Log in

Search

Latest topics

» Retail price mark-up.. how much is enough?by Ken Cook Today at 11:08 am

» Tee Dee .020 combat model

by 1/2A Nut Today at 10:34 am

» Happy 77th birthday Andrew!

by rdw777 Today at 10:04 am

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 8:15 am

» TEE DEE Having issues

by balogh Today at 7:42 am

» Cox films/videos...

by Coxfledgling Today at 4:46 am

» My N-1R build log

by roddie Today at 12:32 am

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

Cox Engine of The Month

KK Cobra 0.8cc

Page 1 of 2

Page 1 of 2 • 1, 2

KK Cobra 0.8cc

KK Cobra 0.8cc

This is the KK Cobra as received. In fair condition for age and well used.

As usual - it was seized and all castored up!

The back plate was loose and the screws were missing. So was the reed valve. I am guessing that the reed had failed and the previous owner couldn't find a spare or didn't realise that it is the same as the Cox reed.

Bearing in mind that this engine is 55 years old, the Interweb is relatively new, this engine had limited production and Cox spares here were almost non existent (and expensive) - I am not surprised that this was put to one side. I am surprised that is wasn't junked but there was obviously an attachment to it.

I left it to soak for quite a few days in one of my brews (oil based - I can't say exactly what it is but it started life as Hoppes No 9 and has had various penetrating fluids added to it and has been filtered and left to settle many times - ready for reuse)

As Ken raised, in another post, I too do not recommend taking engines apart. This one poses the classic dilemma - it is intended to be a running shelf queen but patience is required or you will end up with scrap.

The inside has been well preserved by castor oil - even though it had set like epoxy! After I had left it to soak and cleaned the outside (toothbrush) - rust had left its mark on the cylinder (outside) but there were "gritty" bits in the crankcase and so a complete strip and clean became the order of the day.

After making sure that the piston was free - the cylinder was removed. Do not use a metal tool through the exhaust ports - like Cox engines - the cylinder is a soft steel and will bur easily. I use a leather strap around the lower portion and away from the fins - this a where patience is required! It is easy to get carried away and apply more and more force - a little heat helps but don't over do it! Aluminium alloys have a low melting point - they are not as resilient as aluminium bar stock.

After a further soaking of the "parts" - i ended up with this

A trifle disturbing - although probably carbon - these grits were hard and couldn't be crushed - softer than the piston but harder than the cylinder! Better out than in!

To be continued.

As usual - it was seized and all castored up!

The back plate was loose and the screws were missing. So was the reed valve. I am guessing that the reed had failed and the previous owner couldn't find a spare or didn't realise that it is the same as the Cox reed.

Bearing in mind that this engine is 55 years old, the Interweb is relatively new, this engine had limited production and Cox spares here were almost non existent (and expensive) - I am not surprised that this was put to one side. I am surprised that is wasn't junked but there was obviously an attachment to it.

I left it to soak for quite a few days in one of my brews (oil based - I can't say exactly what it is but it started life as Hoppes No 9 and has had various penetrating fluids added to it and has been filtered and left to settle many times - ready for reuse)

As Ken raised, in another post, I too do not recommend taking engines apart. This one poses the classic dilemma - it is intended to be a running shelf queen but patience is required or you will end up with scrap.

The inside has been well preserved by castor oil - even though it had set like epoxy! After I had left it to soak and cleaned the outside (toothbrush) - rust had left its mark on the cylinder (outside) but there were "gritty" bits in the crankcase and so a complete strip and clean became the order of the day.

After making sure that the piston was free - the cylinder was removed. Do not use a metal tool through the exhaust ports - like Cox engines - the cylinder is a soft steel and will bur easily. I use a leather strap around the lower portion and away from the fins - this a where patience is required! It is easy to get carried away and apply more and more force - a little heat helps but don't over do it! Aluminium alloys have a low melting point - they are not as resilient as aluminium bar stock.

After a further soaking of the "parts" - i ended up with this

A trifle disturbing - although probably carbon - these grits were hard and couldn't be crushed - softer than the piston but harder than the cylinder! Better out than in!

To be continued.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: KK Cobra 0.8cc

Re: KK Cobra 0.8cc

Like enjoying a fine wine a sip at a time sniffing the bouquet as I went along and thinking "this is going to be really good"..... I slowly scrolled down through Ian's text and pictures anticipating a beautifully rendered KK Cobra at the end. Instead, I get a container full of debris and goo and a "to be continued".

Come-on Ian, you got my motor running then the crankshaft broke....

Bob

Come-on Ian, you got my motor running then the crankshaft broke....

Bob

rsv1cox- Top Poster

Posts : 11251

Join date : 2014-08-18

Location : West Virginia

Re: KK Cobra 0.8cc

Re: KK Cobra 0.8cc

Slow but sure! Patience is a virtue and a restoration takes time - Not as much a posting a topic though.

I have to do this in installments - Episodes - I keep losing postings. Soon I will do one sentence at a time!

The cylinder took a turn on the lathe to remove the rust.

Then a little light alkaline degreaser

Rinse and a three minute dip

Rinse and twenty minutes in dewatering fluid

Leave to dry - overnight!

and .....................

Almost like new.

I have to do this in installments - Episodes - I keep losing postings. Soon I will do one sentence at a time!

The cylinder took a turn on the lathe to remove the rust.

Then a little light alkaline degreaser

Rinse and a three minute dip

Rinse and twenty minutes in dewatering fluid

Leave to dry - overnight!

and .....................

Almost like new.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: KK Cobra 0.8cc

Re: KK Cobra 0.8cc

The back plate needed a new gasket and a reed. Luckily, a Cox gasket with a little persuasion fits.

After assembling the engine and seeing this picture - I could see that I hadn't seated the reed properly and it was off centre. Now fixed.

After assembling the engine and seeing this picture - I could see that I hadn't seated the reed properly and it was off centre. Now fixed.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: KK Cobra 0.8cc

Re: KK Cobra 0.8cc

Tis now finished and ready to run.

With a used engine like this one - I prefer to keep the patina of age and I can now see the serial number.

With a used engine like this one - I prefer to keep the patina of age and I can now see the serial number.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: KK Cobra 0.8cc

Re: KK Cobra 0.8cc

rsv1cox wrote:Like enjoying a fine wine a sip at a time sniffing the bouquet as I went along and thinking "this is going to be really good"..... I slowly scrolled down through Ian's text and pictures anticipating a beautifully rendered KK Cobra at the end. Instead, I get a container full of debris and goo and a "to be continued".

I think I've had some wines like that!

I think I've had some wines like that!That is a fascinating engine Ian. So much like a Cox unit but not quite. Yet many parts are similar and with same dimensions. If i had found one like that I would have been ready to bet that "Cobra" was a brand of aftermarket crankcases for Cox... I like the backplate design too. Is the cylinder a Cox one or interchangeable? We all know why Cox started to make the step-style cylinder but this one predates those by a few years. Very interesting indeed.

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: KK Cobra 0.8cc

Re: KK Cobra 0.8cc

I am certain that the cylinder on this is a Cox cylinder as the original pictures and adverts I have seen show a smooth lower cylinder - not stepped and a rounder profile on the fins.

However, the bottom thread is slightly longer than my other Cox cylinders (and I have a few!)and I tried fitting some of them and they got tight very quickly. I didn't bottom them out.

This cylinder screws in nicely. So I am not sure - there is little documentation on these and anything could have changed.

A Cox head fits perfectly, the reeds fit - the rear screws are 8 BA and the propeller screw is 5 BA.

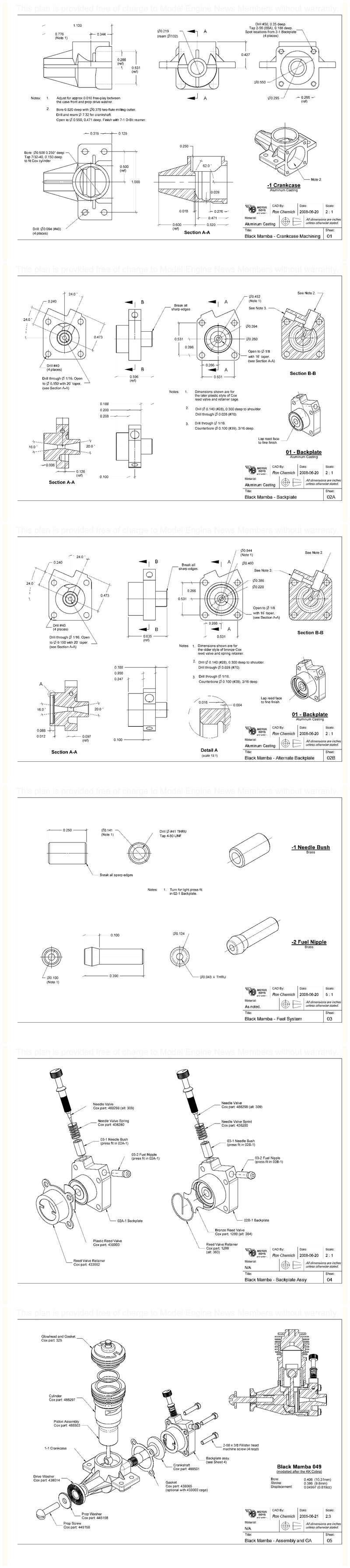

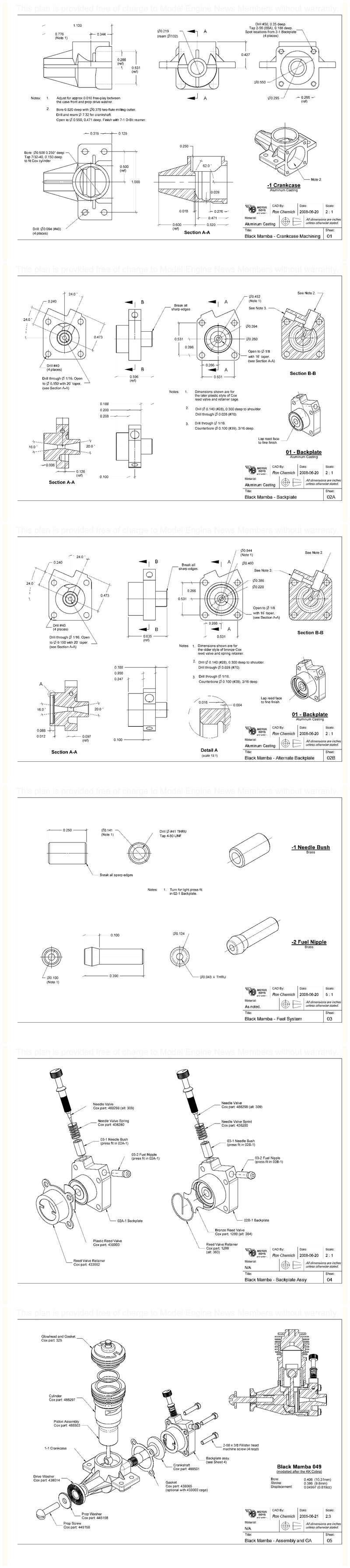

Many years ago - a similar crankcase casting was available for producing a "Black Mamba" from Cox parts. It is very similar to the Cobra.

However, the bottom thread is slightly longer than my other Cox cylinders (and I have a few!)and I tried fitting some of them and they got tight very quickly. I didn't bottom them out.

This cylinder screws in nicely. So I am not sure - there is little documentation on these and anything could have changed.

A Cox head fits perfectly, the reeds fit - the rear screws are 8 BA and the propeller screw is 5 BA.

Many years ago - a similar crankcase casting was available for producing a "Black Mamba" from Cox parts. It is very similar to the Cobra.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: KK Cobra 0.8cc

Re: KK Cobra 0.8cc

Hmmm... I've never seen that Black Mamba case. I'd love to find one someday and make a beam mounted Bee (not counting the Queen Bee). Looking at the drawing, it seems that it'd be more efficient to just produce the case and forget about the backplate. Cheaper and easier to just use a Cox backplate assembly. I can't imagine the Mamba backplate could be much more efficient than a Cox backplate. I guess the only advantage would be that the whole engine is metal. Sort of like a Spook engine. Now I have to get out my calipers and see if the Mamba backplate mounting holes match a Cox crankcase. I'll have to keep an eye out on the usual auction sites for a Mamba case.

The Searcher Mark

The Searcher Mark

batjac- Diamond Member

Posts : 2375

Join date : 2013-05-22

Age : 61

Location : Broken Arrow, OK, USA

Re: KK Cobra 0.8cc

Re: KK Cobra 0.8cc

Nice job Ian as expected.

I find the "Blacking solution" interesting, probably very similar to the gun "blue" that I use. Same with the "Dewatering oil" something like WD-40 that "drives out moisture".

Bob

I find the "Blacking solution" interesting, probably very similar to the gun "blue" that I use. Same with the "Dewatering oil" something like WD-40 that "drives out moisture".

Bob

rsv1cox- Top Poster

Posts : 11251

Join date : 2014-08-18

Location : West Virginia

Re: KK Cobra 0.8cc

Re: KK Cobra 0.8cc

rsv1cox wrote:Nice job Ian as expected.

I find the "Blacking solution" interesting, probably very similar to the gun "blue" that I use. Same with the "Dewatering oil" something like WD-40 that "drives out moisture".

Bob

The "Dewatering Oil" is very similar to WD40 but has a bit more of an oil content to seal the blackening.

The "Blackening solution" isn't "Gun Blue". It forms Black Oxide on the steel.

"Black oxide or blackening is a conversion coating for ferrous materials, stainless steel, copper and copper based alloys, zinc, powdered metals, and silver solder.It is used to add mild corrosion resistance, for appearance and to minimize light reflection.To achieve maximal corrosion resistance the black oxide must be impregnated with oil or wax. One of its advantages over other coatings is its minimal buildup."

It is expensive

http://www.frost.co.uk/frost-metal-blacking-kit-and-solutions.html

but I have had these liquids for many years now and use it to protect and enhance all sorts of things - homemade lathe accessories, tools ....... as well as engine cylinders. It goes a long way and is the only way I know to bring rusty old cylinders back to life.

They seem to stay rust free when protected but one of the restorers I know uses boiled linseed oil after the dewatering fluid. He then heats that with a torch and gets a glossy and quite hard finish. I keep meaning to try that.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: KK Cobra 0.8cc

Re: KK Cobra 0.8cc

This is the product that I use Ian, contains basically the same ingredient (selenious acid) plus some others. Your Blacking solution may mix them differently. I don't know though, "Selenium" and "Selenious" may be completely different animals or just English variations of the same thing.

I find Oxpho Blue adequate for some applications other than guns. It does an excellent job on Cox cylinders as the steel in them seems to accept it readily. Cold blue is not the best, for serious work I always bring those to a gunsmith that uses the hot blue process.

It is expensive, 32 oz runs $45.00 USD.

Bob

I find Oxpho Blue adequate for some applications other than guns. It does an excellent job on Cox cylinders as the steel in them seems to accept it readily. Cold blue is not the best, for serious work I always bring those to a gunsmith that uses the hot blue process.

It is expensive, 32 oz runs $45.00 USD.

Bob

rsv1cox- Top Poster

Posts : 11251

Join date : 2014-08-18

Location : West Virginia

Re: KK Cobra 0.8cc

Re: KK Cobra 0.8cc

It is probably the same price all told. The kit price is all three liquids.

They are not quite the same mix as the the stuff I have produces a very black black.

"Bluing is a passivation process in which steel is partially protected against rust, and is named after the blue-black appearance of the resulting protective finish. True gun bluing is an electrochemical conversion coating resulting from an oxidizing chemical reaction with iron on the surface selectively forming magnetite (Fe3O4), the black oxide of iron. Black oxide provides minimal protection against corrosion, unless also treated with a water-displacing oil to reduce wetting and galvanic action. A distinction can be made between traditional bluing and some other more modern black oxide coatings, although bluing is a subset of black oxide coatings."

The hot treatment is definitely beyond DIY.

"The "Hot" process is an alkali salt solution, referred to as "Traditional Caustic Black", that is typically done at an elevated temperature, 135 to 155 °C (275 to 311 °F). This method was adopted by larger firearm companies for large scale, more economical bluing. It does provide good rust resistance which is improved with the use of oil."

I think that would be a skin remover!

Gun blue kits in the UK are very expensive.

These are 3 ounce bottles in this kit!

http://www.ebay.co.uk/itm/Birchwood-Casey-Perma-Blue-Liquid-Gun-Blue-Kit-Quick-Easy-Gun-Blueing/162092183572?_trksid=p2141725.c100338.m3726&_trkparms=aid%3D222007%26algo%3DSIC.MBE%26ao%3D1%26asc%3D20150313114020%26meid%3D3de2427bd9d8474ca3c3dcba4a151017%26pid%3D100338%26rk%3D3%26rkt%3D28%26sd%3D161776708913

They are not quite the same mix as the the stuff I have produces a very black black.

"Bluing is a passivation process in which steel is partially protected against rust, and is named after the blue-black appearance of the resulting protective finish. True gun bluing is an electrochemical conversion coating resulting from an oxidizing chemical reaction with iron on the surface selectively forming magnetite (Fe3O4), the black oxide of iron. Black oxide provides minimal protection against corrosion, unless also treated with a water-displacing oil to reduce wetting and galvanic action. A distinction can be made between traditional bluing and some other more modern black oxide coatings, although bluing is a subset of black oxide coatings."

The hot treatment is definitely beyond DIY.

"The "Hot" process is an alkali salt solution, referred to as "Traditional Caustic Black", that is typically done at an elevated temperature, 135 to 155 °C (275 to 311 °F). This method was adopted by larger firearm companies for large scale, more economical bluing. It does provide good rust resistance which is improved with the use of oil."

I think that would be a skin remover!

Gun blue kits in the UK are very expensive.

These are 3 ounce bottles in this kit!

http://www.ebay.co.uk/itm/Birchwood-Casey-Perma-Blue-Liquid-Gun-Blue-Kit-Quick-Easy-Gun-Blueing/162092183572?_trksid=p2141725.c100338.m3726&_trkparms=aid%3D222007%26algo%3DSIC.MBE%26ao%3D1%26asc%3D20150313114020%26meid%3D3de2427bd9d8474ca3c3dcba4a151017%26pid%3D100338%26rk%3D3%26rkt%3D28%26sd%3D161776708913

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Wow

Wow

ian1954 wrote:Tis now finished and ready to run.

With a used engine like this one - I prefer to keep the patina of age and I can now see the serial number.

I beautiful restoration there Ian, keep up the amazing work!!

BUZZZ003- AUjack2003

- Posts : 13

Join date : 2016-11-14

Age : 21

Location : Noosa, Queensland, Australia

Question about the bluing/blacking

Question about the bluing/blacking

Ian, do you let the blacking solution into the cylinder interior, or do you block it off with something? If you do let it coat the bore, do you have to remove it somehow? Won't it interfere with the bore/cylinder clearance?

Sorry for the 20 questions. I have a medallion .09 cylinder waiting for the same treatment.

Sorry for the 20 questions. I have a medallion .09 cylinder waiting for the same treatment.

VUgearhead- Gold Member

- Posts : 155

Join date : 2013-07-02

Age : 57

Location : Boynton Beach, FL

Re: KK Cobra 0.8cc

Re: KK Cobra 0.8cc

VUgearhead wrote:Ian, do you let the blacking solution into the cylinder interior, or do you block it off with something? If you do let it coat the bore, do you have to remove it somehow? Won't it interfere with the bore/cylinder clearance?

Sorry for the 20 questions. I have a medallion .09 cylinder waiting for the same treatment.

No - I don't let it coat the bore. I usually use a tight fitting nylon rod that I have turned to size but I couldn't find it.

On this one I used two old Cox pistons - one without the con rod - and that worked.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: KK Cobra 0.8cc

Re: KK Cobra 0.8cc

Being less careful than Ian, I immerse the whole cylinder in the Oxpho blue (which really is black) then using fine steel wool and a light oil I remove the finish from the cylinder internals. But I think the product that I'm using is less probably effective than Ian's.

Bob

Bob

rsv1cox- Top Poster

Posts : 11251

Join date : 2014-08-18

Location : West Virginia

Re: KK Cobra 0.8cc

Re: KK Cobra 0.8cc

Nice restore Ian , The cly came out really good , Bob turned me on to the blueing but i use something a little cheaper ...  works good enough for me >

works good enough for me >

works good enough for me >

works good enough for me >

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: KK Cobra 0.8cc

Re: KK Cobra 0.8cc

When i did it i didnt steel wool the inside it seem to still fit just fine , although i didn't run that engine ? I was wondering about that but don't have a way to keep the blueing from getting into the cly. sleeve .rsv1cox wrote:Being less careful than Ian, I immerse the whole cylinder in the Oxpho blue (which really is black) then using fine steel wool and a light oil I remove the finish from the cylinder internals. But I think the product that I'm using is less probably effective than Ian's.

Bob

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: KK Cobra 0.8cc

Re: KK Cobra 0.8cc

I don't immerse the cylinder in the solution (I use Tetra-Gun). I just paint it on the outside with a small modelling brush. I don't think that it would do any harm on the cylinder bore anyway.

Rod.

Rod.

Oldenginerod- Top Poster

- Posts : 4018

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: KK Cobra 0.8cc

Re: KK Cobra 0.8cc

Fantastic post and restoration Ian, I am very lucky to find one of this rare first Bristish glow engine, of course seem based COX engines, my Cobra has a poor compresion, it run but not increase to top speed, I don´t try to mount new cox piston for example, I like also your blacking liquid product, I have some cox engines that are necessary blacking cylinders.

Soon I post pics and video run.

Adrian Duncan article:

http://www.modelenginenews.org/ad/kkcobra.html

Soon I post pics and video run.

Adrian Duncan article:

http://www.modelenginenews.org/ad/kkcobra.html

Re: KK Cobra 0.8cc

Re: KK Cobra 0.8cc

thats a good looking little dude , good job on the restore Ian and good luck with yours Jim

akjgardner- Diamond Member

Posts : 1602

Join date : 2014-12-28

Age : 65

Location : Greensberg Indiana

Re: KK Cobra 0.8cc

Re: KK Cobra 0.8cc

getback wrote:When i did it i didnt steel wool the inside it seem to still fit just fine , although i didn't run that engine ? I was wondering about that but don't have a way to keep the blueing from getting into the cly. sleeve .rsv1cox wrote:Being less careful than Ian, I immerse the whole cylinder in the Oxpho blue (which really is black) then using fine steel wool and a light oil I remove the finish from the cylinder internals. But I think the product that I'm using is less probably effective than Ian's.

Bob

I typically use earbuds to apply the gunblue on the cylinder exterior. I remember once inadvertently moistening the dry cylinder wall near the exhaust port and the piston then moving a bit tight but that small spot soon wore off. If the cylinder is oily inside then the gunblue does not oxidize the surface.

balogh- Top Poster

Posts : 4959

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Page 1 of 2 • 1, 2

Similar topics

Similar topics» *Cox Engine of The Month* Submit your pictures! -March 2020-

» Reed Speed qualifying photos... Post em if ya got em. (2014)

» Profile P-39, what do you think? A nip here a tuck there........

» OK boyz, here's some red meat on Ebay

» Just received the cobra

» Reed Speed qualifying photos... Post em if ya got em. (2014)

» Profile P-39, what do you think? A nip here a tuck there........

» OK boyz, here's some red meat on Ebay

» Just received the cobra

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules