Log in

Search

Latest topics

» TEE DEE Having issuesby Ken Cook Today at 7:10 am

» Cox films/videos...

by Coxfledgling Today at 4:46 am

» Purchased the last of any bult engines from Ken Enya

by Coxfledgling Today at 4:18 am

» My N-1R build log

by roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

Cox Engine of The Month

Control-line hdwe. for smaller models

Page 1 of 1

Control-line hdwe. for smaller models

Control-line hdwe. for smaller models

Last week I inquired/placed orders with SIG and Tower Hobbies for some bellcranks that I would use for my small (mainly 1/2A) size control-line models.

I was pleased to find that "Sig" is still offering their P/N SH234 1/2A Nylon bellcrank with control horn assembly. Currently $1.24 ea. (USD)

When I searched "Tower Hobbies".. I found offerings from "Sullivan" that are actually "Perfect" brand items. The Perfect #P222 SMALL bellcrank assy. is being sold as the Sullivan #SULP222. Currently $2.91 ea. (USD)

I like these little aluminum bellcranks.. and would have bought a few more, but there were only X3 remaining in Tower's stock. The #SULP223 (Perfect #223) LARGE bellcrank assy. "is" currently in stock as of today through Tower Hobbies.

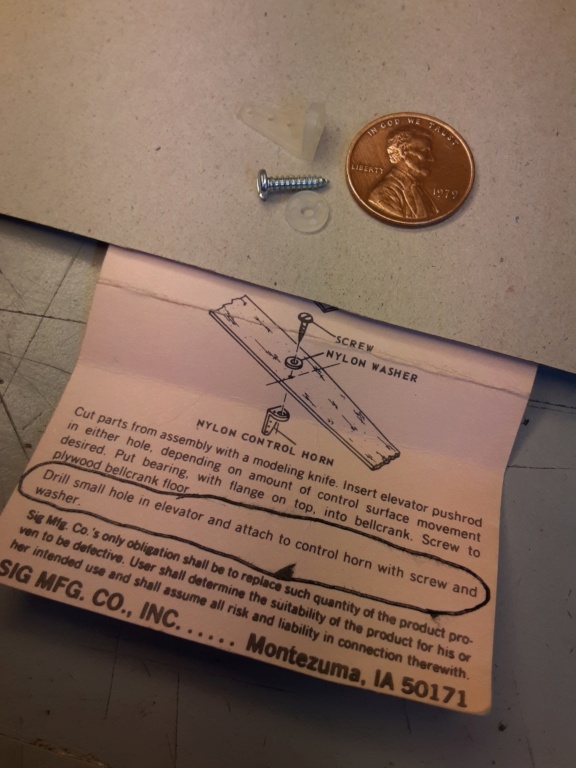

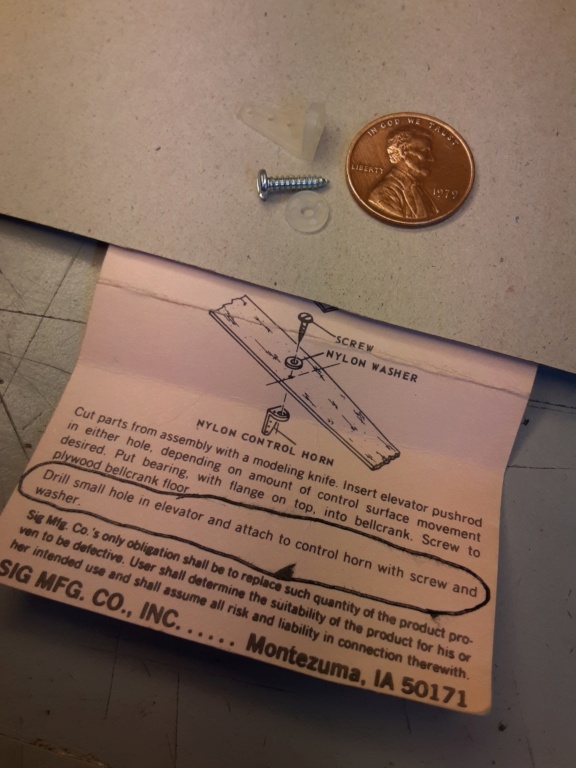

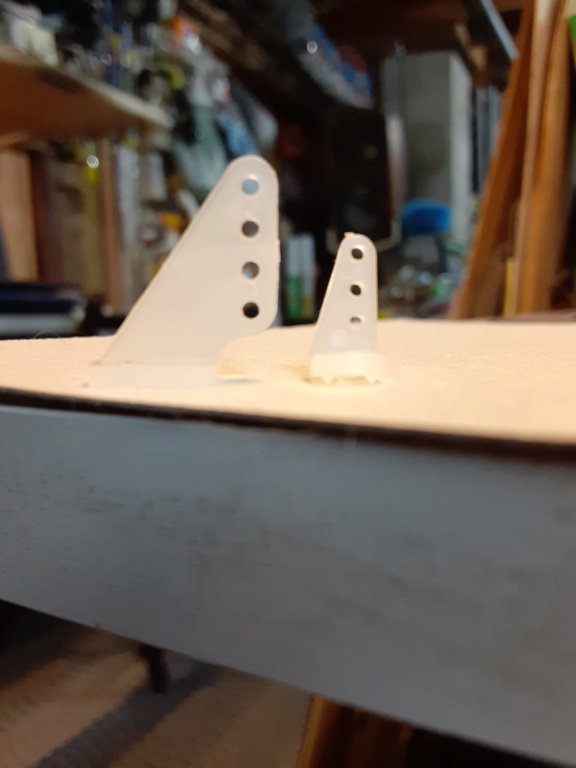

Regarding "control-horns".. I haven't used the ones that come with Sig's P/N SH234. The horns are really small.. and the mounting method just seems sketchy to me. (image below)

to me. (image below)

What do you think? There are external "dimples" molded-into the Sig horn's mounting flange.. which is "good".. but would I trust the supplied wood/SMS-screw instructions shown?

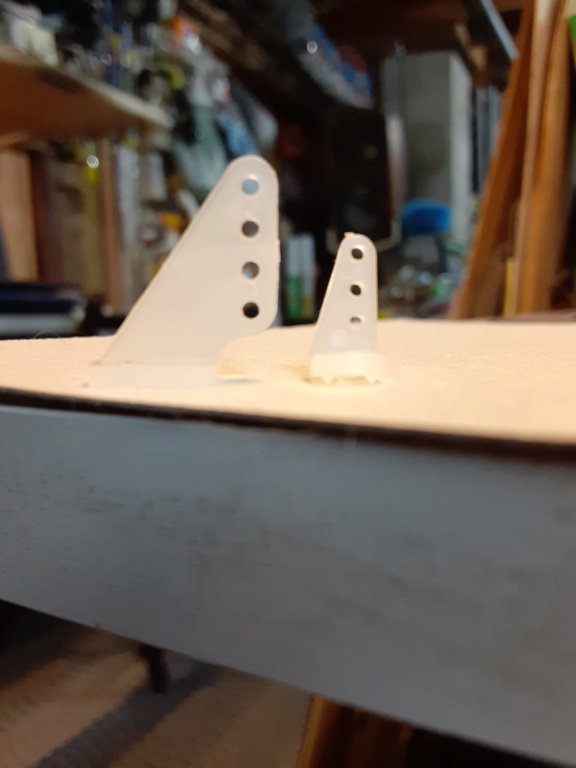

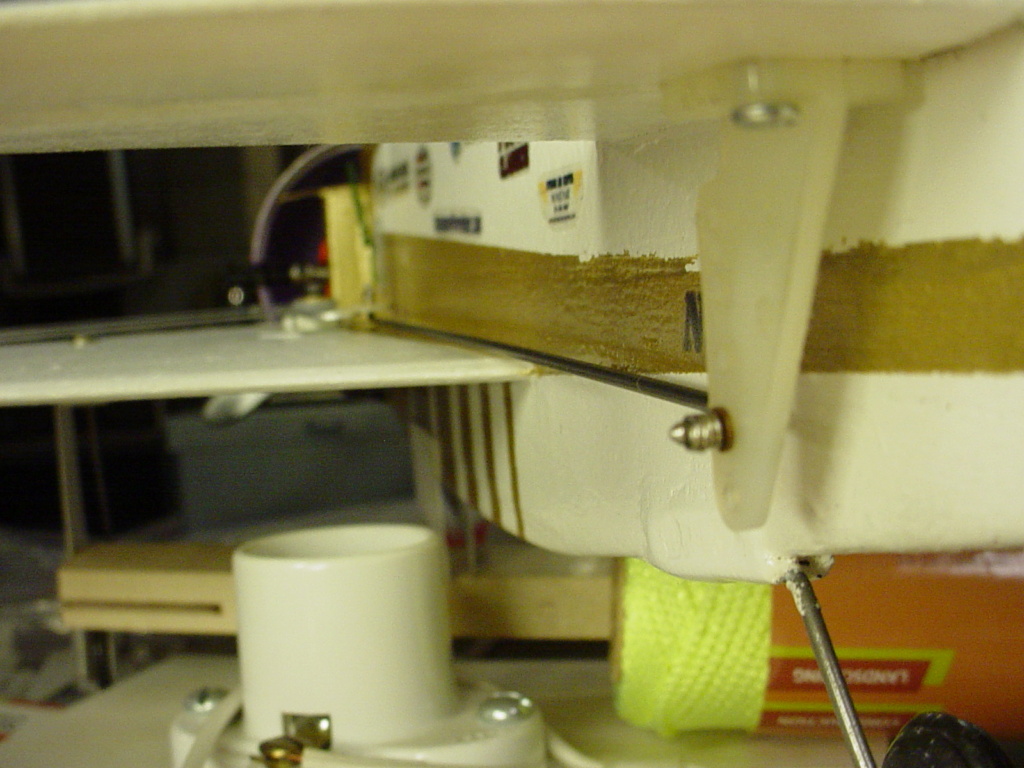

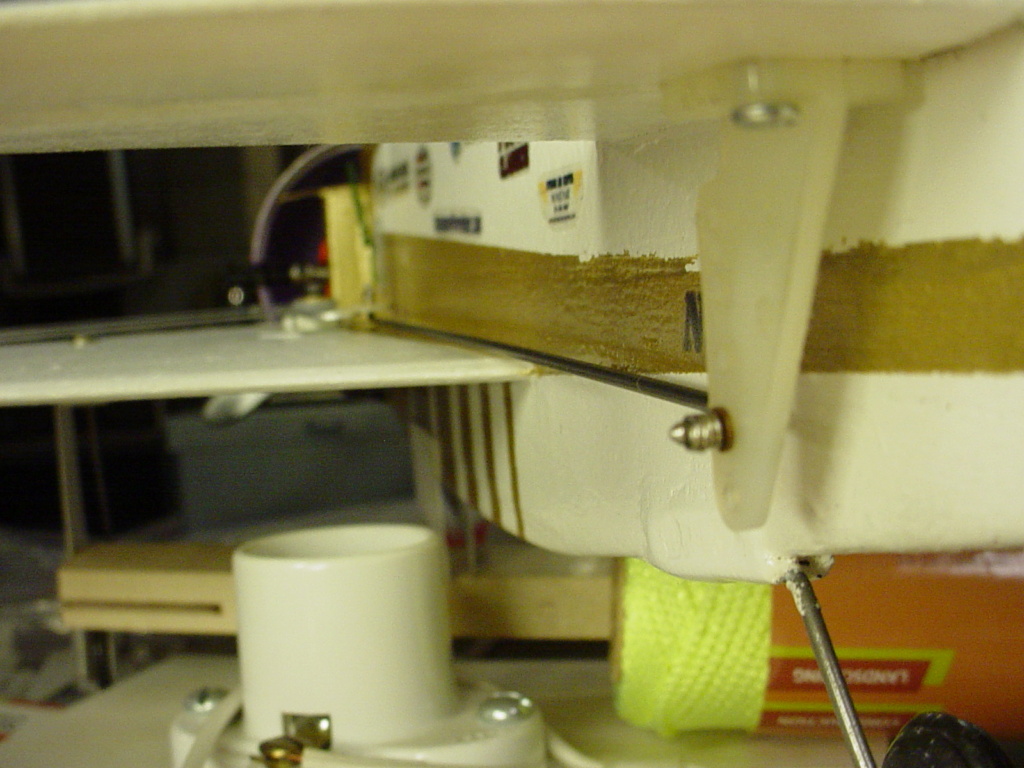

I prefer the adjustment-range of a longer horn. Below; a photo of Dubro's #107 (sm.) horn (left) with the Sig #234 horn (right)

The Dubro #107 (1/2A) horns can be found on all of my designs..

I actually used the larger Dubro #237 horn on my Rare Bear speed-model for less elevator-travel in an effort to desensitize the controls.

Sig currently has some line-connectors in stock too. I got some.. while they were there.. It's those little things that you need.. to get off the ground.

I was pleased to find that "Sig" is still offering their P/N SH234 1/2A Nylon bellcrank with control horn assembly. Currently $1.24 ea. (USD)

When I searched "Tower Hobbies".. I found offerings from "Sullivan" that are actually "Perfect" brand items. The Perfect #P222 SMALL bellcrank assy. is being sold as the Sullivan #SULP222. Currently $2.91 ea. (USD)

I like these little aluminum bellcranks.. and would have bought a few more, but there were only X3 remaining in Tower's stock. The #SULP223 (Perfect #223) LARGE bellcrank assy. "is" currently in stock as of today through Tower Hobbies.

Regarding "control-horns".. I haven't used the ones that come with Sig's P/N SH234. The horns are really small.. and the mounting method just seems sketchy

to me. (image below)

to me. (image below) What do you think? There are external "dimples" molded-into the Sig horn's mounting flange.. which is "good".. but would I trust the supplied wood/SMS-screw instructions shown?

I prefer the adjustment-range of a longer horn. Below; a photo of Dubro's #107 (sm.) horn (left) with the Sig #234 horn (right)

The Dubro #107 (1/2A) horns can be found on all of my designs..

I actually used the larger Dubro #237 horn on my Rare Bear speed-model for less elevator-travel in an effort to desensitize the controls.

Sig currently has some line-connectors in stock too. I got some.. while they were there.. It's those little things that you need.. to get off the ground.

Re: Control-line hdwe. for smaller models

Re: Control-line hdwe. for smaller models

I have used the little Sig horn with no problems. Broke one in a hard crash that was brittle from being 40 years old. MBS Model builders supply carries the Sig horns in a 3 pack pretty cheap too. He has a fair bit of stuff. https://mbsmodelsupply.com/Catalog.pdf

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: Control-line hdwe. for smaller models

Re: Control-line hdwe. for smaller models

No control horn should be used without a plywood pad under it and on top of it. Using CA to harden the area isn't a good solution either. Cut a small square or circle of 1/64" ply and glue it onto the elevator surface and then drill for the horn. It spreads the load and prevents the horn from pulling through the elevator. One would think it's only a 1/2A but a mishap like a ground doink or flip over landing can really over stress the horn and rip it through the elevator. Using the small horn makes this even easier due to having little to no footprint. The single screw is misleading and one can easily over do the tension required squashing the wood which totally compromises the connection.

The main problem with the small horn is it's size, unless your using a larger bellcrank, it really is making the controls too fast. This can be compensated somewhat on the handle end. The single hole though is responsible for several crashes that I've witnessed. Instead of moving the elevator surfaces, I've seen the entire horn rotate until it jams the pushrod locking up the controls. I highly recommend roughing up the nylon, clean it with acetone and put a dab of epoxy onto it prior to installation to hold it firmly in place and prevent it from turning.

One other tip I would like to offer is that prior to installing nylon horns is to wear a glove and run the screws through the horn first. The screws totally suck and if the improper driver is used, the screwdriver slips. This not only can go through your hand, it will go through the elevator. On the Dubro horns and others for larger than 1/2A, I disregard the wood screws and I use 2-56 socket heads. The look cleaner and they install much easier. I cut the balance off with a Dremel disc taking little bites at a time so that it doesn't overheat it melting the nylon.

The main problem with the small horn is it's size, unless your using a larger bellcrank, it really is making the controls too fast. This can be compensated somewhat on the handle end. The single hole though is responsible for several crashes that I've witnessed. Instead of moving the elevator surfaces, I've seen the entire horn rotate until it jams the pushrod locking up the controls. I highly recommend roughing up the nylon, clean it with acetone and put a dab of epoxy onto it prior to installation to hold it firmly in place and prevent it from turning.

One other tip I would like to offer is that prior to installing nylon horns is to wear a glove and run the screws through the horn first. The screws totally suck and if the improper driver is used, the screwdriver slips. This not only can go through your hand, it will go through the elevator. On the Dubro horns and others for larger than 1/2A, I disregard the wood screws and I use 2-56 socket heads. The look cleaner and they install much easier. I cut the balance off with a Dremel disc taking little bites at a time so that it doesn't overheat it melting the nylon.

Ken Cook- Top Poster

- Posts : 5641

Join date : 2012-03-27

Location : pennsylvania

Similar topics

Similar topics» SIG control line models

» [solved].049 Control Line models?

» Birth of control line models in US

» SIG Manufacturing

» Control linkages on bigger models

» [solved].049 Control Line models?

» Birth of control line models in US

» SIG Manufacturing

» Control linkages on bigger models

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules