Log in

Search

Latest topics

» Duende V model from RC Model magazine 1983.by TD ABUSER Today at 9:20 pm

» Roger Harris revisited

by rsv1cox Today at 12:46 pm

» A Little 400 Mile Hop for Some Memory Lane Stuff, and to Hit a Swap Meet.

by getback Today at 9:48 am

» Free Flight Radio Assist

by getback Today at 8:39 am

» Happy 77th birthday Andrew!

by Kim Yesterday at 11:18 am

» Promote the forum with flyers!

by Admin Yesterday at 3:35 am

» Engine choice

by GallopingGhostler Mon Nov 25, 2024 6:03 pm

» My N-1R build log

by roddie Mon Nov 25, 2024 11:19 am

» Night flying at Walters RC park

by 1975 control line guy Sun Nov 24, 2024 9:29 pm

» Cox films/videos...

by GallopingGhostler Sun Nov 24, 2024 9:07 pm

» Cox 020 PeeWee rebuild questions

by LooseSpinner99 Sun Nov 24, 2024 8:13 pm

» Did you spot the Cox engine in this NASA research video?

by balogh Sun Nov 24, 2024 7:08 pm

Cox Engine of The Month

Choosing Balsa

Page 1 of 1

Choosing Balsa

Choosing Balsa

The last post I post I read in the foam board thread inspired me to start this thread so as not to be a hijacker

I'm fairly new to scratch building, just my Li'l Satan and most of my Refried Bean, and the wing of my upcoming Skyray. I've noticed that Brodak kit ribs are super light and fragile. Is that where the lightest balsa in a model generally goes? I expect the stiffest balsa would be for the control surfaces. I have chosen what I call medium grain without weighing it for a few profile fuselages. I never see any weight designations on labels, even at the hobby shop. I think the HS guy thought I was weird one day when I pulled all his 1/4" sheets out onto the floor and got down, spread them all out comparing them.

Rusty

I'm fairly new to scratch building, just my Li'l Satan and most of my Refried Bean, and the wing of my upcoming Skyray. I've noticed that Brodak kit ribs are super light and fragile. Is that where the lightest balsa in a model generally goes? I expect the stiffest balsa would be for the control surfaces. I have chosen what I call medium grain without weighing it for a few profile fuselages. I never see any weight designations on labels, even at the hobby shop. I think the HS guy thought I was weird one day when I pulled all his 1/4" sheets out onto the floor and got down, spread them all out comparing them.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Choosing Balsa

Re: Choosing Balsa

Rusty, I see Bob Hunt a few times a year. He's provided me with some excellent DVD's on the subject. It's sometimes hard to keep focused on what your watching but the information is really good. I may even have a few extras. I will see what I have here. Kits that were die cut would generally use the hardest wood available due to the dies cutting them without squashing them. This happened anyhow due to the dies getting dull . Laser cutting is the opposite, harder variants burn and charcoal badly. While Brodak kits have light wood within them, there are certain items that I'm skeptical using due to having not enough strength. Many times, strength of the balsa comes from certain finishing methods like dope and silkspan therefore the wood type doesn't need to be as strong as one would think. Many of the older kits would rely on the builder to silkspan the entire model with thinned dope as this would provide torsional strength to wings and fuses. You need to take a look at Pat King's models especially his profiles to see how he designs them to provide structural integrity. Pat's design and lightweight wood results in a far greater weight savings than a traditional older profile kit. This does however cost a lot more. He just designed a profile Yak-9 stunter for the LA-46. The entire model is all built up surfaces with some geodetic structures within the rectangular structure of the flaps, elevators, etc. This provides exceptional strength while reducing the weight of that part. Ken

Ken Cook- Top Poster

- Posts : 5644

Join date : 2012-03-27

Location : pennsylvania

Re: Choosing Balsa

Re: Choosing Balsa

I want to fly one of Pat's designs just to see what a super light plane flies like. I have a Ringmaster 576 that I need to build and it has a foam core fuse. It looks daunting. It also has a D tube leading edge and I have no idea what that is...

Ron

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Choosing Balsa

Re: Choosing Balsa

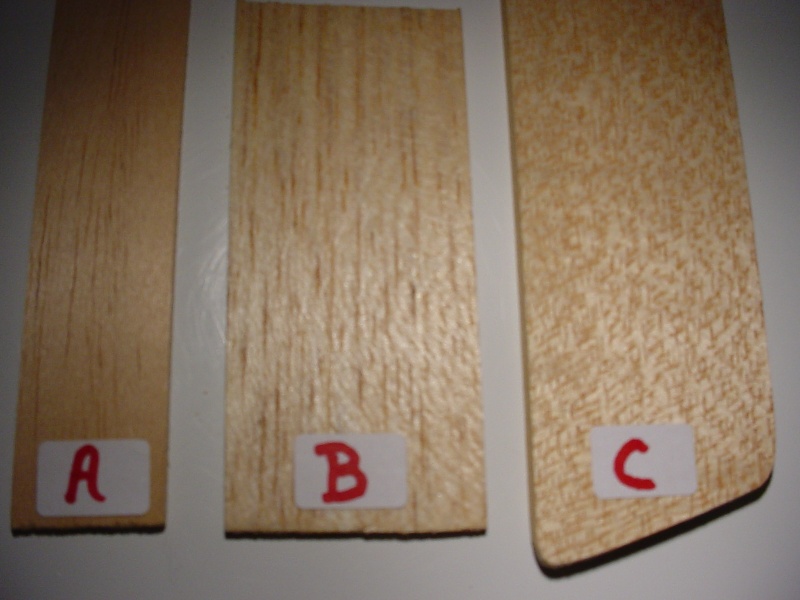

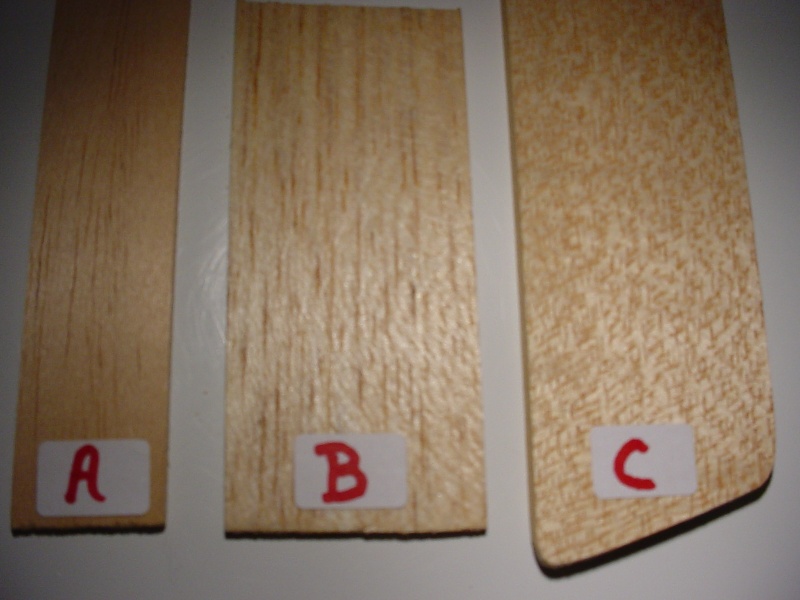

Rusty, it's not odd to pick through balsa wood at the hobby shop. You may have to pick through several sheets of the same size before you find the one that suits your needs. Warp-free and grain-type are the major considerations. Grain type falls into 3 categories.. "A", "B" and "C"... with "A" being the softest and lightest in weight. "B" and "C" are progressively harder and heavier.. with "C" being the hardest, heaviest and most rigid (strong). "C" grain balsa would be a better choice for a wing "spar", whereas "A" grain would be best for wing "ribs".

"Contest" balsa... as referred to in a kit (in my opinion) means that the wood was hand-picked/pre-selected to be the lightest possible weight for the components, without sacrificing strength/integrity of the parts.

Like Ken said; the method of open-frame covering has a lot to do with the strength of the overall airframe.

Once your aware of the grain types, you can pretty much tell by looking; what type of sheet/stick to use for a given application.

Here's an example of different balsa grains.

"Contest" balsa... as referred to in a kit (in my opinion) means that the wood was hand-picked/pre-selected to be the lightest possible weight for the components, without sacrificing strength/integrity of the parts.

Like Ken said; the method of open-frame covering has a lot to do with the strength of the overall airframe.

Once your aware of the grain types, you can pretty much tell by looking; what type of sheet/stick to use for a given application.

Here's an example of different balsa grains.

Re: Choosing Balsa

Re: Choosing Balsa

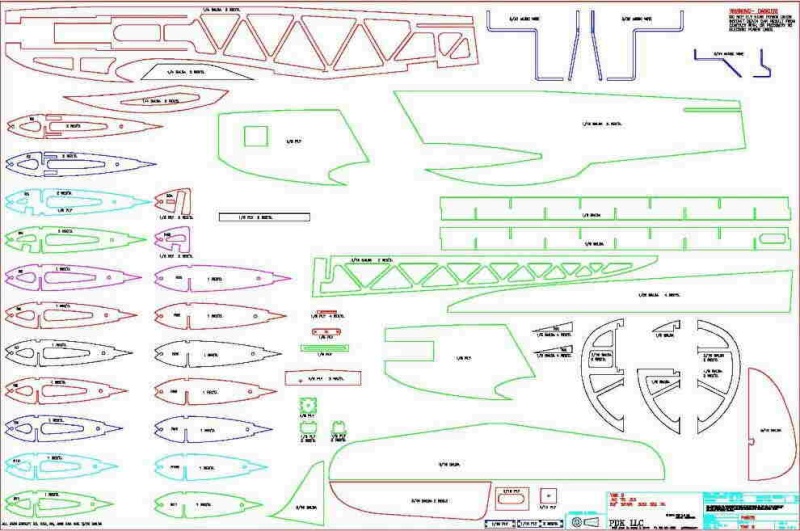

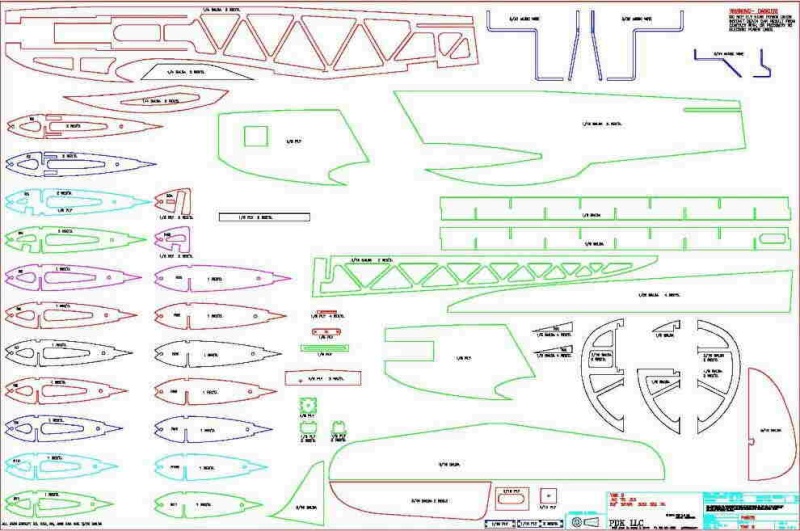

Ron, Pat is a big fan of the spar method on the plans I show. See how the spar is slotted and the ribs are slotted? This is one of Pat's trademark signatures. When you sheet the leading edge from the point of the leading edge just past the spar, you essentially made the D tube. This of course is the D shape you would see if you removed the wingtip and looked at the cross section of the wing. Incredibly strong as you essentially made a box. When you have a traditional top and bottom spar with the leading edge to spar sheeted, the wing can still flex due to the spars bowing within the rib bays. I myself use vertical grain web shears on the back of the spars from top to bottom or you could place these pieces centered on the spar to essentially form an I-beam. A D tube structure MUST be built as warp free as possible. Your not going to easily twist a D tube if at all to straighten it. Ken

Ken Cook- Top Poster

- Posts : 5644

Join date : 2012-03-27

Location : pennsylvania

Re: Choosing Balsa

Re: Choosing Balsa

Anyone choosing to scratch-build from a plan, or design their own flying model, would do very well to read construction articles on making strong joints... how/where to use the correct grade/grain balsa, where to utilize gussets, crutches, trusses and understanding compression/tension loads etc.

There is a chapter in RCM's "For What It's Worth" entitled "Building"... (chapter 2 in Vol. 5) which is very helpful.

Roddie

There is a chapter in RCM's "For What It's Worth" entitled "Building"... (chapter 2 in Vol. 5) which is very helpful.

Roddie

Re: Choosing Balsa

Re: Choosing Balsa

Here's an link to images concerning "balsa joint construction". Just looking at some of the photos will give you ideas on how to build better joints. There are LOTS of airframe photos.

https://www.google.com/search?q=balsa+joint+construction&sa=X&tbm=isch&tbo=u&source=univ&ei=YjvlUvq7IIbmyQG65ICoDA&ved=0CCYQsAQ&biw=1366&bih=588

Roddie

https://www.google.com/search?q=balsa+joint+construction&sa=X&tbm=isch&tbo=u&source=univ&ei=YjvlUvq7IIbmyQG65ICoDA&ved=0CCYQsAQ&biw=1366&bih=588

Roddie

Re: Choosing Balsa

Re: Choosing Balsa

We used to have hobby stores where one could pick through a pile for the right wood. Nowadays everything is bought in online stores, and you never really know what you are going to get. With time I have collected a small stock of balsa though, some of this even dates back to my first build in the early eighties...

I have recently build a few planes from laser cut kits, and I don't like it. In the ones that I have built, there was no distinction in the wood for different parts. The same sheet of balsa is used for many purposes. The worst being laser cut leading edges etc from a regular soft balsa sheet, there is no strength or straightness in those...

I much prefer die cut kits. I might be the only one, but at least they used to have the right wood for the right job. You got proper spars from strong wood and not something that was simply laser cut from soft balsa. I like to see a healthy bunch of wood strips when I open a box.

I have recently build a few planes from laser cut kits, and I don't like it. In the ones that I have built, there was no distinction in the wood for different parts. The same sheet of balsa is used for many purposes. The worst being laser cut leading edges etc from a regular soft balsa sheet, there is no strength or straightness in those...

I much prefer die cut kits. I might be the only one, but at least they used to have the right wood for the right job. You got proper spars from strong wood and not something that was simply laser cut from soft balsa. I like to see a healthy bunch of wood strips when I open a box.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Choosing Balsa

Re: Choosing Balsa

Ken Cook wrote:Ron, Pat is a big fan of the spar method on the plans I show. See how the spar is slotted and the ribs are slotted? This is one of Pat's trademark signatures.

I don't like that construction at all, it is a good example of where laser cut things makes poor job...

Sure it is easy to assemble everything, but the wood fibres are now cut off and you are relying on the glue for strength. One poor glue-joint (near the center) is all it takes for the wing to fold. I think it is much better with traditional spars, supported by webbing. The I shape and uncut fibres is a much better solution, to me.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Choosing Balsa

Re: Choosing Balsa

Looking more carefully at the image it is perhaps only a webbing that is cut, and not the actual spars?

It that case there is no problem of coarse.

I have seen ARFs though with spars made like that...

It that case there is no problem of coarse.

I have seen ARFs though with spars made like that...

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Choosing Balsa

Re: Choosing Balsa

Kris, I couldn't agree with you more in terms of same wood selection for all the parts. I feel this is just the norm anymore due to the complications of laser cutting. You generally just don't see hard wood being used. I'm only guessing it's due to the wood charring badly. While I'm not a big fan of the spar method depicted, it works. What I don't like is that even when this style construction was used by kit manufacturers that die cut kits (Top Flite Flite Streak) this method can easily induce a twist in the wing if not properly assembled. This doesn't need to be a D tube wing either to do so. If the manufacturer doesn't allow a slight bit of clearance in those fits, the end result if the ribs can project up or down which now requires the spar to be twisted to correct. I prefer to have everything relaxed and glued opposed to dialing in unwanted stresses within the structure. My point however was that Pat certainly does a terrific job of trying to design control line planes based upon what the public likes to see and he does so in terms of weight consideration being priority. While this does suggest a lot of laser cutting, I personally know one of Pat's builders and I see many of the designs close up and personal prior to their introduction. I've been fortunate to be able to test fly some of them as well. It's nice when your also able to put some input into certain areas. The newer kits are not going to endure the hangar rash the older kits endured. The construction is different, the wood types equally are different. Were not going to see the kits of yesteryear designed the way that many have come to know. While this is terrific for the weight conscious builder, these newer models are fragile. Ken

Ken Cook- Top Poster

- Posts : 5644

Join date : 2012-03-27

Location : pennsylvania

Similar topics

Similar topics» Pictures added Balsa balsa balsa

» "Molding Balsa"...NOT to be confused with "Moldy Balsa"!!!!! M.A.N 12-64

» Razor Saw Questions And Help Choosing

» Balsa Sources

» Balsa and other woods.

» "Molding Balsa"...NOT to be confused with "Moldy Balsa"!!!!! M.A.N 12-64

» Razor Saw Questions And Help Choosing

» Balsa Sources

» Balsa and other woods.

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules