Log in

Search

Latest topics

» Roger Harris revisitedby Oldenginerod Yesterday at 11:18 pm

» Engine choice

by 1975 control line guy Yesterday at 9:51 pm

» Night flying at Walters RC park

by 1975 control line guy Yesterday at 7:29 pm

» Happy 77th birthday Andrew!

by GallopingGhostler Yesterday at 7:10 pm

» Cox films/videos...

by GallopingGhostler Yesterday at 7:07 pm

» Cox 020 PeeWee rebuild questions

by LooseSpinner99 Yesterday at 6:13 pm

» Did you spot the Cox engine in this NASA research video?

by balogh Yesterday at 5:08 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 2:54 pm

» Tee Dee .020 combat model

by 1/2A Nut Yesterday at 10:34 am

» Purchased the last of any bult engines from Ken Enya

by sosam117 Yesterday at 8:15 am

» TEE DEE Having issues

by balogh Yesterday at 7:42 am

» My N-1R build log

by roddie Yesterday at 12:32 am

Cox Engine of The Month

C-Clip pliers and the clutch connection

Page 1 of 1

C-Clip pliers and the clutch connection

C-Clip pliers and the clutch connection

Copied from the MG Midget forum and reprinted here because most here seem to be asleep. Reference roddie!

I always knew them as "Truarc Pliers", but "C Clip" Pliers now-a-days seems to be the more commonly accepted term.

Was in Tractor Supply yesterday rummaging around in their bargain tool bin when I found a set that may in-fact be useful. I have tried Irwin's and found them finicky to assemble and these pivots (upper right) are down right shameful.. The TS pliers (lower right) seem to be the best compromise, but i haven't tried them yet. The single purpose Vaco (Yellow handle) works best, but you need all types of them to be effective. I would think that Snap-on has a workable set.

Anyhow this all started several months as I was driving home in my 1977 MG Midget. I shifted into second and the clutch felt rather funny, shifted into third and lost it completely. Oh well, I was only half a mile away from home so I left it there. Problem was, my driveway is on a hill and i usually select second going up it. No way this time so I left it in third and lugged up the hill and smoothly glided into the open garage door.

Popped the hood and looked at the clutch master cylinder. Rubber boot had come off and the plunger pin had slipped off the exposed piston. The retaining C clip had failed. Thinking if it happened once, it will happen again so I bought an after-market master cylinder installed and bled it. Which leads me to this:

The clutch pedal itself did not achieve the level of the brake pedal coming in at about 2 inches below. A couple of years before I had redone the pedal box assembly and replaced the worn clutch and pressure plate with new so I knew no problem there but the clutch was engaging very near the floor. No problem it worked Curious I got on line and found out that this is a common problem, that over time the clutch pedal is bent downward and has to be heat treated and bent back up.

Crazy

Just a nothing in particular wake-up call. And............and just maybe you have a better c-clip plier suggestion?

I always knew them as "Truarc Pliers", but "C Clip" Pliers now-a-days seems to be the more commonly accepted term.

Was in Tractor Supply yesterday rummaging around in their bargain tool bin when I found a set that may in-fact be useful. I have tried Irwin's and found them finicky to assemble and these pivots (upper right) are down right shameful.. The TS pliers (lower right) seem to be the best compromise, but i haven't tried them yet. The single purpose Vaco (Yellow handle) works best, but you need all types of them to be effective. I would think that Snap-on has a workable set.

Anyhow this all started several months as I was driving home in my 1977 MG Midget. I shifted into second and the clutch felt rather funny, shifted into third and lost it completely. Oh well, I was only half a mile away from home so I left it there. Problem was, my driveway is on a hill and i usually select second going up it. No way this time so I left it in third and lugged up the hill and smoothly glided into the open garage door.

Popped the hood and looked at the clutch master cylinder. Rubber boot had come off and the plunger pin had slipped off the exposed piston. The retaining C clip had failed. Thinking if it happened once, it will happen again so I bought an after-market master cylinder installed and bled it. Which leads me to this:

The clutch pedal itself did not achieve the level of the brake pedal coming in at about 2 inches below. A couple of years before I had redone the pedal box assembly and replaced the worn clutch and pressure plate with new so I knew no problem there but the clutch was engaging very near the floor. No problem it worked Curious I got on line and found out that this is a common problem, that over time the clutch pedal is bent downward and has to be heat treated and bent back up.

Crazy

Just a nothing in particular wake-up call. And............and just maybe you have a better c-clip plier suggestion?

rsv1cox- Top Poster

Posts : 11253

Join date : 2014-08-18

Location : West Virginia

Re: C-Clip pliers and the clutch connection

Re: C-Clip pliers and the clutch connection

I’ve always considered those to be snap ring pliers. C clips to me are completely different and require only a slot screwdriver to remove.

I have only had that happen one time where the clutch would release right off the floor. It was caused by the pedal travel over extending the plunger and tearing the rear seal. This happened during bleeding. While it still functioned it was not correct at all. Metal fatigue causing a different pedal height is something new to me. It has never happened to me and I have driven manuals exclusively since I was 16. Interesting.

I have only had that happen one time where the clutch would release right off the floor. It was caused by the pedal travel over extending the plunger and tearing the rear seal. This happened during bleeding. While it still functioned it was not correct at all. Metal fatigue causing a different pedal height is something new to me. It has never happened to me and I have driven manuals exclusively since I was 16. Interesting.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: C-Clip pliers and the clutch connection

Re: C-Clip pliers and the clutch connection

Hi Bob,

I hear you loud and clear as a British car type of guy. So my "fish was so big" story finished the same way, but farther from home. Keep in mind I live an hour west of Tuscaloosa, AL.

About twelve years ago I drove my TR6 to Ft. Gordon, Augusta, GA (8 hour drive) for a Senior NCO course. I successfully completed the course, and went to check out of post lodging near the gate. My clutch pedal went soft, and failed to disengage as I parked to turn in room keys.

Returning to the car, I checked clutch fluid and found the master cylinder empty. In the few minutes I was in the building, the slave cylinder dumped it's guts and fluid on the pavement. I was part of a great bunch of Soldiers, so we came up with a plan.

Since the lodging office parking lot dumped out downhill towards the gate, I only had to get the car moving and slip it into gear. The others would cruise ahead and watch signal lights at each of the several intersections to the US Army Reserve center in town (our final check out to go home). They would get ahead of me, and flag me on if the intersecting light was going yellow...which meant my light was about to go green. Once at the Reserve Center, I would park pointing downhill so I could slip into first gear clutch-less by rolling downhill to the required "slip it in gear" speed and begin " ground-looping." Then they would watch the driveway exit and flag me out into a lull in traffic so I could exit the Reserve Center and jump up onto the ring road that caught I-85 and go home.

The plan basically worked! I left base, left the Reserve Center, successfully pulled off fueling up outside of Birmingham by gassing up in a station with a grade at the pumps. I wasn't too concerned until I was getting close to Tuscaloosa. Getting through Tuscaloosa was the hard part. One way is through a manned toll plaza, uphill. I didn't think I could slow down enough to hit the coin box and crawl until the till light could clear me. The other way is MxFarland Blvd...littered with big intersections, Roll Tide, and University Mall (even less likely than the toll plaza), but the last way is to skirt the south edge of the city and pop up just west of the middle of the city...and that is the route I took.

I made it all the way until just after crossing the river, and coming up hill to a red light. I had slowed down and slipped into first gear well before the light, praying it would go green, all while counting the grill rails of the 18 wheeler tailgating me...Bob, as an MGB guy, you know just how much a truck grill spills out of your rearview mirror when he is THAT close! Needless to say, he rode me up the red light where I had no choice but the shut the car off. I got out to motion to the driver that he had to back up 20 feet so I could coast backwards off the road and into the auto repair shop at the intersection.

The shop owner/mechanic had watched the whole mess at the light, and congratulated me on getting off the road. He also said there was nothing he could to my "little British car" since no parts could be available so late in the day. He also said he had too many hours in "this week," so he couldn't help "until next week." I asked if I could use his shop floor jack and one jackstand since I had my own tools in the trunk, at which point he asked if I knew what was wrong with the car. "Yes, Sir," I replied. "My clutch slave cylinder gave out in Augusta several hours ago." He indicated there was no way anyone in Tuscaloosa would have a spare. So I asked again for the use of his jack and stand if I could have the slave cylinder in hand before he locked up. He agreed!

I called home, talked my wife to the spare on the shelf, had her also grab the gallon of silicone brake fluid, and bring them to where I was. Ninety minutes later she and my son roll in, just as the shop owner was clearing his register. As agreed, he lent me his jack and stand, and I slipped under the car to change the failed slave cylinder. My then-eight-year old son helped me bleed it right there in the guy's lot. The shop owner came out and shook my hand...he just couldn't believe it.

My family are dinner in Tuscaloosa that night, and rolled on to the house with a working clutch...after I had done the first 325 miles with no clutch hydraulics!

Yup, true story!

I hear you loud and clear as a British car type of guy. So my "fish was so big" story finished the same way, but farther from home. Keep in mind I live an hour west of Tuscaloosa, AL.

About twelve years ago I drove my TR6 to Ft. Gordon, Augusta, GA (8 hour drive) for a Senior NCO course. I successfully completed the course, and went to check out of post lodging near the gate. My clutch pedal went soft, and failed to disengage as I parked to turn in room keys.

Returning to the car, I checked clutch fluid and found the master cylinder empty. In the few minutes I was in the building, the slave cylinder dumped it's guts and fluid on the pavement. I was part of a great bunch of Soldiers, so we came up with a plan.

Since the lodging office parking lot dumped out downhill towards the gate, I only had to get the car moving and slip it into gear. The others would cruise ahead and watch signal lights at each of the several intersections to the US Army Reserve center in town (our final check out to go home). They would get ahead of me, and flag me on if the intersecting light was going yellow...which meant my light was about to go green. Once at the Reserve Center, I would park pointing downhill so I could slip into first gear clutch-less by rolling downhill to the required "slip it in gear" speed and begin " ground-looping." Then they would watch the driveway exit and flag me out into a lull in traffic so I could exit the Reserve Center and jump up onto the ring road that caught I-85 and go home.

The plan basically worked! I left base, left the Reserve Center, successfully pulled off fueling up outside of Birmingham by gassing up in a station with a grade at the pumps. I wasn't too concerned until I was getting close to Tuscaloosa. Getting through Tuscaloosa was the hard part. One way is through a manned toll plaza, uphill. I didn't think I could slow down enough to hit the coin box and crawl until the till light could clear me. The other way is MxFarland Blvd...littered with big intersections, Roll Tide, and University Mall (even less likely than the toll plaza), but the last way is to skirt the south edge of the city and pop up just west of the middle of the city...and that is the route I took.

I made it all the way until just after crossing the river, and coming up hill to a red light. I had slowed down and slipped into first gear well before the light, praying it would go green, all while counting the grill rails of the 18 wheeler tailgating me...Bob, as an MGB guy, you know just how much a truck grill spills out of your rearview mirror when he is THAT close! Needless to say, he rode me up the red light where I had no choice but the shut the car off. I got out to motion to the driver that he had to back up 20 feet so I could coast backwards off the road and into the auto repair shop at the intersection.

The shop owner/mechanic had watched the whole mess at the light, and congratulated me on getting off the road. He also said there was nothing he could to my "little British car" since no parts could be available so late in the day. He also said he had too many hours in "this week," so he couldn't help "until next week." I asked if I could use his shop floor jack and one jackstand since I had my own tools in the trunk, at which point he asked if I knew what was wrong with the car. "Yes, Sir," I replied. "My clutch slave cylinder gave out in Augusta several hours ago." He indicated there was no way anyone in Tuscaloosa would have a spare. So I asked again for the use of his jack and stand if I could have the slave cylinder in hand before he locked up. He agreed!

I called home, talked my wife to the spare on the shelf, had her also grab the gallon of silicone brake fluid, and bring them to where I was. Ninety minutes later she and my son roll in, just as the shop owner was clearing his register. As agreed, he lent me his jack and stand, and I slipped under the car to change the failed slave cylinder. My then-eight-year old son helped me bleed it right there in the guy's lot. The shop owner came out and shook my hand...he just couldn't believe it.

My family are dinner in Tuscaloosa that night, and rolled on to the house with a working clutch...after I had done the first 325 miles with no clutch hydraulics!

Yup, true story!

_________________

Never enough time to build them all...always enough time to smash them all!

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: C-Clip pliers and the clutch connection

Re: C-Clip pliers and the clutch connection

Our lady neighbour shifted to a more suburban area a number of years ago following the death of her husband. I had serviced her car since new and she still travelled the 45 minutes to my place when she was due. She rang one day saying that she couldn't get the car into gear and could I come and have a look. I instantly suspected the clutch, but the little Kia had a cable clutch rather than hydraulic. I took a bag full of tools and my wife, just in case the problem was too major to fix on the spot and we needed to get it home.

On arrival I found that the whole pedal box had stress-cracked around the pivot. I told the owner that I couldn't fix it here and now and I would need to take it to my place. She was shocked to think that I could possibly drive it with no clutch. "Easy-Peasy" I said.

With Janet following, I hit the key in first gear and it burst forward. After a couple of gear shifts I got accustomed to the shift/rev points and managed to get it into top with very little grinding. First set of traffic lights, saw they were turning red ahead of me so slipped it into neutral and coasted to a gentle stop. First gear, lights go green, hit the key and we were off again. Same story at the next couple of intersections. It was a little nerve-racking in busy suburban traffic but we soon cleared the crush and had a easy drive home. Pulled out the pedal box to weld it up, but the material was so light it was hopeless. Off to the wrecking year for a replacement, fitted and drove back to the lady who still couldn't believe that I drove it home. Might have been a little more difficult if the synchro rings weren't so good, but shifting was easy.

On another note, out here, the pliers that have pointy tips that slot into little holes on the ends of the ring are called Circlip Pliers, and the rings are circlips, either inside or outside. "Snap ring" pliers generally have flat tips which bear directly on the tapered ends of the ring, outside only. The round section rings that secure a C/V joint are also generally called "Snap rings".

The small "C" clips Ron refers to are probably what we call "E" clips. Commonly used on carburettor linkages.

This comment if probably out of character for me (but I still like a joke), but they're also colloquially known as "Jesus clips". That's what you say when it flys off, never to be seen again, and "God only knows" where it went.

On arrival I found that the whole pedal box had stress-cracked around the pivot. I told the owner that I couldn't fix it here and now and I would need to take it to my place. She was shocked to think that I could possibly drive it with no clutch. "Easy-Peasy" I said.

With Janet following, I hit the key in first gear and it burst forward. After a couple of gear shifts I got accustomed to the shift/rev points and managed to get it into top with very little grinding. First set of traffic lights, saw they were turning red ahead of me so slipped it into neutral and coasted to a gentle stop. First gear, lights go green, hit the key and we were off again. Same story at the next couple of intersections. It was a little nerve-racking in busy suburban traffic but we soon cleared the crush and had a easy drive home. Pulled out the pedal box to weld it up, but the material was so light it was hopeless. Off to the wrecking year for a replacement, fitted and drove back to the lady who still couldn't believe that I drove it home. Might have been a little more difficult if the synchro rings weren't so good, but shifting was easy.

On another note, out here, the pliers that have pointy tips that slot into little holes on the ends of the ring are called Circlip Pliers, and the rings are circlips, either inside or outside. "Snap ring" pliers generally have flat tips which bear directly on the tapered ends of the ring, outside only. The round section rings that secure a C/V joint are also generally called "Snap rings".

The small "C" clips Ron refers to are probably what we call "E" clips. Commonly used on carburettor linkages.

This comment if probably out of character for me (but I still like a joke), but they're also colloquially known as "Jesus clips". That's what you say when it flys off, never to be seen again, and "God only knows" where it went.

Oldenginerod- Top Poster

- Posts : 4019

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: C-Clip pliers and the clutch connection

Re: C-Clip pliers and the clutch connection

Fun stories, although the situations may not have felt so funny when they happened

I have a few pairs of those with red-orange-handles in Bob’s picture. Bought at Sears back when I had a job as a ”travelin’ repairman” based in Atlanta, Ga about 20 years ago. Saw many of the pulp&paper mills around the South East. I like the way those pliers can be used on both internal and external clips.

Circlip is the name I am familiar with too. May be a British-English vs American-English thing. In Finland we call them ”seger”, probably originating from an old manufacturer. Just like a wheel loader of any size or color is a ”katepillar”

Yeah, those clips, be they circlips, e-clips or any other variety, have a nasty habit of flyin right past my left ear, never to be seen again. Nowadays I usually cover the pliers and the clip with my free hand to slow the clip down. And stuff rag or something into all oil channels, manifolds, crankcase openings etc where the clip WILL find its way if left uncovered. A long stick with a magnet is a handy tool to have, btw

I have a few pairs of those with red-orange-handles in Bob’s picture. Bought at Sears back when I had a job as a ”travelin’ repairman” based in Atlanta, Ga about 20 years ago. Saw many of the pulp&paper mills around the South East. I like the way those pliers can be used on both internal and external clips.

Circlip is the name I am familiar with too. May be a British-English vs American-English thing. In Finland we call them ”seger”, probably originating from an old manufacturer. Just like a wheel loader of any size or color is a ”katepillar”

Yeah, those clips, be they circlips, e-clips or any other variety, have a nasty habit of flyin right past my left ear, never to be seen again. Nowadays I usually cover the pliers and the clip with my free hand to slow the clip down. And stuff rag or something into all oil channels, manifolds, crankcase openings etc where the clip WILL find its way if left uncovered. A long stick with a magnet is a handy tool to have, btw

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: C-Clip pliers and the clutch connection

Re: C-Clip pliers and the clutch connection

Nothing like an old British car story to liven things up.

I have called them snap ring pliers too Ron, anything that has holes and either expands or compresses works for me. I have tried most of them, at times even grinding down a pair of long nose/needle nose (here we go again) pliers tips in frustration to fit.

I thought these Irwin's were going to be my savior, but no. Different tips are held on by a spring and flop around when used.

Hoping that the new Tractor Supply editions will satisfy. They should, rock solid and easy to use.

My old 1937 Ford had mechanical brakes and clutch. Cables, no hydraulics. Clutch, no problem but stopping was an adventure.

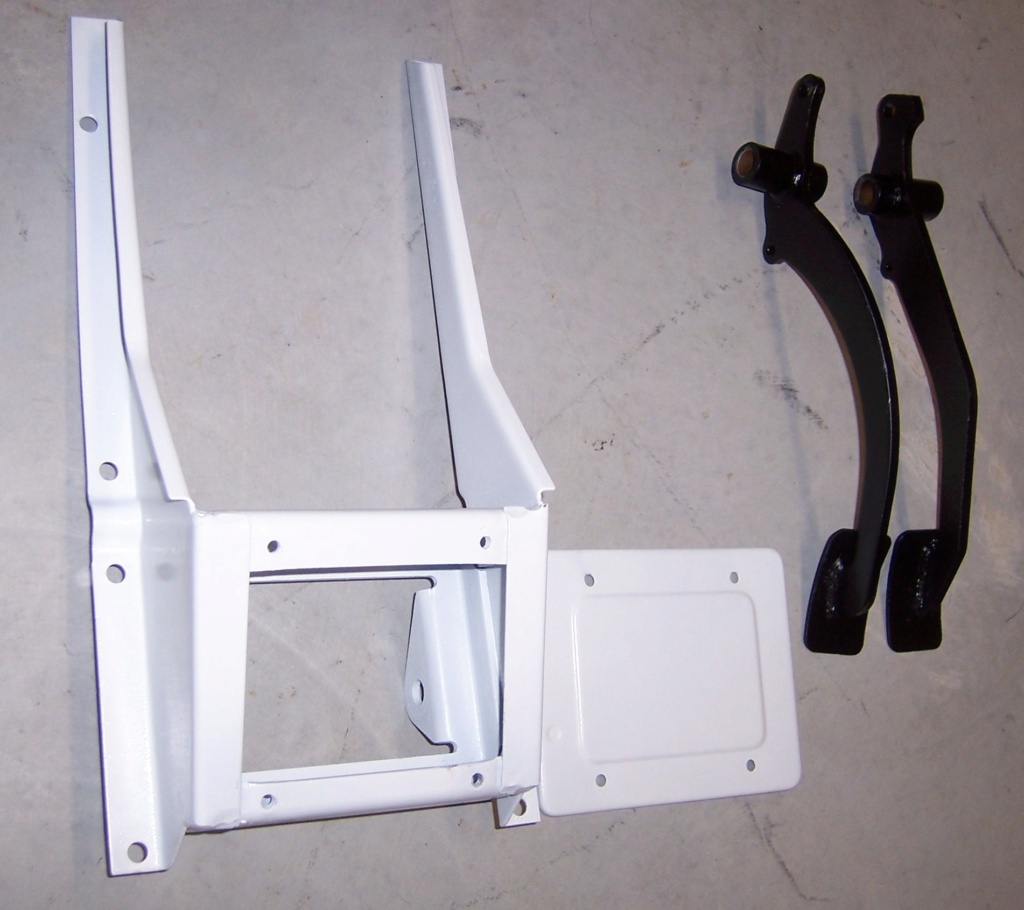

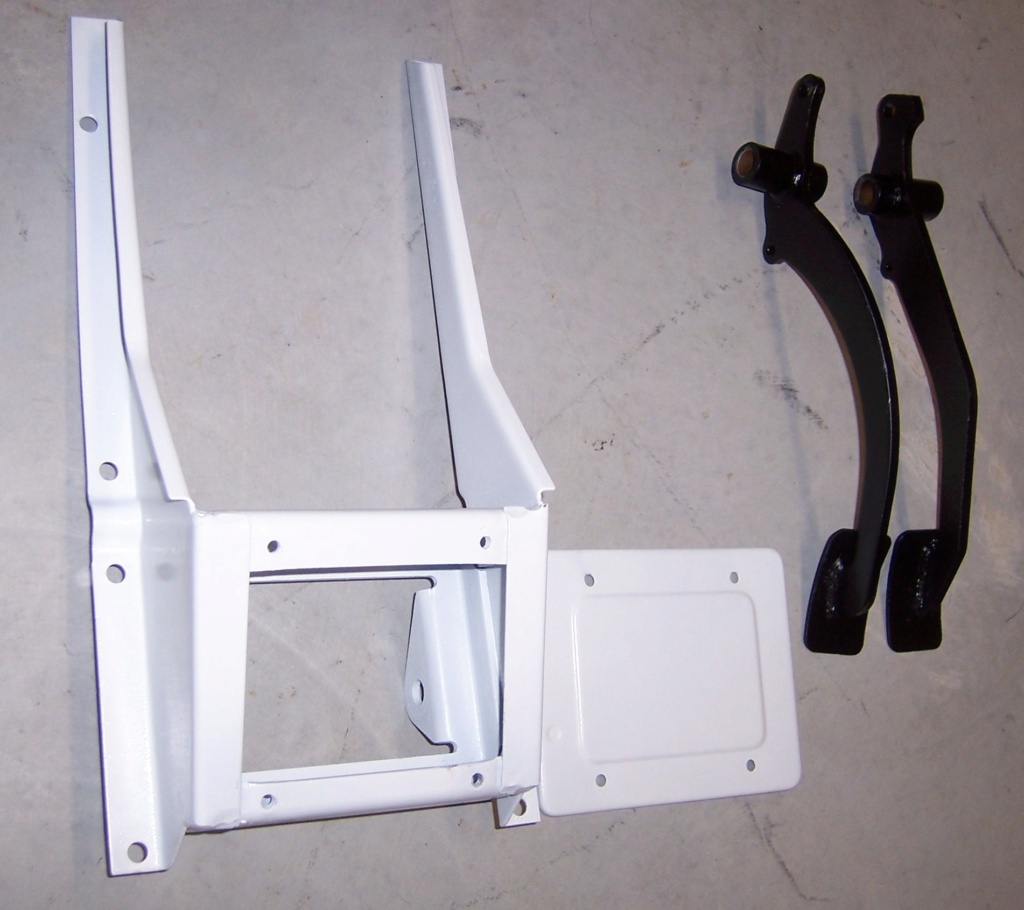

Pedal boxes/hydraulics can be a mess. Out of one of my MG Midgets before and after.

I have called them snap ring pliers too Ron, anything that has holes and either expands or compresses works for me. I have tried most of them, at times even grinding down a pair of long nose/needle nose (here we go again) pliers tips in frustration to fit.

I thought these Irwin's were going to be my savior, but no. Different tips are held on by a spring and flop around when used.

Hoping that the new Tractor Supply editions will satisfy. They should, rock solid and easy to use.

My old 1937 Ford had mechanical brakes and clutch. Cables, no hydraulics. Clutch, no problem but stopping was an adventure.

Pedal boxes/hydraulics can be a mess. Out of one of my MG Midgets before and after.

rsv1cox- Top Poster

Posts : 11253

Join date : 2014-08-18

Location : West Virginia

Re: C-Clip pliers and the clutch connection

Re: C-Clip pliers and the clutch connection

Seems like the clutch hydraulics (among other things) are a weak point of classic British sportscars. I had an MGB with similar problem, although it didn’t fail completely. It would leak a little, and also while waiting in traffic, on 1st gear and the clutch pedal depressed, it would sometimes start to crawl as the work cylinder let go little by little and the clutch started to engage. Well, it is not a good habit to wait on 1st gear for a long time anyway.

If I forgot to refill the fluid, it would take a couple of rapid kicks on the pedal to get the transmission on first. When this happened, I would add fluid when I got home, and by next morning the system had bled itself and worked fine for a while.

I used the car for my daily commute in St. Louis area while working at the big refrigerator plant there. After moving to Atlanta area the traffic with all the nutcases in their Mack-size SUV’s was just too scary. Sitting in the driver’s seat I would look eye-to-eye at the wheel hub of an Escalade on the left lane

If I forgot to refill the fluid, it would take a couple of rapid kicks on the pedal to get the transmission on first. When this happened, I would add fluid when I got home, and by next morning the system had bled itself and worked fine for a while.

I used the car for my daily commute in St. Louis area while working at the big refrigerator plant there. After moving to Atlanta area the traffic with all the nutcases in their Mack-size SUV’s was just too scary. Sitting in the driver’s seat I would look eye-to-eye at the wheel hub of an Escalade on the left lane

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: C-Clip pliers and the clutch connection

Re: C-Clip pliers and the clutch connection

I laughed...did not stress..my TR6 was a daily driver for close to 13 years. The hydraulics lasted fine even after JR rolled the car. Once in its own wheels, we topped off critical fluids and drove it. I expect to return it to daily status as the youngest son gets his license.ans the car gets rebuilt. Yes, these stories are entertaining!

_________________

Never enough time to build them all...always enough time to smash them all!

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: C-Clip pliers and the clutch connection

Re: C-Clip pliers and the clutch connection

Great stories, fun reading!

I frequent many car forums, the other day I read a post from a gent whose throttle cable broke a block away from his house. He went into a whole story about how he had to abandon the car and call for help and what a pain it was. After I stopped laughing I replied and asked why he didn’t just bump the idle and drive the car home…..

When I was young and broke I have driven around without throttle, brakes, clutch, starter several times. One of the many reasons why I only drive manual transmission vehicles.

I frequent many car forums, the other day I read a post from a gent whose throttle cable broke a block away from his house. He went into a whole story about how he had to abandon the car and call for help and what a pain it was. After I stopped laughing I replied and asked why he didn’t just bump the idle and drive the car home…..

When I was young and broke I have driven around without throttle, brakes, clutch, starter several times. One of the many reasons why I only drive manual transmission vehicles.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: C-Clip pliers and the clutch connection

Re: C-Clip pliers and the clutch connection

Love the MGTF in Chevy Chase's Funny Farm.

The pedal box above was out of my 1974 MG Midget, difference between a $5000 car and one for $250, my 1977 Midget. A mess it was dragged out of a damp basement after 18 years of rest or should I say rust. After i restored it the previous owners daughter came out to see it. I had contacted the family to get the original title. Jenny, and her husband and I became quite good friends.

1974 - Day trip to Pittsburg PA to pick it up, son in law and I, got home at dusk. Whole different car. Chrome bumpers, rounded rear wheel wells, 1275 vs. 1500, Su's vs. Stromberg.

1977 "Rubber" not chrome bumpers. Aftermarket, not original master clutch cylinder.

I was able to get the nut off, 9/16" not 1/2" and tilt the PB enough to back the pivot bolt out but not enough to drop the clutch pedal. May have to grind a bit off the PB from inside the car to get it out. Then I can heat the pedal and bend it back to shape.

Think that the clutch doesn't get used more than the brake......it does. Shift four times, brake once. Elongates the master cylinder connection hole.

Got to fix that too while it's out.

BTW - New pliers work great, best yet.

rsv1cox- Top Poster

Posts : 11253

Join date : 2014-08-18

Location : West Virginia

Re: C-Clip pliers and the clutch connection

Re: C-Clip pliers and the clutch connection

Just a Cox Engine Forum Atta-boy.

As noted I posted this exact same thread over on the MG Experience (Midget) forum and did not get a response, not one. This in what is supposed to be a hotbed of sports cars guys. Took a bunch of model engine guys here to pick up on it. Seems someone would have chimed in with - I had the exact same problem and here's what I did about it, or something similar.

It's been a couple of years since I have contributed there, maybe the old guys have died off and they have been replaced by Sunday drivers.....or maybe we are the only ones familiar with C-clip etc. pliers.

As noted I posted this exact same thread over on the MG Experience (Midget) forum and did not get a response, not one. This in what is supposed to be a hotbed of sports cars guys. Took a bunch of model engine guys here to pick up on it. Seems someone would have chimed in with - I had the exact same problem and here's what I did about it, or something similar.

It's been a couple of years since I have contributed there, maybe the old guys have died off and they have been replaced by Sunday drivers.....or maybe we are the only ones familiar with C-clip etc. pliers.

rsv1cox- Top Poster

Posts : 11253

Join date : 2014-08-18

Location : West Virginia

rsv1cox- Top Poster

Posts : 11253

Join date : 2014-08-18

Location : West Virginia

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules