Log in

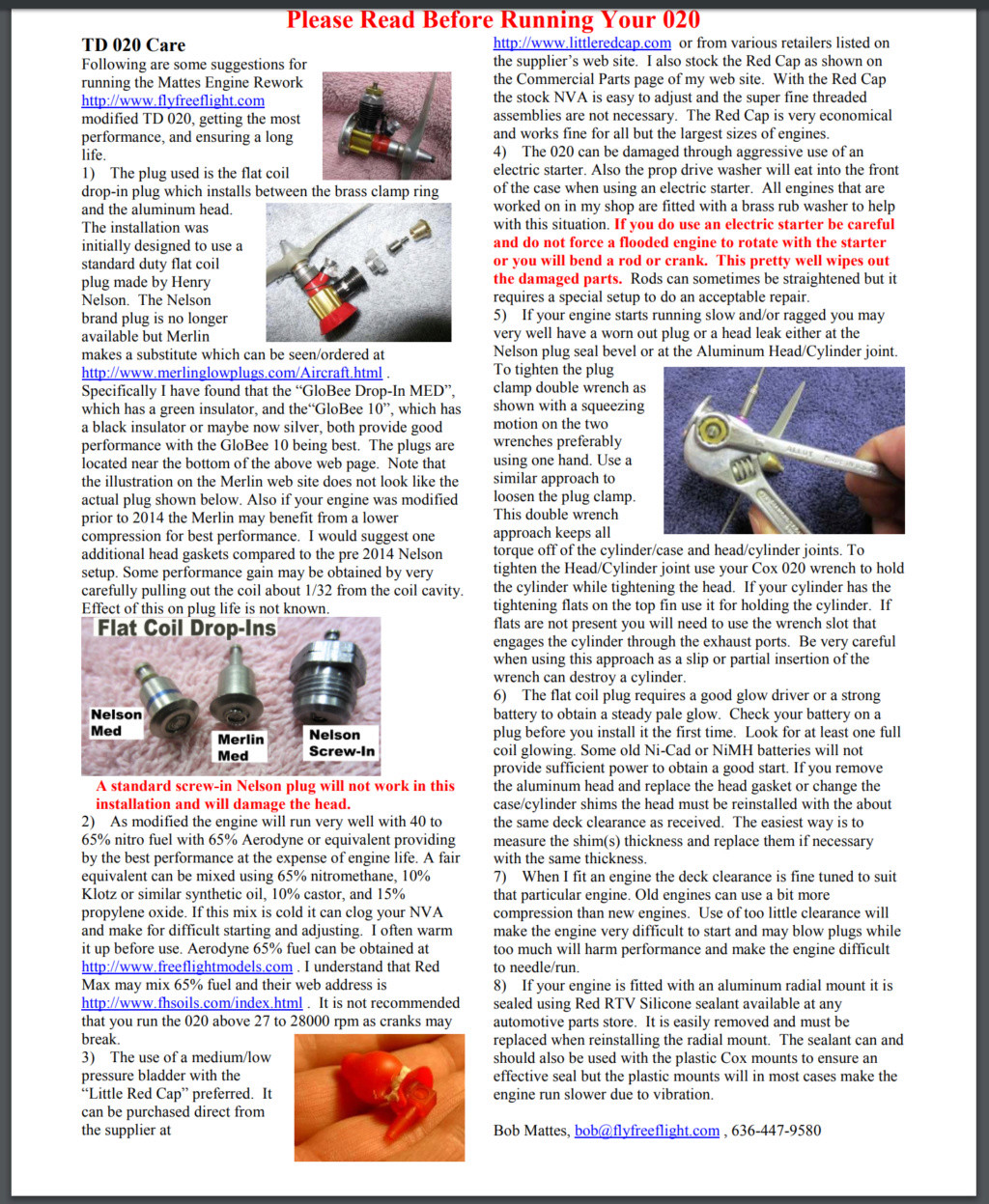

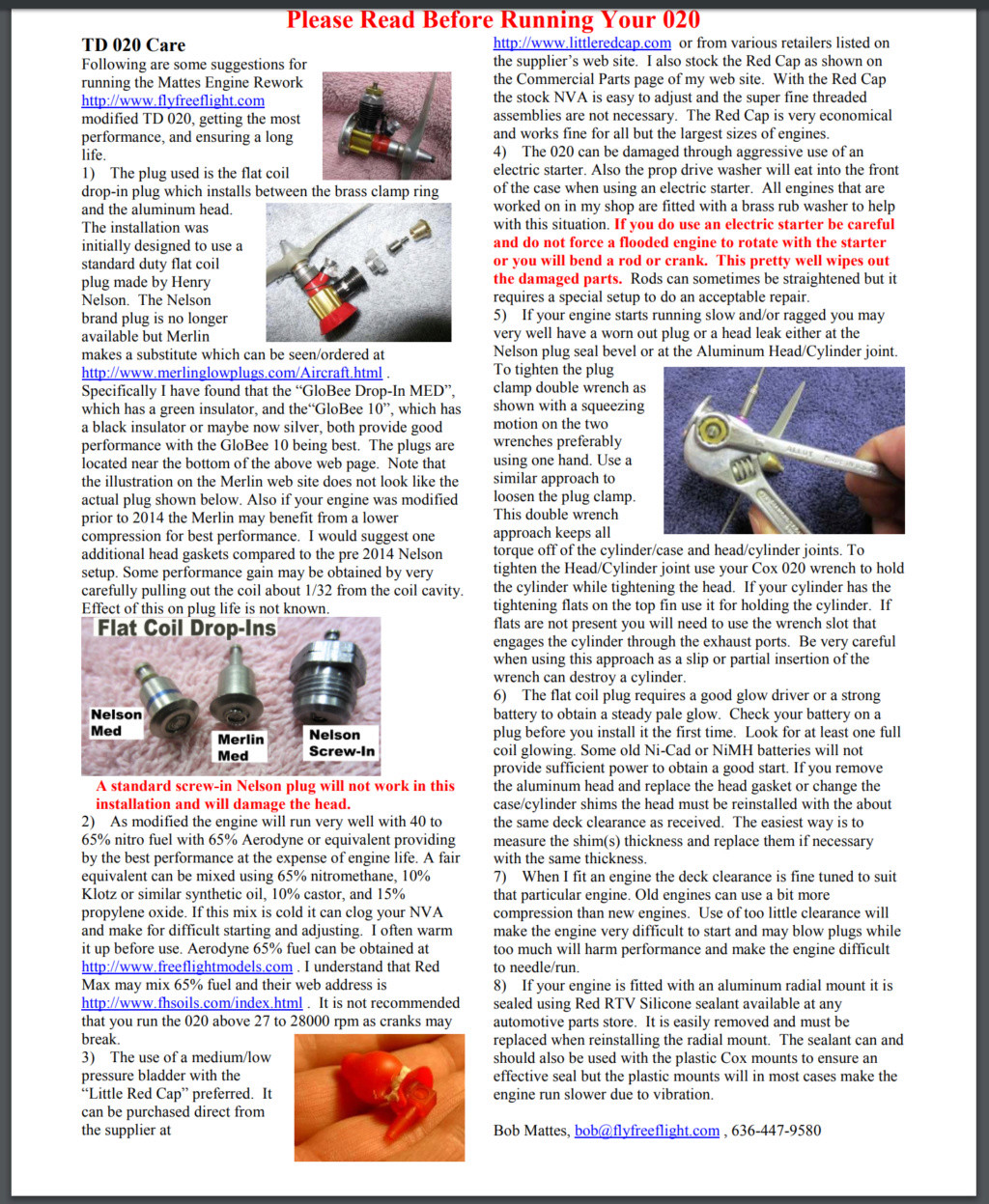

Search

Latest topics

» Purchased the last of any bult engines from Ken Enyaby sosam117 Today at 8:15 am

» TEE DEE Having issues

by balogh Today at 7:42 am

» Retail price mark-up.. how much is enough?

by rsv1cox Today at 7:36 am

» Cox films/videos...

by Coxfledgling Today at 4:46 am

» My N-1R build log

by roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

Cox Engine of The Month

Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Page 23 of 30

Page 23 of 30 •  1 ... 13 ... 22, 23, 24 ... 26 ... 30

1 ... 13 ... 22, 23, 24 ... 26 ... 30

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Yes I have been asking for RC carbs for the .010 and .020 there has been discussion on the design

how to make it cost effective and functional. There will be a muffler for the .020 displacement in

general allowing a conventional pressure tap. There is also something in the works for Pee Wee beyond

having a muffler. Aluminum parts aid in cooling, low weight and solid connection to the air frame helps

pick up some rpm to help the engine sing.

A good example of this is this test vid less the RC carb. The goal is to provide good running

engines reliable as possible for successful steady running strong pulling powered flights all the

way to the very last drop of fuel.

Published on Sep 29, 2018

HQ Carbon 3.6 x 4.5N Prop

Static Hold: 24,870 rpm / 106 mph Pitch Speed / .083 hp / 62w

how to make it cost effective and functional. There will be a muffler for the .020 displacement in

general allowing a conventional pressure tap. There is also something in the works for Pee Wee beyond

having a muffler. Aluminum parts aid in cooling, low weight and solid connection to the air frame helps

pick up some rpm to help the engine sing.

A good example of this is this test vid less the RC carb. The goal is to provide good running

engines reliable as possible for successful steady running strong pulling powered flights all the

way to the very last drop of fuel.

Published on Sep 29, 2018

HQ Carbon 3.6 x 4.5N Prop

Static Hold: 24,870 rpm / 106 mph Pitch Speed / .083 hp / 62w

1/2A Nut- Top Poster

- Posts : 3538

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

How about a flat slide carb, but they are better described as a

flat slide fuel injection.

Bill M.

Where is your carb discussion at?

I was under the impression that max torque/rpm is gained by

using a wide open throttle (venturi) and a throttled exhaust?

flat slide fuel injection.

Bill M.

Where is your carb discussion at?

I was under the impression that max torque/rpm is gained by

using a wide open throttle (venturi) and a throttled exhaust?

wmazz- Bronze Member

- Posts : 40

Join date : 2018-12-31

Location : Riverside CA.

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Hi Bill,

The goal is goo control / tank pressure and throttle. A exhaust sleeve works well

but no control over the oil spray. Small RC planes can do without getting castor

splashed all over the airframe it just degrades them over time. Barrel type carbs

are easy to make and to introduce a spray bar to atomize the air / fuel mix.

Typically any engine with open exhaust will yield good rpm, however with the

right muffler design and pressure tap we can see gains. Same goes for tuned pipes.

Here is the link to the other thread:

https://www.coxengineforum.com/t11610p125-cnc-aluminum-010-to-15-engine-parts-prototype-testing?highlight=backplates

The goal is goo control / tank pressure and throttle. A exhaust sleeve works well

but no control over the oil spray. Small RC planes can do without getting castor

splashed all over the airframe it just degrades them over time. Barrel type carbs

are easy to make and to introduce a spray bar to atomize the air / fuel mix.

Typically any engine with open exhaust will yield good rpm, however with the

right muffler design and pressure tap we can see gains. Same goes for tuned pipes.

Here is the link to the other thread:

https://www.coxengineforum.com/t11610p125-cnc-aluminum-010-to-15-engine-parts-prototype-testing?highlight=backplates

1/2A Nut- Top Poster

- Posts : 3538

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

I don't see any reason that a throttle exhaust needs to use

the sleeve. Over the years I have seen exhaust restrictors

near the piston and far away from the piston. You should be

able to use a barrel or slide valve in the middle or end of a

muffler.

Is crankcase pressure (CP) with a 1-way valve to supply the

carb an option?

the sleeve. Over the years I have seen exhaust restrictors

near the piston and far away from the piston. You should be

able to use a barrel or slide valve in the middle or end of a

muffler.

Is crankcase pressure (CP) with a 1-way valve to supply the

carb an option?

wmazz- Bronze Member

- Posts : 40

Join date : 2018-12-31

Location : Riverside CA.

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

I think the "need" with COX engines to use sleeves as exhaust restrictors is dictated by the lack of stock, barrel type mufflers which were only made for the 049/050/051 and 09 size TeeDee and Medallion engines (of which only the 049 Medallion muffler acts like an efficient controllable throttle) but nothing like a barrel type muffler for 010 and 020 size engines, acting as an efficient exhaust throttle were ever made as stock by COX.

balogh- Top Poster

Posts : 4959

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Hi Bill,

Crank case pressure is good for full throttle runs. If with a RC carb or

sleeve dropped to idle the pressure push with the NV adjust for full

throttle can cause a very rich idle.

Muffler pressure rises and drops with the rpm much smoother transition

to low idle. I have some exhaust valve types they are ok but some designs

tend to be a bit bulky / heavy. The down fall is in the open state most of the

designs are loud. Restricting the exhaust restricts the piston and builds heat

during the transition. A RC carb does not put strain on the mechanical movements

of engine.

Crank case pressure is good for full throttle runs. If with a RC carb or

sleeve dropped to idle the pressure push with the NV adjust for full

throttle can cause a very rich idle.

Muffler pressure rises and drops with the rpm much smoother transition

to low idle. I have some exhaust valve types they are ok but some designs

tend to be a bit bulky / heavy. The down fall is in the open state most of the

designs are loud. Restricting the exhaust restricts the piston and builds heat

during the transition. A RC carb does not put strain on the mechanical movements

of engine.

1/2A Nut- Top Poster

- Posts : 3538

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

1/2A Nut wrote:

Restricting the exhaust restricts the piston and builds heat during the

transition.

It sure does, and it can lead to detonation. But surprisingly detonation

is rare, unless the engine is wot with a restrictive muffler or pipe.

1/2A Nut wrote:

Crank case pressure is good for full throttle runs. If with a RC carb or

sleeve dropped to idle the pressure push with the NV adjust for full

throttle can cause a very rich idle.

But you are not swapping parts from another rc engine. You are

actively trying to design your own carb, and therefore you are

not restricted by normal r/c methods.

My first post is a good example. If you combine a cylinder with SPI

that was designed to run an open exhaust, and then put a muffler

on it, The benefits of the SPI are eliminated.

But when you are modifying your own parts, a combination can be

reached that allows the SPI and muffler to work together.

I suggested a flat slide carb because they are easy to build. We

used to use flat slide carbs with crankcase pressure, and a remote

needle valve that was controlled by a separate servo. Engine tuning

was done with the transmitter by linking the throttle servo and the

remote needle valve servo together.

With today's computer radio's it is possible to adjust the remote

needle valve to open at a different rate than the throttle servo.

You would need to build a smaller version of this remote NV, or

modify it for the small engines.

Bill M.

wmazz- Bronze Member

- Posts : 40

Join date : 2018-12-31

Location : Riverside CA.

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Yes I have used remote NV adjustable by servo to fine tune outrigger hydro engines

that run on tuned pipes. Unloaded on the water you get the water born elements producing

variance from startup in the pits. Cooler layer of dense air so close to the water. The pipe runs

cooler and this requires on the spot fuel / air mix adjusting as an example.

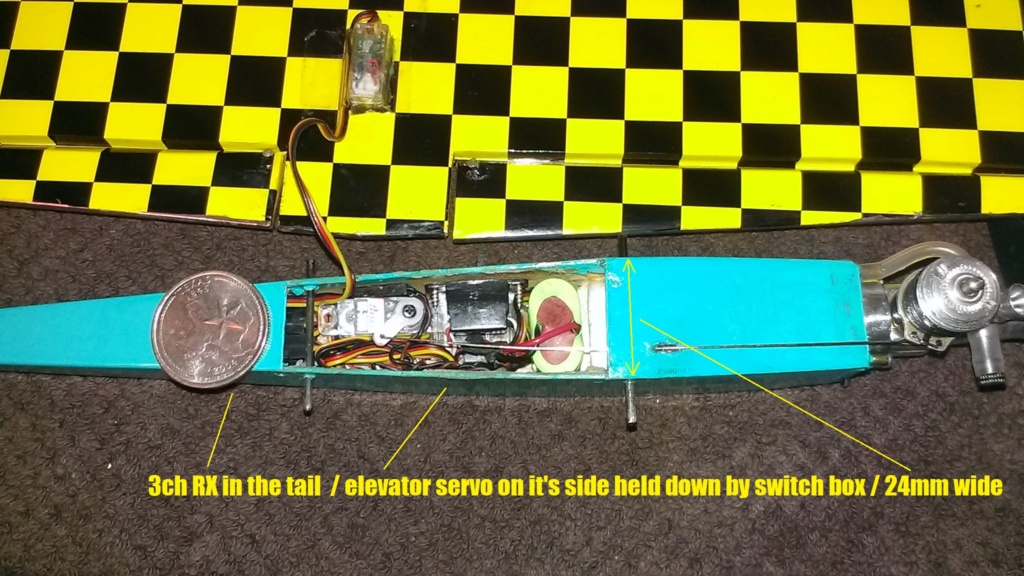

Here is the inside of the smallest TD .020 3ch. plane I have, note quarter for size reference and

24mm width at the widest point. Ready to fly 3.4oz

that run on tuned pipes. Unloaded on the water you get the water born elements producing

variance from startup in the pits. Cooler layer of dense air so close to the water. The pipe runs

cooler and this requires on the spot fuel / air mix adjusting as an example.

Here is the inside of the smallest TD .020 3ch. plane I have, note quarter for size reference and

24mm width at the widest point. Ready to fly 3.4oz

1/2A Nut- Top Poster

- Posts : 3538

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Slightly off topic - Where did you get the TD 020 bullet spinner?

Many Thanks,

=Adrian=

Many Thanks,

=Adrian=

Ada99- Moderate Poster

- Posts : 28

Join date : 2018-07-18

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

https://www.ebay.com/itm/Custom-Cox-Tee-Dee-020-0-33cc-Spinner-and-stud-Cox-Model-Engine/372611400730?hash=item56c15ec41a:g:QKYAAOSw2Qxcc1w2:rk:10 0

0

1/2A Nut- Top Poster

- Posts : 3538

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

We used the flat slide carbs and remote needle valves on our giant scale (80 to 160cc

w/25% nitro) Reno pylon racers. We adjusted them on the ground, but we could also

tinker with the settings later because we had data acquisition or telemetry to a laptop.

We also used a radar gun to measure mph and I carried a weather station with me where

ever we tested or raced.

Perhaps you could increase your performance with some basic data acquisition. Depending

on how your back plate was machined, you may be able to use a Melexis 90217 as a gear

tooth sensor and measure as the big end pin & connecting rod rotate past the hall sensor.

You could also use a Max31855 (a max31856 is not necessary) and a type k thermocouple

to measure cylinder head temp instead of exhaust temp. There is a few good 3.3v micro

controllers out there (if you are limited to a 1S lipo), like the Arduino Pro Mini (8Mhz), Maple

Mini, Blue Pill, and the Parallax Propeller 1.

With these sensors you could measure rpm, +/- acceleration, determine where peak HP is

located (maybe peak torque), Improve your propellers, tuned pipe, and later a PID system

to regulate the fuel system.

I used to run egt's and cht's, but I found CHT provided reliable tuning data over an EGT

when an engine has small a BDT' We used to run cht at 300', but we found best performance

at 330'

A small Arduino weather station would also help with your test data. The pylon racers

would gain 15 to 20 mph on hot days because of the lower air density. We would get

spectacular rpm and mph data, despite loosing 15 to 20% HP **** to the hot weather.

Bill M.

**** using the SAE correction factor as a guideline.

w/25% nitro) Reno pylon racers. We adjusted them on the ground, but we could also

tinker with the settings later because we had data acquisition or telemetry to a laptop.

We also used a radar gun to measure mph and I carried a weather station with me where

ever we tested or raced.

Perhaps you could increase your performance with some basic data acquisition. Depending

on how your back plate was machined, you may be able to use a Melexis 90217 as a gear

tooth sensor and measure as the big end pin & connecting rod rotate past the hall sensor.

You could also use a Max31855 (a max31856 is not necessary) and a type k thermocouple

to measure cylinder head temp instead of exhaust temp. There is a few good 3.3v micro

controllers out there (if you are limited to a 1S lipo), like the Arduino Pro Mini (8Mhz), Maple

Mini, Blue Pill, and the Parallax Propeller 1.

With these sensors you could measure rpm, +/- acceleration, determine where peak HP is

located (maybe peak torque), Improve your propellers, tuned pipe, and later a PID system

to regulate the fuel system.

I used to run egt's and cht's, but I found CHT provided reliable tuning data over an EGT

when an engine has small a BDT' We used to run cht at 300', but we found best performance

at 330'

A small Arduino weather station would also help with your test data. The pylon racers

would gain 15 to 20 mph on hot days because of the lower air density. We would get

spectacular rpm and mph data, despite loosing 15 to 20% HP **** to the hot weather.

Bill M.

**** using the SAE correction factor as a guideline.

wmazz- Bronze Member

- Posts : 40

Join date : 2018-12-31

Location : Riverside CA.

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Good info / thoughts Bill

Weight of any onboard sensors / loggers are possible starting with the .8cc displacements

I use audio software to read real time rpm as the plane passes in front of the camera mic

sub 10ft. generally. I have used a small 11g camera / mic onboard with a 1.2cc engine to

varify my POV data with the onboard data, the onboard was retired as the data was the same

during the passes right in front of me, the benefit of open field flying with no one around me I

can sweep in to capture the top rpm from a shallow dive to near level pass in front of me.

As of last year I started using a tripod mounted radar gun that stays on and holds the current pass

myself and the POV camera picks up on the readings after landing I can display the best reading.

I have but not used a 24" LED display monitor / wifi to the radar locks best read in the right corner

of the screen and displays last pass on main portion of the screen.

The video camera is set up to monitor both plane and readings in the sweet zone when I am making

the best pass by me. I generate momentum as shown in the example vid below.

Knowing prop size used I can calculate unloaded performance and reference it to static

performance on the bench. There I can determine how the weight / drag of the plane is influencing

the rpm numbers in the air then mod props to eek out more speed at the camera. After exhausting

the planes abilities with the given engine used I can do design mods for the next build.

I have 3 gps loggers the smallest has been used with a 1.2cc engine too big for .8cc engines currently

on the hunt for a 12g logger small enough for .8cc although it is just a pacifier as I am only interested

in ground speed as the plane passes in front of me. Radar has already confirm the data reached with

the audio app.

Results:

NANO III / 9oz / 28" span / APC 4.22x5.5N

Best pass 26,647 rpm / 139 mph prop speed

Static Peak: 20,370 rpm / .106hp / 79w / 106 mph PS / 6oz thrust

1oz fuel / 25% nitro / 20 castor

With speed, the sound follows behind the plane neat effect.

Checked all passes found the best per posted vid:

Per Audio RPM Gauge 26,647

Per Prop Calc 139 mph

Per Doppler Wav. Scope software 136 mph / 219 Kp/h

Here is the redesign waiting on good sunny day anything over 70F will test.

Reduces size / weight and added a tuned pipe. Non SPI stock 145 deg. timing

TD .050 the manifold is the best design I have ever seen for a TD. It does have

a bit of refinement needed with the cylinder fit and O ring used to improve sealing.

The aluminum manifold fit has to be tight in cold state so when heated there are no losses.

I plan to show what is possible with a stock engine then step the timing up to 160 deg.

Bench testing has shown improved power to the prop vs a stock muffler and pressure tap.

Published on Jan 12, 2019

1st. test on the NANO-X plane / with backplate pressure.

HQ 4 x 4.5 Peak Static: 26,086 rpm / 111 mph pitch speed

.147hp / 110w / 7.8oz thrust

Published on Dec 21, 2018

1st. bench test:

TD .051 / HQ carbon 4x4.5 / Profi 1/2A Tuned Pipe / MRP 30.8K rpm

Pipe's MRP is 7.5" set for unloaded state 132 mph pitch speed

Peak static 27,051 rpm / 115 mph / .164hp - 122w / 8.5oz thrust

CNC manifold with crank case backplate pressure tap

Size comparison the NX vs NIII

NIII has now done 37,710 rpm / 161 mph prop pitch speed unloaded with a modified 05 car engine shown.

Will get some good sunny day vid passes with it this season.

I use 20% castor but this summer will be trying 24% castor, last year I tested 55% nitro 103F on a Aug. day testing to thwart

the heat it did help but too much the engine went rich once in the air and hot on the ground chasing the needle valve.

You had to sag the engine at launch to compensate for the advantage in the air with a leaner NV. Too much fuss for me to

continue, however with 24% castor I may tip the scales and if a 45% nitro blend balance the ease of use with more consistency

in the air. One change must be the NV to fine thread 128 TPI with the slide carb type you mention will improve the airflow

and tuning. The inside walls of the venturi needs to be hour glass shaped to speed up air and cool the influx. The gate needs

to be above the choke point to reduce inhibition, settings and ease of construction. The backplate mount can have the standoff

for the NV built it. The new version of the backplate mounts for the TD .020 as an example provides room for the hall sensor

which could be within 2 mm of the neodymium pellet magnet in bedded into the flywheel as the bore in the backplate takes

it right to the crankpin. RPM can then be monitored if a small enough data logger is sourced. This of course is a luxury for such

a small engine. In conjunction with Accuweather app I can make note of readings by the airport I fly just outside the no fly zone

the large park field has been calculated to be 5.7 miles from the control tower. Could buy a digital infrared thermal meter to

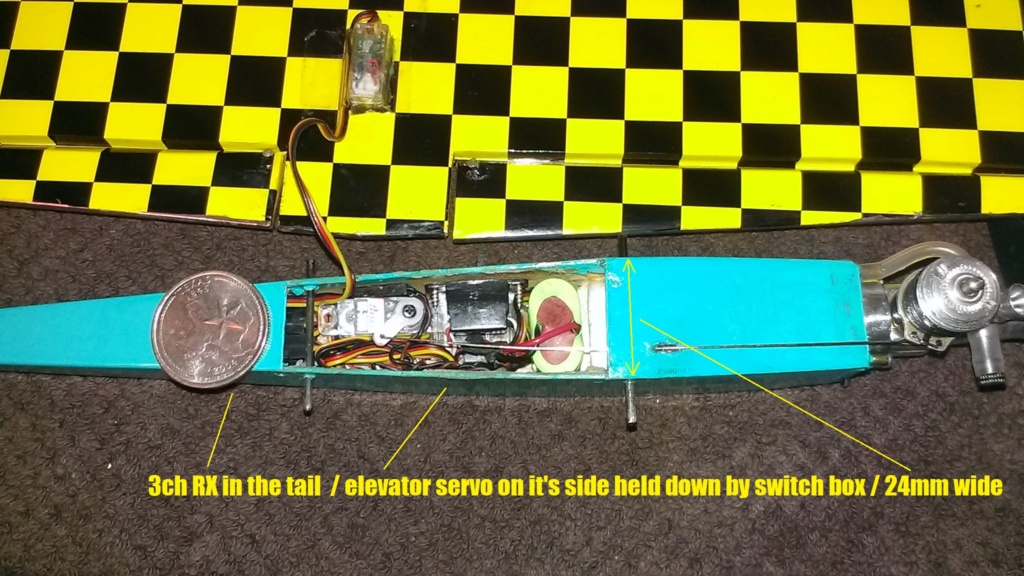

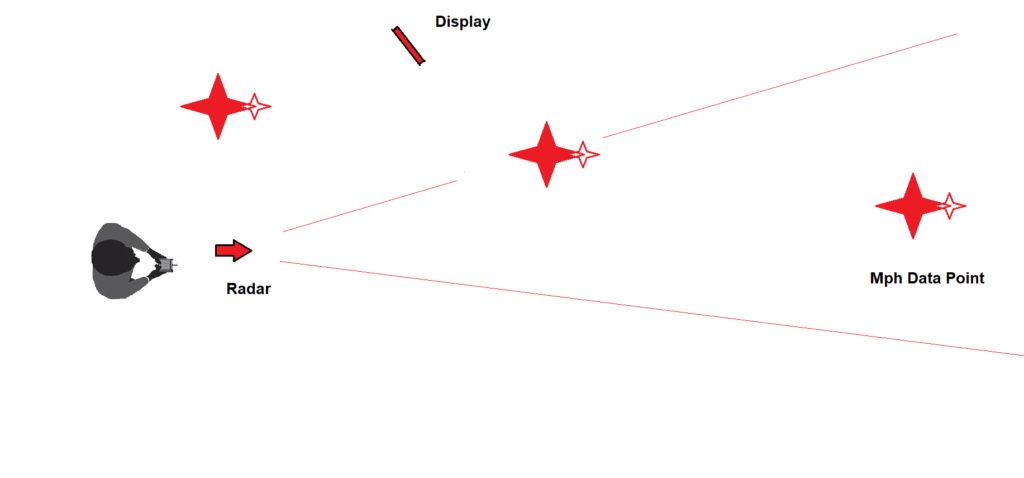

check head temps at launch for external no weight penalty data. Speaking of external here is my gear for radar.

Staged photo for effect / painting a picture:

I bought this carrier has a shoulder strap to walk it out to the middle of the flying field.

Limits of my field use thus far has been just the radar gun and tripod. I stand so close to radar I can actually catch a glimps

of the readings as the plane passes by. I prefer viewing off the right shoulder once the plane is locked into it's pass I have

a moment to see the number. The stand can take it to eye level where you really can't avoid not seeing the number

as the plane passes by me and the radar's gate. There is a audio board for sport use tells you the reading but not able to

read enough mph for my use shame that. The radar I have goes to 200 mph.

Here is the setup, I point the radar gun into the wind direction as the plane passes in front of the camera I will have the

mph readings displayed in view on the large display monitor. Will be good to setup this gear once I have found the best

selection of modified props to test. Normal days I get enough data off my camera and rpm readings to determine if the

efforts are going in the right direction.

Weight of any onboard sensors / loggers are possible starting with the .8cc displacements

I use audio software to read real time rpm as the plane passes in front of the camera mic

sub 10ft. generally. I have used a small 11g camera / mic onboard with a 1.2cc engine to

varify my POV data with the onboard data, the onboard was retired as the data was the same

during the passes right in front of me, the benefit of open field flying with no one around me I

can sweep in to capture the top rpm from a shallow dive to near level pass in front of me.

As of last year I started using a tripod mounted radar gun that stays on and holds the current pass

myself and the POV camera picks up on the readings after landing I can display the best reading.

I have but not used a 24" LED display monitor / wifi to the radar locks best read in the right corner

of the screen and displays last pass on main portion of the screen.

The video camera is set up to monitor both plane and readings in the sweet zone when I am making

the best pass by me. I generate momentum as shown in the example vid below.

Knowing prop size used I can calculate unloaded performance and reference it to static

performance on the bench. There I can determine how the weight / drag of the plane is influencing

the rpm numbers in the air then mod props to eek out more speed at the camera. After exhausting

the planes abilities with the given engine used I can do design mods for the next build.

I have 3 gps loggers the smallest has been used with a 1.2cc engine too big for .8cc engines currently

on the hunt for a 12g logger small enough for .8cc although it is just a pacifier as I am only interested

in ground speed as the plane passes in front of me. Radar has already confirm the data reached with

the audio app.

Results:

NANO III / 9oz / 28" span / APC 4.22x5.5N

Best pass 26,647 rpm / 139 mph prop speed

Static Peak: 20,370 rpm / .106hp / 79w / 106 mph PS / 6oz thrust

1oz fuel / 25% nitro / 20 castor

With speed, the sound follows behind the plane neat effect.

Checked all passes found the best per posted vid:

Per Audio RPM Gauge 26,647

Per Prop Calc 139 mph

Per Doppler Wav. Scope software 136 mph / 219 Kp/h

Here is the redesign waiting on good sunny day anything over 70F will test.

Reduces size / weight and added a tuned pipe. Non SPI stock 145 deg. timing

TD .050 the manifold is the best design I have ever seen for a TD. It does have

a bit of refinement needed with the cylinder fit and O ring used to improve sealing.

The aluminum manifold fit has to be tight in cold state so when heated there are no losses.

I plan to show what is possible with a stock engine then step the timing up to 160 deg.

Bench testing has shown improved power to the prop vs a stock muffler and pressure tap.

Published on Jan 12, 2019

1st. test on the NANO-X plane / with backplate pressure.

HQ 4 x 4.5 Peak Static: 26,086 rpm / 111 mph pitch speed

.147hp / 110w / 7.8oz thrust

Published on Dec 21, 2018

1st. bench test:

TD .051 / HQ carbon 4x4.5 / Profi 1/2A Tuned Pipe / MRP 30.8K rpm

Pipe's MRP is 7.5" set for unloaded state 132 mph pitch speed

Peak static 27,051 rpm / 115 mph / .164hp - 122w / 8.5oz thrust

CNC manifold with crank case backplate pressure tap

Size comparison the NX vs NIII

NIII has now done 37,710 rpm / 161 mph prop pitch speed unloaded with a modified 05 car engine shown.

Will get some good sunny day vid passes with it this season.

I use 20% castor but this summer will be trying 24% castor, last year I tested 55% nitro 103F on a Aug. day testing to thwart

the heat it did help but too much the engine went rich once in the air and hot on the ground chasing the needle valve.

You had to sag the engine at launch to compensate for the advantage in the air with a leaner NV. Too much fuss for me to

continue, however with 24% castor I may tip the scales and if a 45% nitro blend balance the ease of use with more consistency

in the air. One change must be the NV to fine thread 128 TPI with the slide carb type you mention will improve the airflow

and tuning. The inside walls of the venturi needs to be hour glass shaped to speed up air and cool the influx. The gate needs

to be above the choke point to reduce inhibition, settings and ease of construction. The backplate mount can have the standoff

for the NV built it. The new version of the backplate mounts for the TD .020 as an example provides room for the hall sensor

which could be within 2 mm of the neodymium pellet magnet in bedded into the flywheel as the bore in the backplate takes

it right to the crankpin. RPM can then be monitored if a small enough data logger is sourced. This of course is a luxury for such

a small engine. In conjunction with Accuweather app I can make note of readings by the airport I fly just outside the no fly zone

the large park field has been calculated to be 5.7 miles from the control tower. Could buy a digital infrared thermal meter to

check head temps at launch for external no weight penalty data. Speaking of external here is my gear for radar.

Staged photo for effect / painting a picture:

I bought this carrier has a shoulder strap to walk it out to the middle of the flying field.

Limits of my field use thus far has been just the radar gun and tripod. I stand so close to radar I can actually catch a glimps

of the readings as the plane passes by. I prefer viewing off the right shoulder once the plane is locked into it's pass I have

a moment to see the number. The stand can take it to eye level where you really can't avoid not seeing the number

as the plane passes by me and the radar's gate. There is a audio board for sport use tells you the reading but not able to

read enough mph for my use shame that. The radar I have goes to 200 mph.

Here is the setup, I point the radar gun into the wind direction as the plane passes in front of the camera I will have the

mph readings displayed in view on the large display monitor. Will be good to setup this gear once I have found the best

selection of modified props to test. Normal days I get enough data off my camera and rpm readings to determine if the

efforts are going in the right direction.

Last edited by 1/2A Nut on Sun Mar 03, 2019 5:25 am; edited 1 time in total

1/2A Nut- Top Poster

- Posts : 3538

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

I am in the process of writing more

I have a different opinion on tuning your pipes and modifying

the propellers. May I describe the process along with some

pictures to describe my opinion. It is how I tune larger engines

and is contrary to normal aircraft tuning????

That is very impressive! for a single person. It took 3

people to test the giant scale pylon racers. A pilot, A

spotter to tell the pilot when to turn, and a 3rd person

to operate the Radar, or monitor the telemetry.

If the slide carb is going to use pressure, there is no need

for a venturi. Just make the carb bore equal to the inside

diameter of the crankshaft.

There is a point where the id of the venturi will no longer make

a difference, even if a bell-mouth shape exsists.

Have you read any National Free Flight Society Symposiums?

NFFS 2009 Symposium:

Cox TD .020 Nelson Head Development and Other Improvement – Bob Mattes;

Secrets of Speed Engines – How to Make the Most of Your OCD – Scott Newkirk & Ron Bennett;

Free Flight Engine Optimization – Doug Galbreath;

NFFS 2011 Symposium:

Single Cylinder Engine Balance – John Shannon;

Bill M.

National Free Flight Society Symposiums

I have a different opinion on tuning your pipes and modifying

the propellers. May I describe the process along with some

pictures to describe my opinion. It is how I tune larger engines

and is contrary to normal aircraft tuning????

1/2A Nut wrote:

Here is the setup, I point the radar gun into the wind direction as the plane passes in front of the camera I will have the

mph readings displayed in view on the large display monitor. Will be good to setup this gear once I have found the best

selection of modified props to test. Normal days I get enough data off my camera and rpm readings to determine if the

efforts are going in the right direction.

That is very impressive! for a single person. It took 3

people to test the giant scale pylon racers. A pilot, A

spotter to tell the pilot when to turn, and a 3rd person

to operate the Radar, or monitor the telemetry.

1/2A Nut wrote:

One change must be the NV to fine thread 128 TPI with the slide carb type you mention will improve the airflow

and tuning.

If the slide carb is going to use pressure, there is no need

for a venturi. Just make the carb bore equal to the inside

diameter of the crankshaft.

1/2A Nut wrote:

The inside walls of the venturi needs to be hour glass shaped to speed up air and cool the influx.

There is a point where the id of the venturi will no longer make

a difference, even if a bell-mouth shape exsists.

Have you read any National Free Flight Society Symposiums?

NFFS 2009 Symposium:

Cox TD .020 Nelson Head Development and Other Improvement – Bob Mattes;

Secrets of Speed Engines – How to Make the Most of Your OCD – Scott Newkirk & Ron Bennett;

Free Flight Engine Optimization – Doug Galbreath;

NFFS 2011 Symposium:

Single Cylinder Engine Balance – John Shannon;

Bill M.

National Free Flight Society Symposiums

wmazz- Bronze Member

- Posts : 40

Join date : 2018-12-31

Location : Riverside CA.

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Hi Bill  yes feel free to add to the thread good info should be documented.

yes feel free to add to the thread good info should be documented.

I do have a Bob Mattes modified TD .020 engine along with a spare nelson plug adapter and

a handful of the small Nelson flat coil plug inserts no longer available.

I have read through this link but do not have a copy of the NFFS 2009 Symposium:

you can buy a copy as they become available for sale.

http://www.flyfreeflight.com/Site/Cox_020_Rework.html

I have saved the page as one day the link will no longer be good this information is worth saving

far too many dead links out there and photos that no longer open!

His vid APC 4.2x2 prop:

This is Bob Mattes doing a custom performance rework on a TD .020

APC 4.2 x 2 shown tuning a customers engine. Peak 26,001 rpm

9.2 oz thrust / .078hp / 58w /49.2 mph pitch speed / Nelson small insert plug.

Do need a good idle at the expense of top end performance, if the plane gets into trouble I want to throttle down

and recover / to trim surfaces, radio interference, windy weather, tip stalls, low fuel warning down wind etc crawl

backs to the pit area to land etc.

I am going to test the pipe without pressure next, I have removed the crank case backplate from Kirn Kraft and

replaced with a stock backplate. The test is to see how well it will idle and transition along with what loss of top

end rpm. With all the cold weather and wind is allowing me some extra experiments before the plane gets tossed

into some sunny blue sky.

I have bench tested the Profi 1/2A tuned pipe with high performance 05 car engines into 40's best went just past 50k rpm.

Best flown unloaded to 37,710 rpm / 161 mph prop pitch speed.

50k ish / converted car .05 car engine:

Custom crank first bench test:

Picco .85 cc / APC 4.2x4 / 29,473 rpm

This is the highest rpm I have allowed with a TD .049 thus far:

Published on May 7, 2016

TD .049 /SPI / Throttle Sleeve Ports Allow SPI function / Prop 4.1 x 4.1N / 30% Nitro

Static 24,790 rpm / 7.6oz thrust / .127hp / 94.74w / 96.2 mph / 6.1oz RTF

Unloaded 30,492 rpm best on Vid 1 / 118.4 mph per prop calc.

Doppler reading has it at 118mph per pass at 1:47mins into the vid.

Hard tank no pressure tap. 3.7g servos. Cox low compression plug

3mins 20sec of run time on 15cc tank. 16.5"x4" span wing 66sq. in.

The goal with the Profi pipe and Nano X is around 31k unloaded 4 x 5.5 prop / 162 mph prop pitch speed.

yes feel free to add to the thread good info should be documented.

yes feel free to add to the thread good info should be documented. I do have a Bob Mattes modified TD .020 engine along with a spare nelson plug adapter and

a handful of the small Nelson flat coil plug inserts no longer available.

I have read through this link but do not have a copy of the NFFS 2009 Symposium:

you can buy a copy as they become available for sale.

http://www.flyfreeflight.com/Site/Cox_020_Rework.html

I have saved the page as one day the link will no longer be good this information is worth saving

far too many dead links out there and photos that no longer open!

His vid APC 4.2x2 prop:

This is Bob Mattes doing a custom performance rework on a TD .020

APC 4.2 x 2 shown tuning a customers engine. Peak 26,001 rpm

9.2 oz thrust / .078hp / 58w /49.2 mph pitch speed / Nelson small insert plug.

Do need a good idle at the expense of top end performance, if the plane gets into trouble I want to throttle down

and recover / to trim surfaces, radio interference, windy weather, tip stalls, low fuel warning down wind etc crawl

backs to the pit area to land etc.

I am going to test the pipe without pressure next, I have removed the crank case backplate from Kirn Kraft and

replaced with a stock backplate. The test is to see how well it will idle and transition along with what loss of top

end rpm. With all the cold weather and wind is allowing me some extra experiments before the plane gets tossed

into some sunny blue sky.

I have bench tested the Profi 1/2A tuned pipe with high performance 05 car engines into 40's best went just past 50k rpm.

Best flown unloaded to 37,710 rpm / 161 mph prop pitch speed.

50k ish / converted car .05 car engine:

Custom crank first bench test:

Picco .85 cc / APC 4.2x4 / 29,473 rpm

This is the highest rpm I have allowed with a TD .049 thus far:

Published on May 7, 2016

TD .049 /SPI / Throttle Sleeve Ports Allow SPI function / Prop 4.1 x 4.1N / 30% Nitro

Static 24,790 rpm / 7.6oz thrust / .127hp / 94.74w / 96.2 mph / 6.1oz RTF

Unloaded 30,492 rpm best on Vid 1 / 118.4 mph per prop calc.

Doppler reading has it at 118mph per pass at 1:47mins into the vid.

Hard tank no pressure tap. 3.7g servos. Cox low compression plug

3mins 20sec of run time on 15cc tank. 16.5"x4" span wing 66sq. in.

The goal with the Profi pipe and Nano X is around 31k unloaded 4 x 5.5 prop / 162 mph prop pitch speed.

1/2A Nut- Top Poster

- Posts : 3538

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Will process this soon just came in the mail Cox .15 radial mount!

I plan on removing the beams and bench testing it prototype testing.

Shown with a APC 7x5 sport prop and Medallion throttle sleeve.

Unless you have a TD .15 it's hard to tell in the pic this thing is a TD .049 on steroids!

Also testing this GMark .030 at RCU turbo plug with 3 cooling fins and radial mount, here is the link:

http://www.rcuniverse.com/forum/1-2-1-8-airplanes-70/11645434-g-mark-061-prop-question-2.html

I plan on removing the beams and bench testing it prototype testing.

Shown with a APC 7x5 sport prop and Medallion throttle sleeve.

Unless you have a TD .15 it's hard to tell in the pic this thing is a TD .049 on steroids!

Also testing this GMark .030 at RCU turbo plug with 3 cooling fins and radial mount, here is the link:

http://www.rcuniverse.com/forum/1-2-1-8-airplanes-70/11645434-g-mark-061-prop-question-2.html

1/2A Nut- Top Poster

- Posts : 3538

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

...yes except the glow plug dimensions relative to the glow head it really could be seen as a 049 sTEEreoiDEE

...yes except the glow plug dimensions relative to the glow head it really could be seen as a 049 sTEEreoiDEE

balogh- Top Poster

Posts : 4959

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

1/2A Nut- Top Poster

- Posts : 3538

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

G Mark .030 - BENCH TESTING RESULTS:

https://www.youtube.com/watch?v=Hgblj--ZWjo&feature=youtu.be

Published on Apr 5, 2019

G Mark .030 / OS Turbo Plug RP6

Aluminum Radial Mount

3 cooling fin plug adapter with extended cooling via backplate.

Peak 21,398 rpm / .045hp - 34w / 5.2oz thrust / 51 mph pitch speed.

Excellent throttle response / big boost in power / 2 clicks rich.

25% nitro / 20% Castor / 73F / 652ft, from sea level.

Cox 4D x 2.5P / .020 prop

https://www.youtube.com/watch?v=Hgblj--ZWjo&feature=youtu.be

Published on Apr 5, 2019

G Mark .030 / OS Turbo Plug RP6

Aluminum Radial Mount

3 cooling fin plug adapter with extended cooling via backplate.

Peak 21,398 rpm / .045hp - 34w / 5.2oz thrust / 51 mph pitch speed.

Excellent throttle response / big boost in power / 2 clicks rich.

25% nitro / 20% Castor / 73F / 652ft, from sea level.

Cox 4D x 2.5P / .020 prop

Last edited by 1/2A Nut on Fri Apr 05, 2019 5:43 pm; edited 1 time in total

1/2A Nut- Top Poster

- Posts : 3538

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

G Mark .030 / Cox 4.5x2

https://www.youtube.com/watch?v=3tPDuYWEOMc&feature=youtu.be

Published on Apr 5, 2019

G Mark .030 / Cox 4.5D x 2P / OS RP6 Turbo Plug / Aluminum Radial Mount

Peak 21,237 rpm / .056hp - 42w / 8.5oz thrust / 40.2 mph pitch speed

25% Nitro / 20% castor oil

I expect this will unload to 26k ish / good for 50 mph pitch speed / mega thrust for acro.

Summary of 3 props tested:

https://www.youtube.com/watch?v=3tPDuYWEOMc&feature=youtu.be

Published on Apr 5, 2019

G Mark .030 / Cox 4.5D x 2P / OS RP6 Turbo Plug / Aluminum Radial Mount

Peak 21,237 rpm / .056hp - 42w / 8.5oz thrust / 40.2 mph pitch speed

25% Nitro / 20% castor oil

I expect this will unload to 26k ish / good for 50 mph pitch speed / mega thrust for acro.

Summary of 3 props tested:

1/2A Nut- Top Poster

- Posts : 3538

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Stock prop gets 16.75k Muffler Pressure tap and to 17.3k open exhaust per my test with stock plug.

Stock engine with muffler and the Cox 4.5x2 /17.72k / 34mph / 5.7oz thrust

The hop up parts have improved this engine dramatically / truly within it's displacement now.

it has exceeded a stock TD .020 making it a viable in between class engine to the .049.

Without muffler it is 11g more than a TD .020 with throttle ring. Both being RC engines the .03

can now be swapped in on a .020 plane for a boost in power. I have a new TD .020 Turbo plug

adapter looking for better results will test that next.

Note a perfect fit for a split carb body just slip over the cracked part first the APC

prop adapter will then compress the crack and press fit into place with authority.

A simple fix to a old age problem short of buying a new one this is perfect. Note

I used the larger of the two rings that come with 1/2A APC props. You have to

shave off a bit to match the slope of the carb body with a razor blade.

Stock engine with muffler and the Cox 4.5x2 /17.72k / 34mph / 5.7oz thrust

The hop up parts have improved this engine dramatically / truly within it's displacement now.

it has exceeded a stock TD .020 making it a viable in between class engine to the .049.

Without muffler it is 11g more than a TD .020 with throttle ring. Both being RC engines the .03

can now be swapped in on a .020 plane for a boost in power. I have a new TD .020 Turbo plug

adapter looking for better results will test that next.

Note a perfect fit for a split carb body just slip over the cracked part first the APC

prop adapter will then compress the crack and press fit into place with authority.

A simple fix to a old age problem short of buying a new one this is perfect. Note

I used the larger of the two rings that come with 1/2A APC props. You have to

shave off a bit to match the slope of the carb body with a razor blade.

1/2A Nut- Top Poster

- Posts : 3538

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

TEE DEE .15 Special Sleek Radial Mount Conversion!

Excellent fit and finish, robust radial mount for the monster Tee Dee .15 and Medallion engines available soon at

KamTechnik.com this will add improved cooling cleaner set up with better airflow around the crank case and reduce

weight over the conventional beam style bulky nylon engine mounts that require 8 screws. You really have to hold

one of these beasts in your hand to really get an idea of just how sexy clean this set up is! Simple mod all you need

is a bench grinder / buffing wheel and some hand files to feather down the last bits of the old beam mounts smooth.

Excellent fit and finish, robust radial mount for the monster Tee Dee .15 and Medallion engines available soon at

KamTechnik.com this will add improved cooling cleaner set up with better airflow around the crank case and reduce

weight over the conventional beam style bulky nylon engine mounts that require 8 screws. You really have to hold

one of these beasts in your hand to really get an idea of just how sexy clean this set up is! Simple mod all you need

is a bench grinder / buffing wheel and some hand files to feather down the last bits of the old beam mounts smooth.

Last edited by 1/2A Nut on Sat Apr 13, 2019 3:27 pm; edited 1 time in total

1/2A Nut- Top Poster

- Posts : 3538

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

I bought radial mount for 0.010

I wanted to buy 4 but Kam Tchnik Ebay shop allowed only 2. I am really wonder why???

I wanted to buy 4 but Kam Tchnik Ebay shop allowed only 2. I am really wonder why???

aungmyatoo- Gold Member

- Posts : 328

Join date : 2012-06-07

Age : 55

Location : Singapore

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

I do not know why that has happened, send a message to the vendor on ebay.

1/2A Nut- Top Poster

- Posts : 3538

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Cool Deal Brad Thanks , i subscribed to his newsletter so i can get a couple , am looking forward to skinning one down and apply a slide throttle to it !! Should look cool too .

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

1/2A Nut wrote:I do not know why that has happened, send a message to the vendor on ebay.

There is Ebay rule set in, the buyer can buy only 2 items in 10 days from Greg. I sent Ebay screen shot to Greg.

May be this Ebay rule set accidentally.

aungmyatoo- Gold Member

- Posts : 328

Join date : 2012-06-07

Age : 55

Location : Singapore

Page 23 of 30 •  1 ... 13 ... 22, 23, 24 ... 26 ... 30

1 ... 13 ... 22, 23, 24 ... 26 ... 30

Similar topics

Similar topics» CG on Speed Contest Planes

» Anyone here into Giant Scale R/C Planes? Post Pics of your Planes.

» Fellow speed freaks, help me build a pair of speed Bees.

» CL planes...

» How many cox planes do you have?

» Anyone here into Giant Scale R/C Planes? Post Pics of your Planes.

» Fellow speed freaks, help me build a pair of speed Bees.

» CL planes...

» How many cox planes do you have?

Page 23 of 30

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules