Log in

Search

Latest topics

» My latest doodle...by batjac Today at 10:05 pm

» Retail price mark-up.. how much is enough?

by gkamysz Today at 9:29 pm

» Happy 77th birthday Andrew!

by roddie Today at 9:22 pm

» Roger Harris revisited

by rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

NOS (?) .049 engine froze

Page 1 of 1

NOS (?) .049 engine froze

NOS (?) .049 engine froze

Hello,

I found a Cox plane at an estate sale on Friday that looks like it had never been flown. It was still boxed up and everything. Looks really nice, but the prop won't turn. I don't want to force it and screw something up, but I am wondering if there is something safe I can spray in the cylinder that might help free it up?

It is probably a mid-70's vintage plane, judging by the paperwork in the box. I had a couple of these as a kid, but never took the engines apart. Not sure what can of worms I would be getting into by doing that also. Judging by the number of people on here, I would say getting replacement parts (gaskets, etc...) for these old things must not be too difficult?

Any ideas are welcome!

Thanks,

Travis

I found a Cox plane at an estate sale on Friday that looks like it had never been flown. It was still boxed up and everything. Looks really nice, but the prop won't turn. I don't want to force it and screw something up, but I am wondering if there is something safe I can spray in the cylinder that might help free it up?

It is probably a mid-70's vintage plane, judging by the paperwork in the box. I had a couple of these as a kid, but never took the engines apart. Not sure what can of worms I would be getting into by doing that also. Judging by the number of people on here, I would say getting replacement parts (gaskets, etc...) for these old things must not be too difficult?

Any ideas are welcome!

Thanks,

Travis

LBF ARSR- Beginner Poster

- Posts : 5

Join date : 2022-04-29

Re: NOS (?) .049 engine froze

Re: NOS (?) .049 engine froze

Travis, due to the age the engine probably needs to come out of the plane and be disassembled. Gaskets are not a issue. EX Model Engines and Cox International will be where you find the needed parts. Gaskets, reeds, clips, screws etc. The real problem with the old ready to fly stuff is the brittleness of the plastics used.The plastic tank has little nipples and you don't want to break the nipples. Therefore, wiggling and pulling is not a good thing. Maybe try a hair dryer with a little heat and a small screwdriver to assist the tubing to come off even a little oil prior to pulling it. In addition, heat is the best way to unstick a engine. A heat gun works well and some oil like Marvel air tool oil on the piston and everything else that doesn't budge. I'm not a personal fan of 3n1 oil due to the problems it causes when trying to restart as it has a tendency to really make the engine fickle until it burns off which takes some time.

You want to also insure you have the proper tools, Cox wrenches are in order and pliers are out. Parts will clean up fairly well with standard rubbing alcohol.

You want to also insure you have the proper tools, Cox wrenches are in order and pliers are out. Parts will clean up fairly well with standard rubbing alcohol.

Last edited by Ken Cook on Sun May 01, 2022 8:23 am; edited 1 time in total

Ken Cook- Top Poster

- Posts : 5637

Join date : 2012-03-27

Location : pennsylvania

Re: NOS (?) .049 engine froze

Re: NOS (?) .049 engine froze

Almost all parts are still available for .049 engines. And To free the engine try wit wd40 its safe for the plastiques of the plane and wil Not stain or discolor wd40 help make those old plastiques à bit more flexible à litle heat help To but I have To get the engine out the fuselage

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: NOS (?) .049 engine froze

Re: NOS (?) .049 engine froze

Your best friends.

I hate to disagree with David because he's a whole lot smarter than I am regarding this, but there is no way ever again that WD-40 is going to get anywhere near my engines. Maybe short term, but over-time WD-40 will get gummy and freeze up engines requiring a complete tear-down to return to service. Been there!

I hate to disagree with David because he's a whole lot smarter than I am regarding this, but there is no way ever again that WD-40 is going to get anywhere near my engines. Maybe short term, but over-time WD-40 will get gummy and freeze up engines requiring a complete tear-down to return to service. Been there!

rsv1cox- Top Poster

Posts : 11248

Join date : 2014-08-18

Location : West Virginia

Re: NOS (?) .049 engine froze

Re: NOS (?) .049 engine froze

Ok, thanks for the replies. I have all of that here and will give it a try later after doing a couple of other things that need done.

I'm pretty lucky because the engine hasn't been mounted in the plane yet, so I can just work with that in my hand. I'll keep you posted. Might have more questions.

Thanks a lot!

Travis

I'm pretty lucky because the engine hasn't been mounted in the plane yet, so I can just work with that in my hand. I'll keep you posted. Might have more questions.

Thanks a lot!

Travis

LBF ARSR- Beginner Poster

- Posts : 5

Join date : 2022-04-29

Re: NOS (?) .049 engine froze

Re: NOS (?) .049 engine froze

LBF ARSR wrote:Ok, thanks for the replies. I have all of that here and will give it a try later after doing a couple of other things that need done.

I'm pretty lucky because the engine hasn't been mounted in the plane yet, so I can just work with that in my hand. I'll keep you posted. Might have more questions.

Thanks a lot!

Travis

Low heat initially. Always the least aggressive approach first.

rsv1cox- Top Poster

Posts : 11248

Join date : 2014-08-18

Location : West Virginia

Re: NOS (?) .049 engine froze

Re: NOS (?) .049 engine froze

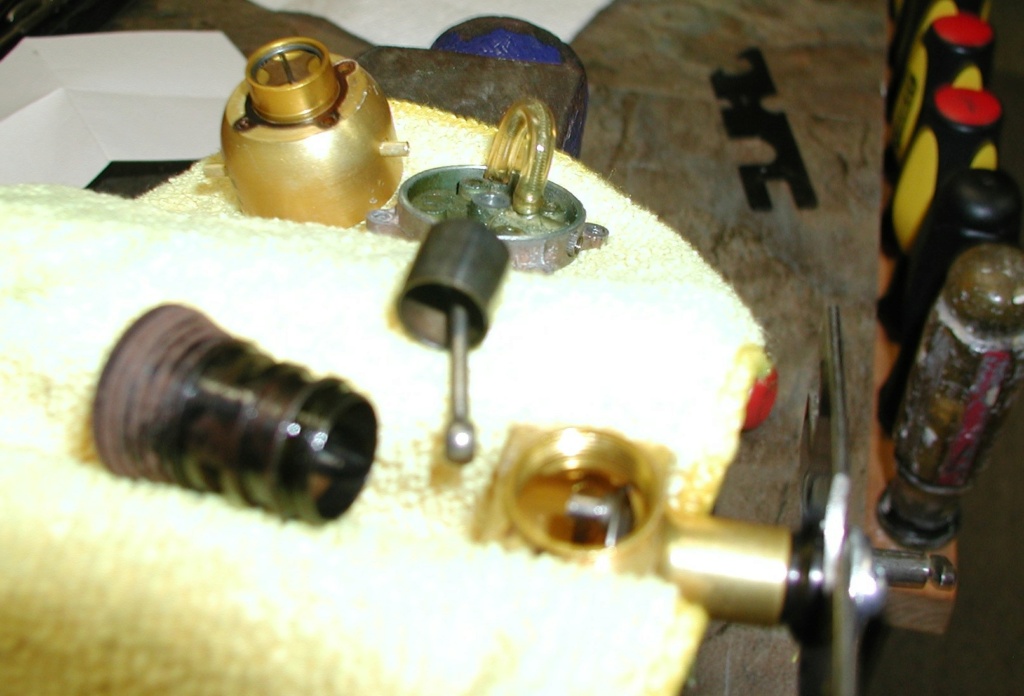

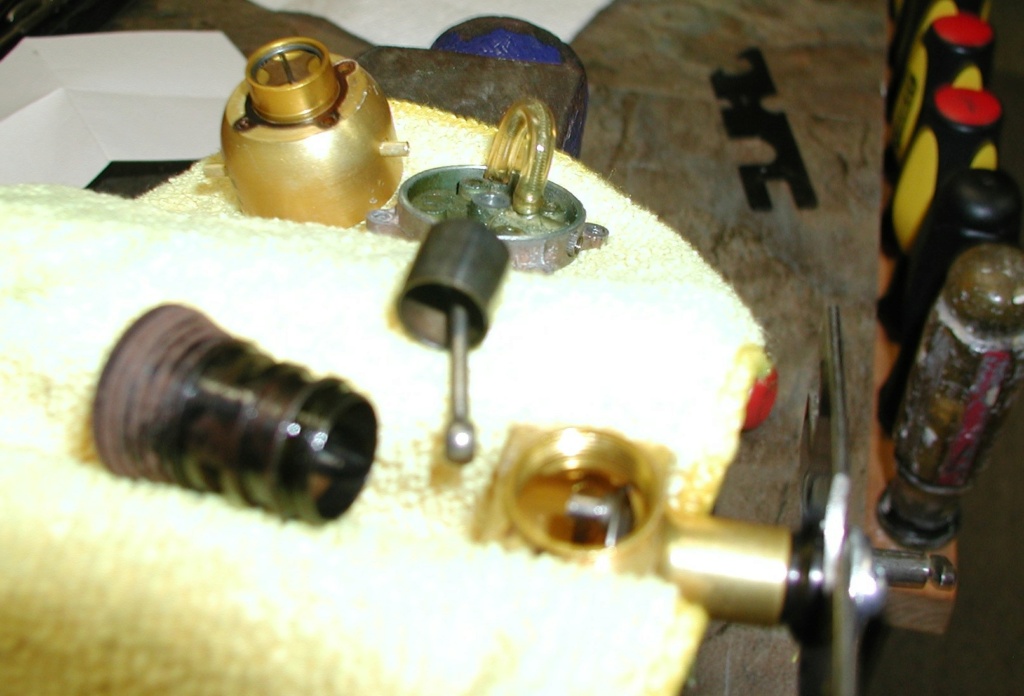

I'm just tearing down this Cox Golden Bee and thought I would share some tips with you. You may know a lot of this already.

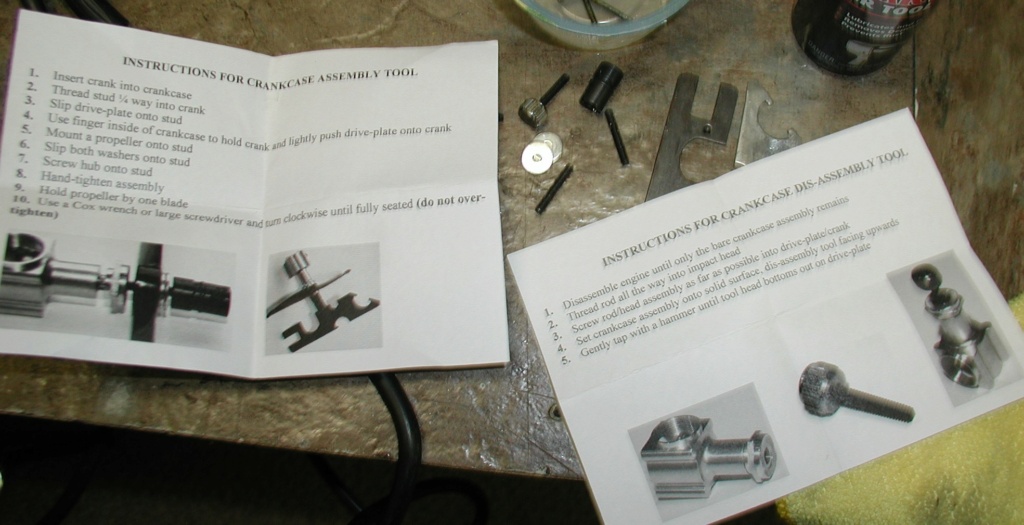

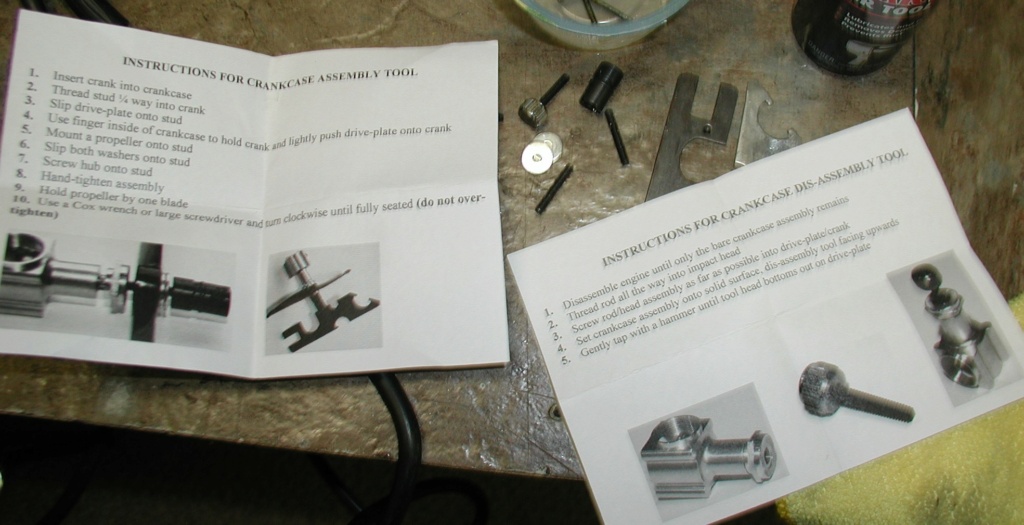

First get a good set of screwdrivers, I like these. A set of Cox engine take-down tools doesn't hurt either, but you can make your own.

You will need to turn the crankshaft, and heat is unfriendly to wood and plastic, so I drilled a hole in a Cox .049 wrench tightly secured to the drive washer and use that. Buffer a vice and snugly not tightly secure the case and using the heat gun remove the glow head and the cylinder. To remove the cylinder ensure that the tool is fully inserted in the exhaust ports, put drops of oil in each port and on top of the piston and just bump the tool with the palm of your hand. Make sure the case is very warm.

Remove the piston and using the tool tap out the crankshaft on a hard flat surface. Notice the congealed castor on the crankshafts relief, the main reason for these dragging. Probably further than you need to go on your engine.

Ready for cleaning. Simple Green or Berryman's carburetor cleaner works well.

If your serious about doing these a connecting rod reset tool available from Matt or Bernie is a good investment.

First get a good set of screwdrivers, I like these. A set of Cox engine take-down tools doesn't hurt either, but you can make your own.

You will need to turn the crankshaft, and heat is unfriendly to wood and plastic, so I drilled a hole in a Cox .049 wrench tightly secured to the drive washer and use that. Buffer a vice and snugly not tightly secure the case and using the heat gun remove the glow head and the cylinder. To remove the cylinder ensure that the tool is fully inserted in the exhaust ports, put drops of oil in each port and on top of the piston and just bump the tool with the palm of your hand. Make sure the case is very warm.

Remove the piston and using the tool tap out the crankshaft on a hard flat surface. Notice the congealed castor on the crankshafts relief, the main reason for these dragging. Probably further than you need to go on your engine.

Ready for cleaning. Simple Green or Berryman's carburetor cleaner works well.

If your serious about doing these a connecting rod reset tool available from Matt or Bernie is a good investment.

rsv1cox- Top Poster

Posts : 11248

Join date : 2014-08-18

Location : West Virginia

Re: NOS (?) .049 engine froze

Re: NOS (?) .049 engine froze

Very cautious work, Bob, nice results. I like especially how you have managed to de-rust the cylinder fins!

I have been encouraged by my successful filing of flats into the top fin of several old-stock cylinders, that I will avoid the use of the COX wrench on the exhaust ports. Even before the first cylinder removal on an old engine, I file the flats, and then I prevent the damage that at least I would highly likely cause in the exhaust ports when forcing a cemented cylinder off the crankcase...

It is always interesting to see how intact the anodization in the crankcase nose remains even after elongated use of the COX engine...of course only with well balanced props...

I have been encouraged by my successful filing of flats into the top fin of several old-stock cylinders, that I will avoid the use of the COX wrench on the exhaust ports. Even before the first cylinder removal on an old engine, I file the flats, and then I prevent the damage that at least I would highly likely cause in the exhaust ports when forcing a cemented cylinder off the crankcase...

It is always interesting to see how intact the anodization in the crankcase nose remains even after elongated use of the COX engine...of course only with well balanced props...

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: NOS (?) .049 engine froze

Re: NOS (?) .049 engine froze

Yes, a very light touch on the wire wheel will remove rust, even inside the fins if you angle it correctly.

Doing one of those cylinders as you describe is on my bucket list. I just haven't worked up the courage to try one yet. I used to buffer the Cox tools ears with masking tape, gave that up. Now I heat the case/cylinder, secure it in a vice and just bump the wrench.

Exterior was a mess (picture) but turned out pretty good. Interior not too bad. Once I dry it off and the oil matures it will look more natural. Too much engine for the Cub, I will probably substitute a standard Babe Bee.

More stuff for Travis. More than he asked for and probably needs.

I'm a big advocate for using the disassembly/assembly tools. Ron Cribbs recommends decking the case, so i gave it a try. 800 grit paper and super smooth and flat MDF board.

Doing one of those cylinders as you describe is on my bucket list. I just haven't worked up the courage to try one yet. I used to buffer the Cox tools ears with masking tape, gave that up. Now I heat the case/cylinder, secure it in a vice and just bump the wrench.

Exterior was a mess (picture) but turned out pretty good. Interior not too bad. Once I dry it off and the oil matures it will look more natural. Too much engine for the Cub, I will probably substitute a standard Babe Bee.

More stuff for Travis. More than he asked for and probably needs.

I'm a big advocate for using the disassembly/assembly tools. Ron Cribbs recommends decking the case, so i gave it a try. 800 grit paper and super smooth and flat MDF board.

rsv1cox- Top Poster

Posts : 11248

Join date : 2014-08-18

Location : West Virginia

Re: NOS (?) .049 engine froze

Re: NOS (?) .049 engine froze

Bob, fantastic job on restoring the Golden Bee engine to its former glory. Regarding the Bee, agreed, too much engine for such a simple lightweight plane. A Golden Bee is deserving of better.  I noticed that the original modeler did not do much to at least round the 1/8" thick sheet wings but left edges square.

I noticed that the original modeler did not do much to at least round the 1/8" thick sheet wings but left edges square.  (This is sacrilege to a perfectionist builder).

(This is sacrilege to a perfectionist builder).  Are you planning to rehab the aircraft?

Are you planning to rehab the aircraft?

If plane is left unrehab'd, do you have an equally un-rehab'd Babe Bee or one that has severely crash dented cylinder fins, head, badly scratched tank (from screwdriver misalignment and crankcase mars

and crankcase mars  that would match the plane's historic rustic vintage look?

that would match the plane's historic rustic vintage look?

If plane is left unrehab'd, do you have an equally un-rehab'd Babe Bee or one that has severely crash dented cylinder fins, head, badly scratched tank (from screwdriver misalignment

and crankcase mars

and crankcase mars

GallopingGhostler- Top Poster

Posts : 5723

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: NOS (?) .049 engine froze

Re: NOS (?) .049 engine froze

I'm leaving it as is George, just a wipe down with a microfiber towel so not to disturb the decals, then an overspray with either matte or gloss clear.

Yes, I have some pretty beat up Babe Bees.

Sorry for the topic drift Travis, sometimes it happens here.

Bob

Yes, I have some pretty beat up Babe Bees.

Sorry for the topic drift Travis, sometimes it happens here.

Bob

rsv1cox- Top Poster

Posts : 11248

Join date : 2014-08-18

Location : West Virginia

Re: NOS (?) .049 engine froze

Re: NOS (?) .049 engine froze

Bob, here in CEF we're family, no?

I've freed a frozen engine, one a 1965 model OS Max .10R/C by boiling in water 10 minutes, softened congealed Castor. Another here, a 1965 model Enya .09-III TV, I'm using anti-freeze in a Poly Perk coffee pot (good substitute for a crock pot):

Application of heat helps to soften old congealed oil. Some have used an air heat gun. I'm not as big of a fan of those, as one can possibly raise temperatures to the point of melting plastic. Boiling water is more gentle, and it doesn't take much, say 5 to 10 minutes in a small sauce pan (without your wife watching ) placed in water sufficient to cover the engine while under a mild simmer.

) placed in water sufficient to cover the engine while under a mild simmer.

The OS Max's cylinder liner was quickly freed up from the aluminum crankcase, easily slid out with a little prodding.

I would not force the .049 to turn by manual force without other gentle coaxing. You can possibly separate the crankshaft ball end from the piston socket, doing irreparable harm.

Of course, this will require you to carefully remove the fuselage assembly screws to remove the engine, but in order to adequately access the engine with heat without damaging the plane, leaves very few other options. If application of penetrating oil on the exposed piston and prop hub with a day or two of work time doesn't free the engine, then will require further surgical procedures.

LBF ARSR wrote:Looks really nice, but the prop won't turn. I don't want to force it and screw something up, but I am wondering if there is something safe I can spray in the cylinder that might help free it up?

I've freed a frozen engine, one a 1965 model OS Max .10R/C by boiling in water 10 minutes, softened congealed Castor. Another here, a 1965 model Enya .09-III TV, I'm using anti-freeze in a Poly Perk coffee pot (good substitute for a crock pot):

Application of heat helps to soften old congealed oil. Some have used an air heat gun. I'm not as big of a fan of those, as one can possibly raise temperatures to the point of melting plastic. Boiling water is more gentle, and it doesn't take much, say 5 to 10 minutes in a small sauce pan (without your wife watching

) placed in water sufficient to cover the engine while under a mild simmer.

) placed in water sufficient to cover the engine while under a mild simmer.The OS Max's cylinder liner was quickly freed up from the aluminum crankcase, easily slid out with a little prodding.

I would not force the .049 to turn by manual force without other gentle coaxing. You can possibly separate the crankshaft ball end from the piston socket, doing irreparable harm.

Of course, this will require you to carefully remove the fuselage assembly screws to remove the engine, but in order to adequately access the engine with heat without damaging the plane, leaves very few other options. If application of penetrating oil on the exposed piston and prop hub with a day or two of work time doesn't free the engine, then will require further surgical procedures.

GallopingGhostler- Top Poster

Posts : 5723

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: NOS (?) .049 engine froze

Re: NOS (?) .049 engine froze

Wow, really great info in you guy's posts!

I was able to get the engine freed up! I let some rem oil soak it for a day or two, but that didn't help any. So I took off the rear plastic assembly that has the thumbscrew in it (Showing my ignorance here, but I assume that is for the fuel flow) so I didn't mess up any plastic parts. Then sprayed in some Blast where the connecting rod is, let that sit. No luck. Took off the glow plug and sprayed down in to the piston, same result. Finally, I used my heat gun and was able to get it to turn some. Probably should have done that sooner. Kept turning the part where the prop fastens and it still turned kind of hard. For the heck of it I turned it counter clockwise and it freed right up. Now does well either way. I will let it sit over night, then get out some of the excess residue tomorrow, and put it back together.

Not sure what I will do then. Try to locate some fuel, or just put it up on the shelf.

Thanks for everything. I may be back with more questions!

Travis

I was able to get the engine freed up! I let some rem oil soak it for a day or two, but that didn't help any. So I took off the rear plastic assembly that has the thumbscrew in it (Showing my ignorance here, but I assume that is for the fuel flow) so I didn't mess up any plastic parts. Then sprayed in some Blast where the connecting rod is, let that sit. No luck. Took off the glow plug and sprayed down in to the piston, same result. Finally, I used my heat gun and was able to get it to turn some. Probably should have done that sooner. Kept turning the part where the prop fastens and it still turned kind of hard. For the heck of it I turned it counter clockwise and it freed right up. Now does well either way. I will let it sit over night, then get out some of the excess residue tomorrow, and put it back together.

Not sure what I will do then. Try to locate some fuel, or just put it up on the shelf.

Thanks for everything. I may be back with more questions!

Travis

LBF ARSR- Beginner Poster

- Posts : 5

Join date : 2022-04-29

Re: NOS (?) .049 engine froze

Re: NOS (?) .049 engine froze

"Thumbscrew" - It's called a needle Travis. It screws into a "spray bar". The whole thing is called a Needle Valve Assembly.

It's a good idea to remove any plastic parts before applying a heat gun.

It's a good idea to remove any plastic parts before applying a heat gun.

rsv1cox- Top Poster

Posts : 11248

Join date : 2014-08-18

Location : West Virginia

Similar topics

Similar topics» *Cox Engine of The Month* Submit your pictures! -December 2015- *ENGINE GIVEAWAY*

» **Black Lynx Engine Giveaway June 2015** Cox Engine of the Month

» **Black Lynx Engine Giveaway June 2016** Cox Engine of the Month

» *Cox Engine of The Month* Submit your pictures! -June 2019- #ENGINE GIVEAWAY#

» *Cox Engine of The Month* Submit your pictures! -December 2013- *ENGINE GIVEAWAY*

» **Black Lynx Engine Giveaway June 2015** Cox Engine of the Month

» **Black Lynx Engine Giveaway June 2016** Cox Engine of the Month

» *Cox Engine of The Month* Submit your pictures! -June 2019- #ENGINE GIVEAWAY#

» *Cox Engine of The Month* Submit your pictures! -December 2013- *ENGINE GIVEAWAY*

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules