Log in

Search

Latest topics

» Engine choice by 1975 control line guy Today at 9:51 pm

» Night flying at Walters RC park

by 1975 control line guy Today at 7:29 pm

» Happy 77th birthday Andrew!

by GallopingGhostler Today at 7:10 pm

» Cox films/videos...

by GallopingGhostler Today at 7:07 pm

» Cox 020 PeeWee rebuild questions

by LooseSpinner99 Today at 6:13 pm

» Did you spot the Cox engine in this NASA research video?

by balogh Today at 5:08 pm

» Roger Harris revisited

by rsv1cox Today at 3:44 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Today at 2:54 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 10:34 am

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 8:15 am

» TEE DEE Having issues

by balogh Today at 7:42 am

» My N-1R build log

by roddie Today at 12:32 am

Cox Engine of The Month

Berryman's parts cleaner works great but when thing get serious

Page 1 of 1

Berryman's parts cleaner works great but when thing get serious

Berryman's parts cleaner works great but when thing get serious

you break out the crock pot.

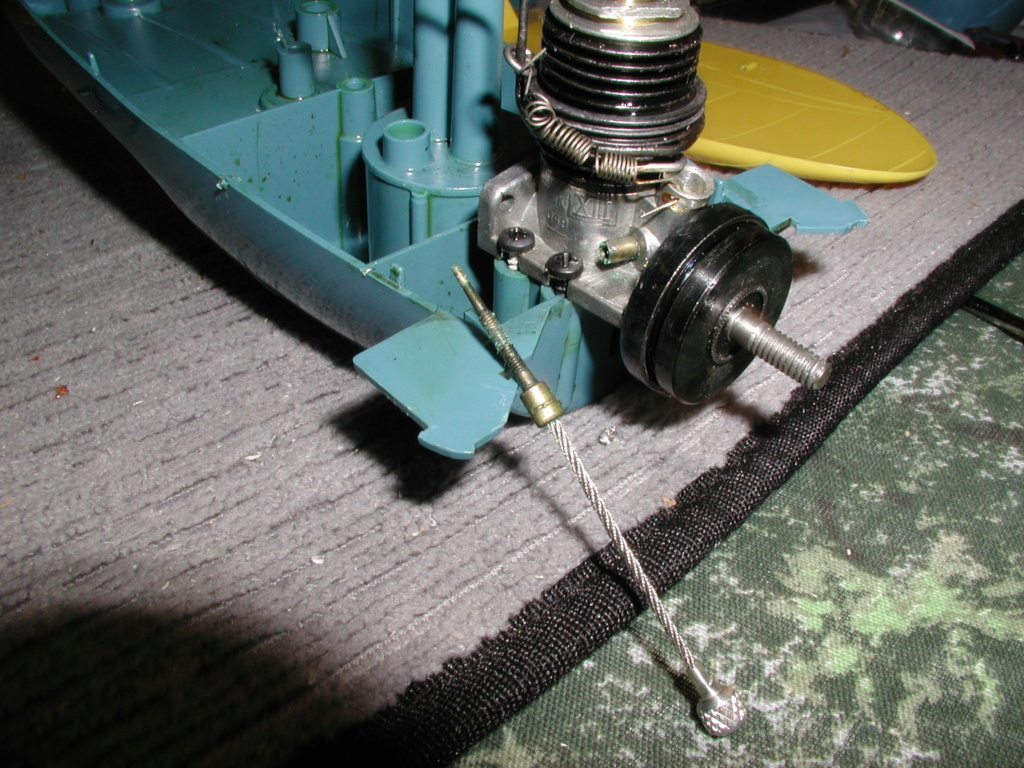

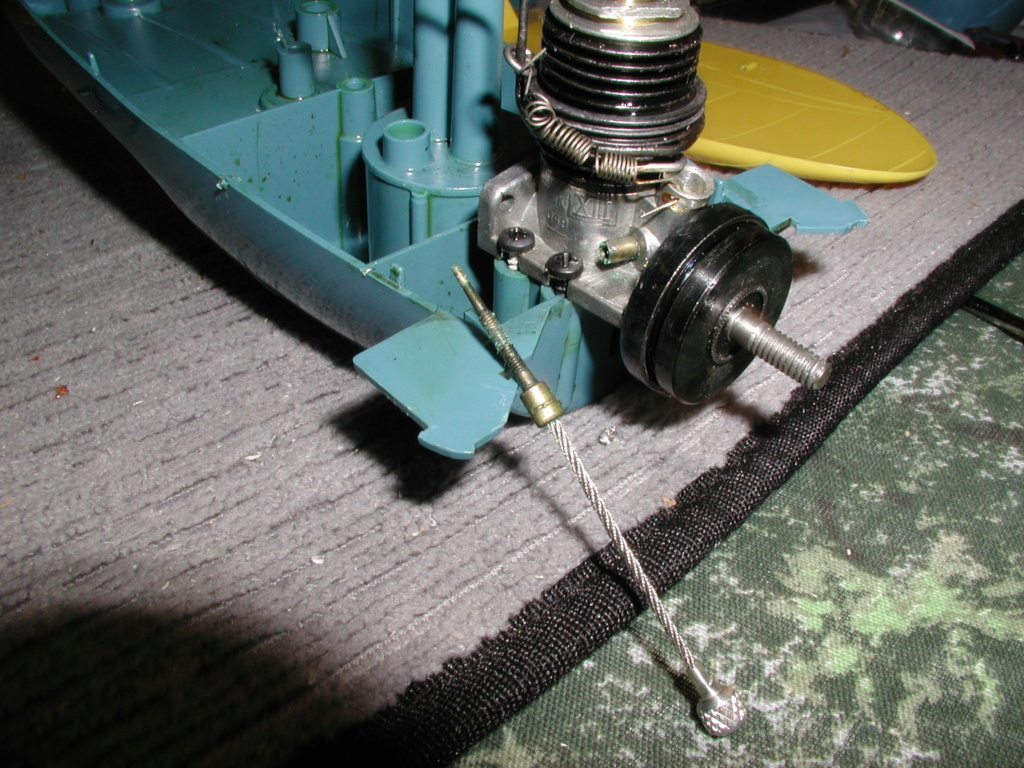

When receiving a castor (or otherwise) locked engine, to free it I always start with the mildest solution first. Turn by hand, no. Apply a little heat gun heat, no. Heat gun plus Remoil, no. 30 minute soak in Berryman's, no. Berryman's plus heat, plus Remoil no. This thing is totally locked, mechanical fault maybe. Rotostarter or something broken or both.

Crock pot, three hour soak, mount on a board to get better leverage. Back in the crock pot to heat back up. Heat is not friendly to plastic or wooden propellors (or fingers) and I get movement on both the throttle sleeve and the crankshaft. Easy back and forth, some oil, more back and forth. Soapy water held under and turned to expel the anti freeze/oil. Compressed air blowout. Flood with Remoil, lots of back and forth flipping until excess oil is expelled. Clean and reinstall the glow head.

Smooth movement on the throttle sleeve and crankshaft with compression.

I had ideas of getting rid of the crock pot, glad I didn't or this rather rare engine might have been a permanent lump.

When receiving a castor (or otherwise) locked engine, to free it I always start with the mildest solution first. Turn by hand, no. Apply a little heat gun heat, no. Heat gun plus Remoil, no. 30 minute soak in Berryman's, no. Berryman's plus heat, plus Remoil no. This thing is totally locked, mechanical fault maybe. Rotostarter or something broken or both.

Crock pot, three hour soak, mount on a board to get better leverage. Back in the crock pot to heat back up. Heat is not friendly to plastic or wooden propellors (or fingers) and I get movement on both the throttle sleeve and the crankshaft. Easy back and forth, some oil, more back and forth. Soapy water held under and turned to expel the anti freeze/oil. Compressed air blowout. Flood with Remoil, lots of back and forth flipping until excess oil is expelled. Clean and reinstall the glow head.

Smooth movement on the throttle sleeve and crankshaft with compression.

I had ideas of getting rid of the crock pot, glad I didn't or this rather rare engine might have been a permanent lump.

rsv1cox- Top Poster

Posts : 11253

Join date : 2014-08-18

Location : West Virginia

Re: Berryman's parts cleaner works great but when thing get serious

Re: Berryman's parts cleaner works great but when thing get serious

That is a very good step by step systematic procedure! I really like my Berryman's Parts cleaner, glad I bought it. It's great for external gunk and goo removal, but heat is still your best friend when trying to get moving parts to move after years of hardened castor

locks them in place. Oh I've broke one or two con-rods (or crank pins) thinking..Oh, She's comming loose! OOps..., guess not! In one of my last teardowns I used my trusty Wen soldering gun to "spot heat" the snout of the crankcase to heat the goo on the inside of the case between the crankshaft and case. Or in a extreme case I got the rear cover unscrewed and applied heat via the soldering tip up inside the crankcase in the bottom skirt of the piston until the 2 or 3 drops of oil on the top of the piston started to bubble! that'll break the castor grip! Berrymans will discolor aluminum if parts are left in too long. I had a cylinder with a throttle sleeve stuck on it, I wasn't worried about discoloring, so I left it soak for 2 days before the sleeve was loose enough to turn.

HEY! I forgot to mention in the last batch of Bee's I bought there were a couple of Unique ones.

The first one was a pristine version of the "taper head" screwed backplate Bee. The second was just a backplate that has the "notched" screen indentations holding the screen in place. SO, Cox must have used that for a short while, cause I checked all my others and this was the first one I've found that had the notches like the one you have. Cool!

locks them in place. Oh I've broke one or two con-rods (or crank pins) thinking..Oh, She's comming loose! OOps..., guess not! In one of my last teardowns I used my trusty Wen soldering gun to "spot heat" the snout of the crankcase to heat the goo on the inside of the case between the crankshaft and case. Or in a extreme case I got the rear cover unscrewed and applied heat via the soldering tip up inside the crankcase in the bottom skirt of the piston until the 2 or 3 drops of oil on the top of the piston started to bubble! that'll break the castor grip! Berrymans will discolor aluminum if parts are left in too long. I had a cylinder with a throttle sleeve stuck on it, I wasn't worried about discoloring, so I left it soak for 2 days before the sleeve was loose enough to turn.

HEY! I forgot to mention in the last batch of Bee's I bought there were a couple of Unique ones.

The first one was a pristine version of the "taper head" screwed backplate Bee. The second was just a backplate that has the "notched" screen indentations holding the screen in place. SO, Cox must have used that for a short while, cause I checked all my others and this was the first one I've found that had the notches like the one you have. Cool!

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 72

Location : Grand Rapids, MI

Re: Berryman's parts cleaner works great but when thing get serious

Re: Berryman's parts cleaner works great but when thing get serious

Yes, I thank you every time I take one of these apart. I also use a soldering gun. Saved me many an engine peg and needle. I muscled off a needle once and broke the tip off right in the spray bar. Never again! I used heat to remove the needle first, it blocks one of the engine mounting screws.

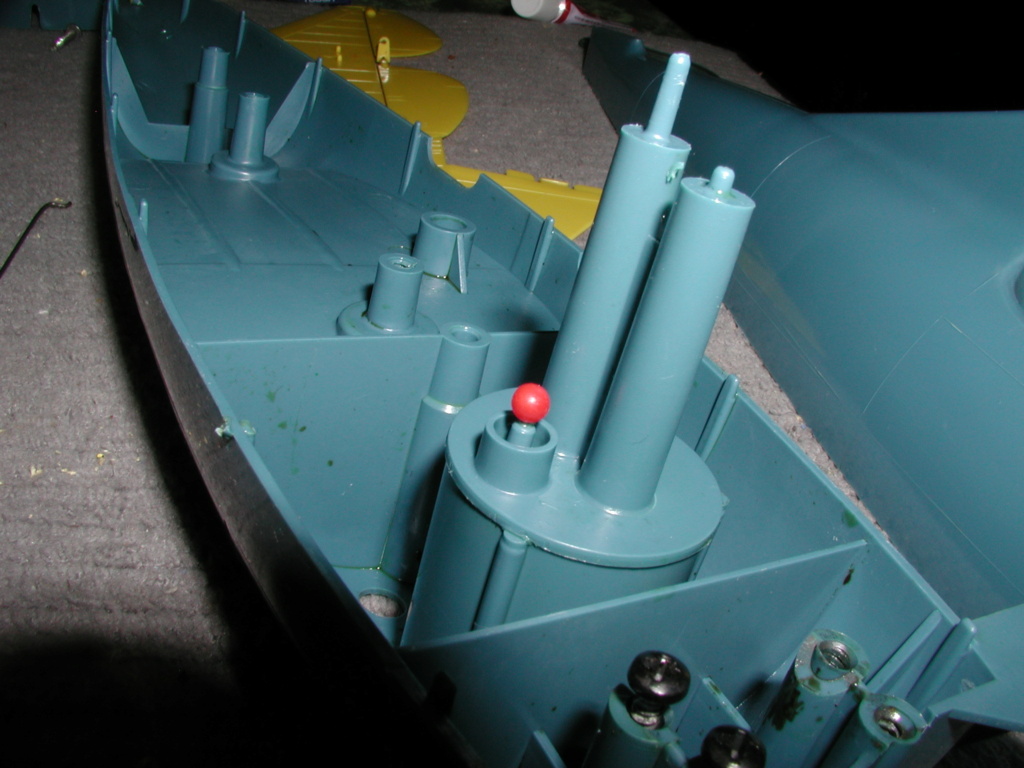

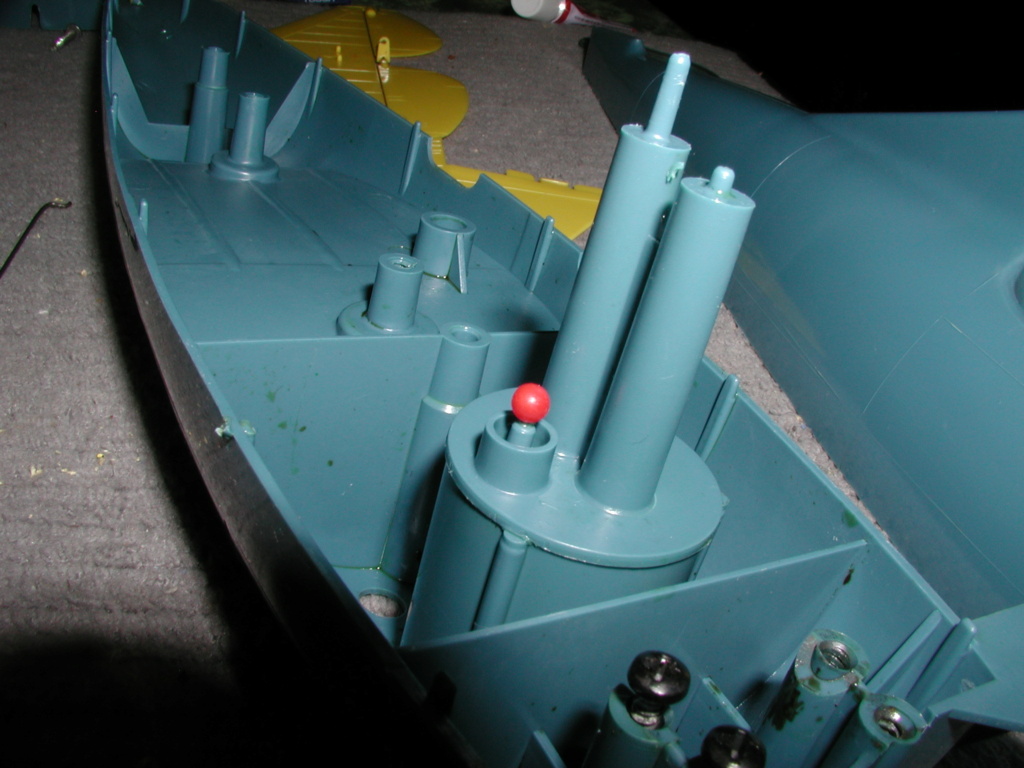

I did not want to disassemble this airplane, externally in perfect condition but the locked engine forced me to. Got inside and found the nipple on the fuel tank broken par for the course on these. Everyone I have has been broken. Only cure if you want to keep it original. Otherwise it's drill out the pipe and replace with an aerosol can straw inserted all the way to the bottom then picked up a sixteenth and glued. Using the original nipple I just glue it in.

SOP run a wire through the NVA and check the glow plug.

Got quite a fleet of these going, and one NIB.

I did not want to disassemble this airplane, externally in perfect condition but the locked engine forced me to. Got inside and found the nipple on the fuel tank broken par for the course on these. Everyone I have has been broken. Only cure if you want to keep it original. Otherwise it's drill out the pipe and replace with an aerosol can straw inserted all the way to the bottom then picked up a sixteenth and glued. Using the original nipple I just glue it in.

SOP run a wire through the NVA and check the glow plug.

Got quite a fleet of these going, and one NIB.

rsv1cox- Top Poster

Posts : 11253

Join date : 2014-08-18

Location : West Virginia

Similar topics

Similar topics» This thing is great!!

» Great Guys that help us do Our Thing !

» new 2.0 rc 1/16 049 powered bugy upgrade tee dee

» What is this thing? Comes from a batch of Cox parts

» Cleaning Engine with Dawn PowerWash

» Great Guys that help us do Our Thing !

» new 2.0 rc 1/16 049 powered bugy upgrade tee dee

» What is this thing? Comes from a batch of Cox parts

» Cleaning Engine with Dawn PowerWash

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules