Log in

Search

Latest topics

» My latest doodle...by batjac Today at 10:05 pm

» Retail price mark-up.. how much is enough?

by gkamysz Today at 9:29 pm

» Happy 77th birthday Andrew!

by roddie Today at 9:22 pm

» Roger Harris revisited

by rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

Cox aluminum piston?

Page 2 of 2

Page 2 of 2 •  1, 2

1, 2

Re: Cox aluminum piston?

Re: Cox aluminum piston?

I think the trick here is what can be done today by most folks without having to

rob rare parts or do any difficult mods. The piston is purpose built back in the day

for more rpm but failed to hold up to that stress. So today one should look at this

as a weight savings project to use on a smaller plane such as a .020 project that

needs the extra boost of power without having to make the engine scream.

In that case one could still have quite a beast of a power plant for 7g more than

a .020. Same thing can go in hand with a CL project that has a issue with a

CG too far forward instead of adding weight in the tail this would be an option.

Then again a purpose built plane for a extremely low weight .049 could bring

forth a interesting and fun plane or car or boat project.

rob rare parts or do any difficult mods. The piston is purpose built back in the day

for more rpm but failed to hold up to that stress. So today one should look at this

as a weight savings project to use on a smaller plane such as a .020 project that

needs the extra boost of power without having to make the engine scream.

In that case one could still have quite a beast of a power plant for 7g more than

a .020. Same thing can go in hand with a CL project that has a issue with a

CG too far forward instead of adding weight in the tail this would be an option.

Then again a purpose built plane for a extremely low weight .049 could bring

forth a interesting and fun plane or car or boat project.

Last edited by 1/2A Nut on Thu Feb 21, 2019 11:35 pm; edited 1 time in total

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox aluminum piston?

Re: Cox aluminum piston?

Could save another gram with a narrow neck crankcase. Also the early baby bee crankshaft had a thinner web.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: Cox aluminum piston?

Re: Cox aluminum piston?

Yes good idea every effort adds up that's the trick.

On page 1 I updated some pics can save .2g going with a Killer Bee crank.

On page 1 I updated some pics can save .2g going with a Killer Bee crank.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox aluminum piston?

Re: Cox aluminum piston?

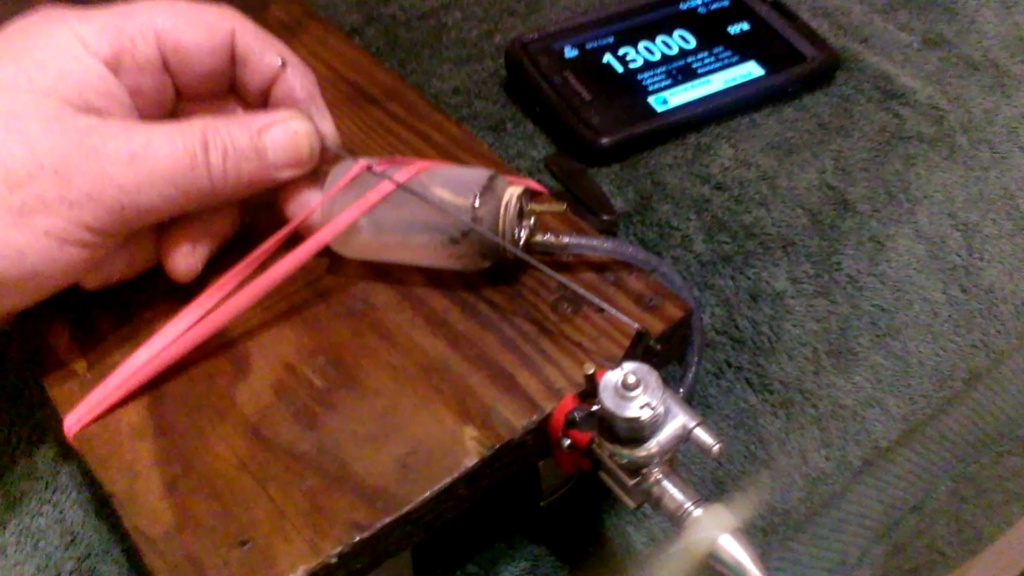

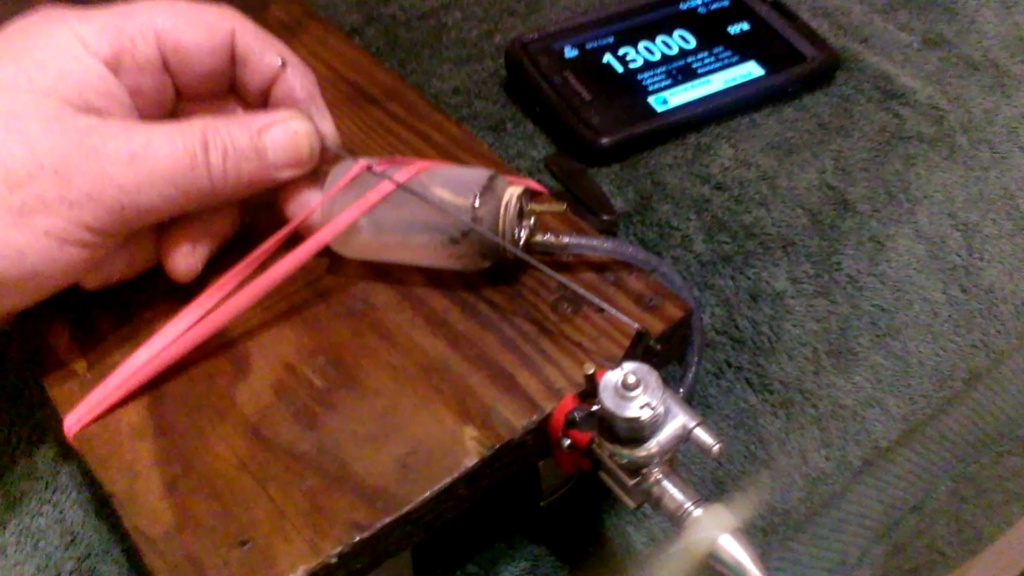

Horse shoe backplate will allow me to bench test the engine as shown.

Least amount of mass to spin with a 4 x 4.5 prop which would be a

considerable boost in speed and power if swapping out a Pee Wee

engine on a existing project plane. To be fare one will have to include

the weight of a fuel tank in my case I would use a 15cc / 4.1g custom

made tank.

For me I would also want a aluminum throttle sleeve for

RC use figure another 2.5g / .515" dia cylinder will need a lapped in

.52 ID sleeve / tight fit to compensate for expansion when hot.

.15% nitro 20% castor would be plenty.

Least amount of mass to spin with a 4 x 4.5 prop which would be a

considerable boost in speed and power if swapping out a Pee Wee

engine on a existing project plane. To be fare one will have to include

the weight of a fuel tank in my case I would use a 15cc / 4.1g custom

made tank.

For me I would also want a aluminum throttle sleeve for

RC use figure another 2.5g / .515" dia cylinder will need a lapped in

.52 ID sleeve / tight fit to compensate for expansion when hot.

.15% nitro 20% castor would be plenty.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox aluminum piston?

Re: Cox aluminum piston?

Brad how does the compression feel with the aluminum piston? Is the theory correct that to consider the higher thermal expansion of aluminum than steel the piston fit when cold was set loose?

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Cox aluminum piston?

Re: Cox aluminum piston?

The cylinder / piston fit is popping over in the "good" category.

It has been oiled with after run oil that aids in compression.

I will have to do a rich break in. I need to put a muffler on it next

keep the noise down during the bench test.

Yes like all model engines with aluminum pistons when running

the compression should improve. I am using a stock low compression

glow plug in anticipation of that happening. I think folks found the

compression was lost after a few runs but in retrospect the compression

was just fine once running with a expanded piston.

It has been oiled with after run oil that aids in compression.

I will have to do a rich break in. I need to put a muffler on it next

keep the noise down during the bench test.

Yes like all model engines with aluminum pistons when running

the compression should improve. I am using a stock low compression

glow plug in anticipation of that happening. I think folks found the

compression was lost after a few runs but in retrospect the compression

was just fine once running with a expanded piston.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox aluminum piston?

Re: Cox aluminum piston?

Brad do you think the engine would benefit with using extra castor ?

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Cox aluminum piston?

Re: Cox aluminum piston?

18 - 22% should be enough depending on the desired rpm and time of year.

Summer time in TX if high rpm is desired would go 20% nitro / 22% castor oil.

18% castor and 6% synthetic has some benefits keeping the engine cleaner

as the thinner oil will seep everywhere washing out the engine reducing

baked on castor build up.

Summer time in TX if high rpm is desired would go 20% nitro / 22% castor oil.

18% castor and 6% synthetic has some benefits keeping the engine cleaner

as the thinner oil will seep everywhere washing out the engine reducing

baked on castor build up.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox aluminum piston?

Re: Cox aluminum piston?

Results:

First rich run, aluminum was dusting off and hardening it's surface to the new piston.

Second tank the aluminum particle mixed goo was reduced quite a bit as it becomes more seated.

At about half way through the tank I started to lean the mix got too greedy with the rpm allowing the piston

to expand too much too soon and caused the engine to stop. Throttle is set low enough to keep the noise down.

Needle was at 3.4 turns which started to "race" the piston. 47g with slide type exhaust throttle.

Uploaded on Feb 24, 2019

Grish 5x4

Cox Aluminum Piston Bench Test Break In .049

1oz rich run prior to this one aluminum surface was

dusting off small particles as it seated into it's thermal

state. If leaned up too much it expands to the next level

of heated state subject to binding enough to shut down.

Will require patience with some rich runs till fully broken in.

Compression seems good still bit less than when new. I imagine

another 2oz of rich running to baby the piston into it's best tuned

thermal state. You want to compress the outer skin of the piston's

molecules into a hardened condition, if rushed you scrub off too much

material too fast. The reward is a piston that will last. Plus you don't

want to stress the ball socket during break in, it is aluminum after all.

First rich run, aluminum was dusting off and hardening it's surface to the new piston.

Second tank the aluminum particle mixed goo was reduced quite a bit as it becomes more seated.

At about half way through the tank I started to lean the mix got too greedy with the rpm allowing the piston

to expand too much too soon and caused the engine to stop. Throttle is set low enough to keep the noise down.

Needle was at 3.4 turns which started to "race" the piston. 47g with slide type exhaust throttle.

Uploaded on Feb 24, 2019

Grish 5x4

Cox Aluminum Piston Bench Test Break In .049

1oz rich run prior to this one aluminum surface was

dusting off small particles as it seated into it's thermal

state. If leaned up too much it expands to the next level

of heated state subject to binding enough to shut down.

Will require patience with some rich runs till fully broken in.

Compression seems good still bit less than when new. I imagine

another 2oz of rich running to baby the piston into it's best tuned

thermal state. You want to compress the outer skin of the piston's

molecules into a hardened condition, if rushed you scrub off too much

material too fast. The reward is a piston that will last. Plus you don't

want to stress the ball socket during break in, it is aluminum after all.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox aluminum piston?

Re: Cox aluminum piston?

Thanks Brad , information taken in , i have 3 pistons and 1 rod coming , i am pretty sure somewhere in all my stuff i have some rods maybe even alum. one ?

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Cox aluminum piston?

Re: Cox aluminum piston?

1/2A Nut wrote:Grish 5x4. Cox Aluminum Piston Bench Test Break In .049 1oz rich run prior to this one aluminum surface was dusting off small particles as it seated into it's thermal state. If leaned up too much it expands to the next level of heated state subject to binding enough to shut down. Will require patience with some rich runs till fully broken in.

Compression seems good still bit less than when new. I imagine another 2oz of rich running to baby the piston into it's best tuned thermal state. You want to compress the outer skin of the piston's molecules into a hardened condition, if rushed you scrub off too much

material too fast. The reward is a piston that will last. Plus you don't want to stress the ball socket during break in, it is aluminum after all.

Thanks for sharing this Brad and for documenting your experiences. Regarding thermal expansion got me a little curious about the theoretical empirical dynamics behind the metallurgy. (I say theoretical because values given are in general and not toward the specific grades of materials involved, and arbitrary assumptions made for the sake of discussion so values can be quantified.)

https://www.engineeringtoolbox.com/linear-expansion-coefficients-d_95.html

Thermal Expansion Coefficients in 10-6 in./(in. Deg-R):

- Steel, 6.11 - 6.94

- Cast Iron, Gray 6

- Aluminum, 11.7 - 13.3

- Brass, 10 - 10.6

Degrees are in Rankine, to convert Fahrenheit, add 459.67.

Cox .049 bore is 0.406 in. Hypothetically, say steady state methanol combustion temperature with 15% - 25% nitro is 500 deg-F (where most synthetic oils vaporize and combust), then we multiply these coefficient values by 1e-6 * [0.406 x (500 + 459.67)] = 0.00039

Arbitrarily rounding values for back of the envelope calculations:

Aluminium (12) = 0.005 in.

Steel (6.2) = 0.002 in.

Cast Iron (6) = 0.002.

We see that at 500 deg F, we have about 3 thousandths of an inch piston expansion toward cylinder walls. Of course, we have not also taken into account that because the piston head is thinner, it doesn't have the heat sink effect of the thicker cylinder, which will not expand as much due to its slightly lower temperature. Piston top will be hotter.

It is not hard to see that one may have to start the engine with lower compression, so that by the time it reaches steady state temperature, the aluminium piston has expanded to the point where it can now maintain a proper compression seal.

Now we can surmise that Leroy Cox went to a steel piston for obvious reasons. The ABC engines work well with aluminium pistons because the brass is a lot closer to aluminium than steel for the sleeve.

GallopingGhostler- Top Poster

Posts : 5723

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Cox aluminum piston?

Re: Cox aluminum piston?

Thank you Eric, it has been fun to play with, something different.

The aluminum rod would surely require some flywheel tweaking

to get it to balance and run smooth.

Yes good info GG the engine temp variance between steel and

good info GG the engine temp variance between steel and

aluminum is requiring me to move with caution giving the piston the

opportunity to scrub off aluminum at a pace that wont over shoot best fit.

A digital meter to read temp would be a good tool to have on

tap during this process. After full break in I will see if my

calipers show much change in dia. range is 0.001 to 6"

The aluminum rod would surely require some flywheel tweaking

to get it to balance and run smooth.

Yes

good info GG the engine temp variance between steel and

good info GG the engine temp variance between steel and aluminum is requiring me to move with caution giving the piston the

opportunity to scrub off aluminum at a pace that wont over shoot best fit.

A digital meter to read temp would be a good tool to have on

tap during this process. After full break in I will see if my

calipers show much change in dia. range is 0.001 to 6"

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Page 2 of 2 •  1, 2

1, 2

Similar topics

Similar topics» Aluminum piston

» Has anyone tried those "Cox .049 Piston (Aluminum)"?

» What causes a piston head to mushroom when you reset the piston rod?

» Wanted: Cox .15 piston, or piston/cylinder - FOUND!

» .010 piston or piston/cyl. assy.

» Has anyone tried those "Cox .049 Piston (Aluminum)"?

» What causes a piston head to mushroom when you reset the piston rod?

» Wanted: Cox .15 piston, or piston/cylinder - FOUND!

» .010 piston or piston/cyl. assy.

Page 2 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules