Log in

Search

Latest topics

» Purchased the last of any bult engines from Ken Enyaby Coxfledgling Today at 4:18 am

» My N-1R build log

by roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

Cox Engine of The Month

Why do you need a JIS screw driver set?

Page 1 of 1

Why do you need a JIS screw driver set?

Why do you need a JIS screw driver set?

I know some members know the reason why that you'll need to have a set of JIS, others on the forum may not know?

Having rebuilt almost 100 Enya engines in the last year, it is important to use the correct tools for the right job.

What is JIS? it's the letters for Japan Industrial Standard.

Those pesky screws that started to creep in to the U.S. from the Asian countries. they look like Philip screws (but are not!)

If you tried to use a Philips screwdriver on the screws that look like standard Philips, you strip the head out and the Philips screwdriver doesn't work any more on the screw.

Well, If it came from an Asian country, it probably had JIS screws and not Philips.

Below is a photo of a Philips screw (on the left) and an JIS screw (on the right). Not much difference?

Well you'll be wrong.

The JIS screw has a different angle (smaller) than the Philips (wider).

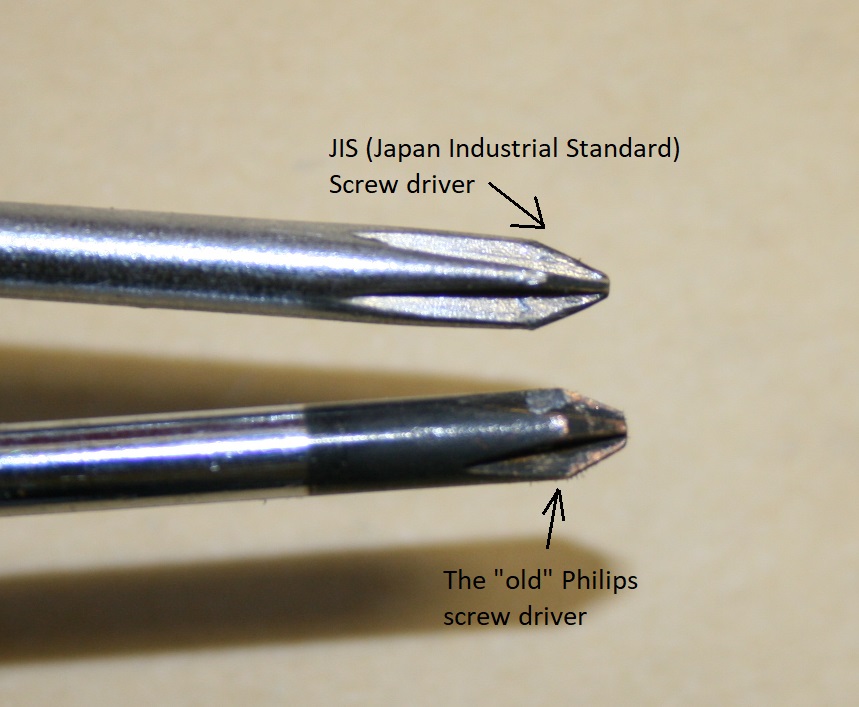

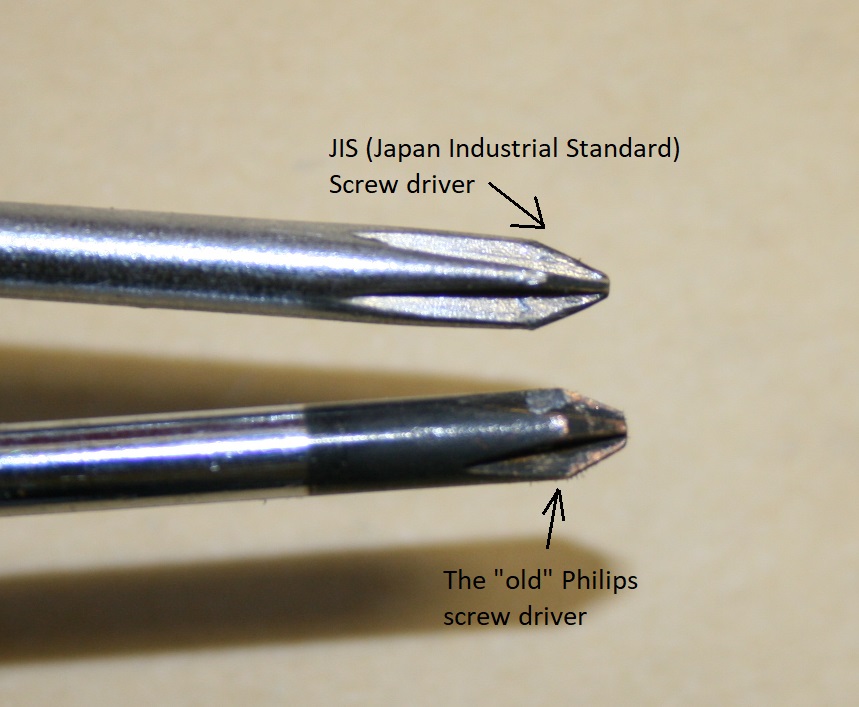

The other thing you will notice, if you have a set of JIS screw drivers is also the difference from the Philips screw driver.

The photo below shows the difference.

The JIS has more of a point and have a better engagement to the screw for a JIS screw than a Philips screwdriver.

So, Use a JIS screwdriver on JIS screws and a Philips screwdriver in Std. Philips screws.

If the Philips screwdriver doesn't feel like it really fits in the screw head try a JIS screwdriver.

Having rebuilt almost 100 Enya engines in the last year, it is important to use the correct tools for the right job.

What is JIS? it's the letters for Japan Industrial Standard.

Those pesky screws that started to creep in to the U.S. from the Asian countries. they look like Philip screws (but are not!)

If you tried to use a Philips screwdriver on the screws that look like standard Philips, you strip the head out and the Philips screwdriver doesn't work any more on the screw.

Well, If it came from an Asian country, it probably had JIS screws and not Philips.

Below is a photo of a Philips screw (on the left) and an JIS screw (on the right). Not much difference?

Well you'll be wrong.

The JIS screw has a different angle (smaller) than the Philips (wider).

The other thing you will notice, if you have a set of JIS screw drivers is also the difference from the Philips screw driver.

The photo below shows the difference.

The JIS has more of a point and have a better engagement to the screw for a JIS screw than a Philips screwdriver.

So, Use a JIS screwdriver on JIS screws and a Philips screwdriver in Std. Philips screws.

If the Philips screwdriver doesn't feel like it really fits in the screw head try a JIS screwdriver.

sosam117- Diamond Member

- Posts : 1350

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Fledgling

Fledgling

Do his screw years have a "dot" on them ?

Coxfledgling- Gold Member

- Posts : 405

Join date : 2021-01-10

Location : Near Caernarfon, Snowdonia, Wales, UK

Re: Why do you need a JIS screw driver set?

Re: Why do you need a JIS screw driver set?

Thanks for sharing I did become aware of this nuance a number of years ago rebuilding a old Japanese motorcycle engines. Could not figure out why I was being forced to drill them out. Then learnt about cross point fasteners and all the variations out there. I now use JIS drivers and an impact driver where required.

Sosam117 could I bent your ear on some Enya advice? I have an old 3303 15-III I'm hoping to put back into service. It's a used new to me motor. My plan is to polish the crank clean it good and see if it will sing again. My questions are;

Is the wrist pin a concern if it appears to have moved to one side (see photo). Should I do anything

Advice on needle settings to start? 3 turns out?

Glow plug, os-8 ok for this motor?

Cheers, and sorry to hijack.

Sosam117 could I bent your ear on some Enya advice? I have an old 3303 15-III I'm hoping to put back into service. It's a used new to me motor. My plan is to polish the crank clean it good and see if it will sing again. My questions are;

Is the wrist pin a concern if it appears to have moved to one side (see photo). Should I do anything

Advice on needle settings to start? 3 turns out?

Glow plug, os-8 ok for this motor?

Cheers, and sorry to hijack.

layback209- Gold Member

- Posts : 283

Join date : 2017-10-13

Age : 38

Location : Okotoks

Re: Why do you need a JIS screw driver set?

Re: Why do you need a JIS screw driver set?

Coxfledgling wrote:Do his screw years have a "dot" on them ?

Yes, larger JIS screw-heads will have the dot on there for safe recognition, but OS and Enya do not have it on their relatively small screws.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Oldenginerod- Top Poster

- Posts : 4018

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

layback209- Gold Member

- Posts : 283

Join date : 2017-10-13

Age : 38

Location : Okotoks

Re: Why do you need a JIS screw driver set?

Re: Why do you need a JIS screw driver set?

I used a Enya .15 for control line many of times. For starters, you inquired about a OS #8. OS plugs differ from others because their length is in between a long and a short. This can alter the timing on modern engines. This really doesn't impact baffle piston engines as it does modern designs. However, your #8 choice is a medium heat range plug. This is designed for 15% nitro and higher. My preference for stunt fuel is a hot r/c long plug. While the Enya #3 isn't a r/c plug, it's one of the hottest high quality plugs available and I highly recommend that plug for this engine. The engines doesn't demand higher nitro but it will tolerate it just fine. More important is the oil content. Enya recommends 20% all castor. I run 50/50 castor/synthetic in mine despite what other will tell me. It's never ruined any of my engines. If you use a higher oil content such as 25%, the Enya in my experience just shuts off.

The 3303 in a control line version came with 3 sizes of venturis. Knowing which one you have can be helpful. Too large and your compromising fuel draw. Too small and the engine runs to economical and overheats slightly. Propping this engine for control line is important. The go to prop for .15's is a 7x6. Yes, the Enya will swing a 8" but while it's not a barn burner in rpm performance, it still likes to run on the fast side so I like to let it run their with the 7" prop.

The main importance with this engine is seeing to the front case portion staying tight and using a good gasket. If these screws come loose, the engine instantly shuts off. Something to keep in mind because that can drive you crazy if you weren't aware of it. Replacing the o-ring under the venturi lip is of the utmost importance. You should need a little more than finger pressure to squash the venturi down to slip the needle valve body through the case. If you can push it through with finger pressure, it's too loose and vibrations will eat the hole away in the venturi making it wobble and suck air causing poor running and poor needling.

There's no number offered for turns out for a needle valve. Enya made too many variants and it's very simple. You open the needle put your finger over the venturi and pull a choke through. If you see fuel coming up the fuel line begin flipping. The engine is either going to run or not run and decide what you need to do from there. If it's flooding out due to being too rich, close it a turn or two.

The 3303 in a control line version came with 3 sizes of venturis. Knowing which one you have can be helpful. Too large and your compromising fuel draw. Too small and the engine runs to economical and overheats slightly. Propping this engine for control line is important. The go to prop for .15's is a 7x6. Yes, the Enya will swing a 8" but while it's not a barn burner in rpm performance, it still likes to run on the fast side so I like to let it run their with the 7" prop.

The main importance with this engine is seeing to the front case portion staying tight and using a good gasket. If these screws come loose, the engine instantly shuts off. Something to keep in mind because that can drive you crazy if you weren't aware of it. Replacing the o-ring under the venturi lip is of the utmost importance. You should need a little more than finger pressure to squash the venturi down to slip the needle valve body through the case. If you can push it through with finger pressure, it's too loose and vibrations will eat the hole away in the venturi making it wobble and suck air causing poor running and poor needling.

There's no number offered for turns out for a needle valve. Enya made too many variants and it's very simple. You open the needle put your finger over the venturi and pull a choke through. If you see fuel coming up the fuel line begin flipping. The engine is either going to run or not run and decide what you need to do from there. If it's flooding out due to being too rich, close it a turn or two.

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: Why do you need a JIS screw driver set?

Re: Why do you need a JIS screw driver set?

Thanks Ken, really appreciate the advice. This gives me a solid starting point. I had no idea about the venturi gasket and was wondering what to do there. Should be a fun little motor. I'm going to put it on a CL airframe if it bench runs reasonably. I have a strap on muffler, experiment with pressure or uniflow to see what it likes.

layback209- Gold Member

- Posts : 283

Join date : 2017-10-13

Age : 38

Location : Okotoks

Re: Why do you need a JIS screw driver set?

Re: Why do you need a JIS screw driver set?

PZ...Pozi-drive.

Standard automotive trim screwdriver from early British Auto industry. I have them all over the TR6.

Standard automotive trim screwdriver from early British Auto industry. I have them all over the TR6.

Last edited by 944_Jim on Thu Apr 01, 2021 7:27 pm; edited 1 time in total

_________________

Never enough time to build them all...always enough time to smash them all!

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: Why do you need a JIS screw driver set?

Re: Why do you need a JIS screw driver set?

layback209 wrote:Thanks Ken, really appreciate the advice. This gives me a solid starting point. I had no idea about the venturi gasket and was wondering what to do there. Should be a fun little motor. I'm going to put it on a CL airframe if it bench runs reasonably. I have a strap on muffler, experiment with pressure or uniflow to see what it likes.

Ken is spot on on may of his points.

I fly them as R/C engines and use the standard Enya 3 or the OS 3 glow plug.

The oil content I use is never over 22%

This is what Enya recommends: No. 3 glow plug / Methyl alcohol 70--60% / Nitro 10--20% / Caster oil 20%

For a starting point on the needle valve 1-1/2 --- 2-1/2 turns

Now for the piston wrist pin.

It is suppose to be free to move. Right now, the connecting rod will either be on the front of the crank or the back?

Use some heat ( I use a paint stripper heat gun) to loosen up the gummed up caster oil.

I place the heated piston and rod onto a wooden block ( with a hole drilled in it) and lightly tap on the pin to remove it..

The wooden block has a concave section in it to rest the piston in ( I used a Dremel drum sanding bit to make it)

The pin should drop into the hole and the piston is free. One more thing that I do is make a small mark on the con rod (on one side) to remember which way is the front of the engine. So, when I reassemble it it goes back to the way it was.

The wrist pin has brass pads on the end so the pin doesn't score the cylinder liner.

So, on the rebuild, you'll need a new front gasket between the front housing and the back crankcase.

2nd, don't really reuse those screws. The have been stretched out from the original assembly.

MECOA use to have rebuild kits but are sold out (not by me).

They had everything you needed. New front gasket, screws, prop driver, and venturi gasket.

What I do for the venturi gasket is go to the hardware store and look in the O-ring section for a tight fitting O-ring.

Buy it, take it home then, using a single edge razor cut the O-ring in 1/2 the width that it was (1/8" to 1/16") on a tight fitting wooden dowel. The profile looks like -- flat on top (to fit under the carb.) and the rounded side to the engine's front case.

It works better that the flat "thin" rubber washer you get from Enya.

sosam117- Diamond Member

- Posts : 1350

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: Why do you need a JIS screw driver set?

Re: Why do you need a JIS screw driver set?

Is your strap on muffler Enya? There was two types of strap on mufflers they used for this engine. Horrible and worse is the way I like to describe them. Horrible has the flipper which when opened allows one to prime through the muffler whereas worse has nothing. The outlet of both absolutely need to be opened up as large as possible. When I fly with the flipper style, I leave it open and I also drilled those holes out larger.

The 3303 uses a web stiffener in the exhaust port in the case. This in my opinion is also causing some obstruction. The liner of the 3303 is very thick and when it doesn't get a chance to run cool, it will start sagging and just seize up and shut off.

The 3304 was offered with a larger head, and no web stiffener in the exhaust port. What I found is that the 3303 likes to run quite rich on take off which is needed later in the flight as the engine begins to lean out. This engine does it far more greater than any engine I've ever experienced. This is why it's important to have the engine run on uniflow to counteract this and offer a steady run from start to finish.

Tank shape is mainly responsible for this as well. A wide wedge is not a good choice. You want longer and narrow to keep the fuel load as close to center of plane as possible.

The 3303 uses a web stiffener in the exhaust port in the case. This in my opinion is also causing some obstruction. The liner of the 3303 is very thick and when it doesn't get a chance to run cool, it will start sagging and just seize up and shut off.

The 3304 was offered with a larger head, and no web stiffener in the exhaust port. What I found is that the 3303 likes to run quite rich on take off which is needed later in the flight as the engine begins to lean out. This engine does it far more greater than any engine I've ever experienced. This is why it's important to have the engine run on uniflow to counteract this and offer a steady run from start to finish.

Tank shape is mainly responsible for this as well. A wide wedge is not a good choice. You want longer and narrow to keep the fuel load as close to center of plane as possible.

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Similar topics

Similar topics» battery for sub-C glow driver

» My ball-driver set

» Cox La Cucaracha

» Glow Plug Igniter with CONSTANT CURRENT --Oz--

» Battery for Glow Plug

» My ball-driver set

» Cox La Cucaracha

» Glow Plug Igniter with CONSTANT CURRENT --Oz--

» Battery for Glow Plug

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules