Log in

Search

Latest topics

» My latest doodle...by batjac Today at 10:05 pm

» Retail price mark-up.. how much is enough?

by gkamysz Today at 9:29 pm

» Happy 77th birthday Andrew!

by roddie Today at 9:22 pm

» Roger Harris revisited

by rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

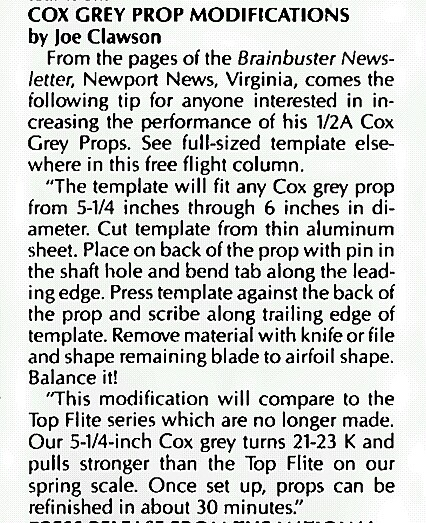

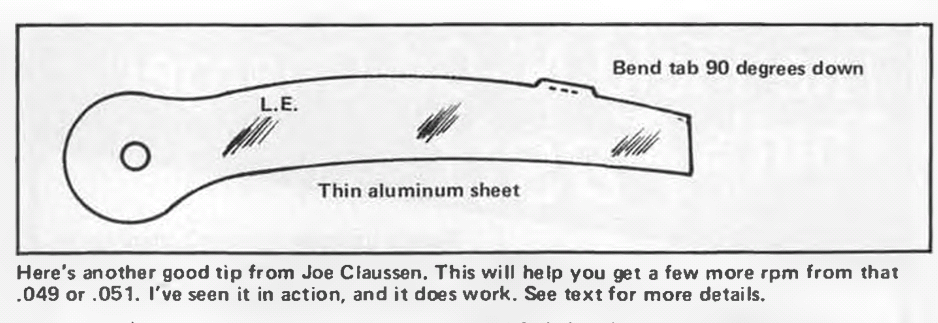

Cox Propeller Modification Tip

Page 1 of 1

Levent Suberk- Diamond Member

- Posts : 2265

Join date : 2017-12-24

Location : Türkiye

Re: Cox Propeller Modification Tip

Re: Cox Propeller Modification Tip

That's great Levent! Thanks for posting it. You wouldn't happen to have the length of the template from hole to tip would you? I'm guessing about 2 1/8"?

Dave P.- Gold Member

- Posts : 477

Join date : 2017-07-31

Age : 67

Location : Durham, NC

Re: Cox Propeller Modification Tip

Re: Cox Propeller Modification Tip

Yes, I also estimated this as about a little more than 2 ins.

Levent Suberk- Diamond Member

- Posts : 2265

Join date : 2017-12-24

Location : Türkiye

Re: Cox Propeller Modification Tip

Re: Cox Propeller Modification Tip

How 'bout 2 5/8"? That would work out to the recommended 5 1/4". It's this "New Math" that has me all confused.

Dave P.- Gold Member

- Posts : 477

Join date : 2017-07-31

Age : 67

Location : Durham, NC

Re: Cox Propeller Modification Tip

Re: Cox Propeller Modification Tip

It says 5 1/4 through 6 " prop So depends on the size ur cutting down .

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Cox Propeller Modification Tip

Re: Cox Propeller Modification Tip

Yes, size changes with propeller diameter. A photocopier can do this. I just measured template by placing a 5" propeller on template, and template is full length of half blade.

Levent Suberk- Diamond Member

- Posts : 2265

Join date : 2017-12-24

Location : Türkiye

Re: Cox Propeller Modification Tip

Re: Cox Propeller Modification Tip

This should and will be interesting. I also wonder about the use of this on other stiff propellers such as the MAS?

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Cox Propeller Modification Tip

Re: Cox Propeller Modification Tip

Geez.. I don't know about taking a knife to one of my Cox grey props..  I have 6 x 3's and 6 x 4's that I sourced before I understood that they were better suited to the higher-performance Cox engines; of which I had none at that time. I now have a few Tee Dees to experiment with..

I have 6 x 3's and 6 x 4's that I sourced before I understood that they were better suited to the higher-performance Cox engines; of which I had none at that time. I now have a few Tee Dees to experiment with..

Re: Cox Propeller Modification Tip

Re: Cox Propeller Modification Tip

I agree Mr. Roddie. I would tread lightly. This modification may cause a out of round crankcase and or crankshaft!!! Due to prop pitch variance. Could Be Bad Vibes Bro. Mark

Mark Diedrichs- Gold Member

- Posts : 434

Join date : 2017-11-11

Age : 72

Location : fairfield ohio

Re: Cox Propeller Modification Tip

Re: Cox Propeller Modification Tip

Mark Diedrichs wrote:I agree Mr. Roddie. I would tread lightly. This modification may cause a out of round crankcase and or crankshaft!!! Due to prop pitch variance. Could Be Bad Vibes Bro. Mark

Agreed.. I'm not experienced with modifying propellers.. and am not about to start learning now. I have an aero-prop balancer that I built.. and feel that it works quite well. It uses a "Kavan" shaft and hubs.. magnetically-suspended between Neo-magnets.

Re: Cox Propeller Modification Tip

Re: Cox Propeller Modification Tip

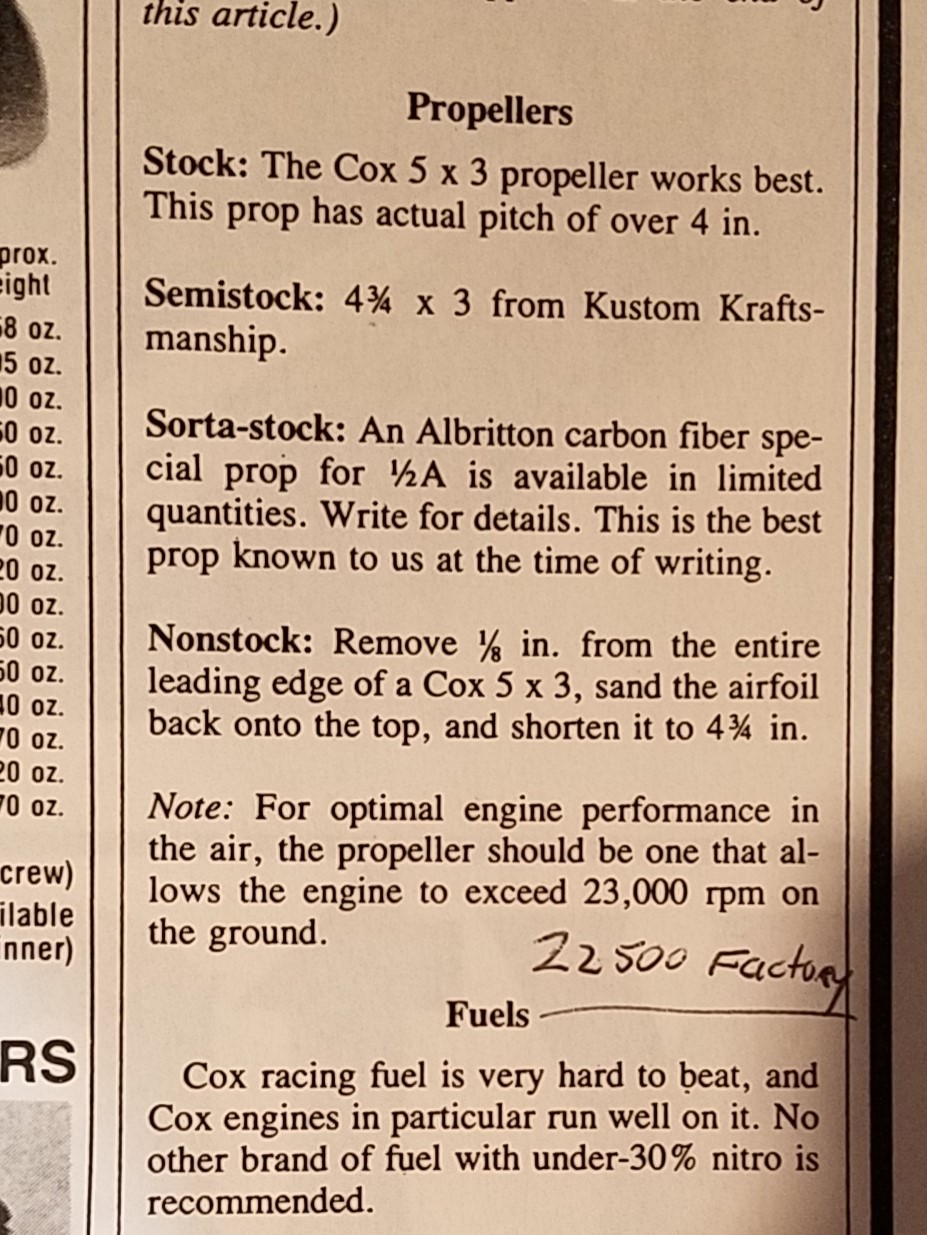

For 1/2a pylon (Tee Dee) we use to cut down Master Airscrews (6x4) to 4.75" anything less just wouldn't pull, Unless they were pretty loose, Tee Dees had a pretty short life at those RPM's.

Re: Cox Propeller Modification Tip

Re: Cox Propeller Modification Tip

When I flew 1/2A Proto (redundant/cancelled class now) and speed in the 1970s, we used the Cox grey 5 1/2" or 5 1/4? -4 and cut it down to a bit less than 4 1/2", reshaped it and thinned it out. I would have been so happy then to have some of the APC props that you can get now. They were a lot of time down the tube when you nicked the ground on takeoff. Nice idea for the template with the locating notch though.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: Cox Propeller Modification Tip

Re: Cox Propeller Modification Tip

I suppose we can agree to disagree. I personally have modified several props. I don't alter the leading edges as suggested in Mark's instructions. In addition, if I'm seeing the template correctly, this leaves the tips squared off. Having square tips is about the most inefficient way to gain thrust. We use it as a tool to slow the engine down. Our speed limit rules in combat is not to exceed 75 MPH, this equates to around 7.2 -7.3 seconds for two laps. For every 1/8" we cut back leaving the tips square, we gain a little in time. I don't recall the actual speed we lose or time gained just due to knowing the exact size prop I need.

Thinning the blades and lessening the weight of the prop blades gains rpm's. There's a point however where this will just beat air and the engine goes into high rpm's with little speed. The props of choice back when these articles were written were made by Kelly props. More common to the speed crowd of the day and probably not recognized by the average modeler. The Grish black Magnum Tornado props in my opinion worked better than any props on the market that were sold in hobby shops.

A larger problem with props is that the prop hole isn't square to the mating side and or either sides of the prop are parallel to each other. Therefore you can have two identical props where one works and the other doesn't work as well. The same goes for pitch. All props regardless if they're the same, one might have slightly more of less pitch to one of the blades. This is a must to check which very few do.

This doesn't mean they have to be identically the same either. The only way to test is by time. It's quite possible that a prop with a heavier pitched blade on one side can work effectively. This is what makes a single propeller effective is that it grabs clean air as it's coming around whereas a two bladed propeller can have it's opposing blade grabbing turbulent air.

As Alan mentioned, we currently have a small variety of APC propellers nowadays to choose from which work exceptionally well for under $3. Others have also experimented with the quad props in carbon and glass varieties.

Thinning the blades and lessening the weight of the prop blades gains rpm's. There's a point however where this will just beat air and the engine goes into high rpm's with little speed. The props of choice back when these articles were written were made by Kelly props. More common to the speed crowd of the day and probably not recognized by the average modeler. The Grish black Magnum Tornado props in my opinion worked better than any props on the market that were sold in hobby shops.

A larger problem with props is that the prop hole isn't square to the mating side and or either sides of the prop are parallel to each other. Therefore you can have two identical props where one works and the other doesn't work as well. The same goes for pitch. All props regardless if they're the same, one might have slightly more of less pitch to one of the blades. This is a must to check which very few do.

This doesn't mean they have to be identically the same either. The only way to test is by time. It's quite possible that a prop with a heavier pitched blade on one side can work effectively. This is what makes a single propeller effective is that it grabs clean air as it's coming around whereas a two bladed propeller can have it's opposing blade grabbing turbulent air.

As Alan mentioned, we currently have a small variety of APC propellers nowadays to choose from which work exceptionally well for under $3. Others have also experimented with the quad props in carbon and glass varieties.

Ken Cook- Top Poster

- Posts : 5637

Join date : 2012-03-27

Location : pennsylvania

Re: Cox Propeller Modification Tip

Re: Cox Propeller Modification Tip

I agree with Ken there is no need to mod the leading edge the factory is more consistent there.

These days I prefer APC E props it is very simple to scissor cut the trailing edge the airfoil tapper

is so thin with E props there is nothing more to do other than check balance. A good eye balling

can normally tell you which blade may need a bit of sanding to match the width of the other.

Calipers confirm your work. I try and keep the dia. for thrust a narrow blade picks up rpm

while thrust picks up due to higher static rpm. Back cut at a angle for a more narrow tip

as shown produces lower weight prop narrow tips for higher rpm cooler running engine.

E props the most easy to redo the more you snip the better you get at it.

In other words less sanding to match blades as your eye ball skills improve.

You can cut one blade then use some tape with color stick it on the cut blade

and trim off the excess then use it as a template for the other blade. Goo way

to go when your first learning to modify.

IC prop requires a extra step you must redo the airfoil's trialing edge I use fine files and a sanding bar.

Followed by fine grit sanding paper to polish the prop to factory sheen. I rarely fly stock props anymore.

The effort happens fast once you have done a few.

With stock internals you will get performance that no other can obtain without prop mods.

After a turbo plug that is.

These days I prefer APC E props it is very simple to scissor cut the trailing edge the airfoil tapper

is so thin with E props there is nothing more to do other than check balance. A good eye balling

can normally tell you which blade may need a bit of sanding to match the width of the other.

Calipers confirm your work. I try and keep the dia. for thrust a narrow blade picks up rpm

while thrust picks up due to higher static rpm. Back cut at a angle for a more narrow tip

as shown produces lower weight prop narrow tips for higher rpm cooler running engine.

E props the most easy to redo the more you snip the better you get at it.

In other words less sanding to match blades as your eye ball skills improve.

You can cut one blade then use some tape with color stick it on the cut blade

and trim off the excess then use it as a template for the other blade. Goo way

to go when your first learning to modify.

IC prop requires a extra step you must redo the airfoil's trialing edge I use fine files and a sanding bar.

Followed by fine grit sanding paper to polish the prop to factory sheen. I rarely fly stock props anymore.

The effort happens fast once you have done a few.

With stock internals you will get performance that no other can obtain without prop mods.

After a turbo plug that is.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules