Log in

Search

Latest topics

» Promote the forum with flyers!by Admin Today at 1:35 am

» Roger Harris revisited

by rsv1cox Yesterday at 7:34 pm

» Engine choice

by GallopingGhostler Yesterday at 4:03 pm

» A Little 400 Mile Hop for Some Memory Lane Stuff, and to Hit a Swap Meet.

by roddie Yesterday at 4:01 pm

» My N-1R build log

by roddie Yesterday at 9:19 am

» Night flying at Walters RC park

by 1975 control line guy Sun Nov 24, 2024 7:29 pm

» Happy 77th birthday Andrew!

by GallopingGhostler Sun Nov 24, 2024 7:10 pm

» Cox films/videos...

by GallopingGhostler Sun Nov 24, 2024 7:07 pm

» Cox 020 PeeWee rebuild questions

by LooseSpinner99 Sun Nov 24, 2024 6:13 pm

» Did you spot the Cox engine in this NASA research video?

by balogh Sun Nov 24, 2024 5:08 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Sun Nov 24, 2024 2:54 pm

» Tee Dee .020 combat model

by 1/2A Nut Sun Nov 24, 2024 10:34 am

Cox Engine of The Month

Changing the crankshaft?

Page 1 of 1

Changing the crankshaft?

Changing the crankshaft?

Ok, don't laugh. I just took the crankshaft out of the engine I plan to run in the contest and I can't remember how to get the new thrust washer back on. I also noticed that the new heavy killer bee type thrust washer has no splines to match the crankshaft. Is there someone still online that can help? Trying to get this ready to fly Sunday afternoon.

duke.johnson- Diamond Member

- Posts : 1734

Join date : 2012-11-05

Age : 53

Location : Rochester, Washington

Re: Changing the crankshaft?

Re: Changing the crankshaft?

Well, I think I remember just putting it on with a prop and prop nut.

duke.johnson- Diamond Member

- Posts : 1734

Join date : 2012-11-05

Age : 53

Location : Rochester, Washington

Re: Changing the crankshaft?

Re: Changing the crankshaft?

duke.johnson wrote:Well, I think I remember just putting it on with a prop and prop nut.

Yes, that is pretty much it. Use a stud and nut so you don't overstress the end of the crank.

The crank "cuts" the splines since it is a press fit.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Changing the crankshaft?

Re: Changing the crankshaft?

Thanks Phil

duke.johnson- Diamond Member

- Posts : 1734

Join date : 2012-11-05

Age : 53

Location : Rochester, Washington

Re:Changing the crankshaft

Re:Changing the crankshaft

duke.johnson wrote:Ok, don't laugh. I just took the crankshaft out of the engine I plan to run in the contest and I can't remember how to get the new thrust washer back on. I also noticed that the new heavy killer bee type thrust washer has no splines to match the crankshaft. Is there someone still online that can help? Trying to get this ready to fly Sunday afternoon.

There was a large number of new KB prop drivers that came on the market a few years ago that never had the splines cut from the factory. Be careful if you have one in that you can shear off your prop bolt or stud before the crank can cut the splines.I know this because I bought a lot of the Cox R&D replacement parts and I got about a dozen of the "blank" prop drivers. You'll be better off if you buy a new one from Matt or Bernie.....FWIW...Steve

66 Malibu- Gold Member

- Posts : 477

Join date : 2012-02-28

Location : Georgia

Re: Changing the crankshaft?

Re: Changing the crankshaft?

I always remove crankshafts using a vice, a hammer can produce some unwanted results.

For replacement ther are several methods I use.

The best one I have found is using the hub from a rubber spinner.

First I use my little finger to steady the crankshaft and get everything lined up. Tighten up finger tight and then if the back of the propellor is serrated it will grip and it is ready to tighten fully.

Remember to grip the propellor and remove your little finger from the crankcase!

Use the flat edge of the wrench to tighten up

The hub works on all the 049s.

Another method uses an allen headed bolt.

If you are desperate - use a screwdrive with a slotted screw - but be warned! It is easy to slip with the screwdriver and gouge little bits of finger. The screws are also quite soft and the effort turning them to refit the driver can distort the slot

For replacement ther are several methods I use.

The best one I have found is using the hub from a rubber spinner.

First I use my little finger to steady the crankshaft and get everything lined up. Tighten up finger tight and then if the back of the propellor is serrated it will grip and it is ready to tighten fully.

Remember to grip the propellor and remove your little finger from the crankcase!

Use the flat edge of the wrench to tighten up

The hub works on all the 049s.

Another method uses an allen headed bolt.

If you are desperate - use a screwdrive with a slotted screw - but be warned! It is easy to slip with the screwdriver and gouge little bits of finger. The screws are also quite soft and the effort turning them to refit the driver can distort the slot

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

What am I doing wrong?

What am I doing wrong?

I have a Medallion .049 that I got off of eBay, and the thrust washer isn't seated well in the crankshaft, giving lots of end play. I tried using the install setup I bought from Bernie. I threaded the stud in, put a prop on, then the washers, and the hub. I used a drop of light machine oil between the washers to minimize friction, and started tightening using a glow plug wrench. Instead of tightening the thrust wsher on the crank, the stud broke. What did I do wrong?

batjac- Diamond Member

Posts : 2375

Join date : 2013-05-22

Age : 61

Location : Broken Arrow, OK, USA

Re: Changing the crankshaft?

Re: Changing the crankshaft?

Thanks guys. I remembered a little more after I got a little sleep. I took a couple off and on today.

duke.johnson- Diamond Member

- Posts : 1734

Join date : 2012-11-05

Age : 53

Location : Rochester, Washington

Re: Changing the crankshaft?

Re: Changing the crankshaft?

Did the stud break and leave a piece inside the crankshaft that you can't remove? I can't imagine why the stud would snap off if the drive plate wasn't even pressed on. They're pretty soft metal and usually press right onto the splines without much force. Certainly not enough force to break a steel stud. I've been using those studs forever to mount drive plates and never had such a thing happen. I'm not sure why the instructions say to only screw it in 1/4 of the way. I put it in as far as I can leaving enough threads out to get the prop and screw on. I've never used one of those tools, but my prop nut and stud are just the same as Bernie's tool, actually the same parts, minus the washers. I just put the nut down right onto the prop face.batjac wrote:I have a Medallion .049 that I got off of eBay, and the thrust washer isn't seated well in the crankshaft, giving lots of end play. I tried using the install setup I bought from Bernie. I threaded the stud in, put a prop on, then the washers, and the hub. I used a drop of light machine oil between the washers to minimize friction, and started tightening using a glow plug wrench. Instead of tightening the thrust wsher on the crank, the stud broke. What did I do wrong?

E-mail Bernie and ask him to read your post in this thread and see what he thinks.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Changing the crankshaft?

Re: Changing the crankshaft?

I broke a stud some time ago on an engine I was restoring. The drive plate wasn't seated on the splined crankshaft squarely. Rather than take it off and reseat it - I thought it would just be quicker to use the hub to tighten and square it up at the same time.

Wrong!. The angle had well and truly jammed the driveplate tight. As I tightened the hub - the stud snapped!

Wrong!. The angle had well and truly jammed the driveplate tight. As I tightened the hub - the stud snapped!

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Changing the crankshaft?

Re: Changing the crankshaft?

Depending on how difficult it is to get the drive-plate back on, the studs can break. That is why we include a couple of spares with each "assembly tool".

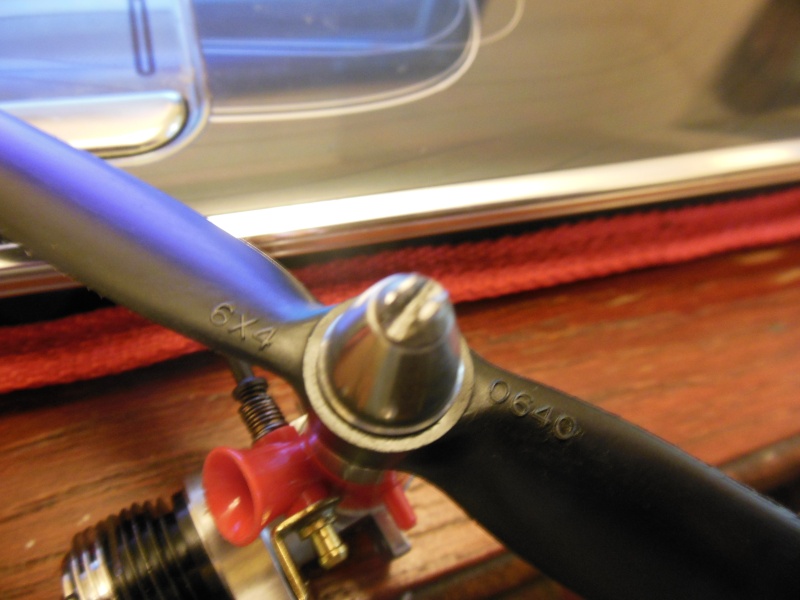

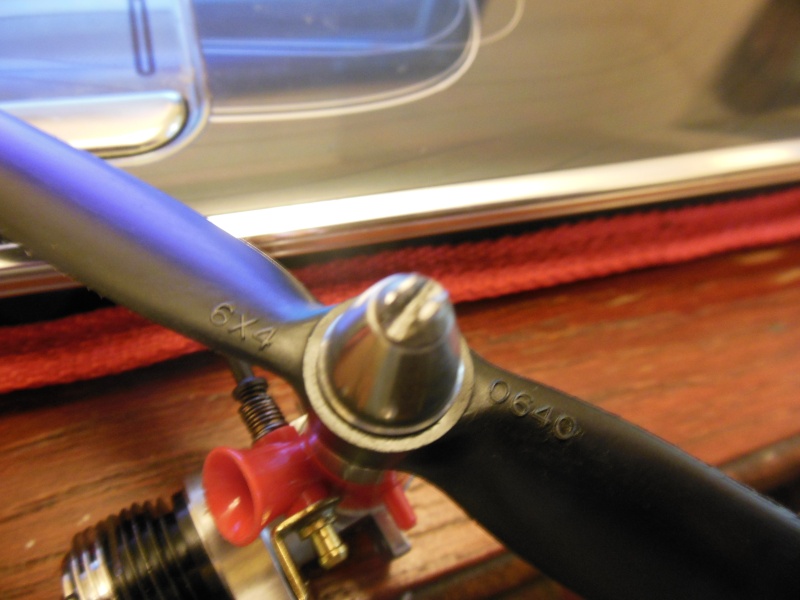

Here, at the office we do as in the pics. Machined one bolt to fit regular cranks and one for the Killer Bee cranks. Insert into vise and tighten. Stand assembly upright and gently tap drive-plate with a hammer to straighten if required.

Here, at the office we do as in the pics. Machined one bolt to fit regular cranks and one for the Killer Bee cranks. Insert into vise and tighten. Stand assembly upright and gently tap drive-plate with a hammer to straighten if required.

Re: Changing the crankshaft?

Re: Changing the crankshaft?

After changing a few this weekend, I think I'm going to use a vise both on and off from now on. I broke two stud this weekend.

duke.johnson- Diamond Member

- Posts : 1734

Join date : 2012-11-05

Age : 53

Location : Rochester, Washington

Re: Changing the crankshaft?

Re: Changing the crankshaft?

Bernie, what size/diameter bolts do you use?

Mark

Mark

batjac- Diamond Member

Posts : 2375

Join date : 2013-05-22

Age : 61

Location : Broken Arrow, OK, USA

Re: Changing the crankshaft?

Re: Changing the crankshaft?

you can also use wood, piece of dowel, etc., less chance of damage. Be sure to recess front for crank counterweight. When done trimming soak up with thin CA to help strengthen wood and minimize oil soak.

Re: Changing the crankshaft?

Re: Changing the crankshaft?

batjac wrote:Bernie, what size/diameter bolts do you use?

Mark

Diameter is 13.5 mm (.53") and 25 mm (1") shaft below the head.

You will have to grind down the OD on the bottom half to 12.5 mm (.49") and then take a dremel tool with a ball-shaped grinder and grind a groove for the crank pin.

For the KB crank the mating surface can be straight and for the regular cranks grind the surface to match the crank faceplate.

One does not have to use a vise. Standing the crankcase on its head and tapping with a hammer also works well.

Similar topics

Similar topics» Changing employers.. Roddie's nervous

» Just won a Cox .15 Sportsman

» Narrowing engine bearers

» Is Tee Dee 0.049 crankcase is the same with Tee Dee 0.051?

» TD 010 Crankshaft.

» Just won a Cox .15 Sportsman

» Narrowing engine bearers

» Is Tee Dee 0.049 crankcase is the same with Tee Dee 0.051?

» TD 010 Crankshaft.

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules