Log in

Search

Latest topics

» Promote the forum with flyers!by Admin Today at 1:35 am

» Roger Harris revisited

by rsv1cox Yesterday at 7:34 pm

» Engine choice

by GallopingGhostler Yesterday at 4:03 pm

» A Little 400 Mile Hop for Some Memory Lane Stuff, and to Hit a Swap Meet.

by roddie Yesterday at 4:01 pm

» My N-1R build log

by roddie Yesterday at 9:19 am

» Night flying at Walters RC park

by 1975 control line guy Sun Nov 24, 2024 7:29 pm

» Happy 77th birthday Andrew!

by GallopingGhostler Sun Nov 24, 2024 7:10 pm

» Cox films/videos...

by GallopingGhostler Sun Nov 24, 2024 7:07 pm

» Cox 020 PeeWee rebuild questions

by LooseSpinner99 Sun Nov 24, 2024 6:13 pm

» Did you spot the Cox engine in this NASA research video?

by balogh Sun Nov 24, 2024 5:08 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Sun Nov 24, 2024 2:54 pm

» Tee Dee .020 combat model

by 1/2A Nut Sun Nov 24, 2024 10:34 am

Cox Engine of The Month

APC 6x4 shaft hole to large for TeeDee 049

Page 1 of 1

APC 6x4 shaft hole to large for TeeDee 049

APC 6x4 shaft hole to large for TeeDee 049

Hello gentlemen, I would like to know if anyone purchased an APC 6 x 4 prop for a tee dee 049?

Had I noticed the prop hole and the spacers were to big to fit the prop screw I wouldn't have bought it. So I would like to know if there is a quick fix for this because the hobby shop i ordered it from has a no return policy.

Kevin.

Had I noticed the prop hole and the spacers were to big to fit the prop screw I wouldn't have bought it. So I would like to know if there is a quick fix for this because the hobby shop i ordered it from has a no return policy.

Kevin.

kevin king- Silver Member

- Posts : 95

Join date : 2020-04-16

Re: APC 6x4 shaft hole to large for TeeDee 049

Re: APC 6x4 shaft hole to large for TeeDee 049

I'm not all that familiar with these props, but it looks to me like this may be for an electric motor. If that's the case, I certainly wouldn't use it on a Tee Dee. If it's not for electric, then you can use a small piece of fuel line on the prop screw to firm up the fit.

Oldenginerod- Top Poster

- Posts : 4019

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: APC 6x4 shaft hole to large for TeeDee 049

Re: APC 6x4 shaft hole to large for TeeDee 049

I would do like Oldenginerod posted.

1st cut from the plastic tree the thicker of the center prop filler.

Then using a piece of fuel line insert that into the center hole to fit tightly around the screw.

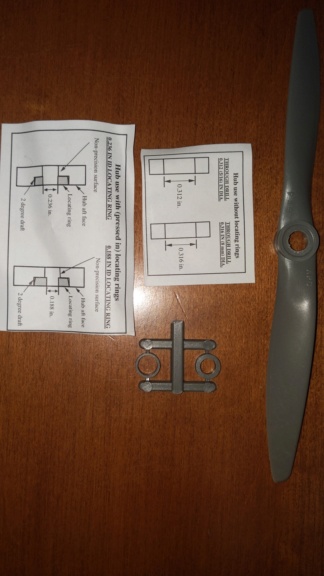

If it is an APC prop for electric it would say 8x4E ("E" after the 4 lets you know it's an electric prop.)

APC has gotten cheap on supplying all the different size adapters for their props.

Years ago, that plastic "tree" would have at least six different size adapters.

I have a special drawer in my workshop for the ones I don't use. (haven't used yet!)

Don't forget to balance your prop or you'll have a bad vibration problems!

1st cut from the plastic tree the thicker of the center prop filler.

Then using a piece of fuel line insert that into the center hole to fit tightly around the screw.

If it is an APC prop for electric it would say 8x4E ("E" after the 4 lets you know it's an electric prop.)

APC has gotten cheap on supplying all the different size adapters for their props.

Years ago, that plastic "tree" would have at least six different size adapters.

I have a special drawer in my workshop for the ones I don't use. (haven't used yet!)

Don't forget to balance your prop or you'll have a bad vibration problems!

sosam117- Diamond Member

- Posts : 1351

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: APC 6x4 shaft hole to large for TeeDee 049

Re: APC 6x4 shaft hole to large for TeeDee 049

Kevin, first question I have is why are you using a 6x4 on a Tee Dee? Seeing you had inquired to me in regards to the Voodoo, I'm assuming this is a combat 1/2A? You also asked for a fine threaded needle valve. When running bladder, you need to run smaller props then you would on suction. Even with a fine threaded needle valve having so much prop on the engine makes the needle hard to set. You either need to shrink your prop or increase your nitro above 35%. With the price of nitro today, it's easier to opt for the other. 5" max on a TD.

For instance, when we fly .25 engine sized combat we run 8" props. The TD even on suction wants to run small props. Good size APC props for a TD would be the 4.4 x 4, 4.4x2. The APC 4.5 x 3.5 is my go to prop. However, even with the smaller props, they're not going to fit. I had bushings made and I was selling them on EBAY years back. I've been very generous giving them away and I kept only a small amount. I might have some more.

For instance, when we fly .25 engine sized combat we run 8" props. The TD even on suction wants to run small props. Good size APC props for a TD would be the 4.4 x 4, 4.4x2. The APC 4.5 x 3.5 is my go to prop. However, even with the smaller props, they're not going to fit. I had bushings made and I was selling them on EBAY years back. I've been very generous giving them away and I kept only a small amount. I might have some more.

Last edited by Ken Cook on Sat Dec 11, 2021 12:51 pm; edited 1 time in total

Ken Cook- Top Poster

- Posts : 5644

Join date : 2012-03-27

Location : pennsylvania

Re: APC 6x4 shaft hole to large for TeeDee 049

Re: APC 6x4 shaft hole to large for TeeDee 049

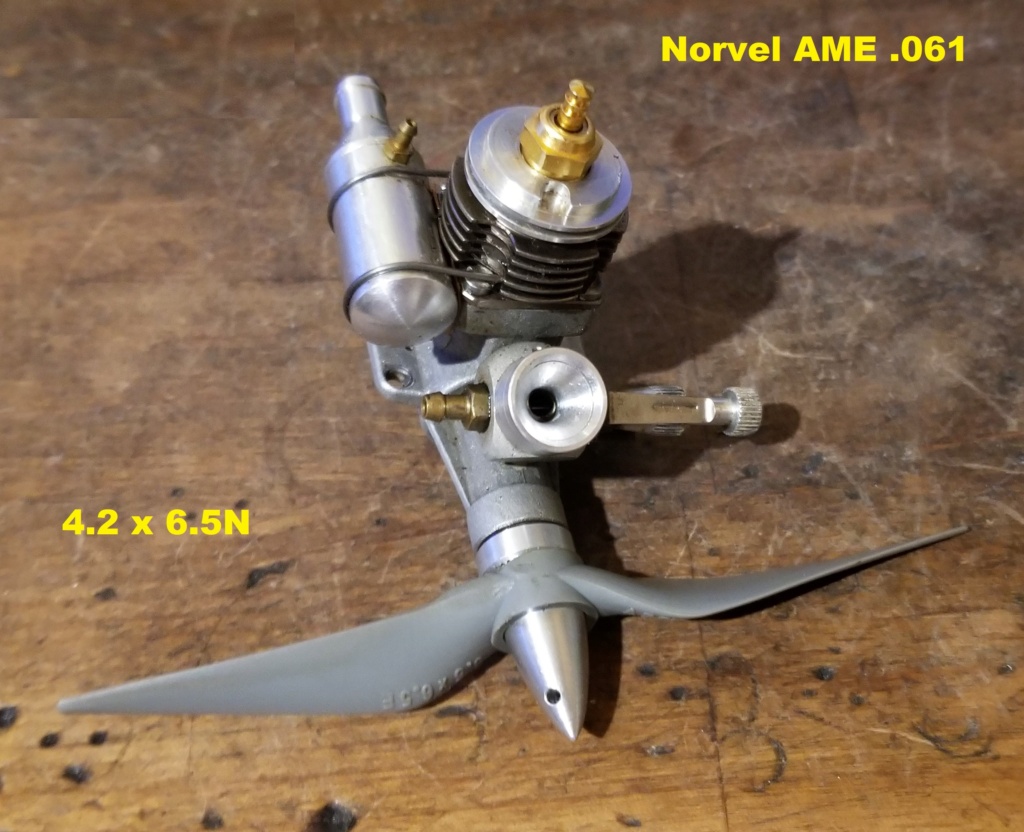

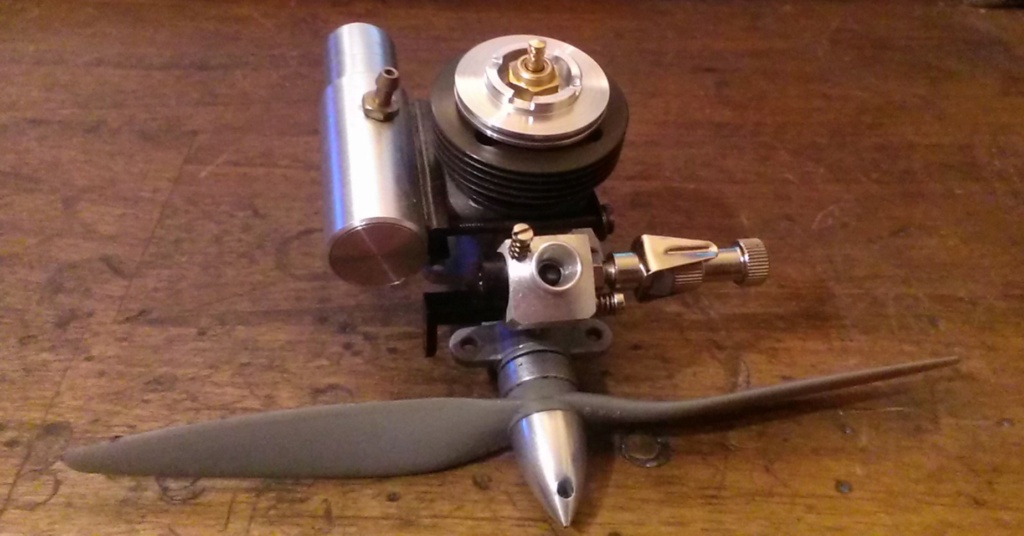

APC 6x4 makes great thrust and pitch speed performance with the Norvel .074 and TT .07

I use the small ID insert and fill the void with suitable dia. fuel line. Tube expands with

the prop bolt and during compression enough for a snug centered fit if cut a bit long.

Norvel .074 static stats: 30% Nitro 20% Castor

Static test APC 6x4E - Modified Heli Muffler 19,147 rpm

196w / .262hp / 22oz thrust / 73 mph pitch speed

I use the small ID insert and fill the void with suitable dia. fuel line. Tube expands with

the prop bolt and during compression enough for a snug centered fit if cut a bit long.

Norvel .074 static stats: 30% Nitro 20% Castor

Static test APC 6x4E - Modified Heli Muffler 19,147 rpm

196w / .262hp / 22oz thrust / 73 mph pitch speed

Last edited by 1/2A Nut on Sat Dec 11, 2021 3:28 pm; edited 4 times in total

1/2A Nut- Top Poster

- Posts : 3540

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: APC 6x4 shaft hole to large for TeeDee 049

Re: APC 6x4 shaft hole to large for TeeDee 049

Brad, I have a lot of admiration for what you do with those props. I also modify props and I know what I need to do to them for my useage. I should be going to the next level as yourself and do more. Seeing that we have a speed limit, I alter the prop generally to slow it down vs gain more.

Ken Cook- Top Poster

- Posts : 5644

Join date : 2012-03-27

Location : pennsylvania

1/2A Nut- Top Poster

- Posts : 3540

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

.

.

@oldenginerod, The prop is not for electric so I'm good there. And thanks for the fuel tubing tip.

@sosam117, I will definately not forget to balance the props. Thank you.

@Ken, The reason I wanted to change the 5x3 prop that's on it to a 6" prop was to make it easier to start, at least until I can sort our why the engine is so hard to start. Also Its going on a somewhat heavy stunt plane and I recall my previous TD 049 stunt plane worked well with an APC 6 x 3 prop, which the hobby shop didnt have. Thanks for the info on prop sizes. I wasnt aware APC made smaller props.

Also I suspect the tank might be the source of the problem, which is the reason i want to run it on a bladder. Thanks for the reply Ken.

Kevin.

@sosam117, I will definately not forget to balance the props. Thank you.

@Ken, The reason I wanted to change the 5x3 prop that's on it to a 6" prop was to make it easier to start, at least until I can sort our why the engine is so hard to start. Also Its going on a somewhat heavy stunt plane and I recall my previous TD 049 stunt plane worked well with an APC 6 x 3 prop, which the hobby shop didnt have. Thanks for the info on prop sizes. I wasnt aware APC made smaller props.

Also I suspect the tank might be the source of the problem, which is the reason i want to run it on a bladder. Thanks for the reply Ken.

Kevin.

kevin king- Silver Member

- Posts : 95

Join date : 2020-04-16

Re: APC 6x4 shaft hole to large for TeeDee 049

Re: APC 6x4 shaft hole to large for TeeDee 049

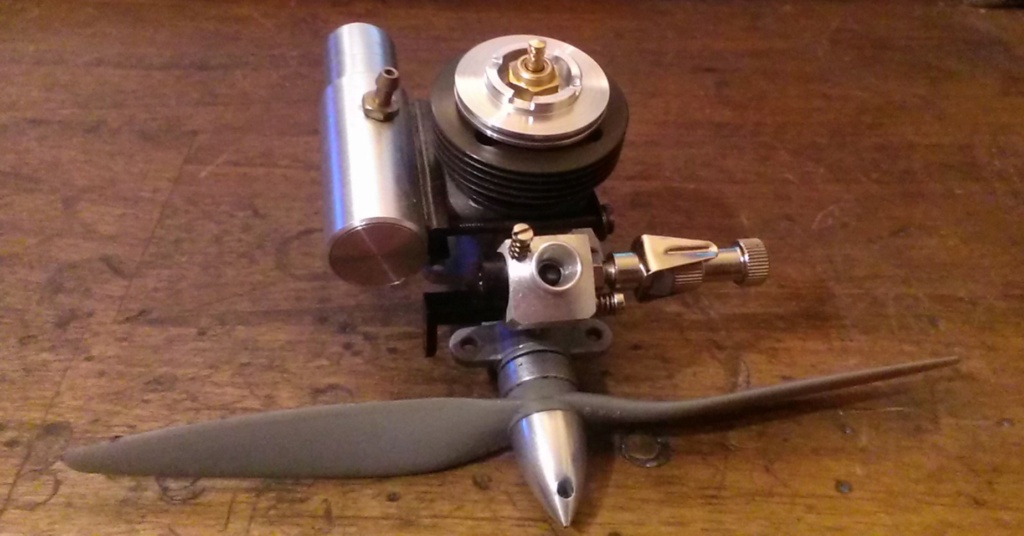

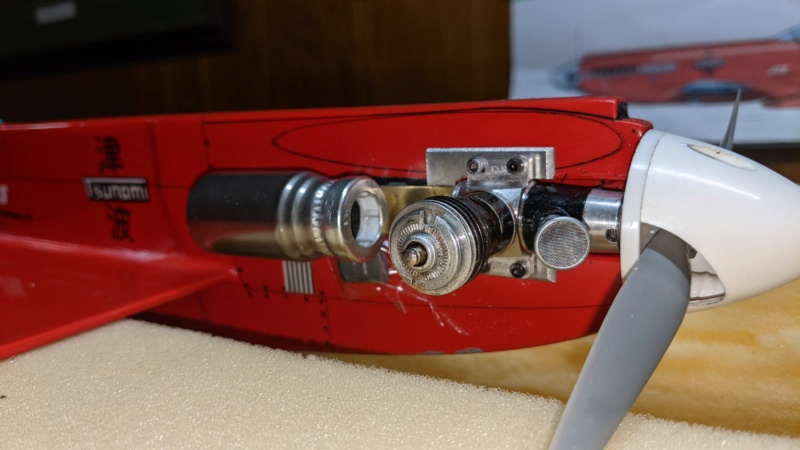

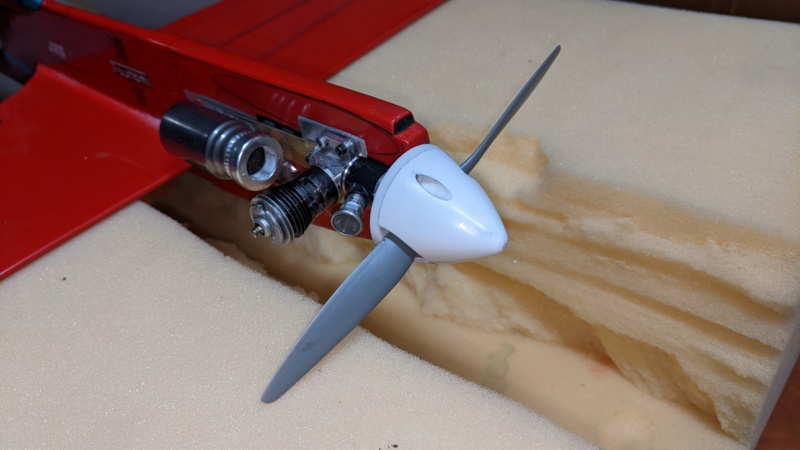

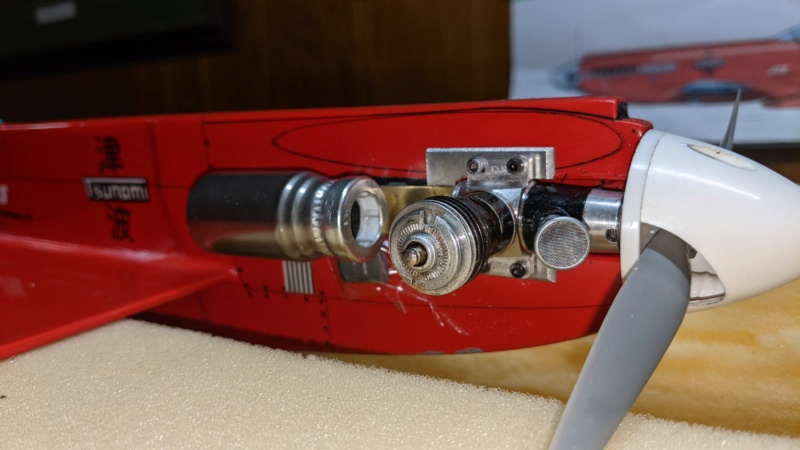

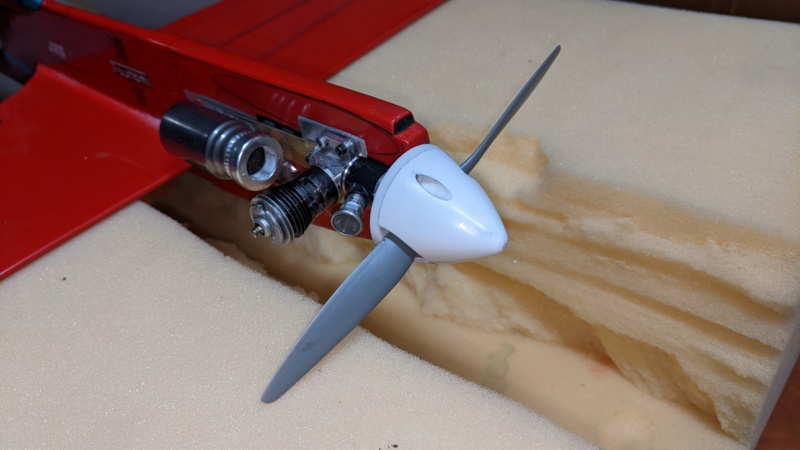

Kevin, I can already see issues. Your on the right track using a narrower longer wedge like you have done. The problem is that the tank is still too wide off of the fuse. You can place a slightly thicker shim under the engine lugs even if it's a 1/16". I don't typically recommend engine offset but in this case even another washer under the front lug kicks the centerline of venturi further outboard. You can also flip the needle valve assembly over which will place the barb of the carb body further out as well it will also get the needle further away from your prop for your fingers. That looks like a Perfect tank and truthfully, they're crap. Yes, they worked for many but they have a lot of flaws. If it's a Brodak version it's even worse.

See how your fuel line is going up and then down and then back up to your needle valve body. That's a BIG problem. Second, the brass tubing they used is complete crap. Tubing isn't seamless and old Perfect tubing splits and you can't see it. Third and most important, Perfect NEVER SOLDERED THE TUBING inside. I mention this a million times and there's those that don't believe this is a issue and like to fiddle with stuff for a eternity. I will tell you first hand it needs to be soldered in the center of the wedge approx 1/8-1/4" off of the back wall.

If it's not split now it will be at some point. Remove that brass and replace it with K&S 1/8 tubing and not the 3/32" crap they use. Don't put the tubing back in the hole you removed it. Put it straight in through the front end cap as far to the outside as possible. In other words right down the center on the outboard side and solder it in the rear. This will make the fuel line shorter and it's a straighter shot to your needle valve.

To use the engine properly, the tank really should be made into uniflow but I've experienced problems with doing using wedge shaped tanks like you have as I feel it causes a backlash of turbulence internally inside the tank.

Did you air test this tank as if you were trying to pop it? This is critical and needs to be done . Even one little pin hole the engine will not draw fuel properly. Try using a drinking straw with a pin hole in it. A bladder will resolve all of your issues but that tank can be made to work and even flipping your needle valve over should improve what I already see.

I see the screen on the venturi, I have drilled and opened up venturi's but the screen on it makes a bit more difficult to do so. You never know if the venturi is opened up unless it's checked. 5/32" is the max before breaking into the jet holes but if the venturi has been opened too far, the engine usually quits a second or two after you release it. This wouldn't be a issue using a bladder.

See how your fuel line is going up and then down and then back up to your needle valve body. That's a BIG problem. Second, the brass tubing they used is complete crap. Tubing isn't seamless and old Perfect tubing splits and you can't see it. Third and most important, Perfect NEVER SOLDERED THE TUBING inside. I mention this a million times and there's those that don't believe this is a issue and like to fiddle with stuff for a eternity. I will tell you first hand it needs to be soldered in the center of the wedge approx 1/8-1/4" off of the back wall.

If it's not split now it will be at some point. Remove that brass and replace it with K&S 1/8 tubing and not the 3/32" crap they use. Don't put the tubing back in the hole you removed it. Put it straight in through the front end cap as far to the outside as possible. In other words right down the center on the outboard side and solder it in the rear. This will make the fuel line shorter and it's a straighter shot to your needle valve.

To use the engine properly, the tank really should be made into uniflow but I've experienced problems with doing using wedge shaped tanks like you have as I feel it causes a backlash of turbulence internally inside the tank.

Did you air test this tank as if you were trying to pop it? This is critical and needs to be done . Even one little pin hole the engine will not draw fuel properly. Try using a drinking straw with a pin hole in it. A bladder will resolve all of your issues but that tank can be made to work and even flipping your needle valve over should improve what I already see.

I see the screen on the venturi, I have drilled and opened up venturi's but the screen on it makes a bit more difficult to do so. You never know if the venturi is opened up unless it's checked. 5/32" is the max before breaking into the jet holes but if the venturi has been opened too far, the engine usually quits a second or two after you release it. This wouldn't be a issue using a bladder.

Ken Cook- Top Poster

- Posts : 5644

Join date : 2012-03-27

Location : pennsylvania

germanbuddy- Gold Member

- Posts : 197

Join date : 2017-10-18

Age : 67

Location : near Heidelberg

Re: APC 6x4 shaft hole to large for TeeDee 049

Re: APC 6x4 shaft hole to large for TeeDee 049

Thanks for that solid info Ken. I believe it when you say the tanks are not good. I found that out when the filler vent slid right out of the tank as if like you said, it was never soldered. Total fail. No time for that. The tank is coming off and will spend the rest of its life in a junk box. Im going straight to a pressure bladder.

I took the NVA off to check if the venturi was drilled, and since an 1/8" drill bit would not go through it I am assuming it wasn't drilled? I just put the NVA back on so I wont lose it, hence the incorrect position. I am going to replace it asap with an Ace RC fine thread NVA. Thanks for sharing the info. Much appreciated.

Kevin

I took the NVA off to check if the venturi was drilled, and since an 1/8" drill bit would not go through it I am assuming it wasn't drilled? I just put the NVA back on so I wont lose it, hence the incorrect position. I am going to replace it asap with an Ace RC fine thread NVA. Thanks for sharing the info. Much appreciated.

Kevin

kevin king- Silver Member

- Posts : 95

Join date : 2020-04-16

Re: APC 6x4 shaft hole to large for TeeDee 049

Re: APC 6x4 shaft hole to large for TeeDee 049

Nice Job. I have no idea what APC was thinking using such a large diameter hole.

Kevin.

kevin king- Silver Member

- Posts : 95

Join date : 2020-04-16

Re: APC 6x4 shaft hole to large for TeeDee 049

Re: APC 6x4 shaft hole to large for TeeDee 049

Kevin the NVAs are in the mail

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: APC 6x4 shaft hole to large for TeeDee 049

Re: APC 6x4 shaft hole to large for TeeDee 049

fredvon4 wrote:Kevin the NVAs are in the mail

kevin king- Silver Member

- Posts : 95

Join date : 2020-04-16

Re: APC 6x4 shaft hole to large for TeeDee 049

Re: APC 6x4 shaft hole to large for TeeDee 049

As for the APC props, I found a near perfect fit for a bushing by using a roller on an old VHS tape. Just had to run a drill bit through it. Speaking of Vhs tapes please subscribe to my control line channel. There are over 500 videos converted from vhs and dvd. https://www.youtube.com/channel/UCQLZOloDrMlE4LDcTwc1wvw

kevin king- Silver Member

- Posts : 95

Join date : 2020-04-16

Re: APC 6x4 shaft hole to large for TeeDee 049

Re: APC 6x4 shaft hole to large for TeeDee 049

from Kevin:

I have no idea what APC was thinking using such a large diameter hole.

maybe they think we run such props on our Nelson on bladder for

"the BLADDER GRABBER Combat Contest" Wash. .

Just click the APC contact button for your question.

I have no idea what APC was thinking using such a large diameter hole.

maybe they think we run such props on our Nelson on bladder for

"the BLADDER GRABBER Combat Contest" Wash. .

Just click the APC contact button for your question.

germanbuddy- Gold Member

- Posts : 197

Join date : 2017-10-18

Age : 67

Location : near Heidelberg

Re: APC 6x4 shaft hole to large for TeeDee 049

Re: APC 6x4 shaft hole to large for TeeDee 049

Since APC has gotten stingy on the center prop adapters. I have found plastic tubing when I went over to the train side of my hobby shop.

There are different diameter sizes of plastic tubing that you can purchase to make up the spacers needed for what you need.

They slip into each other like the brass tubing.

The wall thickness on the plastic tubing is more than the brass tubing and you can super glue the spacers in the prop center hub when you get the right size you want.

FYI

There are different diameter sizes of plastic tubing that you can purchase to make up the spacers needed for what you need.

They slip into each other like the brass tubing.

The wall thickness on the plastic tubing is more than the brass tubing and you can super glue the spacers in the prop center hub when you get the right size you want.

FYI

Last edited by sosam117 on Sun Dec 12, 2021 2:44 pm; edited 1 time in total (Reason for editing : added prop center hub)

sosam117- Diamond Member

- Posts : 1351

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: APC 6x4 shaft hole to large for TeeDee 049

Re: APC 6x4 shaft hole to large for TeeDee 049

Thanks Sosam. I suppose brass would be better than plastic, but i dont have any in stock. Pre covid days I could go into the local hobby shop and find what I need. The plastic bushing was off a smidge. It was obvious after balancing it. So i filed the hole in the bushing toward the heavy side. Also got rid of that Perfect suction tank and got the new bladder housing made and installed. I need nose weight on this plane I'm not concerned about weight. The motor is now waiting for the Ace RC NVA and some bladder hardware from Texas Timers.

kevin king- Silver Member

- Posts : 95

Join date : 2020-04-16

Similar topics

Similar topics» WTB shaft spacer for props with larger hole

» Cox powered jet-pump for model Sprint Boat

» Parts for RR-1

» Cox 049 Crank Shaft and Case Types

» Pee Wee - Play in prop shaft?

» Cox powered jet-pump for model Sprint Boat

» Parts for RR-1

» Cox 049 Crank Shaft and Case Types

» Pee Wee - Play in prop shaft?

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules