gold Member

- Posts : 157

Join date : 2023-01-12

Re: Musings on balsa vs. coroplast.

Re: Musings on balsa vs. coroplast.

batjac wrote:

Yes, balsa flies better. But why not see how far we can take the cheaper and more available coroplast for Cox engines? Maybe I should also take a look at a couple of the S.P.A.D. websites also. Who knows what we can learn from them for, say, .35 sized planes?

The Reanimator Mark

Innovation and experimentation are the lifeblood of this hobby, especially when the cost, quality and availability of classic building material is becoming a major factor. I'm looking forward to your comparison.

When RC combat was popular in our club, coroplast was the material of choice: tough, cheap, fuel proof and easily manipulated. When you stuck one, usually it was repairable; if not, then, "D@mn, there goes another $2.00!"

Here are some sites that may be of interest:

Harbor Sales

SPAD to the Bone

a--

Re: Musings on balsa vs. coroplast.

Re: Musings on balsa vs. coroplast.

Coroplast and corrugated cardboard are limited workable materials. Can not be sandable to form a shape. Corrugated cardboard is heavy and fuelproofing is difficult.

Levent Suberk- Diamond Member

- Posts : 2265

Join date : 2017-12-24

Location : Türkiye

Cardboard airplanes

Cardboard airplanes

We used to make U/C planes with cardboard wings 1/2" square balsa fuselage and Meccano pieces for engine mounts. Bend the engine mount outward and upward and we could sabre dance the airplanes on our 8' lines in a tiny front yard. All cox 0.049's sometimes OK Cubs or Tornados.

So long ago

So long ago

706jim- Gold Member

- Posts : 472

Join date : 2013-11-29

Re: Musings on balsa vs. coroplast.

Re: Musings on balsa vs. coroplast.

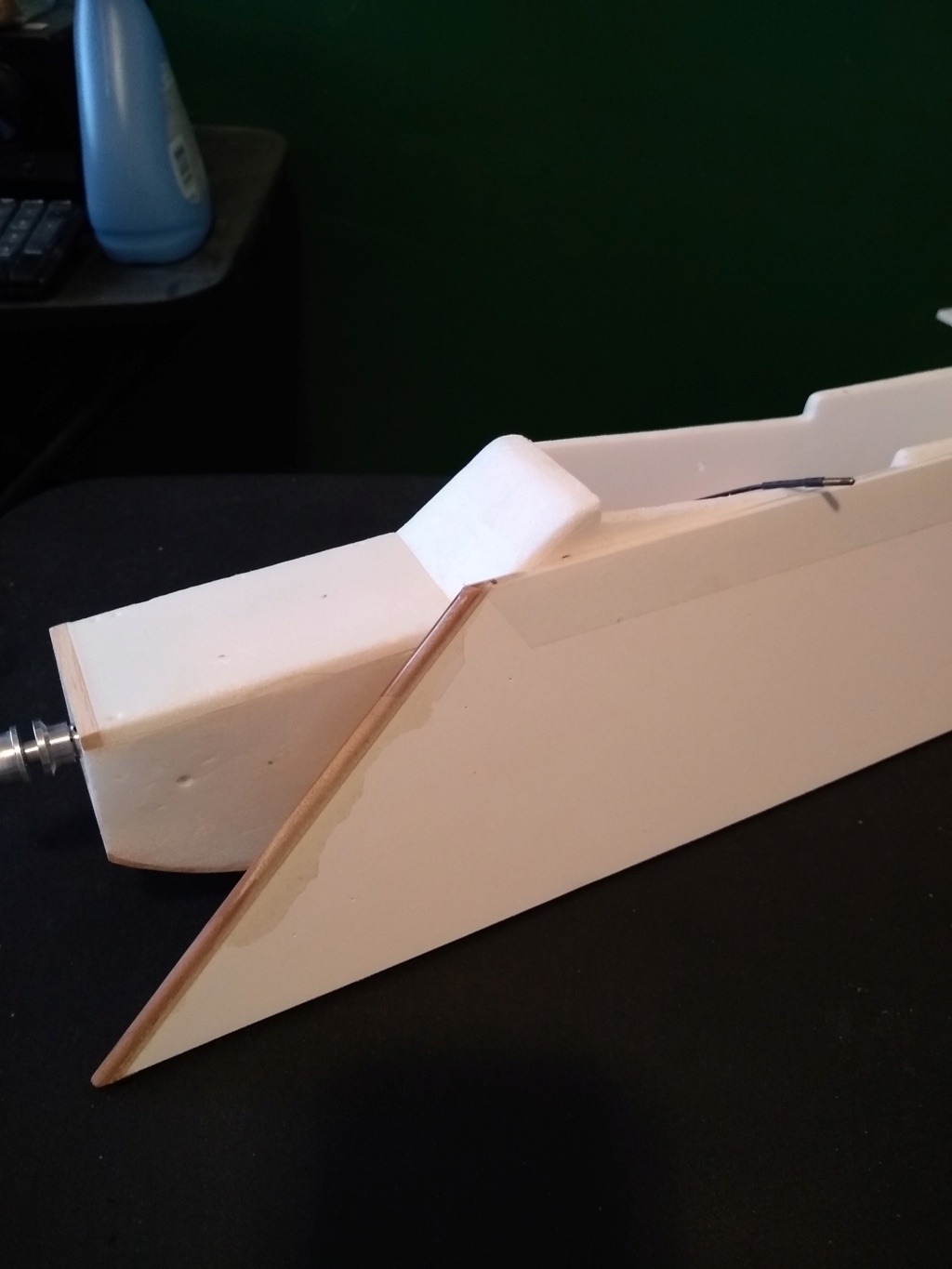

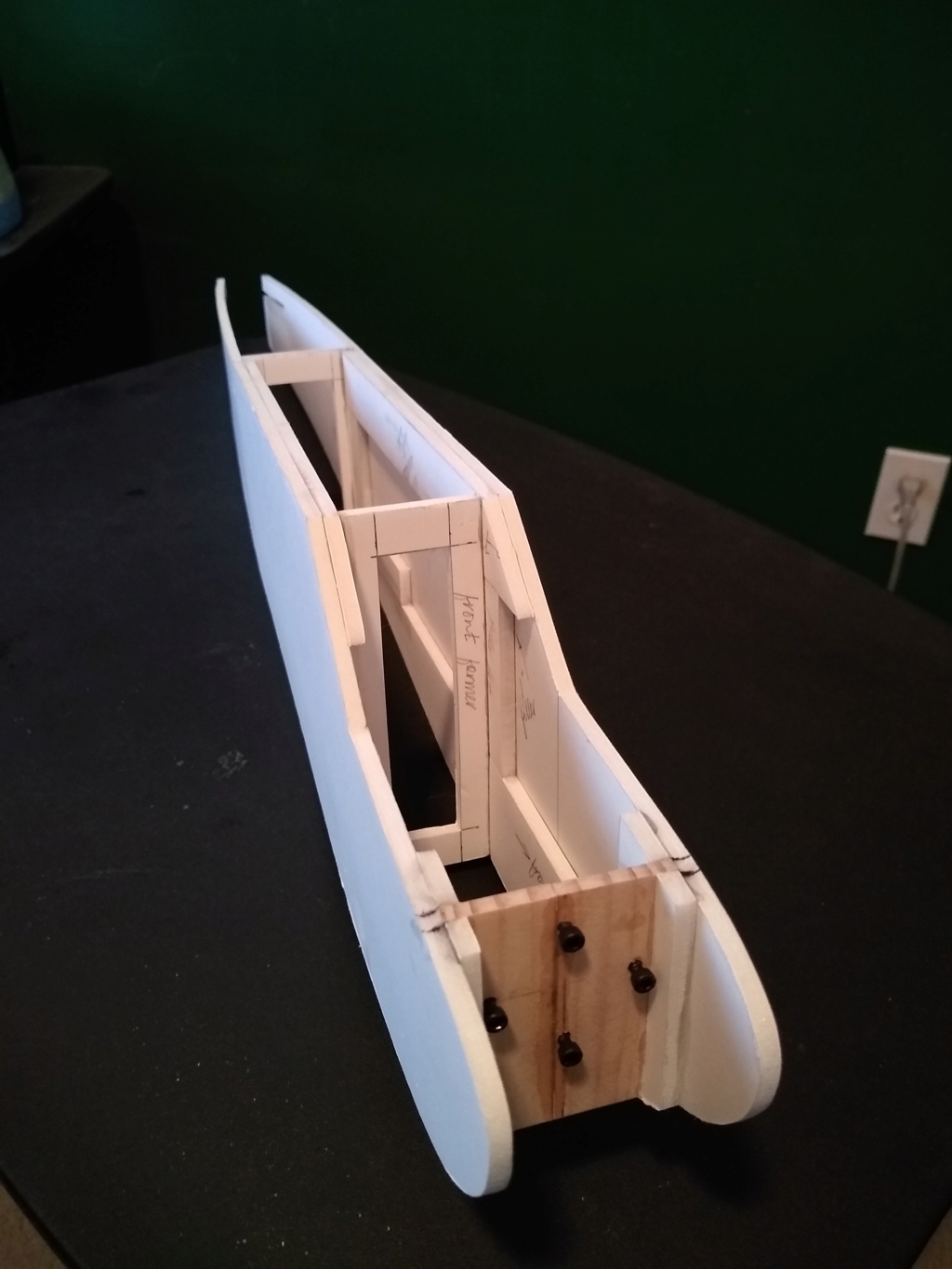

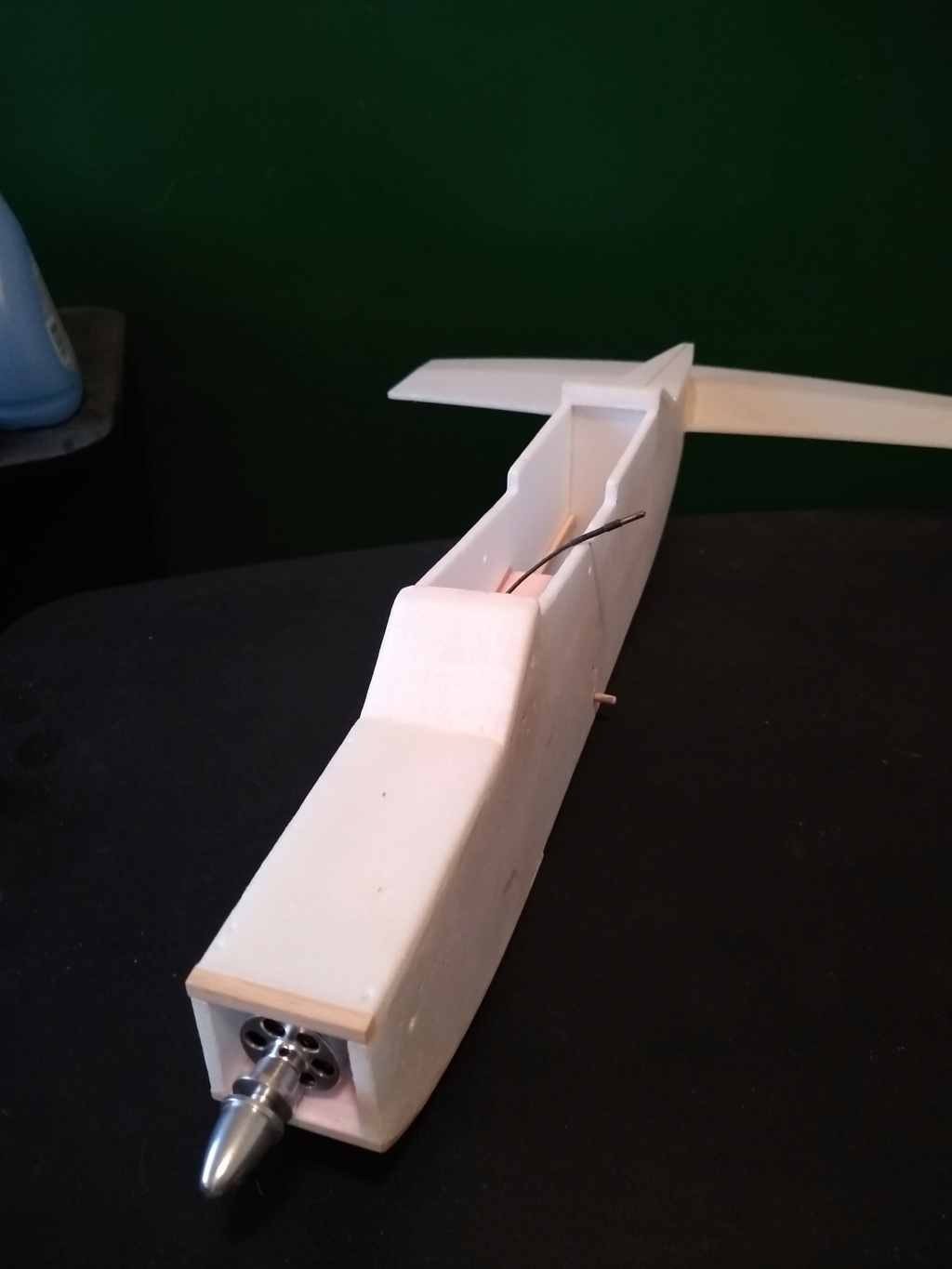

I'm testing out foam board. You can get a pretty big piece from the dollar store for 2$. Using ply for engine mounting to the board. See what happens. It's light and pretty darn strong for what it is. Was planning to just rattle can it.

layback209- Gold Member

- Posts : 283

Join date : 2017-10-13

Age : 38

Location : Okotoks

Re: Musings on balsa vs. coroplast.

Re: Musings on balsa vs. coroplast.

layback209 wrote:I'm testing out foam board. You can get a pretty big piece from the dollar store for 2$. Using ply for engine mounting to the board. ...............Was planning to just rattle can it.

Be careful with your rattle can paint; a friend and I built a couple of combat deltas and he wanted to paint his like a Blue Angel (had some rattle can blue and yellow in his shop). He sprayed it and hung it up to dry -- when he returned, much of the foam had dissolved and it was held together with the reinforcing tape!!

I very much like foam board and have worked quite a bit with it. It can be shaped somewhat and can be used with or without the paper covering. My foamies are all electric, so I don't worry about fuel proofing. Here are some pics:

If you need to reinforce the LE, a 3/16" dowel glued on works well. Packing tape on other edges will keep the paper from delaminating and add strength.

The following two pics are the fuselage for a sport cub (37" span). Glueing on additional strips of foam board strengthens and stiffens; note the firewall. Staying with the cheap theme, this firewall was constructed from Lowes paint sticks. As it is shown, the fuselage weighs 3 5/8 oz.

This fuselage is built up with delaminated foam, i.e., the paper has been removed from both sides.

This 37" wing has a full airfoil, has paper removed from the bottom of the top skin and partially removed from the bottom skin. The black dihedral reinforcement is fiberglass window screen material. This wing weighs 6 1/2 oz.

Re: Musings on balsa vs. coroplast.

Re: Musings on balsa vs. coroplast.

There are some threads on the blue fanfold foam. FFF. It has a plastic covering instead of paper. May be a bit hard to find now. The pink stuff may be good too. About 1/4" thick. Another thread on the corro in one of the other forums, there was some guys that made some great gliders that were scale with great workmanship. I think they were in South Africa slope soaring. Maybe from this longish thread. https://www.rcgroups.com/forums/showthread.php?1969788-Beyond-gutter-pipes-and-yardsticks-Share-your-new-S-P-A-D-build-tips-and-techniques Also there is the option of the 2mm corro which is lighter and easier to bend than the 4mm. Some combat guys in the London Ont. club used it for WW1 and II combat with .25s. HalfADave would know more about this than me.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: Musings on balsa vs. coroplast.

Re: Musings on balsa vs. coroplast.

I have a small sheet of cloroplast from a sign and the Keith Morgan/ Balsa Beavers

PT-19 plan for a “one of these days “ build…. My sheet is white on one side…. Does anyone know if paint will stick to it???

Excellent job on the Cub Andrew!… Nice photography as well!!! Love the cheap theme too…I love working with balsa and will take weeks to finish a project… When a whim comes along will knock it out quick using alternative materials…..This one took about a couple of days…. Dollar store foam wing…. 1” blue foam insulation fuse…. Balsa tail feathers..,

PT-19 plan for a “one of these days “ build…. My sheet is white on one side…. Does anyone know if paint will stick to it???

Excellent job on the Cub Andrew!… Nice photography as well!!! Love the cheap theme too…I love working with balsa and will take weeks to finish a project… When a whim comes along will knock it out quick using alternative materials…..This one took about a couple of days…. Dollar store foam wing…. 1” blue foam insulation fuse…. Balsa tail feathers..,

rdw777- Diamond Member

Posts : 1720

Join date : 2021-03-11

Location : West Texas

Re: Musings on balsa vs. coroplast.

Re: Musings on balsa vs. coroplast.

Wow awesome build Andrew, i like it a lot, thanks for sharing your experience. I think you just saved me big time on the paint end, thank you thank you. Figure something else out. I have some rc car lexan body paint that may do the job.

Also like The reinforcing tips I was just thinking packing tape but never consider some wood as an option Brilliant.

Also like The reinforcing tips I was just thinking packing tape but never consider some wood as an option Brilliant.

layback209- Gold Member

- Posts : 283

Join date : 2017-10-13

Age : 38

Location : Okotoks

Re: Musings on balsa vs. coroplast.

Re: Musings on balsa vs. coroplast.

A free flight plane I made from coroplast:

https://www.coxengineforum.com/t12774-my-latest-free-flight-plane-a-peewee-powered-jet-fighter-don-t-miss-the-vid

https://www.coxengineforum.com/t12774-my-latest-free-flight-plane-a-peewee-powered-jet-fighter-don-t-miss-the-vid

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: Musings on balsa vs. coroplast.

Re: Musings on balsa vs. coroplast.

batjac wrote:............

Even though I really need to not build any more planes right now, I’m very tempted to build some comparison planes. I’m thinking a Sarpolus Flip and a Netezband/Testors Ambush. I have these on the shelf that I can use to compare weight and flight characteristics between balsa versions and coroplast versions...............

The Reanimator Mark

Both of those would be excellent candidates for comparison builds.

If you can locate some 2mm coroplast, it may be possible to build in an airfoil shape by using under ribs like in a Jedelsky wing -- the wing would not need a bottom skin. Small diameter carbon fiber tubing could be used for spanwise stiffening.

a--

Re: Musings on balsa vs. coroplast.

Re: Musings on balsa vs. coroplast.

I have trouble cutting the Dam stuff making the ManWin was about all i needed of the stuff . Maybe I am not cutting it right or let me ask , Is the dollar store foam board Ya'll speak of cut different ,better, ? I feel only to build precut laser or die crush is in my path , Arthur in my hands don't help , if I can find something that will help with that and don't have to refinance my house every month may would help ? Those are some very impressing models being built right Here !

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Musings on balsa vs. coroplast.

Re: Musings on balsa vs. coroplast.

I like the Foam Board that the FliteTest team uses to build all sorts of crazy stuff.

I have not built any of their kits, as? I'm not a RC guy

but i bet some of their jobs would be awesome for cox motors

https://store.flitetest.com/foam-board-sheets/

and their youtube channel is certainly entertaining

https://www.youtube.com/watch?v=Uw0_9Zmcewc

I have not built any of their kits, as? I'm not a RC guy

but i bet some of their jobs would be awesome for cox motors

https://store.flitetest.com/foam-board-sheets/

and their youtube channel is certainly entertaining

https://www.youtube.com/watch?v=Uw0_9Zmcewc

cstatman- Platinum Member

Posts : 568

Join date : 2021-02-17

Age : 60

Location : San Jose, CA

Re: Musings on balsa vs. coroplast.

Re: Musings on balsa vs. coroplast.

Hi batjac,

Nice thread about alternate materials...

I was part of a 'coro boom' around here, until the 2mm stuff ran out.. ~15yrs ago.

I'll dig back in the rccanada Combat forum, there are some nice build threads...(I'll link here)

Basicly, the Dave West Mig from the spadtothebone site, tweaked over years. (and .25 r/c scale combat!)

( the good hobby shop CA and kicker was the expensive part)

Other materials to consider,

-1/8th fg rods used in kites for spars.

-all kinds of adhesive tapes to cover styrofoam wings/fuses...

-the gorilla type polyU glues are fun, if they only did not go solid, after you open them...

Later,

Heavy snow, means smaller shovels, Dave

Nice thread about alternate materials...

I was part of a 'coro boom' around here, until the 2mm stuff ran out.. ~15yrs ago.

I'll dig back in the rccanada Combat forum, there are some nice build threads...(I'll link here)

Basicly, the Dave West Mig from the spadtothebone site, tweaked over years. (and .25 r/c scale combat!)

( the good hobby shop CA and kicker was the expensive part)

Other materials to consider,

-1/8th fg rods used in kites for spars.

-all kinds of adhesive tapes to cover styrofoam wings/fuses...

-the gorilla type polyU glues are fun, if they only did not go solid, after you open them...

Later,

Heavy snow, means smaller shovels, Dave

HalfaDave- Platinum Member

- Posts : 615

Join date : 2022-12-06

Location : Oakville, Ontario

Re: Musings on balsa vs. coroplast.

Re: Musings on balsa vs. coroplast.

look into depron sheet

One year at the RCU Design contest Dickeybird built a .049 powered Bearcat...[I think it was a 3D Profile] out of depron.

One year at the RCU Design contest Dickeybird built a .049 powered Bearcat...[I think it was a 3D Profile] out of depron.

TD ABUSER- Gold Member

- Posts : 410

Join date : 2020-11-01

Age : 69

Location : Washington

Re: Musings on balsa vs. coroplast.

Re: Musings on balsa vs. coroplast.

Hi batjac,

Still looking for the coro build thread from way back then.

Here is one, when we first tried WW1s, at a WW2 demo at another field:

https://www.rccanada.ca/rccforum/showthread.php?t=40916

I am sure there is a coro build thread, I'll find it....

The coro WW1s were cool sport planes to fly... at 4.5lbs with a good .25.

WW2s were 3lbs and went like snot. OSFX.25s on 9-4s on%15. No straight and level, in the combat box!

This is the ultimate of coro building I have seen.

The wings had the 2mil flutes going chordwise, bending over a spar to make an airfoil...

Ran out of 2mil here, before 2014 came here...

Otherwise, WW1 combat could have ruled here...

Anyways,

It was all about each match we flew, and how coro building evolved...

JohonnyG made a cnc router that cut coro into kits. With Pete molded cowls and canopys. Cheap.

Fold it up together, follow the CD instructions... Easy.

I have fellow flying friends,

Who have never tried building with balsa...

Still flying today...

I tried Corrogated cardboard and, that is another story...

Take care,

Have fun,

Dave

Still looking for the coro build thread from way back then.

Here is one, when we first tried WW1s, at a WW2 demo at another field:

https://www.rccanada.ca/rccforum/showthread.php?t=40916

I am sure there is a coro build thread, I'll find it....

The coro WW1s were cool sport planes to fly... at 4.5lbs with a good .25.

WW2s were 3lbs and went like snot. OSFX.25s on 9-4s on%15. No straight and level, in the combat box!

This is the ultimate of coro building I have seen.

The wings had the 2mil flutes going chordwise, bending over a spar to make an airfoil...

Ran out of 2mil here, before 2014 came here...

Otherwise, WW1 combat could have ruled here...

Anyways,

It was all about each match we flew, and how coro building evolved...

JohonnyG made a cnc router that cut coro into kits. With Pete molded cowls and canopys. Cheap.

Fold it up together, follow the CD instructions... Easy.

I have fellow flying friends,

Who have never tried building with balsa...

Still flying today...

I tried Corrogated cardboard and, that is another story...

Take care,

Have fun,

Dave

HalfaDave- Platinum Member

- Posts : 615

Join date : 2022-12-06

Location : Oakville, Ontario

Re: Musings on balsa vs. coroplast.

Re: Musings on balsa vs. coroplast.

Hi All,

I looked back, on the coro days,

And it is pointless, if you cannot get 2mil coro anymore. (for under r/c .25 power)

Just like 94yr old Dad and I cannot get silk and dope from the local hobby shop anymore.

And pick the nice spars from the balsa rack.

We just built planes, and flew them. Had Fun.

The good thing I have learned,

There is always a way to fly.

Foam and tape is way lighter than coro.

Glues are way better these days.

I had a shop with a wicked vac and kiln to do foils for olympic dingys. Latest of the epoxys.

I am allergic now, so, be carefull ! ! !

The fun is,

Building a plane, (1/2A is hard) And go fly it...

I built two 'semi Swordsmans' out of a big cardboard box. Flew just as good as balsa.

Humidity took its toll, the fuel proof finish worked good, cardboard turned to mush...

The cool thing is I am not an expert.

And I like learning.

Why I joined CEF.

Take care,

Have fun,

Dave

I looked back, on the coro days,

And it is pointless, if you cannot get 2mil coro anymore. (for under r/c .25 power)

Just like 94yr old Dad and I cannot get silk and dope from the local hobby shop anymore.

And pick the nice spars from the balsa rack.

We just built planes, and flew them. Had Fun.

The good thing I have learned,

There is always a way to fly.

Foam and tape is way lighter than coro.

Glues are way better these days.

I had a shop with a wicked vac and kiln to do foils for olympic dingys. Latest of the epoxys.

I am allergic now, so, be carefull ! ! !

The fun is,

Building a plane, (1/2A is hard) And go fly it...

I built two 'semi Swordsmans' out of a big cardboard box. Flew just as good as balsa.

Humidity took its toll, the fuel proof finish worked good, cardboard turned to mush...

The cool thing is I am not an expert.

And I like learning.

Why I joined CEF.

Take care,

Have fun,

Dave

HalfaDave- Platinum Member

- Posts : 615

Join date : 2022-12-06

Location : Oakville, Ontario

Re: Musings on balsa vs. coroplast.

Re: Musings on balsa vs. coroplast.

HalfaDave wrote:Hi All,

I looked back, on the coro days,

And it is pointless, if you cannot get 2mil coro anymore. (for under r/c .25 power)

..................

Dave

Actually, Dave, 2mm coroplast is still available through Harbor Sales. Pricing is for a 4'x8' sheet with the flutes running longways. Since you likely would not want to ship a 4x8 sheet, they will custom cut sheets to your specifications -- I had all my panels cut into 2'x4' sheets, flutes longways. My 2mm sheets were in yellow, but I see that they are only offering white. I'm sure a little searching will locate other suppliers, perhaps with better pricing and other colors. At the time, this company offered the best in selection, size and color for the price.

Re: Musings on balsa vs. coroplast.

Re: Musings on balsa vs. coroplast.

Hi Andrew,

The cheap 2mil we got was from Quebec, 4X8 sheets, bulk.

20 yrs ago. Everyone has moved on.

Even Pylon racing is electric these days.

2mil is good for wings.

Too heavy for a good .049, I think. .15 or.25 it works.

I'll dig out a build thread from rccanada if anyone is interested.

Sore snow shovelling,

Dave

P.S. It was less than $5 per 4X8 back then.

The cheap 2mil we got was from Quebec, 4X8 sheets, bulk.

20 yrs ago. Everyone has moved on.

Even Pylon racing is electric these days.

2mil is good for wings.

Too heavy for a good .049, I think. .15 or.25 it works.

I'll dig out a build thread from rccanada if anyone is interested.

Sore snow shovelling,

Dave

P.S. It was less than $5 per 4X8 back then.

HalfaDave- Platinum Member

- Posts : 615

Join date : 2022-12-06

Location : Oakville, Ontario

Re: Musings on balsa vs. coroplast.

Re: Musings on balsa vs. coroplast.

Regarding glow-ignition aero-modeling and the cost of quality balsa/spruce/and plywood; we as aero-modelers find ourselves having to continuously adapt to what's available "NOW" in the way of building-materials and their joinery.. oftentimes to dis-similar materials.. while trying to keep the airframe's weight to a minimum.... while also maintaining structural-integrity.

I like the idea of using a bio-degradable material for an airframe.. and wonder if "bamboo" could be a viable building material?

Imagine bamboo doweling, as a miniature form of chrome-moly tubing for a built-up fuse. A pkg. of bamboo BBQ skewers is CHEAP. You'll find a variety of sizes/lengths available. They're almost as uniform as round Birch toothpicks.. and that's saying something. Cut the points off the ends and you've got dowels.

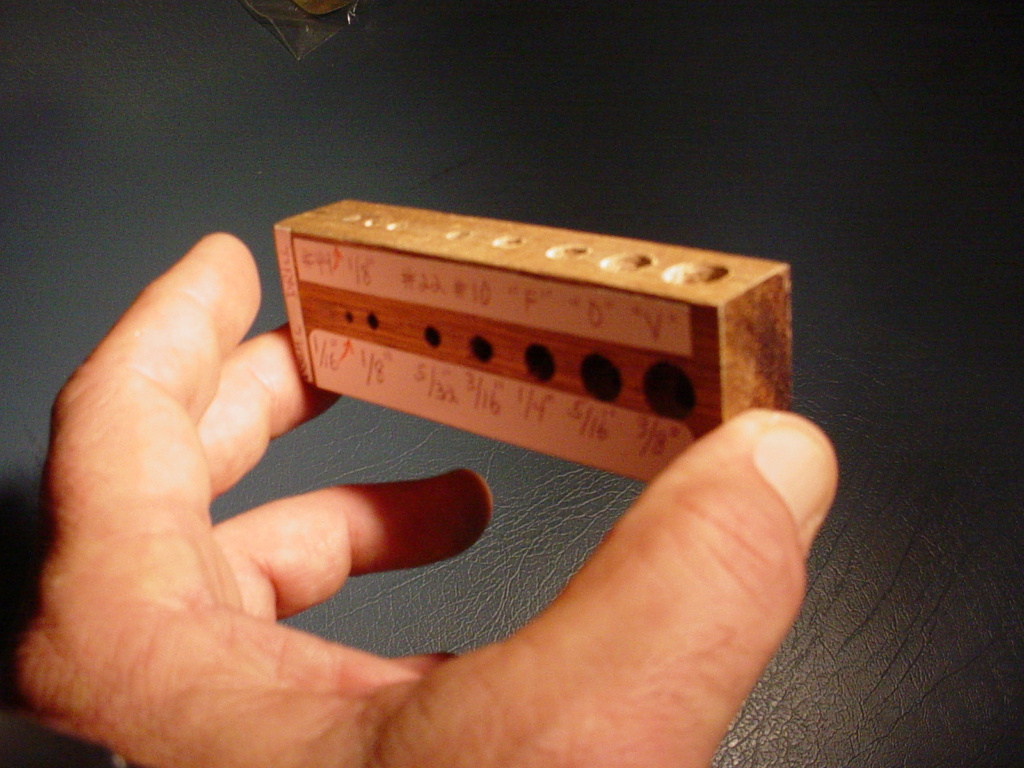

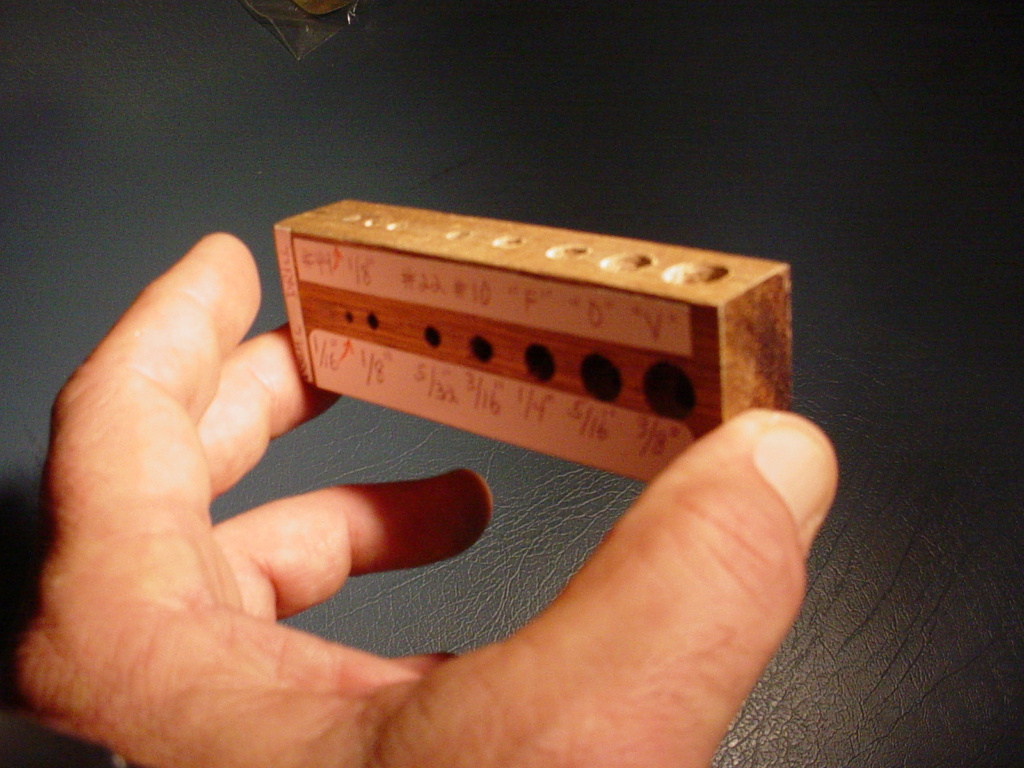

Naturally.. there needs to be a method of joinery. A "fishmouth" tool can be made by drilling a pair of intersecting-holes in a block of hardwood. A "drill-press" is preferred for accurate alignment of the bores. A series of 90 degree intersections to start with.. using drill-diameters to closely match whatever diameter dowels you have on hand.

I made this 90-degree block for several different diameter dowels that I had at the time.

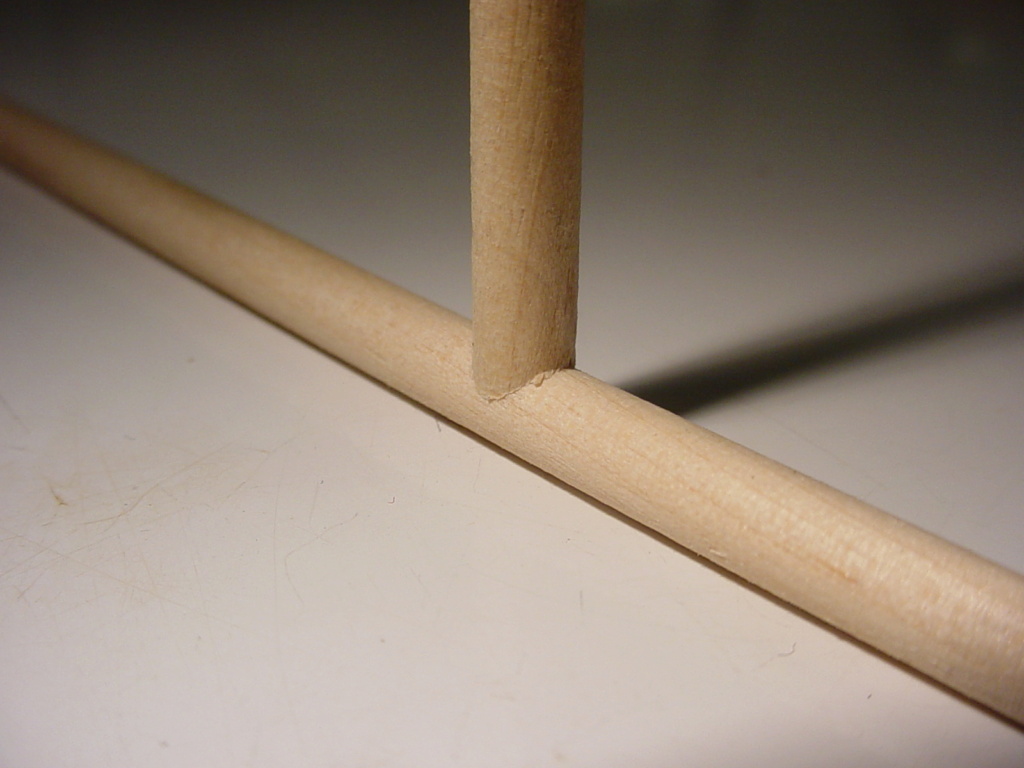

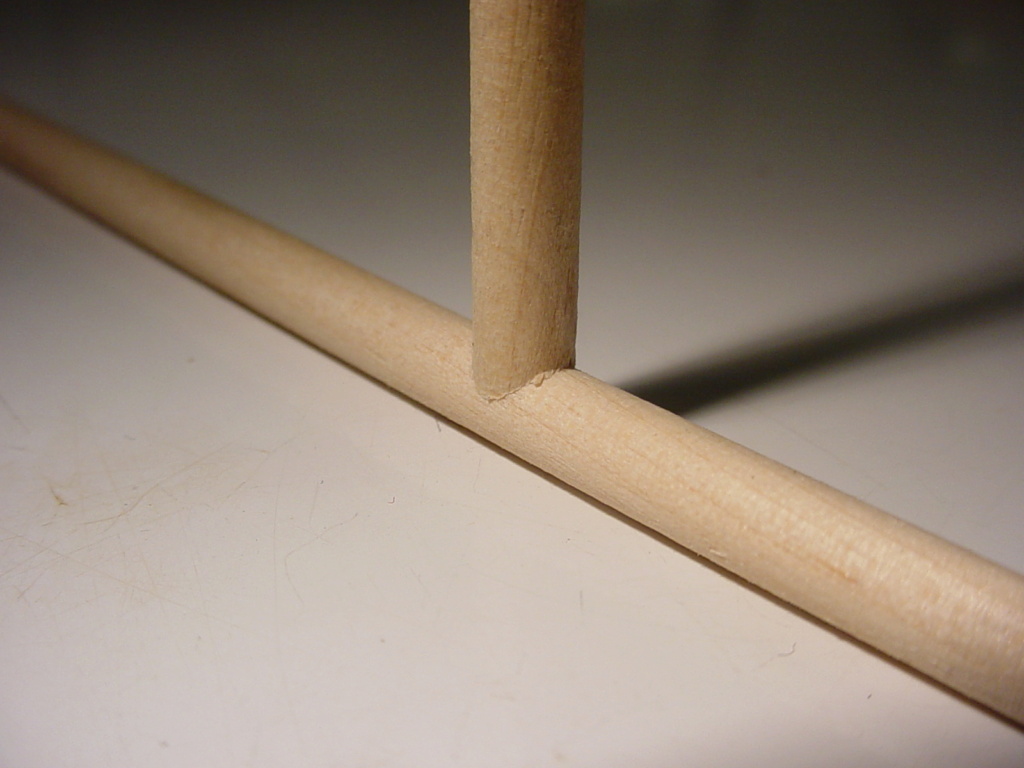

Here's an example of a wood-dowel joint that replicates an alloy tubing-union..

A model fuselage built this way.. could be quite strong.. as well as fun to build. Why not take-on the challenge of building a flying scale-model?

We could also experiment with forming bamboo dowels into an airfoil-shape for wing-ribs.

Sound scary? If so.. you could build flat-framed panels.. and cover them with silk-span or "doctor's paper".. to replicate a sheet-wing. There will always be a way to build a model that's airworthy.

I like the idea of using a bio-degradable material for an airframe.. and wonder if "bamboo" could be a viable building material?

Imagine bamboo doweling, as a miniature form of chrome-moly tubing for a built-up fuse. A pkg. of bamboo BBQ skewers is CHEAP. You'll find a variety of sizes/lengths available. They're almost as uniform as round Birch toothpicks.. and that's saying something. Cut the points off the ends and you've got dowels.

Naturally.. there needs to be a method of joinery. A "fishmouth" tool can be made by drilling a pair of intersecting-holes in a block of hardwood. A "drill-press" is preferred for accurate alignment of the bores. A series of 90 degree intersections to start with.. using drill-diameters to closely match whatever diameter dowels you have on hand.

I made this 90-degree block for several different diameter dowels that I had at the time.

Here's an example of a wood-dowel joint that replicates an alloy tubing-union..

A model fuselage built this way.. could be quite strong.. as well as fun to build. Why not take-on the challenge of building a flying scale-model?

We could also experiment with forming bamboo dowels into an airfoil-shape for wing-ribs.

Sound scary? If so.. you could build flat-framed panels.. and cover them with silk-span or "doctor's paper".. to replicate a sheet-wing. There will always be a way to build a model that's airworthy.

Re: Musings on balsa vs. coroplast.

Re: Musings on balsa vs. coroplast.

roddie wrote:.............

I like the idea of using a bio-degradable material for an airframe.. and wonder if "bamboo" could be a viable building material?

.............

Imagine bamboo doweling, as a miniature form of chrome-moly tubing for a built-up fuse. A pkg. of bamboo BBQ skewers is CHEAP. You'll find a variety of sizes/lengths available. They're almost as uniform as round Birch toothpicks.. and that's saying something. Cut the points off the ends and you've got dowels.

.............

Sound scary? If so.. you could build flat-framed panels.. and cover them with silk-span or "doctor's paper".. to replicate a sheet-wing. There will always be a way to build a model that's airworthy.

I am a big believer in searching for alternative building materials. Currently, I have 6 packs of bamboo skewers on hand -- the quality has fallen over the past 3 years (smaller diameter, more bendable, less straight), so finding a good one becomes more difficult. I use them for pushrods, wing hold down dowels, pinning foam together, as a reinforcement doubler and, just a few minutes ago, as a pick to punch tumbling media (crushed walnut shells) out of primer pocket flash holes.

I had not considered framing up a wing or fuselage, but it's not that far fetched.

Small diameter carbon fiber tubing, which is light, strong, straight and relatively inexpensive from Aliexpress or Banggood is another possibility. I have already incorporated carbon fiber arrow shafts in some wing builds.

I have a fiberglass project scheduled for late spring and want to try laying up some prefabricated fiberglass panels using either .5 oz or .75 oz fiberglass over waxed glass with any excess resin I have. Once peeled off, they should be pretty flexible and, perhaps, could be used as a wing skin.

a--

Re: Musings on balsa vs. coroplast.

Re: Musings on balsa vs. coroplast.

A couple friends of mine did the fiberglass skin off the glass like that. Not sure what weight of cloth was used, but they were .40 to .60 size WW2 planes probably fiberglass fuselages. The one guy sold hockey stick epoxy resin, so they used that ____ on everything. They flew well. I think foam cores that were sliced like ribs. They were not showoff scale, but pretty nice. The leading edge needed attention the way it was joined.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: Musings on balsa vs. coroplast.

Re: Musings on balsa vs. coroplast.

Well, a little change of plans. I considered doing a Flip or an Ambush to test, but since I just did seven Skyray kits, that's what I have the best comparison data to go off of. So I've made a Skyray kit from coroplast. I just need to glue it all together. I'm stalled at what is the best glue to use. Looking online, the recommended glues are things that glue the sheets surface to surface, but not really good for edge gluing, such as for the wing to fuselage joint of a profile CL plane. The best method seems to be premium hot glue at a very hot temperature which more or less 'welds' the coroplast according to the S.P.A.D. guys. I've ordered the premium hot melt glue along with a premium glue gun for the test. Never hurts to get the premium tools for longevity.

The Investor Mark

The Investor Mark

batjac- Diamond Member

Posts : 2375

Join date : 2013-05-22

Age : 61

Location : Broken Arrow, OK, USA

Page 1 of 2 • 1, 2

Similar topics

Similar topics» RARE COX THIMBLE DROME PROTOTYPE "PT-19 COROPLAST BUILD" GAS MODEL AIRPLANE

» "Molding Balsa"...NOT to be confused with "Moldy Balsa"!!!!! M.A.N 12-64

» Stunt Man 23

» Coroplast models

» Getting Ready to Attempt some Restorations - Newbie

» "Molding Balsa"...NOT to be confused with "Moldy Balsa"!!!!! M.A.N 12-64

» Stunt Man 23

» Coroplast models

» Getting Ready to Attempt some Restorations - Newbie

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules