Log in

Search

Latest topics

» My latest doodle...by batjac Today at 10:05 pm

» Retail price mark-up.. how much is enough?

by gkamysz Today at 9:29 pm

» Happy 77th birthday Andrew!

by roddie Today at 9:22 pm

» Roger Harris revisited

by rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

Tee Dee Crankcase Assemblies

Page 1 of 1

Tee Dee Crankcase Assemblies

Tee Dee Crankcase Assemblies

Goodaye All,

Maybe this should be in the buyer seller feedback, but the issue is not only buyer seller, but a genuine technical issue.

I recently purchased six (6) Cox .049 Crankcase Assemblies from Matt at Ex Model engines. There has been quite a bit of discussion in the forum over the years about issues with drive plates fitting properly and crankshaft endplay, and differences in the lengths of some crankshafts and their fitting or not fitting properly in the crankcase.

Out of the six crankcase assemblies I received only one was really within an acceptable tolerance and the others were progressively worse to the point of two not being fit for purpose in my view. I wasted an awful lot of my time working out why I could not get the endplay to be reasonable. I eventually disassembled all of the crankcases and examined them very carefully. The reason why the end play was so bad on many of them was because the crankshaft shoulder protruded beyond the end of the crankcase. Clearly given this situation it doesnt matter how many thrust washers I put in there, the play is due to the crankshaft shoulder sticking out beyond the crankcase.

I have mixed and matched a whole lot of the parts to get half reasonable assemblies and could always machine the drive plates or the crankshaft but Im not really that keen. I have emailed Matt Multiple times and am unable to even get an answer, Other parts are still somewhere between USA and Oz and I have emailed but again, not response.

Maybe I just got some really bad parts and normally they are great parts, but for those of you who have trouble with crankshaft endplay on Tee Dee cases, check and see if the crankshaft is protruding from the crankcase, if thats the case, thrust washers wont fix it.

Think I will stick with reedies from the other vendor. The parts and service have been top class!

Cheers,

Gary

Maybe this should be in the buyer seller feedback, but the issue is not only buyer seller, but a genuine technical issue.

I recently purchased six (6) Cox .049 Crankcase Assemblies from Matt at Ex Model engines. There has been quite a bit of discussion in the forum over the years about issues with drive plates fitting properly and crankshaft endplay, and differences in the lengths of some crankshafts and their fitting or not fitting properly in the crankcase.

Out of the six crankcase assemblies I received only one was really within an acceptable tolerance and the others were progressively worse to the point of two not being fit for purpose in my view. I wasted an awful lot of my time working out why I could not get the endplay to be reasonable. I eventually disassembled all of the crankcases and examined them very carefully. The reason why the end play was so bad on many of them was because the crankshaft shoulder protruded beyond the end of the crankcase. Clearly given this situation it doesnt matter how many thrust washers I put in there, the play is due to the crankshaft shoulder sticking out beyond the crankcase.

I have mixed and matched a whole lot of the parts to get half reasonable assemblies and could always machine the drive plates or the crankshaft but Im not really that keen. I have emailed Matt Multiple times and am unable to even get an answer, Other parts are still somewhere between USA and Oz and I have emailed but again, not response.

Maybe I just got some really bad parts and normally they are great parts, but for those of you who have trouble with crankshaft endplay on Tee Dee cases, check and see if the crankshaft is protruding from the crankcase, if thats the case, thrust washers wont fix it.

Think I will stick with reedies from the other vendor. The parts and service have been top class!

Cheers,

Gary

bakergw- Account Deactivated by Owner

- Posts : 76

Join date : 2020-09-20

Re: Tee Dee Crankcase Assemblies

Re: Tee Dee Crankcase Assemblies

Gary,

I have ordered from both Bernie and Matt and had the same problem.

I also rebuild engines that have been used (abused) over the years and have had to make my own shims

to reduce the shaft play in the crankcases.

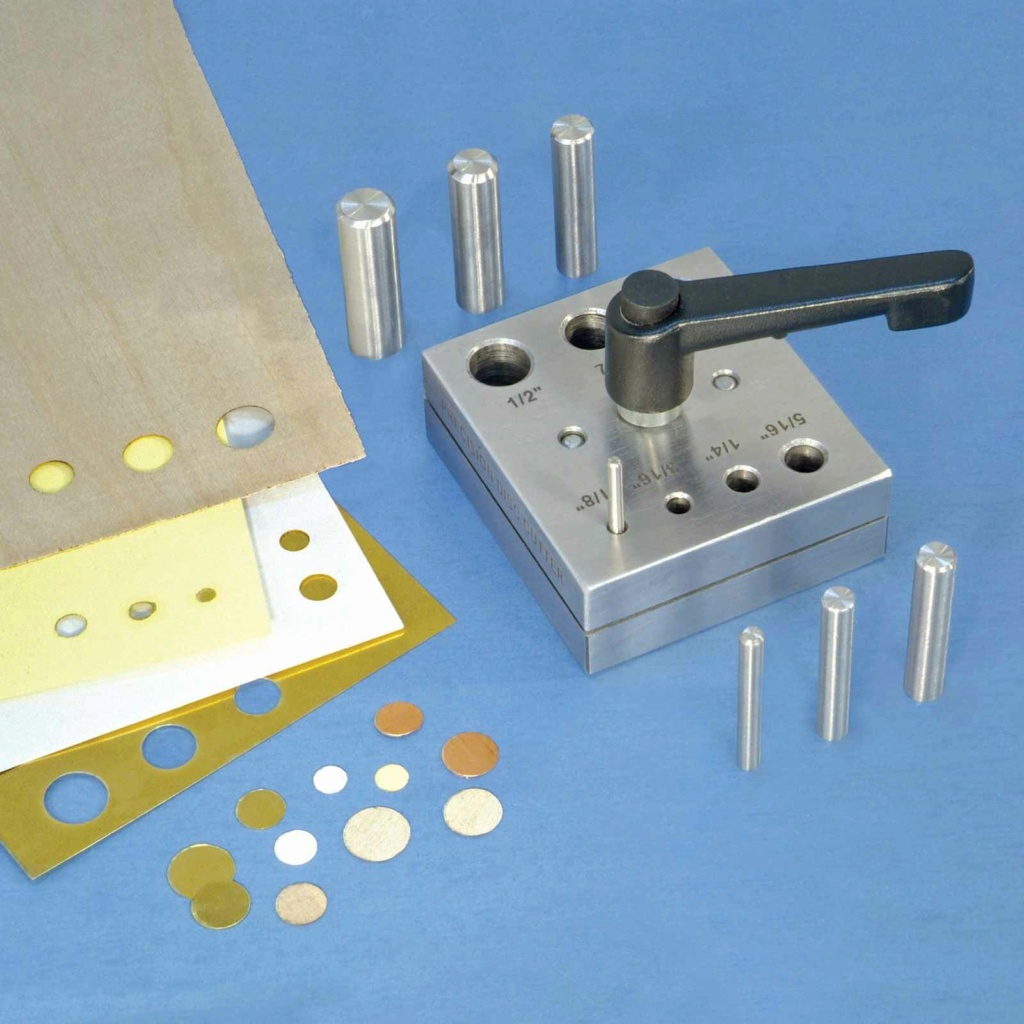

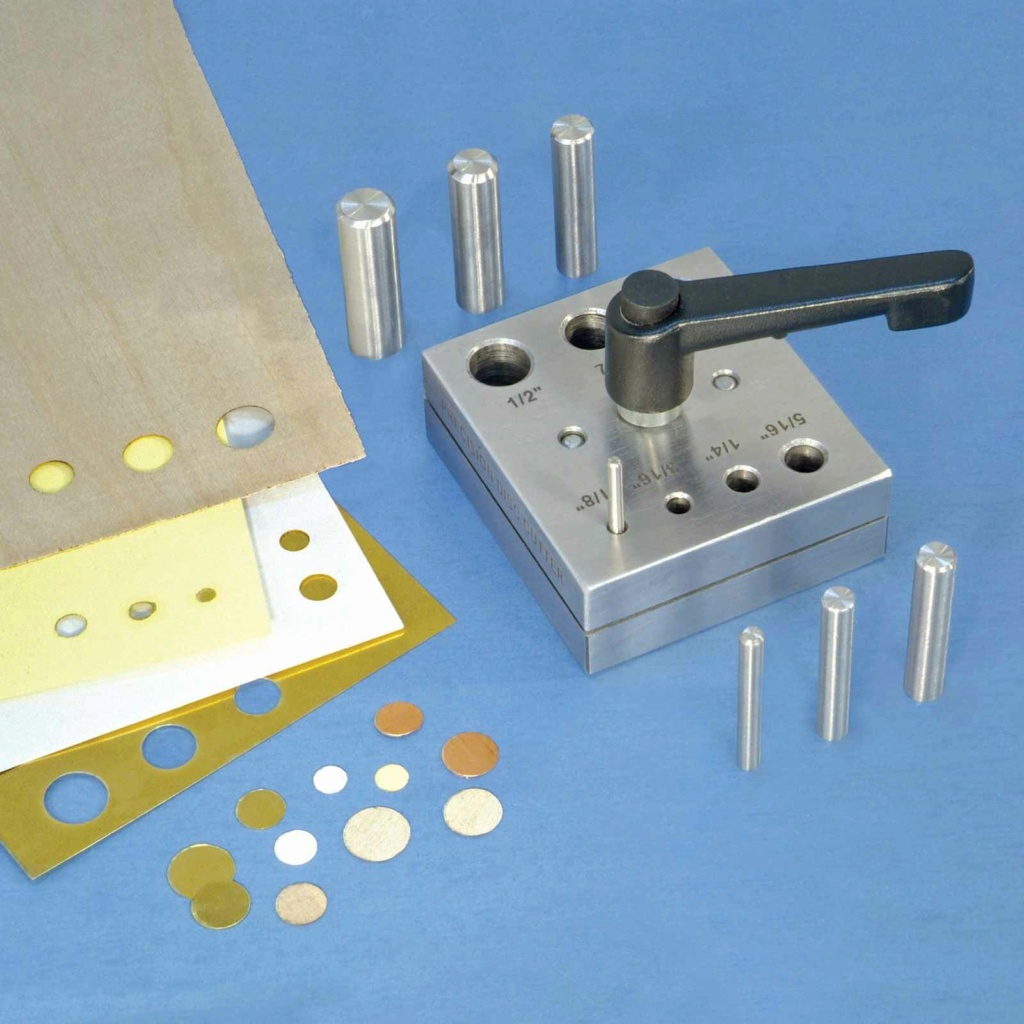

I purchased from Micro-Mark a few years ago (about 3 yrs.) a punch set to make my own shims to fit over the crankshaft

and install it before the thrust washer (prop driver).

I know what you mean about the thrust washer stopping at the end of the crankshaft.

Even "if" you purchase the phenolic (or metal) washer for the Tee Dees it stops at the crankshaft shoulder.

I know it's not the right solution but it is the only way (right now) to reduce the crankshaft end play in the crankcase

is to purchase from Micro-Mark the precision punch set ($99.95 -USD) and use K&S shim stock to make your own

shims to reduce the crankshaft play in the crankcase housings.

You can also make cylinder head shims and glow head gaskets with this punch set as well when you purchase the copper shim sheets. I have the copper shim sheets from .0025 / .005 / .010 / .015 / .020 / .025 and it works out well for all the shims I need to make for the crankshaft to cylinder head to glow head gaskets (shims).

Micro-Mark web page of the Precision Punch Set:

https://www.micromark.com/Precision-Disk-Punch-Set

I have ordered from both Bernie and Matt and had the same problem.

I also rebuild engines that have been used (abused) over the years and have had to make my own shims

to reduce the shaft play in the crankcases.

I purchased from Micro-Mark a few years ago (about 3 yrs.) a punch set to make my own shims to fit over the crankshaft

and install it before the thrust washer (prop driver).

I know what you mean about the thrust washer stopping at the end of the crankshaft.

Even "if" you purchase the phenolic (or metal) washer for the Tee Dees it stops at the crankshaft shoulder.

I know it's not the right solution but it is the only way (right now) to reduce the crankshaft end play in the crankcase

is to purchase from Micro-Mark the precision punch set ($99.95 -USD) and use K&S shim stock to make your own

shims to reduce the crankshaft play in the crankcase housings.

You can also make cylinder head shims and glow head gaskets with this punch set as well when you purchase the copper shim sheets. I have the copper shim sheets from .0025 / .005 / .010 / .015 / .020 / .025 and it works out well for all the shims I need to make for the crankshaft to cylinder head to glow head gaskets (shims).

Micro-Mark web page of the Precision Punch Set:

https://www.micromark.com/Precision-Disk-Punch-Set

sosam117- Diamond Member

- Posts : 1350

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: Tee Dee Crankcase Assemblies

Re: Tee Dee Crankcase Assemblies

Roughly how much is the axial play on those assemblies, and what would be ”ideal” or acceptable amount of play?

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: Tee Dee Crankcase Assemblies

Re: Tee Dee Crankcase Assemblies

Hello Gary,

We have received an email from you last week when we were out of the office for the Christmas Holiday. We only received a single email and did not see anything in our Spam folder, but if I missed anything on my end I apologize.

In regards to your order, I will address that in an email directly to you.

On the issue of end-play in general, 0.03" - 0.05" is acceptable.

As always, if there is an order a customer is not 100% satisfied with, we will replace the parts or issue a complete refund.

Matt

We have received an email from you last week when we were out of the office for the Christmas Holiday. We only received a single email and did not see anything in our Spam folder, but if I missed anything on my end I apologize.

In regards to your order, I will address that in an email directly to you.

On the issue of end-play in general, 0.03" - 0.05" is acceptable.

As always, if there is an order a customer is not 100% satisfied with, we will replace the parts or issue a complete refund.

Matt

Re: Tee Dee Crankcase Assemblies

Re: Tee Dee Crankcase Assemblies

This end-play problem may have (???) something to do with the geometry of Tee Dee 049 crankcases and shafts changing over time

1. Old stock Tee Dee 049-s had a thin crankshaft web that tended to break.

2. Later production shafts had their web thickened, and this necessitated some change in the longitudinal dimensions of the matching crankcase too. To avoid wrong case-to-shaft pairing, later Tee Dee 049 crankcases carry a No. 2 stamped on their left (from pilot's view) mounting beam. A shaft made to meet old stock dimensions may end up having too much axial play in a No 2 case (or vice versa).....just my 10 cents...

Maybe (???) the aftermarket case or shaft supplier mixed up the old-stock and later production dimensions?

1. Old stock Tee Dee 049-s had a thin crankshaft web that tended to break.

2. Later production shafts had their web thickened, and this necessitated some change in the longitudinal dimensions of the matching crankcase too. To avoid wrong case-to-shaft pairing, later Tee Dee 049 crankcases carry a No. 2 stamped on their left (from pilot's view) mounting beam. A shaft made to meet old stock dimensions may end up having too much axial play in a No 2 case (or vice versa).....just my 10 cents...

Maybe (???) the aftermarket case or shaft supplier mixed up the old-stock and later production dimensions?

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Tee Dee Crankcase Assemblies

Re: Tee Dee Crankcase Assemblies

Hi All,

Matt has responded to me by email and I am very happy with the response. As I am in Oz he has offered to refund the money without the need to ship the parts back. I am grateful for his offer, but I do not wish the money to be refunded or parts swapped out, as I have found a way to make them work.

I am thankful Matt manufactures the parts he does, and sells and distributed them at the prices he does. I am sure it is extremely difficult to produce these parts, maintain all the controls, sell the parts and run a viable business.

I have resolved the technical issue with a method similar to sosam117 in is post above.

Cheers,

Gary

Matt has responded to me by email and I am very happy with the response. As I am in Oz he has offered to refund the money without the need to ship the parts back. I am grateful for his offer, but I do not wish the money to be refunded or parts swapped out, as I have found a way to make them work.

I am thankful Matt manufactures the parts he does, and sells and distributed them at the prices he does. I am sure it is extremely difficult to produce these parts, maintain all the controls, sell the parts and run a viable business.

I have resolved the technical issue with a method similar to sosam117 in is post above.

Cheers,

Gary

bakergw- Account Deactivated by Owner

- Posts : 76

Join date : 2020-09-20

Re: Tee Dee Crankcase Assemblies

Re: Tee Dee Crankcase Assemblies

If the miss-match has been caused by changes in the crank web thickness as sosam117 has suggested, then I would think that the crank pin would now be shifted forward in relation to the case. If this is the case then a solution would be to use a shim between the crank web and case, moving the whole crankshaft back slightly. This would eliminate the excessive clearance at the case nose and also potentially align the rod with the crank pin better. I would suggest a stainless steel shim would be required to take the full thrust load.

Oldenginerod- Top Poster

- Posts : 4018

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: Tee Dee Crankcase Assemblies

Re: Tee Dee Crankcase Assemblies

Oldenginerod wrote:If the miss-match has been caused by changes in the crank web thickness as sosam117 has suggested, then I would think that the crank pin would now be shifted forward in relation to the case. If this is the case then a solution would be to use a shim between the crank web and case, moving the whole crankshaft back slightly. This would eliminate the excessive clearance at the case nose and also potentially align the rod with the crank pin better. I would suggest a stainless steel shim would be required to take the full thrust load.

In the old days we used copper shims as the spacers because it was more sacrificial that a "steel" shim.

It would be better to use a copper shim between the crank and the aluminum housing (inside).

Also, with the copper behind the prop washer it took more of the wear when someone used a starter on the prop and pushed the crank backwards (prop driver into the front crankcase). Also the reason Cox has phenolic washers for behind the prop washer (as an option).

sosam117- Diamond Member

- Posts : 1350

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: Tee Dee Crankcase Assemblies

Re: Tee Dee Crankcase Assemblies

sosam117 wrote:Oldenginerod wrote:If the miss-match has been caused by changes in the crank web thickness as sosam117 has suggested, then I would think that the crank pin would now be shifted forward in relation to the case. If this is the case then a solution would be to use a shim between the crank web and case, moving the whole crankshaft back slightly. This would eliminate the excessive clearance at the case nose and also potentially align the rod with the crank pin better. I would suggest a stainless steel shim would be required to take the full thrust load.

In the old days we used copper shims as the spacers because it was more sacrificial that a "steel" shim.

It would be better to use a copper shim between the crank and the aluminum housing (inside).

Also, with the copper behind the prop washer it took more of the wear when someone used a starter on the prop and pushed the crank backwards (prop driver into the front crankcase). Also the reason Cox has phenolic washers for behind the prop washer (as an option).

I suggested steel because the spacing washer in the crankcase would be under constant thrust load, unlike the thrust washer behind the prop driver which only comes under occasional load when starting. I would personally think the copper would be too soft for this purpose.

My comment was also partly to do with crankshaft position in relation to the rod. "If" the crank sits too far into the case due to a miss-match of early & later parts, the big-end of the rod would not sit fully home on the crank pin, and the pin itself would sit further from the backplate than designed, leaving a gap which would allow the rod to float.

Oldenginerod- Top Poster

- Posts : 4018

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Similar topics

Similar topics» Cox .020 Pee Wee backplate Assemblies

» Backplate assemblies for Cox .020 Pee Wee

» Is Tee Dee 0.049 crankcase is the same with Tee Dee 0.051?

» Any idea who made these needle valve assemblies?

» Dismantle the Cox conrod from the piston. Help

» Backplate assemblies for Cox .020 Pee Wee

» Is Tee Dee 0.049 crankcase is the same with Tee Dee 0.051?

» Any idea who made these needle valve assemblies?

» Dismantle the Cox conrod from the piston. Help

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules