Log in

Search

Latest topics

» My latest doodle...by batjac Today at 10:05 pm

» Retail price mark-up.. how much is enough?

by gkamysz Today at 9:29 pm

» Happy 77th birthday Andrew!

by roddie Today at 9:22 pm

» Roger Harris revisited

by rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

FINALLY!!!!! An Engine Day out in the Shop! Black Lynx Break-In and Pee Wee Backplate Run !!!

Page 1 of 1

FINALLY!!!!! An Engine Day out in the Shop! Black Lynx Break-In and Pee Wee Backplate Run !!!

FINALLY!!!!! An Engine Day out in the Shop! Black Lynx Break-In and Pee Wee Backplate Run !!!

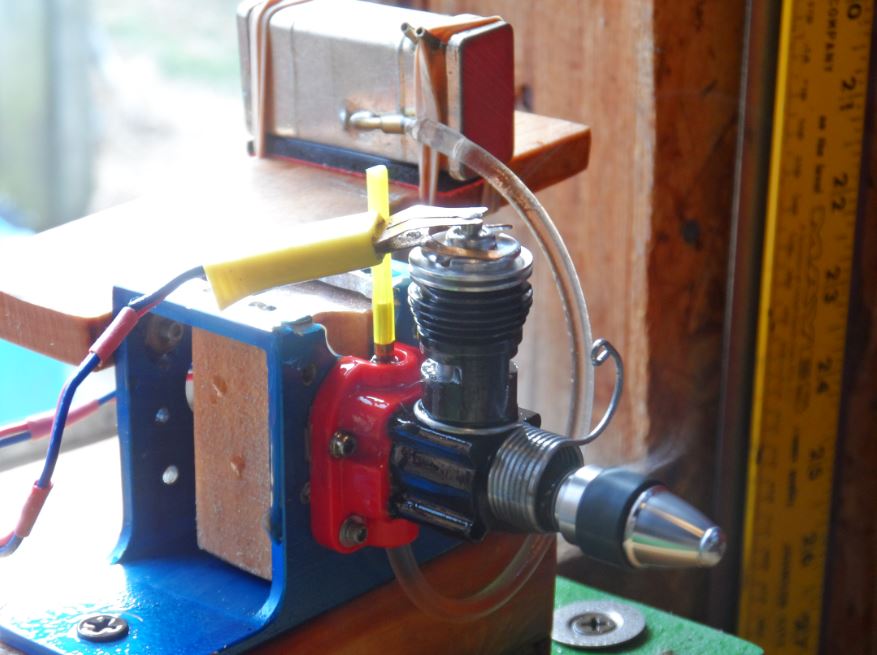

After several false recoveries, it appears that I AM actually doing better...health-wise...so-much-so that I cranked up the heat out in the shop for a break-in of Matt's "Black Lynx" .049 (THANK YOU ALL VERY MUCH AGAIN!!!)), along with my first test run of Bernie's .020 Pee Wee Backplate Assembly.

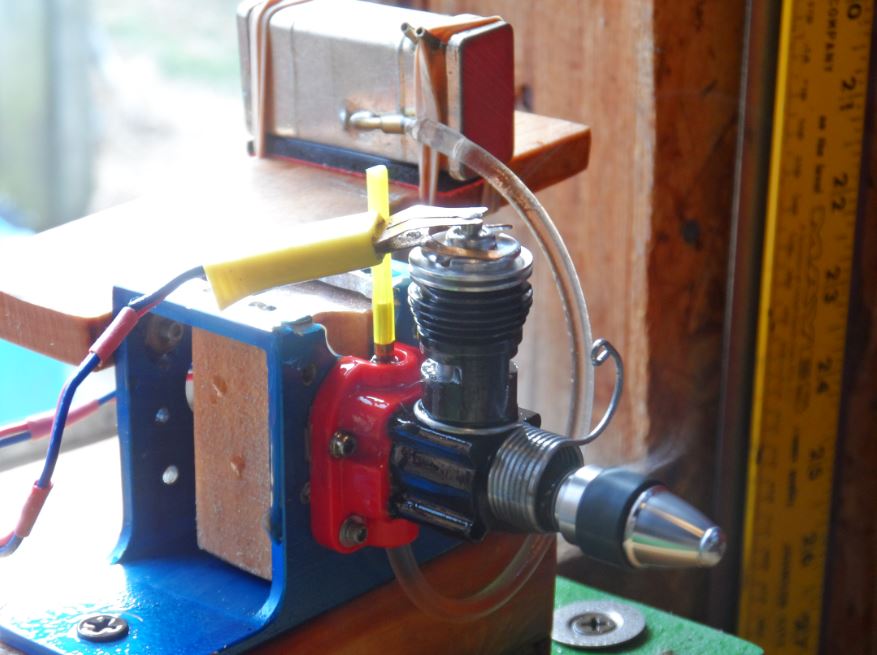

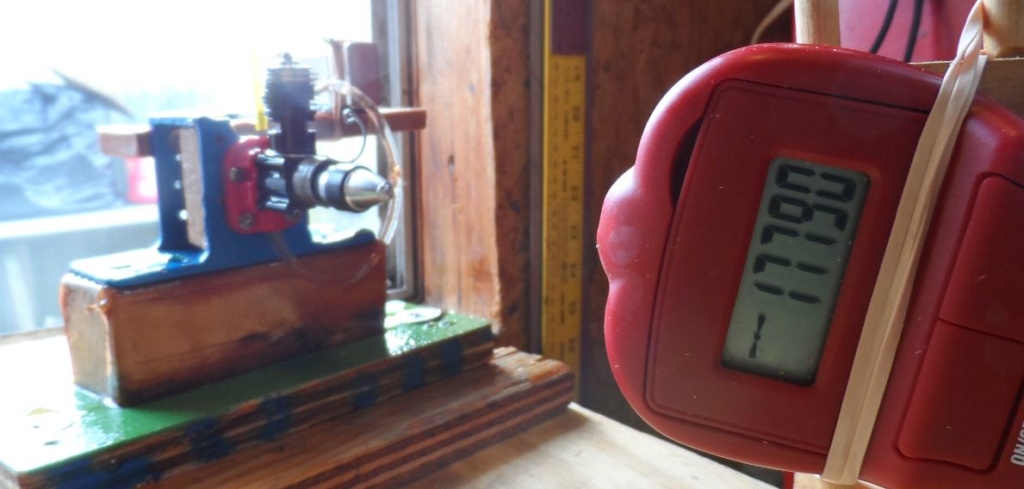

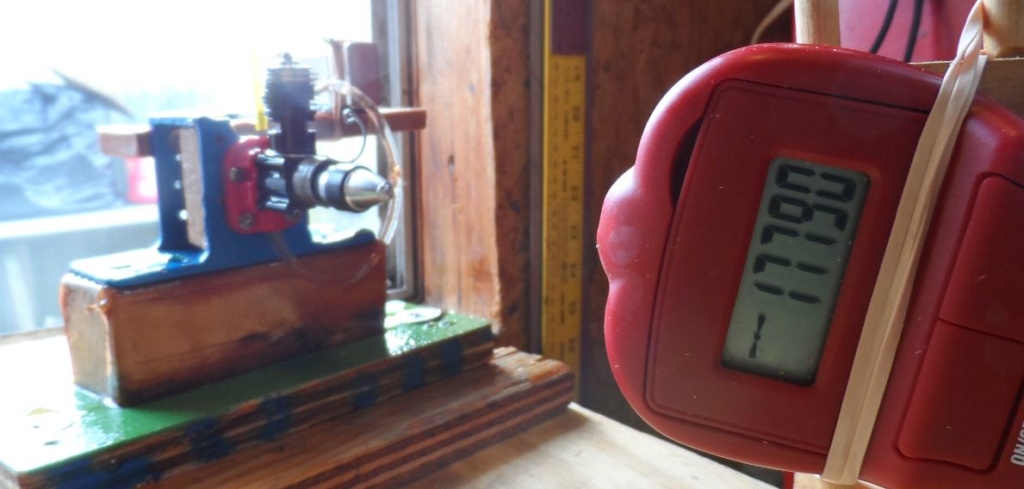

The Black Lynx was started up on Sig Champion 25% fuel, turning a 5-3 gray. I ran it for over 1/2 hour nonstop with refuels on the run. leaning it out to peak and back as the time passed. Toward the last 5 minutes, it was peaking in the mid 17k's, with good needle valve response.

While it may get some photo ops with the 2m B.O.T. before too long, it'll probably end up in my Cox Viper for this year's S.M.A.L.L. Fly-Ins. Thanks again for this great engine!

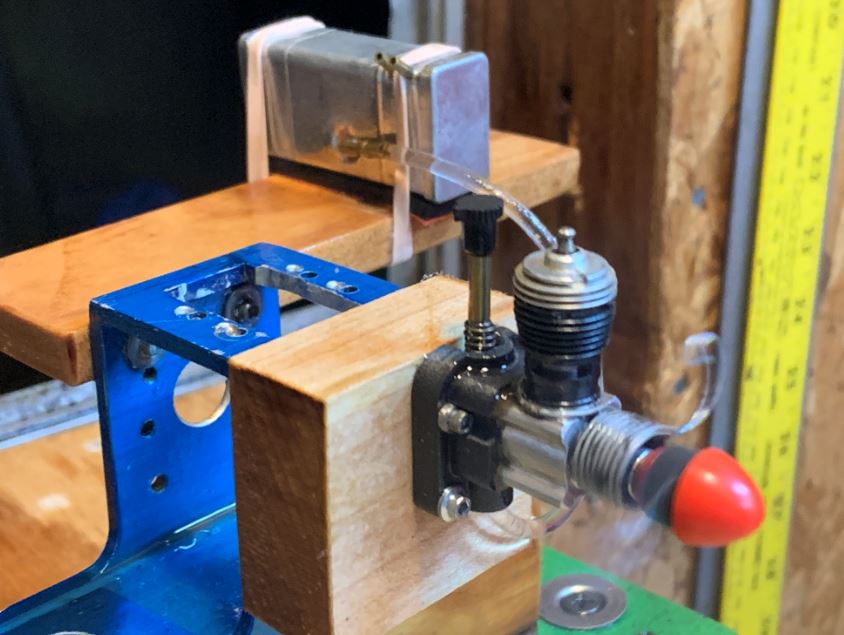

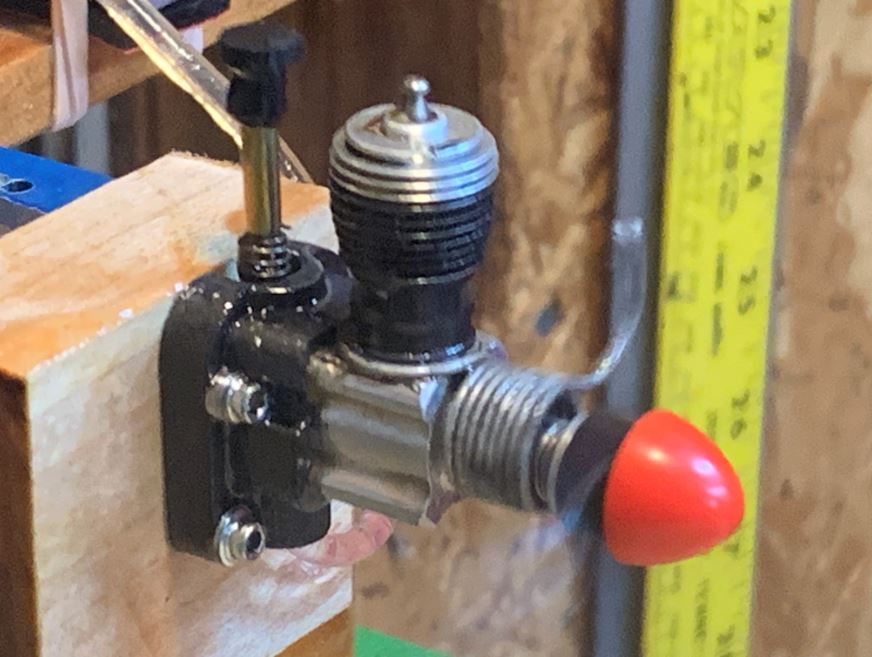

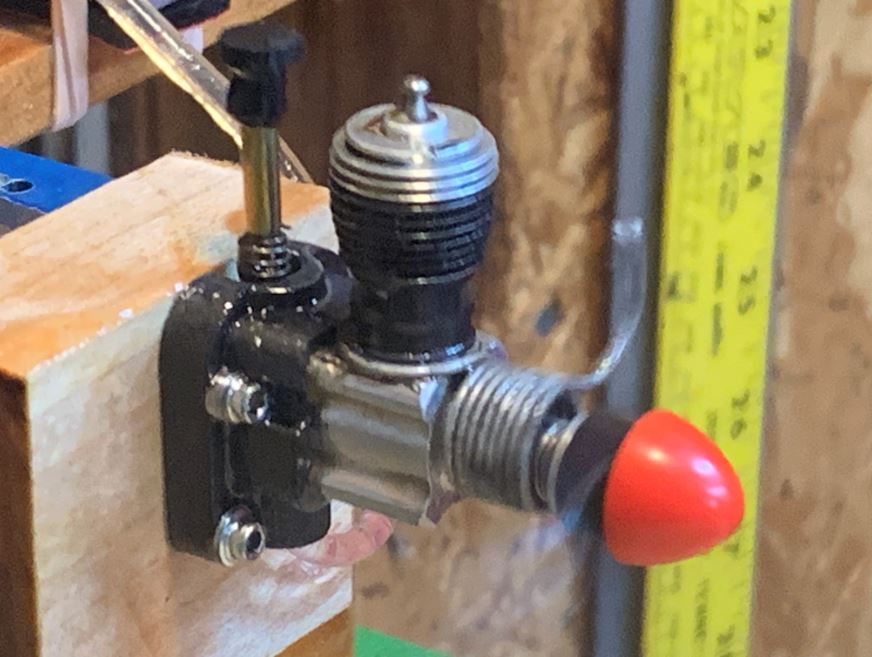

THEN....I assembled an .020 with the new backplate I got from Bernie. I chose one of my healthier .020's, hoping for as little hassle as possible, and am proud to say it all went well.

The upper mounting holes are REAL snug for my #2 socket head servo screws, and I wanted a washer of some sort to keep them from digging into the plastic. So, I used a drill motor and Dremel to first, turn down the flange under the socket, and also rounded the flats of a couple #2 machine nuts.

Drilled out, the machine nuts became thick washers, and fit into the backplate's top two grooves pretty nicely. I know this all seems like a lot of fuss, and I'm totally prepared for someone to show me an embarrassingly easier way to do this. The little sucker looks good to me now though!

It started up after little coaxing, fired up and ran steadily...also for a 1/2 hour +. I'd lost my light, and was too lazy to set up an led lamp for the tach, but sounding in it's zone.

Now, on to assemble another .020 and it's backplate for installation on my slowly moving Carl Goldberg Skylark project.

The Black Lynx was started up on Sig Champion 25% fuel, turning a 5-3 gray. I ran it for over 1/2 hour nonstop with refuels on the run. leaning it out to peak and back as the time passed. Toward the last 5 minutes, it was peaking in the mid 17k's, with good needle valve response.

While it may get some photo ops with the 2m B.O.T. before too long, it'll probably end up in my Cox Viper for this year's S.M.A.L.L. Fly-Ins. Thanks again for this great engine!

THEN....I assembled an .020 with the new backplate I got from Bernie. I chose one of my healthier .020's, hoping for as little hassle as possible, and am proud to say it all went well.

The upper mounting holes are REAL snug for my #2 socket head servo screws, and I wanted a washer of some sort to keep them from digging into the plastic. So, I used a drill motor and Dremel to first, turn down the flange under the socket, and also rounded the flats of a couple #2 machine nuts.

Drilled out, the machine nuts became thick washers, and fit into the backplate's top two grooves pretty nicely. I know this all seems like a lot of fuss, and I'm totally prepared for someone to show me an embarrassingly easier way to do this. The little sucker looks good to me now though!

It started up after little coaxing, fired up and ran steadily...also for a 1/2 hour +. I'd lost my light, and was too lazy to set up an led lamp for the tach, but sounding in it's zone.

Now, on to assemble another .020 and it's backplate for installation on my slowly moving Carl Goldberg Skylark project.

Last edited by Kim on Mon Jan 20, 2020 8:43 pm; edited 1 time in total

Kim- Top Poster

Posts : 8625

Join date : 2011-09-06

Location : South East Missouri

Re: FINALLY!!!!! An Engine Day out in the Shop! Black Lynx Break-In and Pee Wee Backplate Run !!!

Re: FINALLY!!!!! An Engine Day out in the Shop! Black Lynx Break-In and Pee Wee Backplate Run !!!

I'm really happy to see the Black Lynx running! It's good to hear that the PeeWee likes the backplate too. I don't have any advice on the upper washers, what you did looks great. I'm filing that one away for future use.

It's really good to hear that you're doing better too. That's the best news.

Thanks for posting!

It's really good to hear that you're doing better too. That's the best news.

Thanks for posting!

Dave P.- Gold Member

- Posts : 477

Join date : 2017-07-31

Age : 67

Location : Durham, NC

Re: FINALLY!!!!! An Engine Day out in the Shop! Black Lynx Break-In and Pee Wee Backplate Run !!!

Re: FINALLY!!!!! An Engine Day out in the Shop! Black Lynx Break-In and Pee Wee Backplate Run !!!

Thanks Dave, it was a really good day!

Kim- Top Poster

Posts : 8625

Join date : 2011-09-06

Location : South East Missouri

Re: FINALLY!!!!! An Engine Day out in the Shop! Black Lynx Break-In and Pee Wee Backplate Run !!!

Re: FINALLY!!!!! An Engine Day out in the Shop! Black Lynx Break-In and Pee Wee Backplate Run !!!

Good to see another Pee Wee backplate running.

For screws I used some #2 Phillips head wood screws to mount to the backplate in all my testing. I included these same screws with the CEF version backplates. I never used washers. The backplates are printed with 100% infill and are pretty solid. The screws will make a circular depression but hasn’t caused any issues.

Spring starter helps get these guys running. I have used the same intake opening as a helicopter backplate. The heli version .020 always was fitted with a spring starter. The larger intake really opens up these little engine.

For screws I used some #2 Phillips head wood screws to mount to the backplate in all my testing. I included these same screws with the CEF version backplates. I never used washers. The backplates are printed with 100% infill and are pretty solid. The screws will make a circular depression but hasn’t caused any issues.

Spring starter helps get these guys running. I have used the same intake opening as a helicopter backplate. The heli version .020 always was fitted with a spring starter. The larger intake really opens up these little engine.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: FINALLY!!!!! An Engine Day out in the Shop! Black Lynx Break-In and Pee Wee Backplate Run !!!

Re: FINALLY!!!!! An Engine Day out in the Shop! Black Lynx Break-In and Pee Wee Backplate Run !!!

Kim wrote:Thanks Dave, it was a really good day!

We take those when we can, don't we?

Dave P.- Gold Member

- Posts : 477

Join date : 2017-07-31

Age : 67

Location : Durham, NC

Re: FINALLY!!!!! An Engine Day out in the Shop! Black Lynx Break-In and Pee Wee Backplate Run !!!

Re: FINALLY!!!!! An Engine Day out in the Shop! Black Lynx Break-In and Pee Wee Backplate Run !!!

Dave P. wrote:Kim wrote:Thanks Dave, it was a really good day!

We take those when we can, don't we?

Yes Sir....Absolutely !!!!!

Kim- Top Poster

Posts : 8625

Join date : 2011-09-06

Location : South East Missouri

Kim- Top Poster

Posts : 8625

Join date : 2011-09-06

Location : South East Missouri

Re: FINALLY!!!!! An Engine Day out in the Shop! Black Lynx Break-In and Pee Wee Backplate Run !!!

Re: FINALLY!!!!! An Engine Day out in the Shop! Black Lynx Break-In and Pee Wee Backplate Run !!!

Jason_WI wrote:Good to see another Pee Wee backplate running.

For screws I used some #2 Phillips head wood screws to mount to the backplate in all my testing. I included these same screws with the CEF version backplates. I never used washers. The backplates are printed with 100% infill and are pretty solid. The screws will make a circular depression but hasn’t caused any issues.

Spring starter helps get these guys running. I have used the same intake opening as a helicopter backplate. The heli version .020 always was fitted with a spring starter. The larger intake really opens up these little engine.

Well, it makes sense. I'll probably get some more of these, and use the types you did. Thanks again for your work (mechanical AND mental!!) in getting these figured out. Pee Wee's apparently love them!

Kim- Top Poster

Posts : 8625

Join date : 2011-09-06

Location : South East Missouri

Re: FINALLY!!!!! An Engine Day out in the Shop! Black Lynx Break-In and Pee Wee Backplate Run !!!

Re: FINALLY!!!!! An Engine Day out in the Shop! Black Lynx Break-In and Pee Wee Backplate Run !!!

First off Good to hear ur feeling better than before , good to hear you had a positive experience with the PeeWEEs ! I had been thinking about running something myself as soon as the weather breaks from cold to cool , haven't smelt castor in awhile now need a fix !!

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: FINALLY!!!!! An Engine Day out in the Shop! Black Lynx Break-In and Pee Wee Backplate Run !!!

Re: FINALLY!!!!! An Engine Day out in the Shop! Black Lynx Break-In and Pee Wee Backplate Run !!!

getback wrote:First off Good to hear ur feeling better than before , good to hear you had a positive experience with the PeeWEEs ! I had been thinking about running something myself as soon as the weather breaks from cold to cool , haven't smelt castor in awhile now need a fix !!

Yes you do !!!!!!!!!!!

Kim- Top Poster

Posts : 8625

Join date : 2011-09-06

Location : South East Missouri

Similar topics

Similar topics» **Black Lynx Engine Giveaway June 2019** Cox Engine of the Month

» **Black Lynx Engine Giveaway Jan-June 2022** Cox Engine of the Month

» **Black Lynx Engine Giveaway Jan-June 2023** Cox Engine of the Month

» **Black Lynx Engine Giveaway June 2016** Cox Engine of the Month

» **Black Lynx Engine Giveaway June 2018** Cox Engine of the Month

» **Black Lynx Engine Giveaway Jan-June 2022** Cox Engine of the Month

» **Black Lynx Engine Giveaway Jan-June 2023** Cox Engine of the Month

» **Black Lynx Engine Giveaway June 2016** Cox Engine of the Month

» **Black Lynx Engine Giveaway June 2018** Cox Engine of the Month

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules