Log in

Search

Latest topics

» Cox films/videos...by Coxfledgling Today at 4:46 am

» Purchased the last of any bult engines from Ken Enya

by Coxfledgling Today at 4:18 am

» My N-1R build log

by roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

Cox Engine of The Month

My New Handle

Page 1 of 1

My New Handle

My New Handle

Hi All,

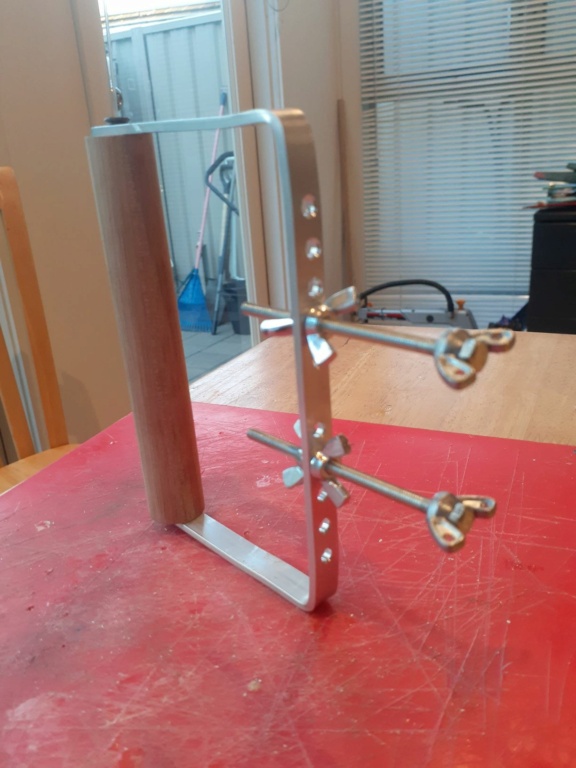

My new handle. Might not be anything new really. But its the handle I made for myself, which is very adjustable, easy to adjust, light, cheap to make, and easy to make, and actually worked very well for me.

Its a piece of broomstick with a piece of 10mm x 3mm aluminum flat bent, drilled and screwed to the broomstick piece. the holes have been drilled bigger than the 90 mm long bolts diameter so as that they dont have to be screwed and twist the lines. just loosen the wing nuts to adjust and tighten when correct. The wing nuts at the end of the bolts are glued in place and drilled so as that line clips can be connected to them.

Worked surprisingly well for me and only cost me about $5 ozzy in materials to make and half an hour of my time.

Cheers,

Gary

My new handle. Might not be anything new really. But its the handle I made for myself, which is very adjustable, easy to adjust, light, cheap to make, and easy to make, and actually worked very well for me.

Its a piece of broomstick with a piece of 10mm x 3mm aluminum flat bent, drilled and screwed to the broomstick piece. the holes have been drilled bigger than the 90 mm long bolts diameter so as that they dont have to be screwed and twist the lines. just loosen the wing nuts to adjust and tighten when correct. The wing nuts at the end of the bolts are glued in place and drilled so as that line clips can be connected to them.

Worked surprisingly well for me and only cost me about $5 ozzy in materials to make and half an hour of my time.

Cheers,

Gary

bakergw- Account Deactivated by Owner

- Posts : 76

Join date : 2020-09-20

Re: My New Handle

Re: My New Handle

Beautiful work, Gary. The only suggestion

I could make, is maybe wrap the dowel with

some handlebar tape. The bare wood might get

a little slick from body oils over time. Most any

bicycle shop will have tape in assorted colors.

I see a clone of your handle in my future. Thanks.

Bob

I could make, is maybe wrap the dowel with

some handlebar tape. The bare wood might get

a little slick from body oils over time. Most any

bicycle shop will have tape in assorted colors.

I see a clone of your handle in my future. Thanks.

Bob

dckrsn- Diamond Member

- Posts : 2750

Join date : 2010-10-21

Age : 71

Location : Long Island, New York

Re: My New Handle

Re: My New Handle

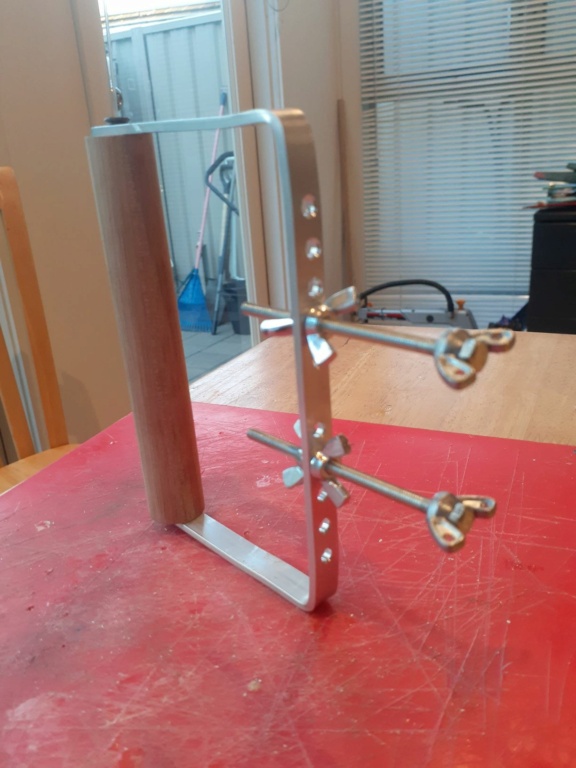

Thanks for the encouraging comments Bob.

It is a proof of concept for me at the moment. The dowel definately needs something done to it, maybe bike tape, maybe wood oil it, maybe hit it with bright blue rustoleum, or even sand it to fit my fingers a bit. The aluminum is screwed to the dowel with a couple of old screws I had in my box and haven't even been countersunk. Now Ive flown a fair bit with it, and used the adjustments I am happy it works, and the adjustments are very easy to make, I will make another one for real use. The holes are all one centimeter apart but I guessed the up/down center point, so this time I will scribe the centers, punch them, and drill with a drill press After I took this photo I made some little grooved fittings out of JB weld that were on the front bracket far ends to hold my lines wrapped around the handle. Didnt work well at all. Lol. I need to re think how to do that. Might make a bit of dowel that attaches easily on and off to the bracket part at one end, then I can rotate the handle easily to wind my lines up on it. I use stranded stainless .008 so I need to look after my lines well.

After I took this photo I made some little grooved fittings out of JB weld that were on the front bracket far ends to hold my lines wrapped around the handle. Didnt work well at all. Lol. I need to re think how to do that. Might make a bit of dowel that attaches easily on and off to the bracket part at one end, then I can rotate the handle easily to wind my lines up on it. I use stranded stainless .008 so I need to look after my lines well.

I''l post some photos when the upgraded and better looking model comes out. :-)

Take it easy.

Cheers,

Gary

It is a proof of concept for me at the moment. The dowel definately needs something done to it, maybe bike tape, maybe wood oil it, maybe hit it with bright blue rustoleum, or even sand it to fit my fingers a bit. The aluminum is screwed to the dowel with a couple of old screws I had in my box and haven't even been countersunk. Now Ive flown a fair bit with it, and used the adjustments I am happy it works, and the adjustments are very easy to make, I will make another one for real use. The holes are all one centimeter apart but I guessed the up/down center point, so this time I will scribe the centers, punch them, and drill with a drill press

I''l post some photos when the upgraded and better looking model comes out. :-)

Take it easy.

Cheers,

Gary

bakergw- Account Deactivated by Owner

- Posts : 76

Join date : 2020-09-20

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules