Log in

Search

Latest topics

» My N-1R build logby roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Fri Nov 22, 2024 11:32 am

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

Cox Engine of The Month

Playing With Foam

Page 1 of 1

Playing With Foam

Playing With Foam

Recently, I've been experimenting and building with foam board, both with and without the paper backing. Without the backing, it's pretty flimsy so I needed a strong, but lightweight material to add strength in certain locations. I've settled on fiberglass window screen -- it's light, flexible and incredibly strong, plus CHEAP. After wiping down with acetone (there may be release agents on it, maybe not), I stick it on like fiberglass using Elmer's ProBond Advanced glue. The glue choice is probably not too important, but I don't think CA would be the best bet. It should work great for reinforcing the butt joint in a wing. I have also laminated it between sheets -- adds a lot of stiffness.

The downside is that it is not very smooth, but at the speeds we fly, I doubt parasitic drag is a big player.

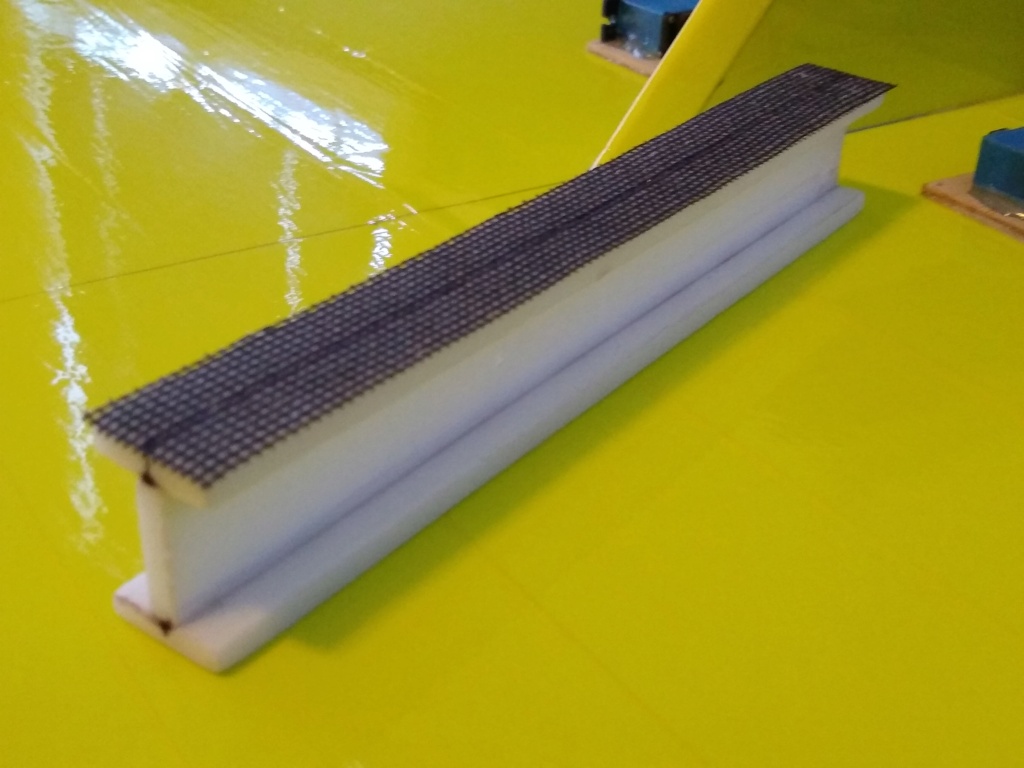

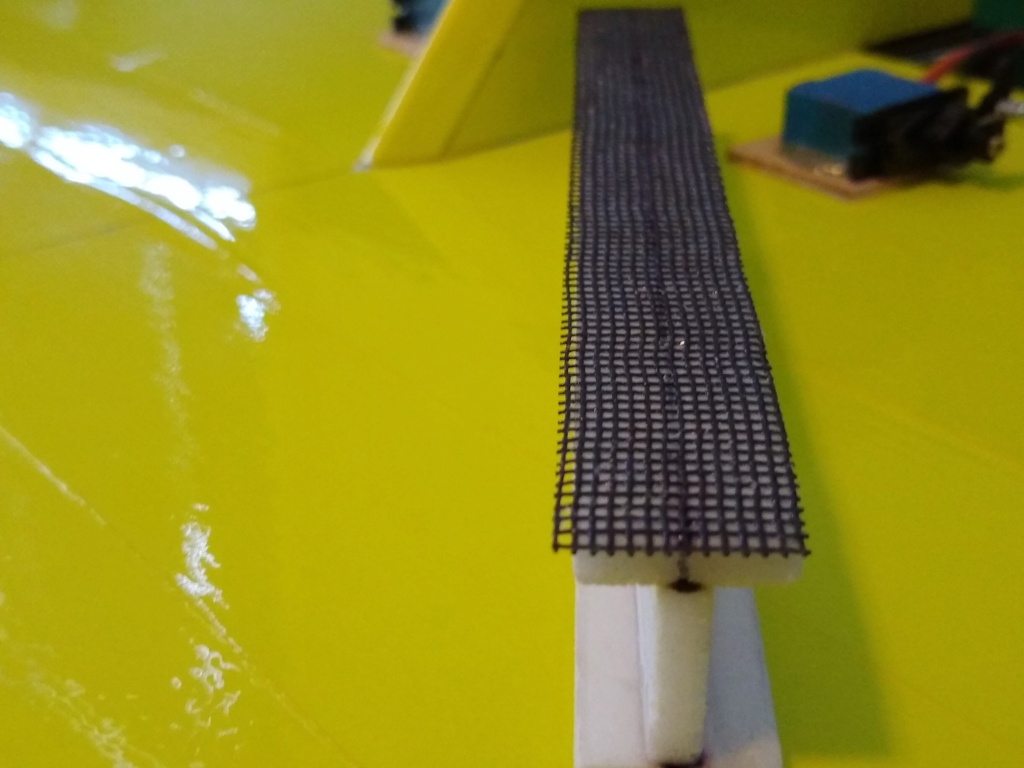

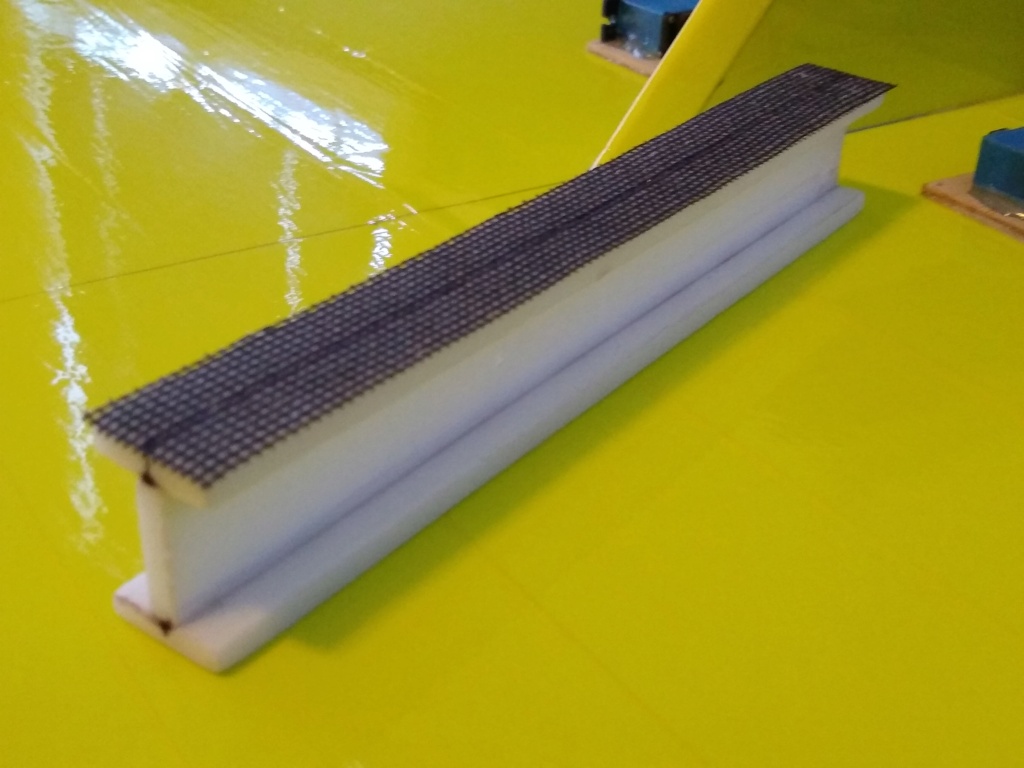

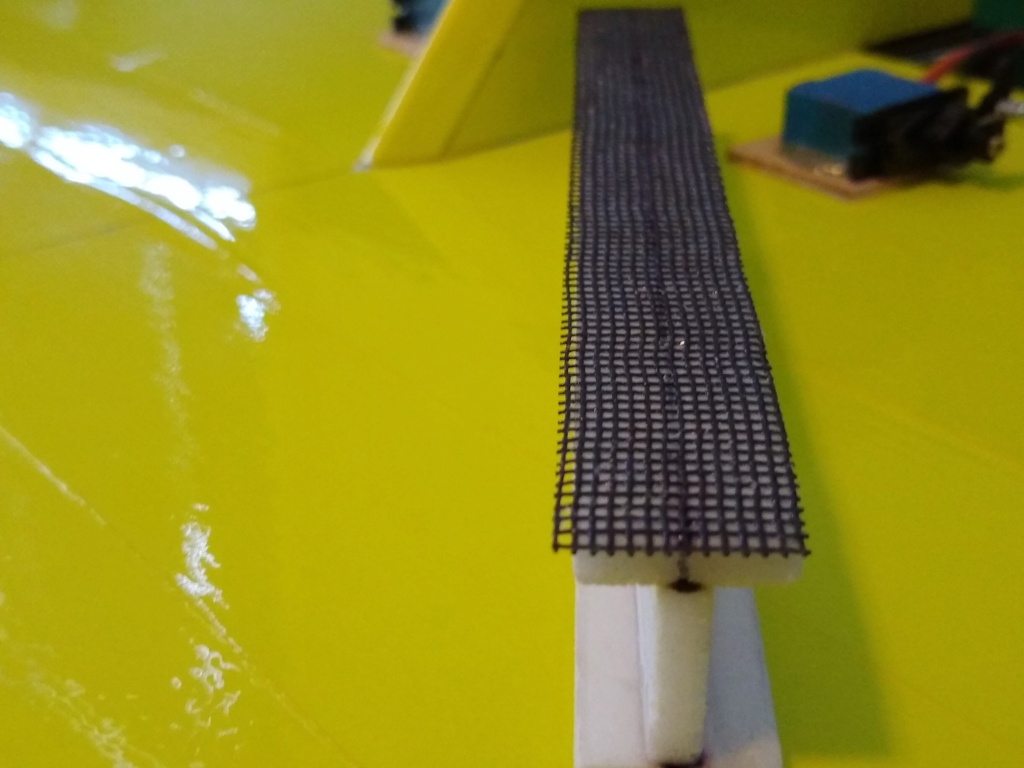

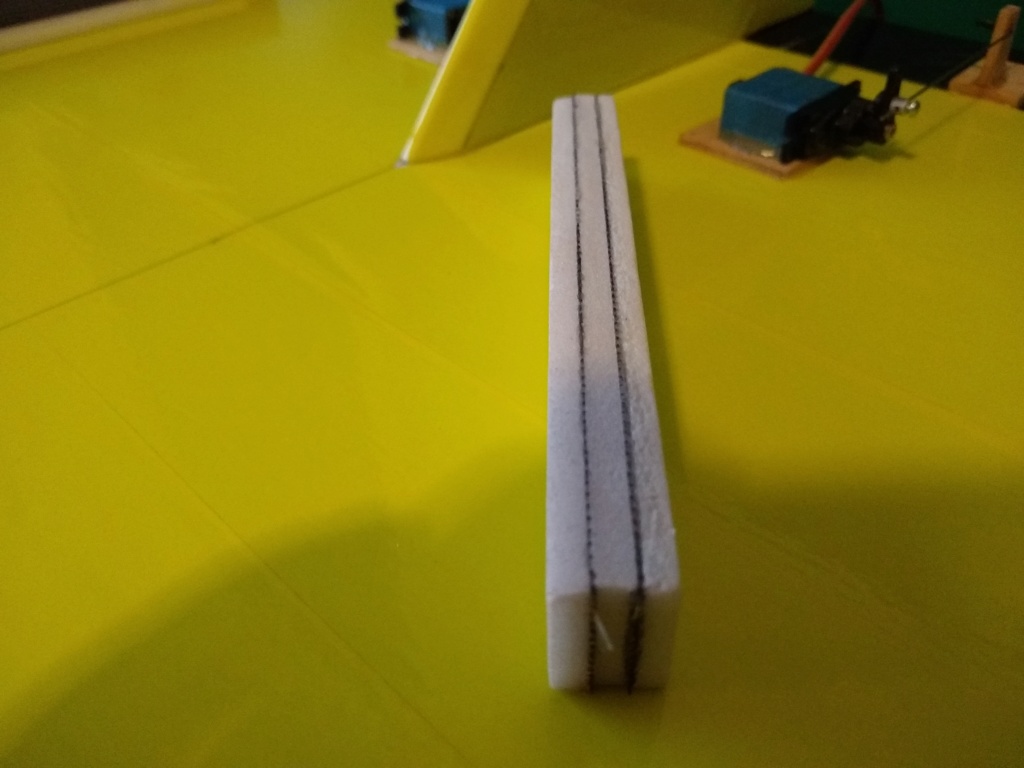

Here's a little I-beam spar test piece -- finished product is nicely trimmed.

That I-beam is made from Dollar Tree foam board (20"x30" board is $0.99 IIRC), 3/16" thick after the paper is removed. The beam is 3/4" wide, 1"tall and 7.125" long; weight is 3.19 grams. I supported each end on 3/4" blocks, then loaded it with 6.4 pounds W/O much deflection. My weights were 25.75 ozs. The 5th weight caused twisting deflection. This beam had screen only on one flange and when tested, I put it on the bottom -- under tension.

I have two other constructions with the screen running vertically -- each supported over 8 pounds. I'll see if I can get some pics this evening.

The downside is that it is not very smooth, but at the speeds we fly, I doubt parasitic drag is a big player.

Here's a little I-beam spar test piece -- finished product is nicely trimmed.

That I-beam is made from Dollar Tree foam board (20"x30" board is $0.99 IIRC), 3/16" thick after the paper is removed. The beam is 3/4" wide, 1"tall and 7.125" long; weight is 3.19 grams. I supported each end on 3/4" blocks, then loaded it with 6.4 pounds W/O much deflection. My weights were 25.75 ozs. The 5th weight caused twisting deflection. This beam had screen only on one flange and when tested, I put it on the bottom -- under tension.

I have two other constructions with the screen running vertically -- each supported over 8 pounds. I'll see if I can get some pics this evening.

Re: Playing With Foam

Re: Playing With Foam

You can use the lightweight spackle from DAP to fill in the window screen on your spar.

https://www.dap.com/products-projects/product-categories/patch-repair/drywall-spackling/fast-n-final/

I have been using this spackle for almost a year on my planes to fill in the balsa grain before painting/doping.

It is white in color and if you add one or two shots of water from a bottle sprayer to thin it out it fills the grain extremely well.

Though you really don't need to thin it out as is.

Just if it seems to be drying out?

After it dries, I lightly sand it with 320 or 400 grit sand paper to knock off the high spots.

https://www.dap.com/products-projects/product-categories/patch-repair/drywall-spackling/fast-n-final/

I have been using this spackle for almost a year on my planes to fill in the balsa grain before painting/doping.

It is white in color and if you add one or two shots of water from a bottle sprayer to thin it out it fills the grain extremely well.

Though you really don't need to thin it out as is.

Just if it seems to be drying out?

After it dries, I lightly sand it with 320 or 400 grit sand paper to knock off the high spots.

sosam117- Diamond Member

- Posts : 1350

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: Playing With Foam

Re: Playing With Foam

sosam117 wrote:You can use the lightweight spackle from DAP to fill in the window screen on your spar.

That's a good idea and absolutely true. I have been using it for some time, even as a filler for cut foam wings.

It seems to be a mixture of glass microspheres and an air drying binder. I once tried to thin it enough to paint on as a primer, but ended up with the microspheres floating to the top and liquid in the bottom. That didn't work out ..........

Last edited by andrew on Wed Aug 25, 2021 8:45 pm; edited 1 time in total

Re: Playing With Foam

Re: Playing With Foam

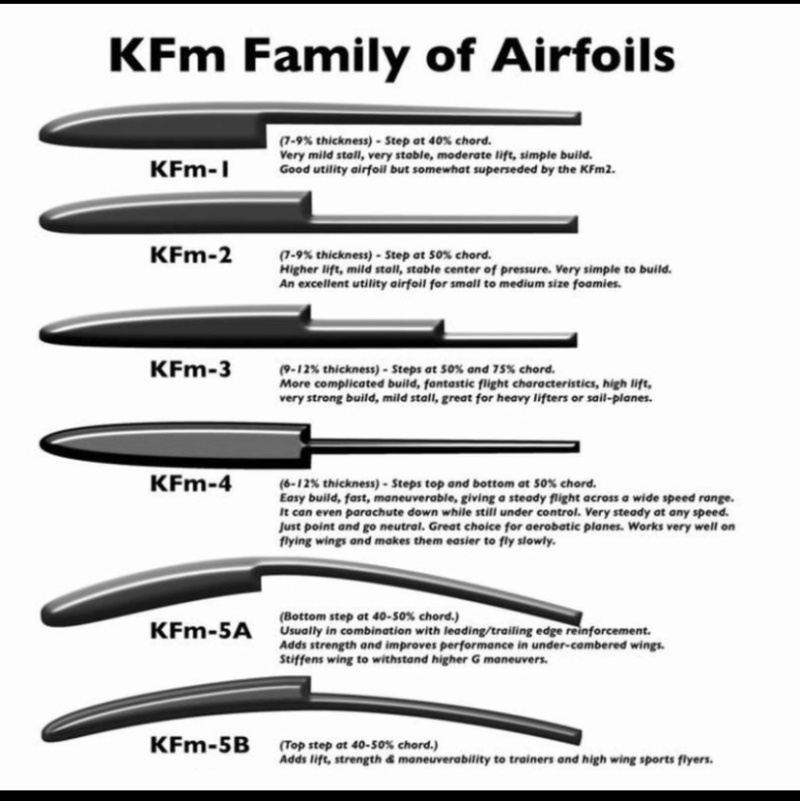

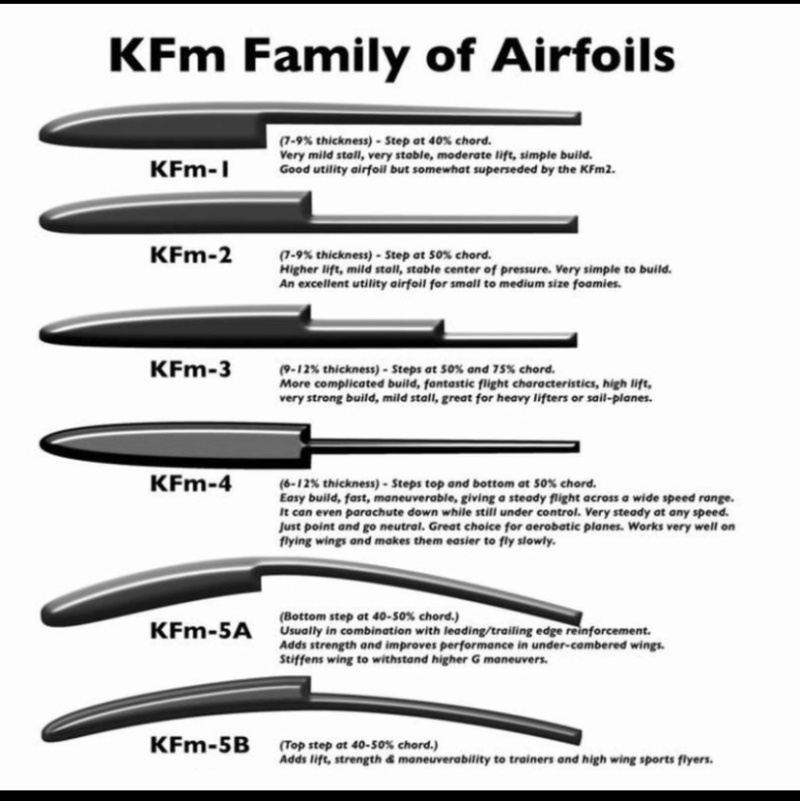

That’s a lot of weight to support with that little mass…. Congratulations! …. Good engineering….. I think the fg caps are key… Still without adding much mass….I remember the Ace foam wing kits instructed to add strapping tape to the top and bottom of their foam wings…. Made them much stiffer!!… The KM series foam airfoils look interesting for quick builds…. Would be interesting to compare deflection on one of those

Robert

Robert

rdw777- Diamond Member

Posts : 1718

Join date : 2021-03-11

Location : West Texas

Re: Playing With Foam

Re: Playing With Foam

rdw777 wrote:….I remember the Ace foam wing kits instructed to add strapping tape to the top and bottom of their foam wings…. Made them much stiffer!!… The KM series foam airfoils look interesting for quick builds…. Would be interesting to compare deflection on one of those.

Robert -

I still have a couple of molded foam wings with strapping tape on the bottom -- it added significant stiffness!!

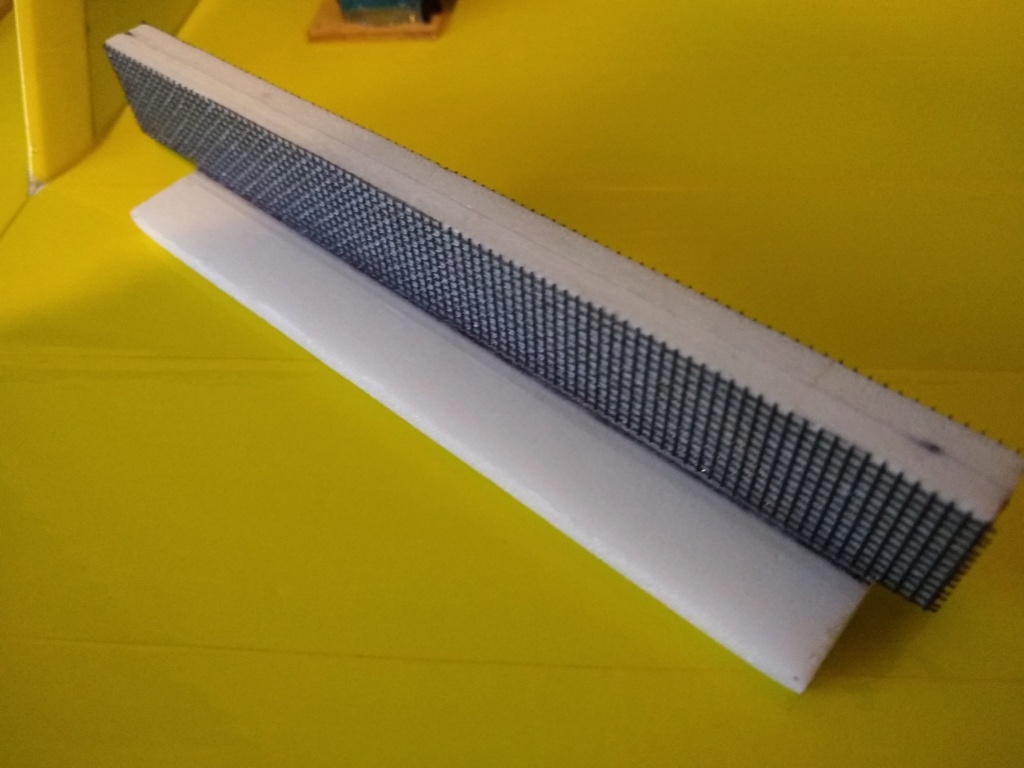

Here are a couple of "foolin' around" pieces. The verticals in each are 3/4" tall. The double laminate is 5.375" long and weighs 3.1 grams. The larger piece is 6.5" long and weighs 4.7 grams. I loaded both with just over 8 pounds (3628 grams) in the center -- the pics were after the load test. Obviously, they're not very long, but are still strong enough to be used as a spar in a foam wing. Having the screen laminated within the foam or on both sides seems to help reduce the tendency to twist under load. This approach is almost identical to sailboat construction where nidacore, hexcel, honeycomb composite, closed cell foam or balsa is sandwiched between fiberglass layers, except it's a ton cheaper and much easier to lay up.

Re: Playing With Foam

Re: Playing With Foam

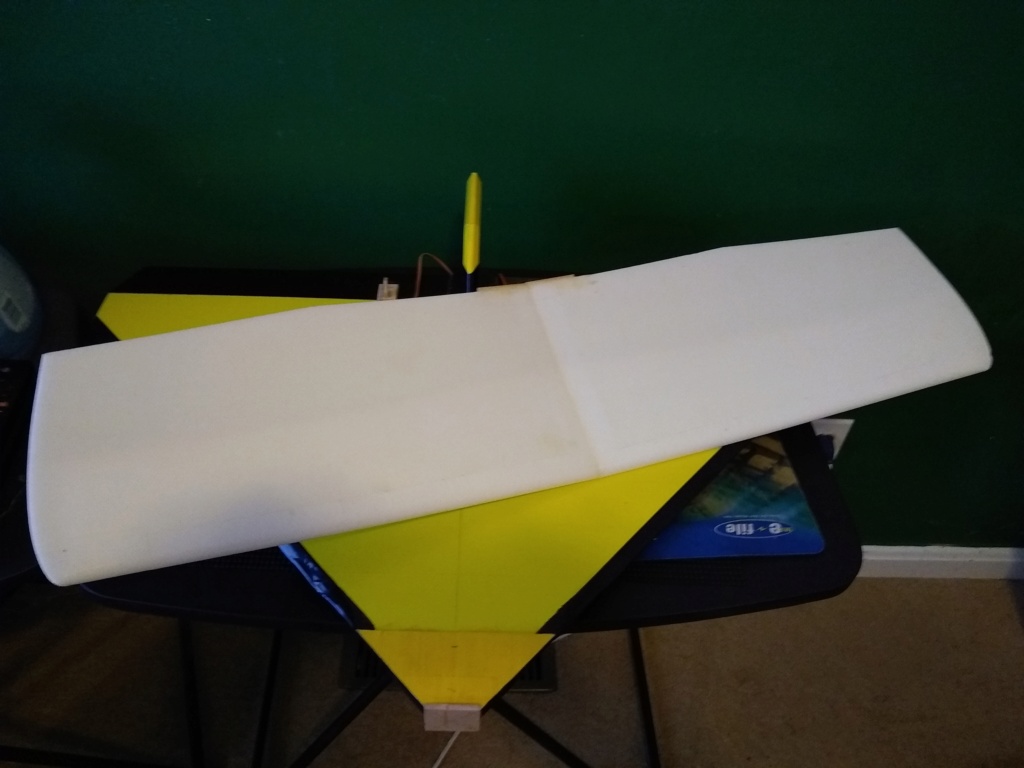

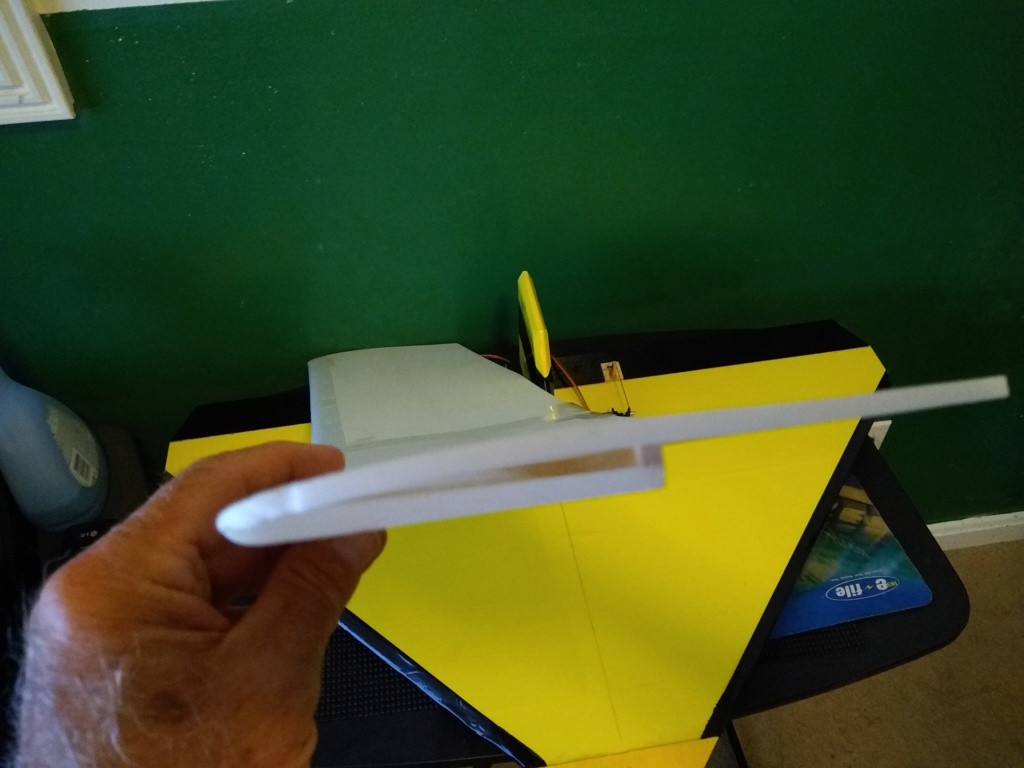

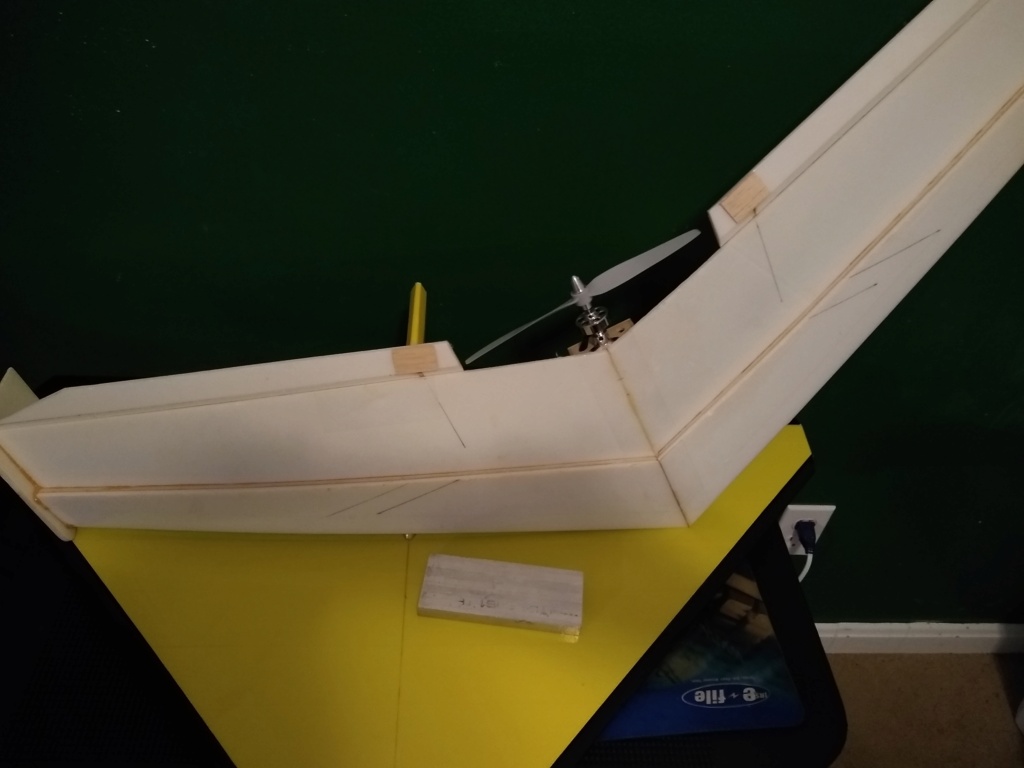

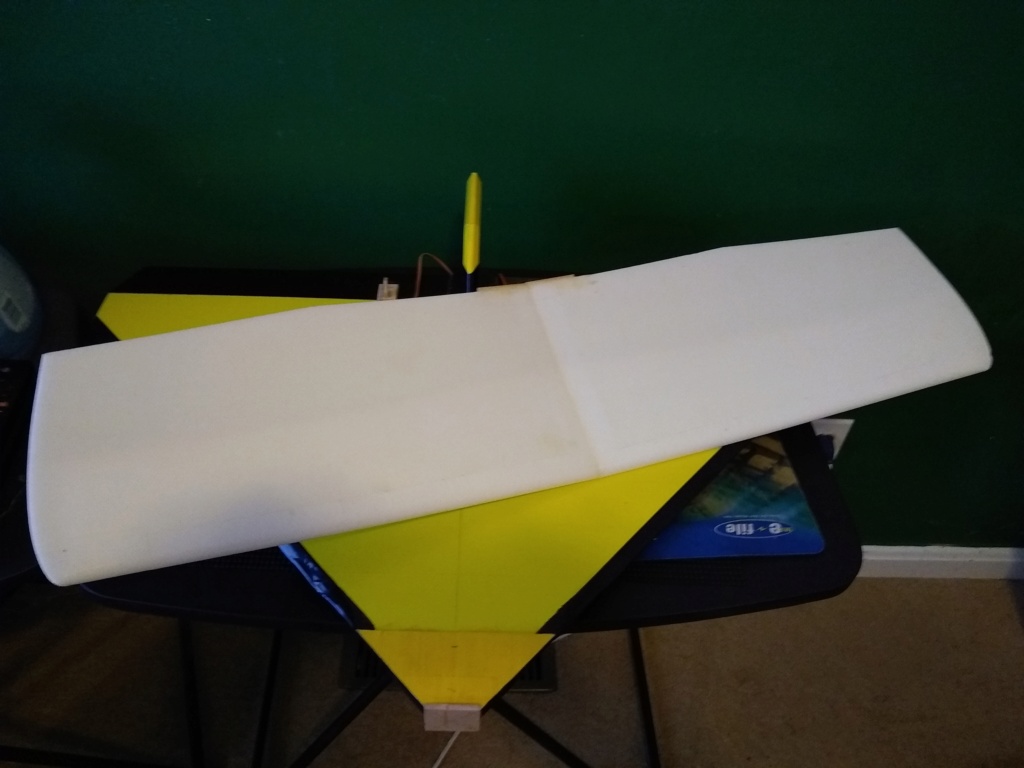

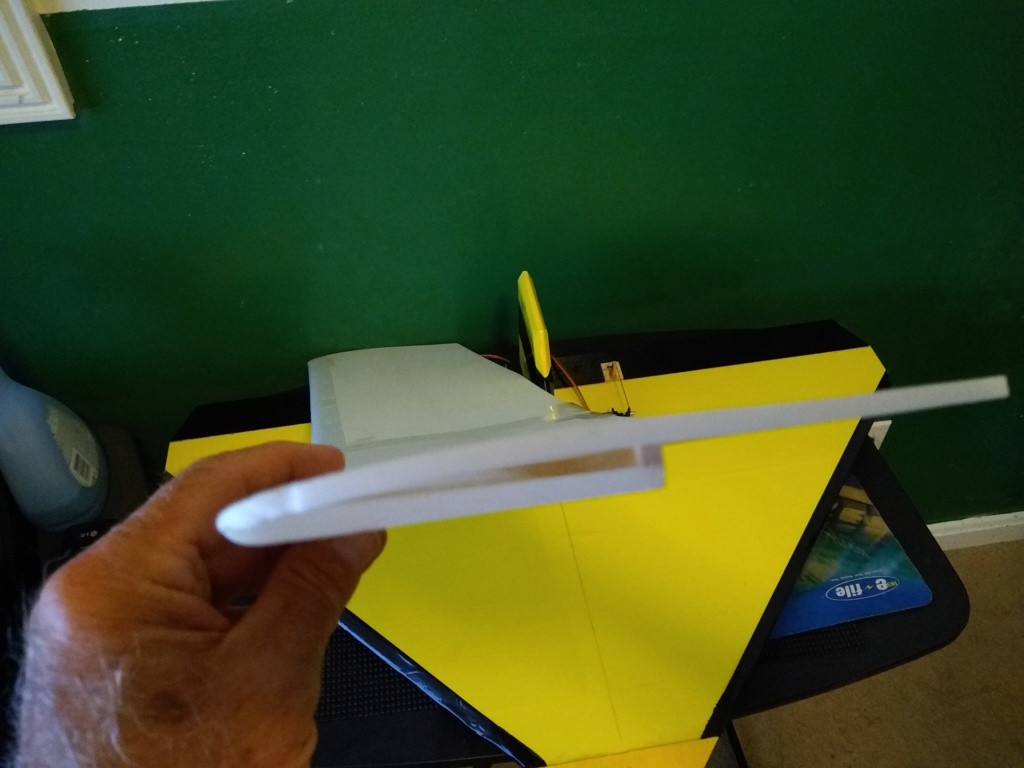

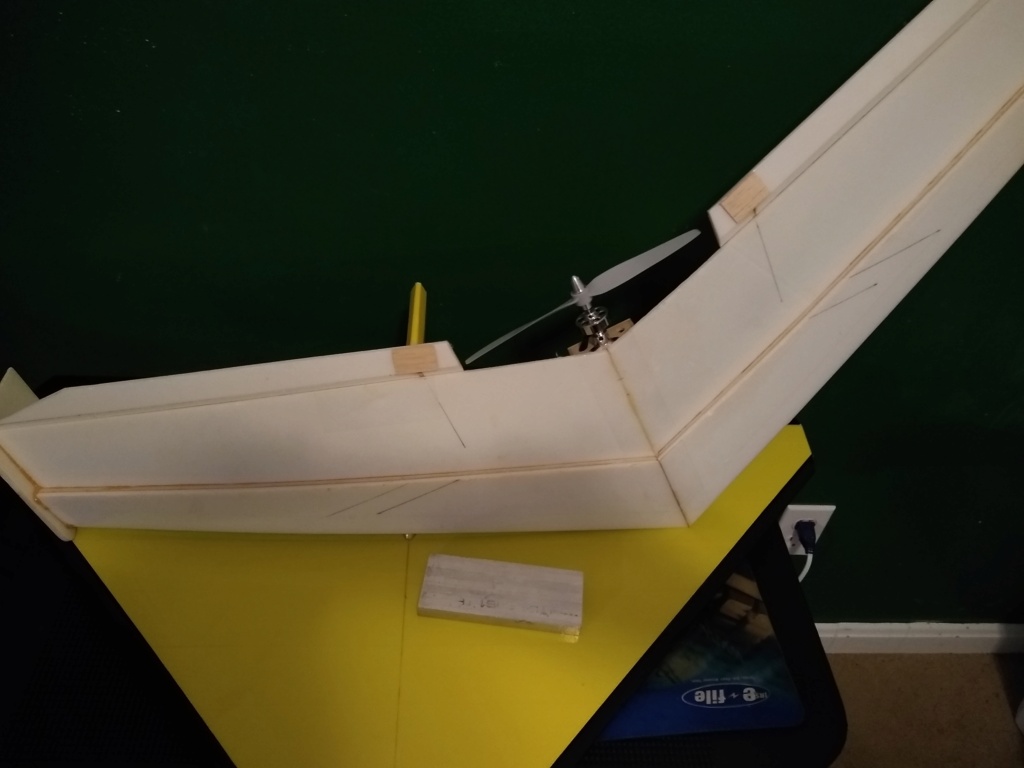

You mentioned the KM series airfoil -- I'm not familiar with those. Did you perhaps mean the KF (Kline-Fogleman) series found in foamys? I've built a few of those, but without using the fiberglass screen. I wish I had applied a strip, maybe 4 strands wide on the bottom, at the spar location, to help maintain the shape -- this stuff is so tough that I can't pull a 4 strand piece apart -- not saying much at my age.

The flying wing is 36"; the conventional wing is about 34".

The flying wing is 36"; the conventional wing is about 34".

Re: Playing With Foam

Re: Playing With Foam

Interesting work on the laminate beams and stress testing them….If you wanted you could make an example a bit longer, say 12”, Then support it at set intervals, weight it, and measure deflections…. You could then establish a curve to see how longer sections may behave….. If you like doing that sort of thing

Yup, KF…. Not KM….My bad…I had a couple of wings with true wing type air foils and they were pitch sensitive with speed change….. Your flying wing is a single fold with a spar?….How does it fly?….I thought about another flying wing someday and maybe using KFm4….. Basically symmetrical….. Bet it would be stout with the fg mesh laminated in….

Yup, KF…. Not KM….My bad…I had a couple of wings with true wing type air foils and they were pitch sensitive with speed change….. Your flying wing is a single fold with a spar?….How does it fly?….I thought about another flying wing someday and maybe using KFm4….. Basically symmetrical….. Bet it would be stout with the fg mesh laminated in….

rdw777- Diamond Member

Posts : 1718

Join date : 2021-03-11

Location : West Texas

Similar topics

Similar topics» Playing With Planes....

» Foam safe CA?

» Playing with Engines Out in the Shop

» foam board

» Playing around with a sandcast Enya .29 Tornado

» Foam safe CA?

» Playing with Engines Out in the Shop

» foam board

» Playing around with a sandcast Enya .29 Tornado

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules