Log in

Search

Latest topics

» Cox films/videos...by Coxfledgling Today at 4:46 am

» Purchased the last of any bult engines from Ken Enya

by Coxfledgling Today at 4:18 am

» My N-1R build log

by roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

Cox Engine of The Month

Phred's way control systems

Page 1 of 1

Phred's way control systems

Phred's way control systems

Over the years many a modeler has tried to create a RIGID control link from the Bell Crank (or a servo) to a Flap, Elevator, Aileron, or Rudder

Many times, just cuz the instruction said so.. we did some interesting adaptations----like adding a Fair-Lead part way down the fuselage to prevent linkage flex ...or using a balsa stick or dowel to connect the "Z" bend wire(s)

Most folks knew intuitively that a long small diameter music wire link was too flexible

An interesting exercise---- you do not have to go try because you already did it.... Fly your flat hand out a car window

We all did it -----and we flew our hand up and down just like a wing------ some times deliberately stalling the "wing" and remember the back of arm smacking the rear of the window opening from the sudden drag

But!!

I wonder HOW many of us think on this this experience--- and contemplate the forces on a flap or elevator at slow(ish) stunt speeds of 40~58 MPH ---or Faster 75~120MPH combat speeds.

Think about a flying surface that might be 2 or more times the surface area of our "hand out the window".

In flight, there is a LOT of force on the movable surface

Fortunately since the very early model flight experiments there has been a lot of nice rigid (and importantly) light weight control linkage methods

An Engineering and physics fact is that a Round Tube the same weight and length as a similar Rod has much more resistance to bending (flex)

We can also demonstrate using differing materials such as a much lighter item ---say 1/8th aluminum tube vs a solid 1/16th steel music wire OK, bad example cuz they both are pretty flexy.. BUT the Aluminum Tube is actually much more rigid in push pull and measurably lighter

Things to ponder as I set up the next post with some photos and notes

Many times, just cuz the instruction said so.. we did some interesting adaptations----like adding a Fair-Lead part way down the fuselage to prevent linkage flex ...or using a balsa stick or dowel to connect the "Z" bend wire(s)

Most folks knew intuitively that a long small diameter music wire link was too flexible

An interesting exercise---- you do not have to go try because you already did it.... Fly your flat hand out a car window

We all did it -----and we flew our hand up and down just like a wing------ some times deliberately stalling the "wing" and remember the back of arm smacking the rear of the window opening from the sudden drag

But!!

I wonder HOW many of us think on this this experience--- and contemplate the forces on a flap or elevator at slow(ish) stunt speeds of 40~58 MPH ---or Faster 75~120MPH combat speeds.

Think about a flying surface that might be 2 or more times the surface area of our "hand out the window".

In flight, there is a LOT of force on the movable surface

Fortunately since the very early model flight experiments there has been a lot of nice rigid (and importantly) light weight control linkage methods

An Engineering and physics fact is that a Round Tube the same weight and length as a similar Rod has much more resistance to bending (flex)

We can also demonstrate using differing materials such as a much lighter item ---say 1/8th aluminum tube vs a solid 1/16th steel music wire OK, bad example cuz they both are pretty flexy.. BUT the Aluminum Tube is actually much more rigid in push pull and measurably lighter

Things to ponder as I set up the next post with some photos and notes

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: Phred's way control systems

Re: Phred's way control systems

You got it , just gotta design it.  Like on the larger Giant scale R/C planes or some RTF powered gliders they use the pull/pull method of control using separate cables or in the case of RTF gliders fishing line. The controls usually go from a Tee type servo horn to control horns on the top and bottom of the control surfaces. No flexing of the controls happen during operation. My glider has little thumb nuts and screws on the control horns to adjust line length.

Like on the larger Giant scale R/C planes or some RTF powered gliders they use the pull/pull method of control using separate cables or in the case of RTF gliders fishing line. The controls usually go from a Tee type servo horn to control horns on the top and bottom of the control surfaces. No flexing of the controls happen during operation. My glider has little thumb nuts and screws on the control horns to adjust line length.

Now if there was some way to design a bellcrank system that would utilize this design, unless they already exist

Still Addicted

Coxaddict

Like on the larger Giant scale R/C planes or some RTF powered gliders they use the pull/pull method of control using separate cables or in the case of RTF gliders fishing line. The controls usually go from a Tee type servo horn to control horns on the top and bottom of the control surfaces. No flexing of the controls happen during operation. My glider has little thumb nuts and screws on the control horns to adjust line length.

Like on the larger Giant scale R/C planes or some RTF powered gliders they use the pull/pull method of control using separate cables or in the case of RTF gliders fishing line. The controls usually go from a Tee type servo horn to control horns on the top and bottom of the control surfaces. No flexing of the controls happen during operation. My glider has little thumb nuts and screws on the control horns to adjust line length. Now if there was some way to design a bellcrank system that would utilize this design, unless they already exist

Still Addicted

Coxaddict

coxaddict- Gold Member

- Posts : 429

Join date : 2013-01-27

Location : north shore oahu, Hawaii

Re: Phred's way control systems

Re: Phred's way control systems

I actually saw a flat plane horizontal C/L bell crank linked to drive a 90 degree vertical second bell crank that was cable lashed to top and bottom horns on a elevator.... from what I saw a precise setup BUT IMO just and exercise is fabricating with little gain in actual needed control responsiveness

Most current state of the art push pull (control rod) systems can be really free moving with very little measurable slop using good hinges, horns and ball links

and there is a camp that suggest a little slop in the flap or elevator is a good thing to dampen "Hunting"

I also saw in the RC club some guys with BIG 3D planes that needed 2 or more ganged servos in Pull Pull to have the ass (torque) to move the big rudder or elevator

Most current state of the art push pull (control rod) systems can be really free moving with very little measurable slop using good hinges, horns and ball links

and there is a camp that suggest a little slop in the flap or elevator is a good thing to dampen "Hunting"

I also saw in the RC club some guys with BIG 3D planes that needed 2 or more ganged servos in Pull Pull to have the ass (torque) to move the big rudder or elevator

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: Phred's way control systems

Re: Phred's way control systems

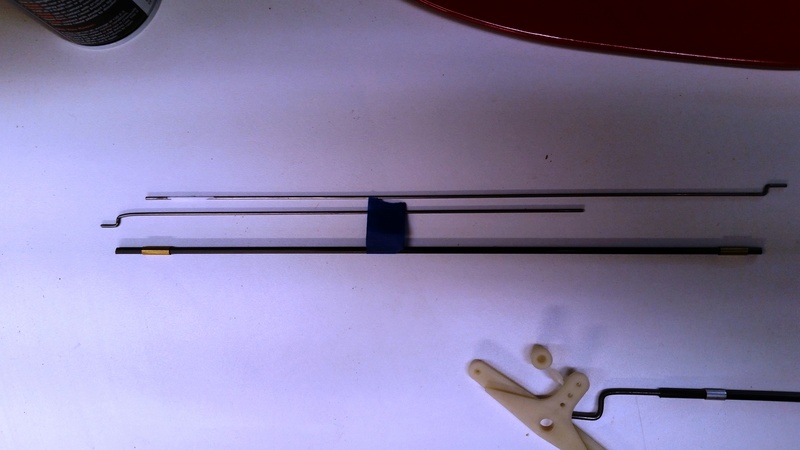

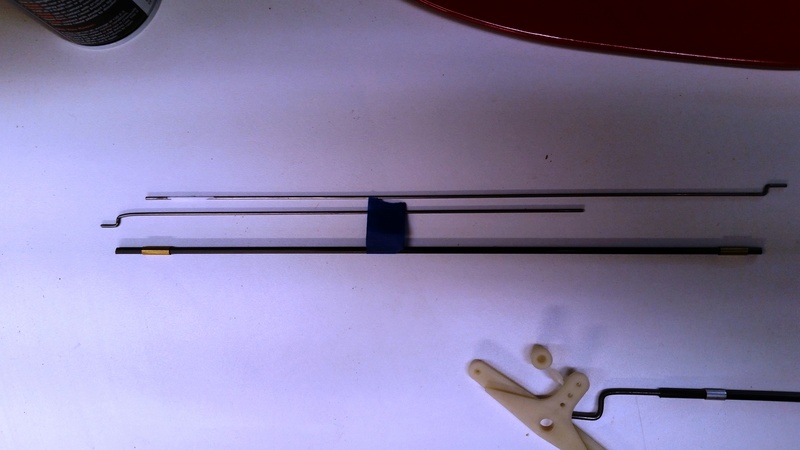

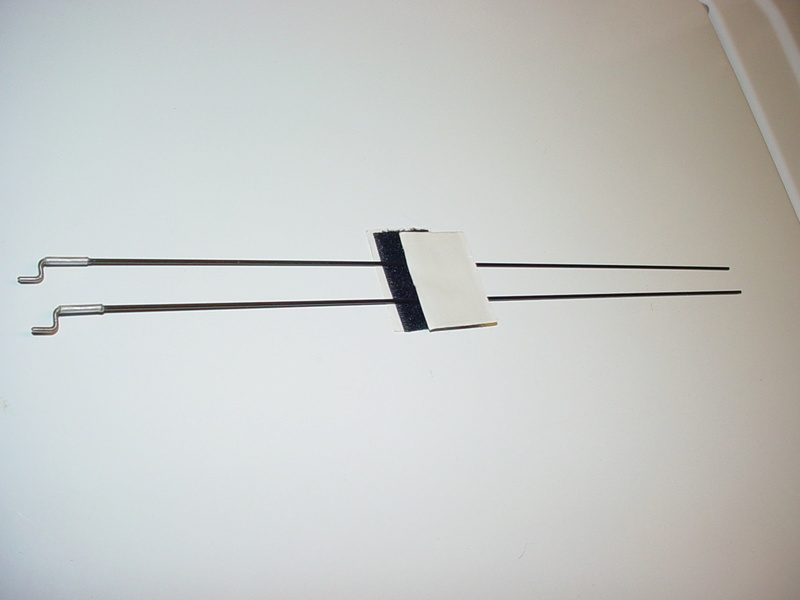

Upper left is typical kit supplied music wire, a length of small diameter carbon tube and two brass ends the fit OD of the CF tube

I cut the BC side of wire to have enough length to fit 1.5" inside the tube and still have full clearance on the BC. The aft end to the Horn is also cut for 1.5" inside the tube. I only J&B glue in the aft once I set and hold Neutral elevator. Lighter and no flex than just the plain music wire

Very bottom is the large diameter Arrow shaft CF tube I used on the Ring Master. I really do not like the thick diameter look but it is still light.

In this case, I used a wood dowel inside the tube drilled to accept a length of 4-40 all thread at the aft, and 5/32 Music wire with "Z" bend to the BC. The various pieces of Brass or aluminum tube you see are for the outside of each end of the CF tube to prevent breakout. Some folks just CA and thread wrapped on the end to prevent any splitting

There are all sorts of pre made ends you can buy...some insert into the correct tube diameter and others slip over the outside

Mine are from Central Hobbies with a size I like for my preferred smaller diameter CF Tube. They are Titanium with 4-40 thread on the end and there are some folks who claim the machining of the Titanium bakes it brittle and stress breakage prone.... I do not fly enough to have had a failure ---yet

I prefer J&B cuz it is easy to mix up the very small amount needed and stays where you put it. But 30 min epoxy (I think with some thickener like Micro balloons) will work. I know a guy who does all his with Thick CA

Prep is the key, light sanding for all the glued surfaces, and a good cleaning to remove finger oils. I use Acetone but 91% Alcohol will work

Another plus is the system holds paint a lot better than the music wire in case you do not want the black tube look

I cut the BC side of wire to have enough length to fit 1.5" inside the tube and still have full clearance on the BC. The aft end to the Horn is also cut for 1.5" inside the tube. I only J&B glue in the aft once I set and hold Neutral elevator. Lighter and no flex than just the plain music wire

Very bottom is the large diameter Arrow shaft CF tube I used on the Ring Master. I really do not like the thick diameter look but it is still light.

In this case, I used a wood dowel inside the tube drilled to accept a length of 4-40 all thread at the aft, and 5/32 Music wire with "Z" bend to the BC. The various pieces of Brass or aluminum tube you see are for the outside of each end of the CF tube to prevent breakout. Some folks just CA and thread wrapped on the end to prevent any splitting

There are all sorts of pre made ends you can buy...some insert into the correct tube diameter and others slip over the outside

Mine are from Central Hobbies with a size I like for my preferred smaller diameter CF Tube. They are Titanium with 4-40 thread on the end and there are some folks who claim the machining of the Titanium bakes it brittle and stress breakage prone.... I do not fly enough to have had a failure ---yet

I prefer J&B cuz it is easy to mix up the very small amount needed and stays where you put it. But 30 min epoxy (I think with some thickener like Micro balloons) will work. I know a guy who does all his with Thick CA

Prep is the key, light sanding for all the glued surfaces, and a good cleaning to remove finger oils. I use Acetone but 91% Alcohol will work

Another plus is the system holds paint a lot better than the music wire in case you do not want the black tube look

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: Phred's way control systems

Re: Phred's way control systems

Pretty slick man! It's good to see and have explained how "you" do it. I've made some small pushrods from .060" CF rod.. but haven't put them into service yet. I went the thick CA route for the links.

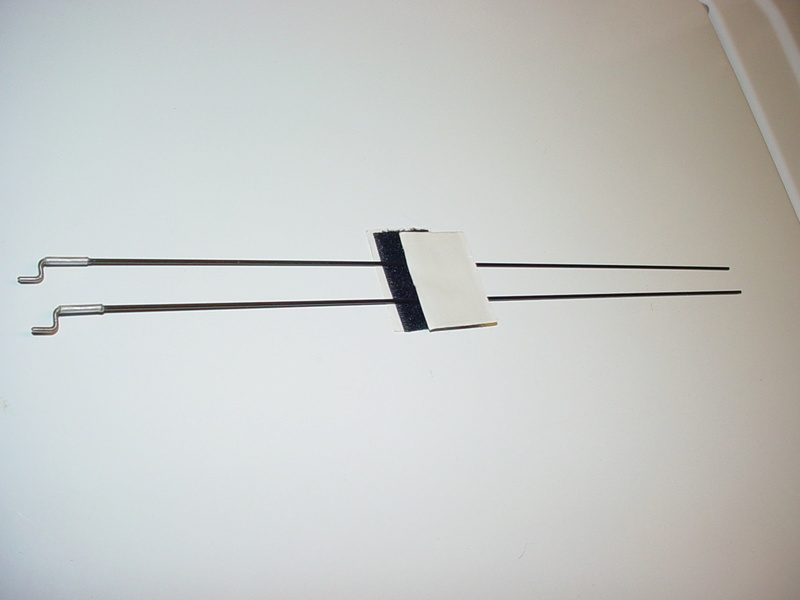

The sleeves are aluminum tube (.062" ID) and the Z-bent links are .062" music-wire. I filed some light notches in the music-wire ends, to be inserted into the sleeves beforehand.. and also roughed them up with coarse abrasive. The sleeves are only .5" long though.. so there's only .25" of retention for the MW and the CF rod.. Strong enough? Only God knows. It's said that CA glue lacks strength in the "shear-plane" which concerns me. There wasn't much I could do to "rough-up" the insides of the sleeves for glue-retention, their being of such a small inner-diameter. They're very lightweight though..

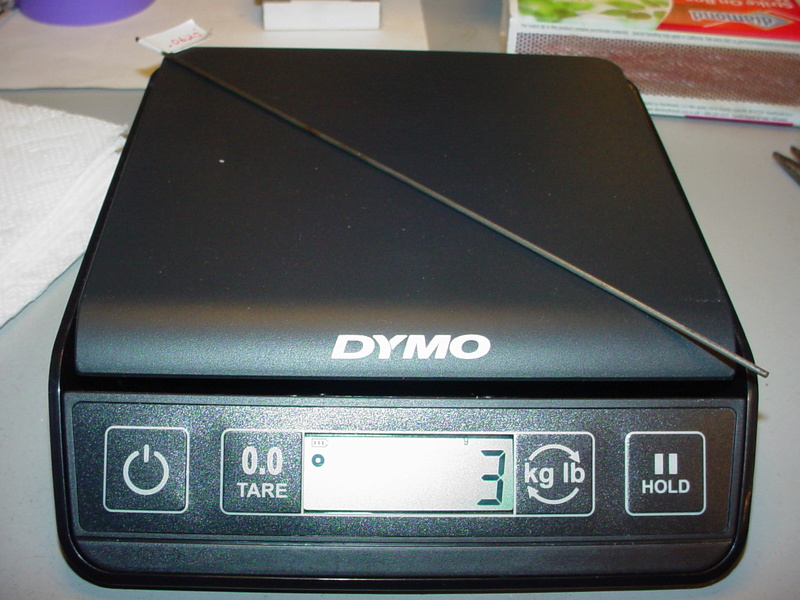

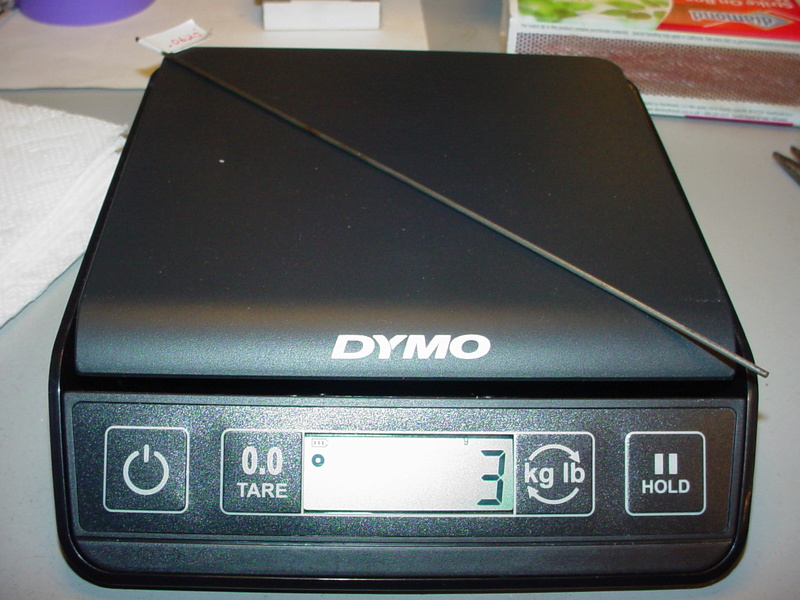

Here's the weight in grams, of "one" length of .062" music-wire..

And here's the weight in grams, of "two lengths" CF rod with links installed on one end..

Interesting isn't it? I have to wonder how much lighter a single CF rod is.. than a single MW rod of the same length? This would make quite a difference on a small model. My "Phred's Phault" 1/2-scale VooDoo has been eating at me lately to finish the damned thing.. A CF pushrod would actually be easier to install.. than my usual method.

A CF pushrod would actually be easier to install.. than my usual method.

The sleeves are aluminum tube (.062" ID) and the Z-bent links are .062" music-wire. I filed some light notches in the music-wire ends, to be inserted into the sleeves beforehand.. and also roughed them up with coarse abrasive. The sleeves are only .5" long though.. so there's only .25" of retention for the MW and the CF rod.. Strong enough? Only God knows. It's said that CA glue lacks strength in the "shear-plane" which concerns me. There wasn't much I could do to "rough-up" the insides of the sleeves for glue-retention, their being of such a small inner-diameter. They're very lightweight though..

Here's the weight in grams, of "one" length of .062" music-wire..

And here's the weight in grams, of "two lengths" CF rod with links installed on one end..

Interesting isn't it? I have to wonder how much lighter a single CF rod is.. than a single MW rod of the same length? This would make quite a difference on a small model. My "Phred's Phault" 1/2-scale VooDoo has been eating at me lately to finish the damned thing..

Similar topics

Similar topics» 1/2A Control Line Handles

» The infamous Cox PT-19 Control Line Trainer

» Half Pint (Louis Garami) 1940

» throttle control

» Another proposed design by Roddie

» The infamous Cox PT-19 Control Line Trainer

» Half Pint (Louis Garami) 1940

» throttle control

» Another proposed design by Roddie

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules