Log in

Search

Latest topics

» My N-1R build logby roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Fri Nov 22, 2024 11:32 am

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

Cox Engine of The Month

cowled fuse-kits for 1/2A profile scratch-building

Page 1 of 1

cowled fuse-kits for 1/2A profile scratch-building

cowled fuse-kits for 1/2A profile scratch-building

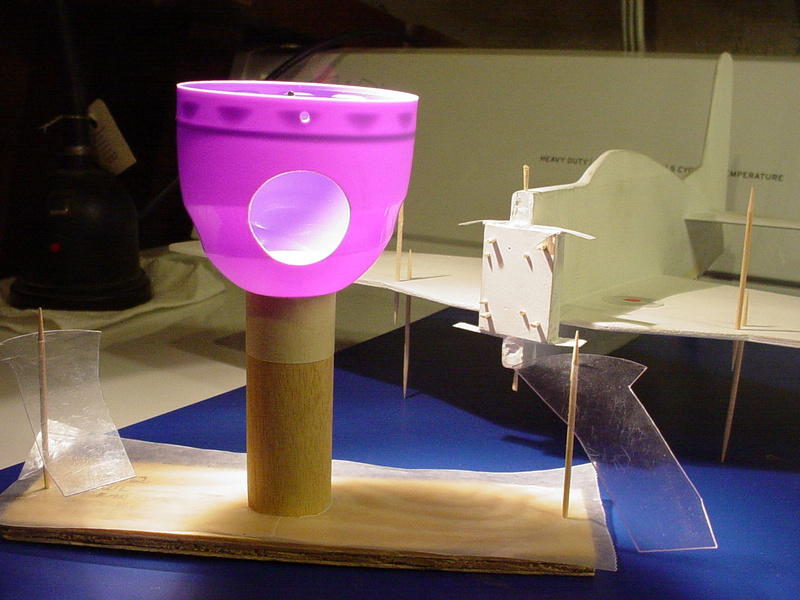

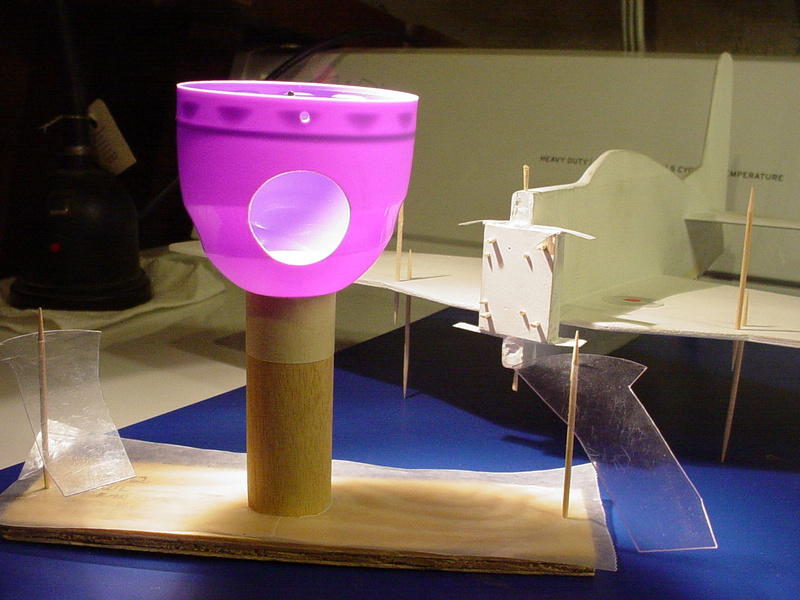

Opinion/survey.. I think I might enjoy making some up to sell. It would include instructions/diagrams, a bullet-cowl, (like on my Bearcat) a sheet of 1/4" balsa (fuse-blank; 3" x 18") and 1/4" sq. top/bottom hardwood cowl-blocks, as a minimalist short-kit. Engine-mount kits would include either radial-mount (plywood and cheek-blocks) or beam-mount (1/4" sq. Maple) materials. Any nose-doublers would be added at the builders' discretion. The builder can shape the fuses' length and side-profile to their liking.. and add their own wing/tail parts. A needle-valve extension will likely be needed.. and the ability to fuel, prime/choke the engine can be somewhat impaired. read-on..

I used a 1" hole-saw to make the two cut-outs required in the cowling for the engine.. but the cylinder-hole location needs to be carefully planned with the fore/aft locating of the engine and its mount. With Cox Bee's, the back-end chosen will be the only type that will fit that cowl.

A Cox horseshoe backplate mounted on-center to a near flush to the nose firewall, places the cylinder hole at 1.25" o/c from the back-edge of the cowl. Once this is established, the cylinder-orientation can be whatever is desired.. and the cowl rotated to that position. A beam-mount would need to extend further into the cowl.. while maintaining the noses' vertical measurement to fit inside the cowl.

The cowl measures 2.5" (ID) at the back.. and has a shoulder/ridge 5/16" inside, providing an alignment stop for the fuse. The nose-end of the 3" fuse-blank would taper (top/bottom) to fit inside and against the cowl's inside shoulder/ridge with the 1/4" sq. cowl mount-blocks installed.

A Medallion/Tee Dee would need mounts to center the crankshaft inside the cowl. A quick check with an .051 looks to require beams affixed to a ply doubler on the inboard side of the fuse.. and the balsa cut out for the engine to sit down-into. Maybe my math's off.. but a flush-side mount won't line-up.

I include these details.. because it might possibly be you that would have an interest. What would you expect to pay for a short-kit? (cowling, mount-blocks and the 3" X 18" X 1/4" balsa plank un-cut/un-assembled) That would be a minimalist kit.. but enough for some. Others may want an engine-mount upgrade.

I guess I should weigh-up a viable shipping-container.. viable meaning; able to survive the chosen postal-system. I would guess that a capped 3" ID cardboard tube 24"L. would be the way to go. The cowl material is flexible.. and the balsa sheet would tightly span the tube; giving it strength on opposing sides. Shipping damage in such a tube would be minimal.. unless it was mutilated.

In closing.. I'd like you to imagine modeling a favorite radial/rotary-engine powered aircraft in 1/2A C/L profile scale. The engine-cowl really makes it pop.. especially with a tasty paint-job.

Anybody interested?

I used a 1" hole-saw to make the two cut-outs required in the cowling for the engine.. but the cylinder-hole location needs to be carefully planned with the fore/aft locating of the engine and its mount. With Cox Bee's, the back-end chosen will be the only type that will fit that cowl.

A Cox horseshoe backplate mounted on-center to a near flush to the nose firewall, places the cylinder hole at 1.25" o/c from the back-edge of the cowl. Once this is established, the cylinder-orientation can be whatever is desired.. and the cowl rotated to that position. A beam-mount would need to extend further into the cowl.. while maintaining the noses' vertical measurement to fit inside the cowl.

The cowl measures 2.5" (ID) at the back.. and has a shoulder/ridge 5/16" inside, providing an alignment stop for the fuse. The nose-end of the 3" fuse-blank would taper (top/bottom) to fit inside and against the cowl's inside shoulder/ridge with the 1/4" sq. cowl mount-blocks installed.

A Medallion/Tee Dee would need mounts to center the crankshaft inside the cowl. A quick check with an .051 looks to require beams affixed to a ply doubler on the inboard side of the fuse.. and the balsa cut out for the engine to sit down-into. Maybe my math's off.. but a flush-side mount won't line-up.

I include these details.. because it might possibly be you that would have an interest. What would you expect to pay for a short-kit? (cowling, mount-blocks and the 3" X 18" X 1/4" balsa plank un-cut/un-assembled) That would be a minimalist kit.. but enough for some. Others may want an engine-mount upgrade.

I guess I should weigh-up a viable shipping-container.. viable meaning; able to survive the chosen postal-system. I would guess that a capped 3" ID cardboard tube 24"L. would be the way to go. The cowl material is flexible.. and the balsa sheet would tightly span the tube; giving it strength on opposing sides. Shipping damage in such a tube would be minimal.. unless it was mutilated.

In closing.. I'd like you to imagine modeling a favorite radial/rotary-engine powered aircraft in 1/2A C/L profile scale. The engine-cowl really makes it pop.. especially with a tasty paint-job.

Anybody interested?

Re: cowled fuse-kits for 1/2A profile scratch-building

Re: cowled fuse-kits for 1/2A profile scratch-building

I tried to delete this thread, but I can't. Kind of a dumb idea.

Re: cowled fuse-kits for 1/2A profile scratch-building

Re: cowled fuse-kits for 1/2A profile scratch-building

I don't think it's a dumb idea, but postage and packing cost would probably make it "not feasible" for many. I don't know... It would be a neat concept to sell in a swap meet, or maybe as a club event or something, but I think the kit should then include the balsa for the wing and tail, ply and hardwood for the engine mount and maybe even the steel wire for the pushrod and the fabric for hinges. Bellcranks and horns could be made of plywood. And an instruction sheet would be nice too  I.e a complete kit less glue and paint.

I.e a complete kit less glue and paint.

But then again, there are lots of 1/2A kits in the 20-30$ range, and it would be hard to compete against them.

I don't know if I would order one (even if I lived closer) but it would be definitely possible that I'd grab a kit like that in a swap meet or such

I have an article related to this type of plane design but need to go to work, I'll post it later so stand by

Great idea as always, Roddie

But then again, there are lots of 1/2A kits in the 20-30$ range, and it would be hard to compete against them.

I don't know if I would order one (even if I lived closer) but it would be definitely possible that I'd grab a kit like that in a swap meet or such

I have an article related to this type of plane design but need to go to work, I'll post it later so stand by

Great idea as always, Roddie

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: cowled fuse-kits for 1/2A profile scratch-building

Re: cowled fuse-kits for 1/2A profile scratch-building

Thanks Kari. Years ago I put together a boxed 1/2A C/L profile scratch-build kit as a "Yankee-swap" gift for a club Christmas party. It was a big hit.

I'd need to provide more fabrication to this concept, to make it worth the cost of shipping. A garden-variety profile model fuse-kit doesn't consist of much more than a plank of balsa. A cap-cowl (less fabrication) like the ones I use, can be obtained locally and cheaply by anyone.. therefor the "short-kit" was a dumb idea. If I built the nose; engine/cowl mounts installed to fit a particular/common Cox .049 engine-configuration, cowl-holes all pre-drilled and a hardware package that included a NV-extension.. it might be more attractive.

I figured that omitting wing/tail parts would be cheaper and allow the builder to choose what they wanted. I have boxes full of 1/4" balsa and a few dozen cowls.. so it would only cost "me" the price of a shipping-tube.. and my time to fabricate.

Thanks for commenting. I appreciate it.

I'd need to provide more fabrication to this concept, to make it worth the cost of shipping. A garden-variety profile model fuse-kit doesn't consist of much more than a plank of balsa. A cap-cowl (less fabrication) like the ones I use, can be obtained locally and cheaply by anyone.. therefor the "short-kit" was a dumb idea. If I built the nose; engine/cowl mounts installed to fit a particular/common Cox .049 engine-configuration, cowl-holes all pre-drilled and a hardware package that included a NV-extension.. it might be more attractive.

I figured that omitting wing/tail parts would be cheaper and allow the builder to choose what they wanted. I have boxes full of 1/4" balsa and a few dozen cowls.. so it would only cost "me" the price of a shipping-tube.. and my time to fabricate.

Thanks for commenting. I appreciate it.

Re: cowled fuse-kits for 1/2A profile scratch-building

Re: cowled fuse-kits for 1/2A profile scratch-building

Here's the plan I mentioned earlier. It might make a fun kit for a club event or maybe even a "postal" speed contest or something. The wingspan, tail feather dimensions and fuselage length would be kept as they are, otherwise the shape could be unlimited.

It would be an easy kit to make as all the parts are more or less rectangular. Unfortunately I only have a copy of this one page, I don't know which magazine it is from.

It would be an easy kit to make as all the parts are more or less rectangular. Unfortunately I only have a copy of this one page, I don't know which magazine it is from.

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: cowled fuse-kits for 1/2A profile scratch-building

Re: cowled fuse-kits for 1/2A profile scratch-building

Kari, it says it on the plan: Model Aviation:

http://library.modelaviation.com/ma/1987/2

Lieven

http://library.modelaviation.com/ma/1987/2

Lieven

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: cowled fuse-kits for 1/2A profile scratch-building

Re: cowled fuse-kits for 1/2A profile scratch-building

OVERLORD wrote:Kari, it says it on the plan: Model Aviation:

http://library.modelaviation.com/ma/1987/2

Lieven

'Scuse me while I slap myself on the back of my head a couple of times and yell stoopid

Didn't realize that was the name of the publication. Thanks. I read the article and one of the kids had actually built a plane with an aerosol cap for a cowl. Kinda like a Corsair but with straight wings.

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: cowled fuse-kits for 1/2A profile scratch-building

Re: cowled fuse-kits for 1/2A profile scratch-building

KariFS wrote:OVERLORD wrote:Kari, it says it on the plan: Model Aviation:

http://library.modelaviation.com/ma/1987/2

Lieven

'Scuse me while I slap myself on the back of my head a couple of times and yell stoopid

Didn't realize that was the name of the publication. Thanks. I read the article and one of the kids had actually built a plane with an aerosol cap for a cowl. Kinda like a Corsair but with straight wings.

Ha ha! Thanks guys! Kari.. stop slapping.. I've slapped myself enough for both of us. The "Pattern Plane" plan/pic that you posted, is similar to the idea behind my concept. The rough-dimensions/moments are there to get you in the ballpark. Judicial use of a French-Curve turns square-corners into a stylish flying-machine!

Come "Hell or High Water".. I'm going to apply myself more with modeling this Winter. (it's not Winter yet.. is it?

Finger-joint example.. (super-tight/strong)

Four profiles in the X-shape of a rolling-pin and wooden-spoon were router-cut from the blank to make a "Bakery" sign. I ran the CNC routers. Scrap was discarded.. so I ripped boxes full.. down to gen. hobby sheet-thicknesses (1/8", 3/16" and 1/4") using the panel-saw in the wood-shop. The lengths that I ended up with, vary from 18" to 30". We made 100's of those signs for a major supermarket chain in the Northeast U.S. When I think about the amount of useable scrap-balsa that was thrown away.. it makes me sigh.. because I think about the amount of models that could be built.. the retail-cost of wood today.. and all of us who love to build model airplanes. My fear; is that I know that I'll never come close to using it all in my lifetime. I want to share it somehow.

Grain-pattern and density varies WIDELY.. as there were no structural demands on its intended end-use. Some pieces are very dense/heavy C-grain, where others could be considered contest-grade.

I'd probably pick the heavier 1/4" thick stock for my 1/2A cowled profile-fuse kit. Since it's all 1.75"W.; I'd butt-join two pieces (3.5") and rip-down to 2.5" (cowl-opening ID). The leftover scrap-strip can be used for canopy/turtle-deck/belly profiling. My Grumman F8F-2 fuse started-out pretty much square. The 1/4" hardwood rails top/bottom are vertically-spaced 2.5" apart to fit inside the cowl and accept #2 wood-screws to secure it.

The belly and canopy profiles; I studied drawings of.. and drew-out on scrap-pieces with a French-curve.

prototype with Babe Bee vertical engine..

The nose of the fuse ended-up being designed completely around the Cox Horseshoe backplate and the cowl I planned to use.

Having built it; replicating for that same cowl (I have many..) would be relatively easy.. maybe not quick.. but easy. I have some ideas for the cowl's horizontal-bracing that I want to try. My Bearcat has six-point bracing. I'd like to try a single 2.5" long plastic stick or rod as a "spar-brace" that would locate just behind a 1/32" ply fire-wall skin. I'd have to notch the 3/8" sq. backing hardwood cheek-blocks in their centers for it to pass-through the nose on-center. That would provide four equal radial-points of bracing.

I know that it can be hard to read this stuff and picture it. I often design through writing. It moves an idea/image/calculation from my brain to a hard-copy. Sorry about that.. but many of you will choose to read this far.

Re: cowled fuse-kits for 1/2A profile scratch-building

Re: cowled fuse-kits for 1/2A profile scratch-building

Is it winter yet... Well, around here the sunrise was at 9.13 am today and it'll set at 3.18 pm, so there's not a lot of sunlight these days, and in the morning it was about 7 deg F. No snow yet, but the river froze overnight. But it looks like the hydropower plant a couple of miles upstream has its turbines on "high" as it now flows pretty fast and that broke the ice.

Right now it's about 10 am, and you can see how low the sun still is. So it is early winter here, and a good time to sit by the fireplace and design (dream up) some airplanes Today I am at home, "telecommuting", since the younger son has the flu and quite a fever. He's getting better already so tomorrow it'll be another day at the office again.

Today I am at home, "telecommuting", since the younger son has the flu and quite a fever. He's getting better already so tomorrow it'll be another day at the office again.

Anyway, here is a little sketch about what I had in mind for the echu... etchy... achoo... pipe collar I showed earlier (in the thread about repurposing things for model parts) and my thoughts about how to mount it. Turns out the part is the perfect size for a 15" span profile model of a Gee Bee (the black and yellow one), an obvious choice for the reed speed event I thought I'll "integrate" the engine mount supports and cowl mounts as seen in the picture, and the cowl would be mounted with 4 small screws. The right side mount would be shorter to make room for the fuel tank. The parts could be plywood, since the model would have a very short nose and that would help to get the CG where it belongs.

I thought I'll "integrate" the engine mount supports and cowl mounts as seen in the picture, and the cowl would be mounted with 4 small screws. The right side mount would be shorter to make room for the fuel tank. The parts could be plywood, since the model would have a very short nose and that would help to get the CG where it belongs.

Just my

Right now it's about 10 am, and you can see how low the sun still is. So it is early winter here, and a good time to sit by the fireplace and design (dream up) some airplanes

Anyway, here is a little sketch about what I had in mind for the echu... etchy... achoo... pipe collar I showed earlier (in the thread about repurposing things for model parts) and my thoughts about how to mount it. Turns out the part is the perfect size for a 15" span profile model of a Gee Bee (the black and yellow one), an obvious choice for the reed speed event

Just my

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: cowled fuse-kits for 1/2A profile scratch-building

Re: cowled fuse-kits for 1/2A profile scratch-building

Wow.. Finland is roughly at the same latitude as the state of Alaska, here in the US. Thanks for taking the photo! In what town do you live? That's a beautiful area! Of all the places in the world I've wanted to visit; the Scandinavian countries have topped my list since I was a child. I've always wanted to see their fjords/fiords.

I hope your son feels better.. and I hope no one else gets sick. Maybe open the windows for an hour or two.. 7 deg. F would kill most germs that I know of..

Sitting by the warm fireplace, dreaming-up model-airplanes sounds inviting! Put on a pot of coffee.. and I'll be right over!

I hope your son feels better.. and I hope no one else gets sick. Maybe open the windows for an hour or two.. 7 deg. F would kill most germs that I know of..

Sitting by the warm fireplace, dreaming-up model-airplanes sounds inviting! Put on a pot of coffee.. and I'll be right over!

Re: cowled fuse-kits for 1/2A profile scratch-building

Re: cowled fuse-kits for 1/2A profile scratch-building

Sure thing Roddie, I'll dig up another sketch pad and sharpen my pencils while the coffee is brewing

I live in a village called Hämeenkyrö, it is near Tampere, one of the biggest cities in Finland (200 thousand people, our "big cities" are small). I don't live by the coast, the coast and most of the country is rather flat (highest elevation is less than a mile) and we don't have fjords. We do have pretty nice archipelagos and literally tens of thousands of lakes. Fortunately it is not as cold as in Alaska either, since the Gulf stream brings us warm seawater from your coast

Here are some pictures from my area that a fellow with a paraglider has taken:

http://www.paramotor.fi/260712.htm

My house is hidden behind the trees and not seen in the pics, but you can see the waterfall, papermill and the hydropower plant in one or two of the pictures. That waterfall is pretty much the reason this village exists, as the falls were and still are a good source for power. Most waterfalls in Finland have a 100+ years old papermill and/or powerplant built to harness the power.

Oh, the fjords are beautiful and quite impressive. I have visited Alta and Trondheim in the Norwegian coast, certainly impressive views for a "flatlander" like me. Well worth a visit.

I live in a village called Hämeenkyrö, it is near Tampere, one of the biggest cities in Finland (200 thousand people, our "big cities" are small). I don't live by the coast, the coast and most of the country is rather flat (highest elevation is less than a mile) and we don't have fjords. We do have pretty nice archipelagos and literally tens of thousands of lakes. Fortunately it is not as cold as in Alaska either, since the Gulf stream brings us warm seawater from your coast

Here are some pictures from my area that a fellow with a paraglider has taken:

http://www.paramotor.fi/260712.htm

My house is hidden behind the trees and not seen in the pics, but you can see the waterfall, papermill and the hydropower plant in one or two of the pictures. That waterfall is pretty much the reason this village exists, as the falls were and still are a good source for power. Most waterfalls in Finland have a 100+ years old papermill and/or powerplant built to harness the power.

Oh, the fjords are beautiful and quite impressive. I have visited Alta and Trondheim in the Norwegian coast, certainly impressive views for a "flatlander" like me. Well worth a visit.

Last edited by KariFS on Tue Nov 29, 2016 11:49 pm; edited 1 time in total

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: cowled fuse-kits for 1/2A profile scratch-building

Re: cowled fuse-kits for 1/2A profile scratch-building

Absolutely beautiful area! Very picturesque. Thanks for sharing the link!

I like your 4-point cowl-bracing. My Bearcats' cowl is six-point but I only needed a top and a bottom wood-screw to fasten it, due to the ridge inside the cap. You could use two screws (top/bottom) if you install stop-blocks (PVC/PVC-cement?) inside the back of the collar for the horizontal bracing to bear on, eliminating side-movement.

I'd like to test a cowl-mount/bracing with alternate fasteners. Tiny snap-closures (craft-jewelry items) would be cool if they could be mounted securely.. maybe even hook & loop (Velcro) tabs or magnets. It would be nice to be able to easily pull the cowl off after removing the prop.. but there's also the needle-valve to consider. Maybe just an "access-hole" could be drilled in the cowl.. and a needle-adjusting tool inserted to tune the engine.. and then removed once tuned? Something of a cup that would fit over the needle-knob or shaft and be able to rotate it without slipping. This would eliminate the need for a needle-extension.. and the possible "tuning-fork" effect that can cause settings to wander.

I had an idea for the product engine's brass needle that uses a small hex-socket set-screw inside a brass sleeve. Tap the brass-sleeve to accept the set-screw and solder the whole assembly together.

The hex-wrench could be sleeved to form a "cup" for easier locating into the socket.

It's non-destructive to the needle.. and provides a more positive means of adjustment.

I like your 4-point cowl-bracing. My Bearcats' cowl is six-point but I only needed a top and a bottom wood-screw to fasten it, due to the ridge inside the cap. You could use two screws (top/bottom) if you install stop-blocks (PVC/PVC-cement?) inside the back of the collar for the horizontal bracing to bear on, eliminating side-movement.

I'd like to test a cowl-mount/bracing with alternate fasteners. Tiny snap-closures (craft-jewelry items) would be cool if they could be mounted securely.. maybe even hook & loop (Velcro) tabs or magnets. It would be nice to be able to easily pull the cowl off after removing the prop.. but there's also the needle-valve to consider. Maybe just an "access-hole" could be drilled in the cowl.. and a needle-adjusting tool inserted to tune the engine.. and then removed once tuned? Something of a cup that would fit over the needle-knob or shaft and be able to rotate it without slipping. This would eliminate the need for a needle-extension.. and the possible "tuning-fork" effect that can cause settings to wander.

I had an idea for the product engine's brass needle that uses a small hex-socket set-screw inside a brass sleeve. Tap the brass-sleeve to accept the set-screw and solder the whole assembly together.

The hex-wrench could be sleeved to form a "cup" for easier locating into the socket.

It's non-destructive to the needle.. and provides a more positive means of adjustment.

Similar topics

Similar topics» Profile VS Built up fuse

» Narrowing engine bearers

» New P-38 profile scratch build log

» Scratch building a new plane - without plans, just an idea

» Hybrid-Profile Flite Streak/Cox Hyper Viper scratch build

» Narrowing engine bearers

» New P-38 profile scratch build log

» Scratch building a new plane - without plans, just an idea

» Hybrid-Profile Flite Streak/Cox Hyper Viper scratch build

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules