Log in

Search

Latest topics

» Engine choice by 1975 control line guy Today at 9:51 pm

» Night flying at Walters RC park

by 1975 control line guy Today at 7:29 pm

» Happy 77th birthday Andrew!

by GallopingGhostler Today at 7:10 pm

» Cox films/videos...

by GallopingGhostler Today at 7:07 pm

» Cox 020 PeeWee rebuild questions

by LooseSpinner99 Today at 6:13 pm

» Did you spot the Cox engine in this NASA research video?

by balogh Today at 5:08 pm

» Roger Harris revisited

by rsv1cox Today at 3:44 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Today at 2:54 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 10:34 am

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 8:15 am

» TEE DEE Having issues

by balogh Today at 7:42 am

» My N-1R build log

by roddie Today at 12:32 am

Cox Engine of The Month

O49 pan glass or other

Page 1 of 1

O49 pan glass or other

O49 pan glass or other

Anyone seen an 049 pan with mount to suit killer bee

Or could make a glass one 3rd choice us profile

Fusrlage & bernies profile engine mount any suggestions

Rex f.

Or could make a glass one 3rd choice us profile

Fusrlage & bernies profile engine mount any suggestions

Rex f.

rex f.- Banned

- Posts : 40

Join date : 2019-07-11

Age : 81

Location : Scone nsw aust 2337

Re: O49 pan glass or other

Re: O49 pan glass or other

Never seen a pan for a Killer Bee but a glass one would be neat .

Mike1484

Mike1484

Mike1484- Gold Member

- Posts : 303

Join date : 2011-10-28

Age : 76

Location : Northern Ohio

Re: O49 pan glass or other

Re: O49 pan glass or other

Rex, most speed pans are designed for beam mounting as your more than likely aware of. The Killer Bee uses a product backplate. Even in the 50's engines like the Cox Spacebug were utilized with just a L shaped bracket attached at the back of the case. I personally don't like doing this as I feel unless the bracket is of adequate material and attached properly, you give up rpm's due to vibration. The Cox speed pan designed for the TD is extremely fragile due to being magnesium. They're certainly becoming increasingly harder to find and the price lately has been reflecting it's rarity.

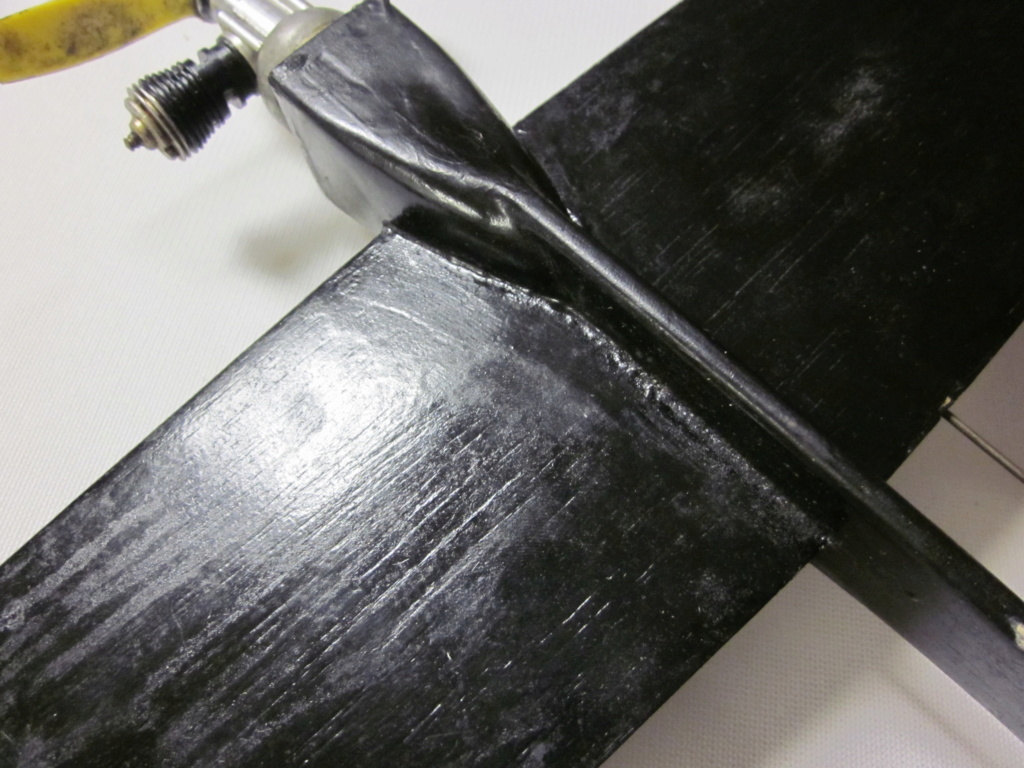

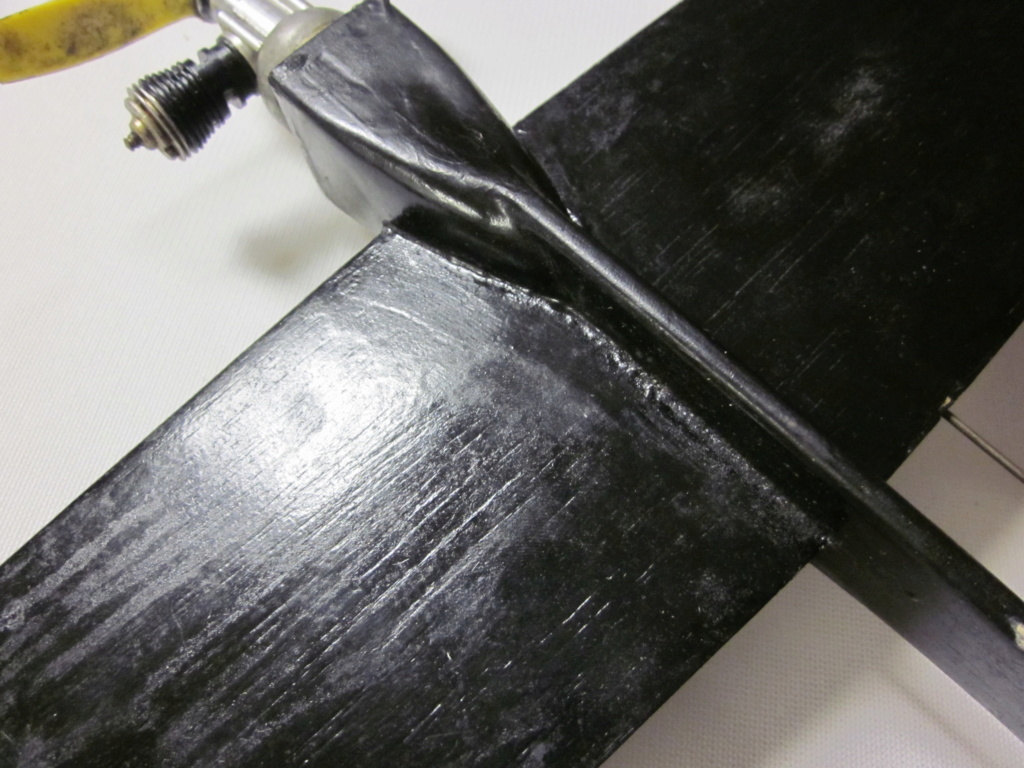

I built this pan from mahogany and bass. The upper portion uses a 3/32" 5 ply platform and balsa glued and shaped on top of it. The lower portion could essentially utilize a dado in the side halves of the body to encapsulate a product backplate similar to the way it's done in the ready to fly plastic models. My model originally had it's wing fixed to the upper portion. Currently, I use a bladder which is a real pain to use internally. If filled too much, I get into control binding issues due to the bellcrank hanging under the wing. I place the bladder inside a party balloon to insure it doesn't get punctured but when under pressure, this is easily done and has happened. Some time ago I purchased bladder material which was reinforced and it wouldn't expand in diameter like the newer stuff I have. This product was pink and skinny, it would expand length wise which was real good for my tight quarters inside.

The front portion of the pan uses a continuous piece of 1/8" ply which has 3- 48 blind nuts bedded into it. In the event I was to use a product engine, this is where a piece of inverted extruded aluminum angle could be use with proper attachment for the engine of your choice.

I built this pan from mahogany and bass. The upper portion uses a 3/32" 5 ply platform and balsa glued and shaped on top of it. The lower portion could essentially utilize a dado in the side halves of the body to encapsulate a product backplate similar to the way it's done in the ready to fly plastic models. My model originally had it's wing fixed to the upper portion. Currently, I use a bladder which is a real pain to use internally. If filled too much, I get into control binding issues due to the bellcrank hanging under the wing. I place the bladder inside a party balloon to insure it doesn't get punctured but when under pressure, this is easily done and has happened. Some time ago I purchased bladder material which was reinforced and it wouldn't expand in diameter like the newer stuff I have. This product was pink and skinny, it would expand length wise which was real good for my tight quarters inside.

The front portion of the pan uses a continuous piece of 1/8" ply which has 3- 48 blind nuts bedded into it. In the event I was to use a product engine, this is where a piece of inverted extruded aluminum angle could be use with proper attachment for the engine of your choice.

Ken Cook- Top Poster

- Posts : 5644

Join date : 2012-03-27

Location : pennsylvania

Re: O49 pan glass or other

Re: O49 pan glass or other

I have never heard of a pan for a Surestart style motor. I think just a standard radial mount - piece of plywood with 3/8" balsa fairings behind and blind nuts behind the plywood is standard on a profile fuselage. Here is a pic of a fiberglass pan. It was an epoxy casting resin with aluminum dust in it. Some mat was used. The mold was from a Cox mag pan. The interior mold was sanded at the bottom to make it thicker for landing gear. The balogna cut was backwards on this one. Nice plane there Ken.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: O49 pan glass or other

Re: O49 pan glass or other

Closest thing I can think of is this magnesium speed pan I bought from Mike Hazel a few years ago. Looks like it was made for a Thermal Hopper. Unfortunately, it was not made with the firewall welded in at a 90 degree angle to the pan.

A product engine mount will not fit. On the other hand, a postage stamp engine would fit.

And, just for fun, it looks like a .020 helicopter engine would fit. But what would you call it? It’s too small to be a Mouse racer. Shrew racer?

The Bard Mark

A product engine mount will not fit. On the other hand, a postage stamp engine would fit.

And, just for fun, it looks like a .020 helicopter engine would fit. But what would you call it? It’s too small to be a Mouse racer. Shrew racer?

The Bard Mark

batjac- Diamond Member

Posts : 2375

Join date : 2013-05-22

Age : 61

Location : Broken Arrow, OK, USA

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules