Log in

Search

Latest topics

» Roger Harris revisitedby TD ABUSER Today at 10:34 pm

» Engine choice

by 1975 control line guy Today at 9:51 pm

» Night flying at Walters RC park

by 1975 control line guy Today at 7:29 pm

» Happy 77th birthday Andrew!

by GallopingGhostler Today at 7:10 pm

» Cox films/videos...

by GallopingGhostler Today at 7:07 pm

» Cox 020 PeeWee rebuild questions

by LooseSpinner99 Today at 6:13 pm

» Did you spot the Cox engine in this NASA research video?

by balogh Today at 5:08 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Today at 2:54 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 10:34 am

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 8:15 am

» TEE DEE Having issues

by balogh Today at 7:42 am

» My N-1R build log

by roddie Today at 12:32 am

Cox Engine of The Month

Skyray 35 Wings

Page 1 of 1

Skyray 35 Wings

Skyray 35 Wings

Rusty gave me the inspiration to build a Skyray 35 and pointed me towards the weaknesses in the wings when adopting the "standard" kit build.

It would appear that, contra to my initials thoughts, the plywood wing ribs, make the wing more liable to breaking.

Also quite a few builders increase the wing area to lower the wing loading.

I have several options open to me now following the application of a little "technology".

Any thickness balsa, plywood, number of ribs, half ribs, rib lightening, tapering ...............

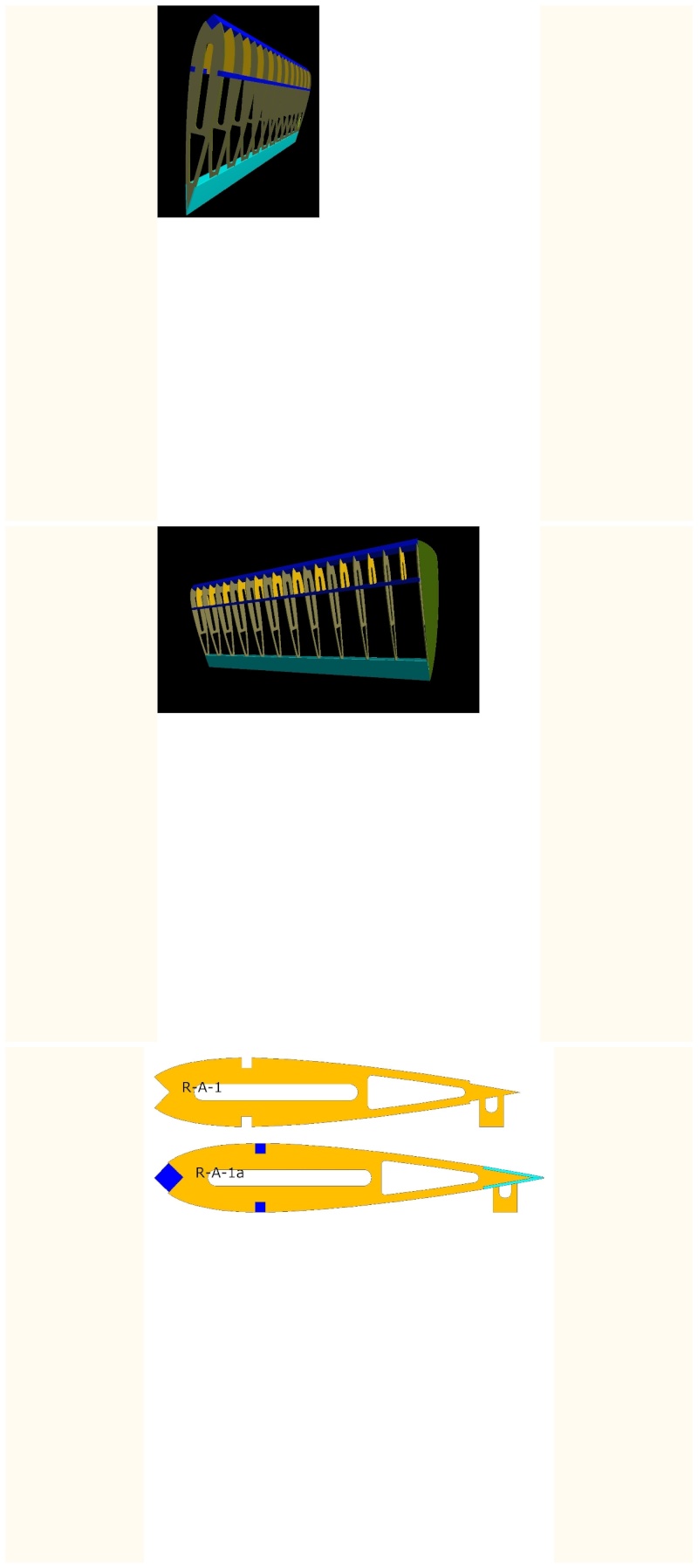

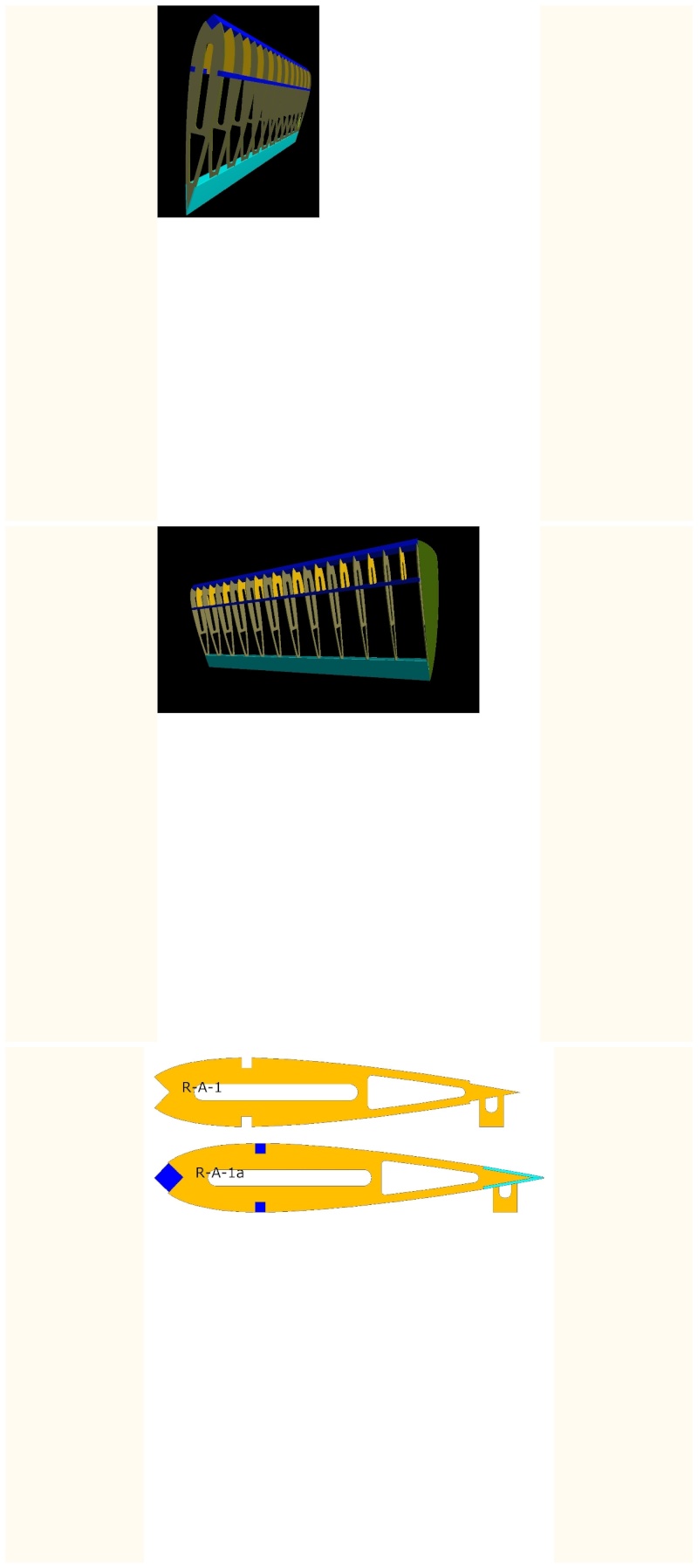

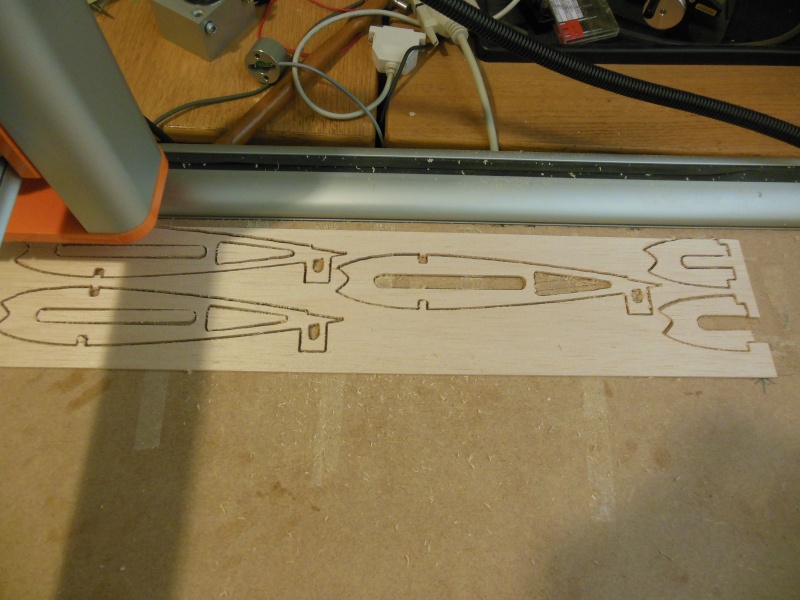

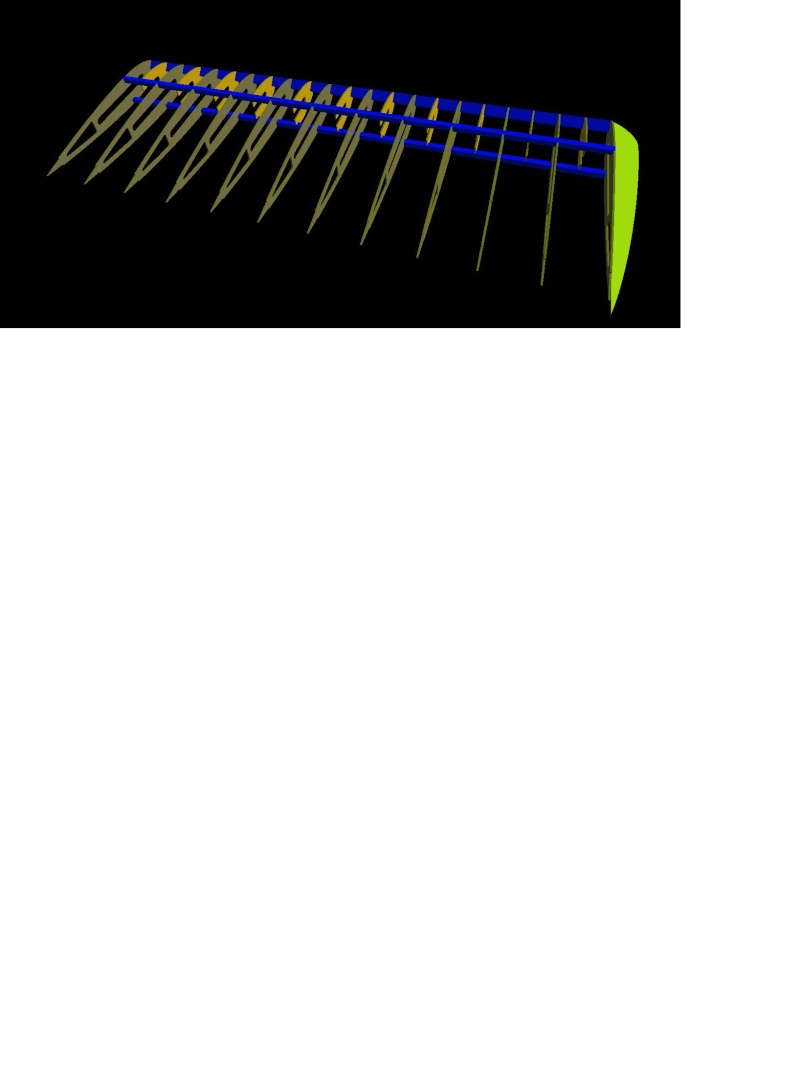

This is the wing with half ribs following standard build and a little lightening.

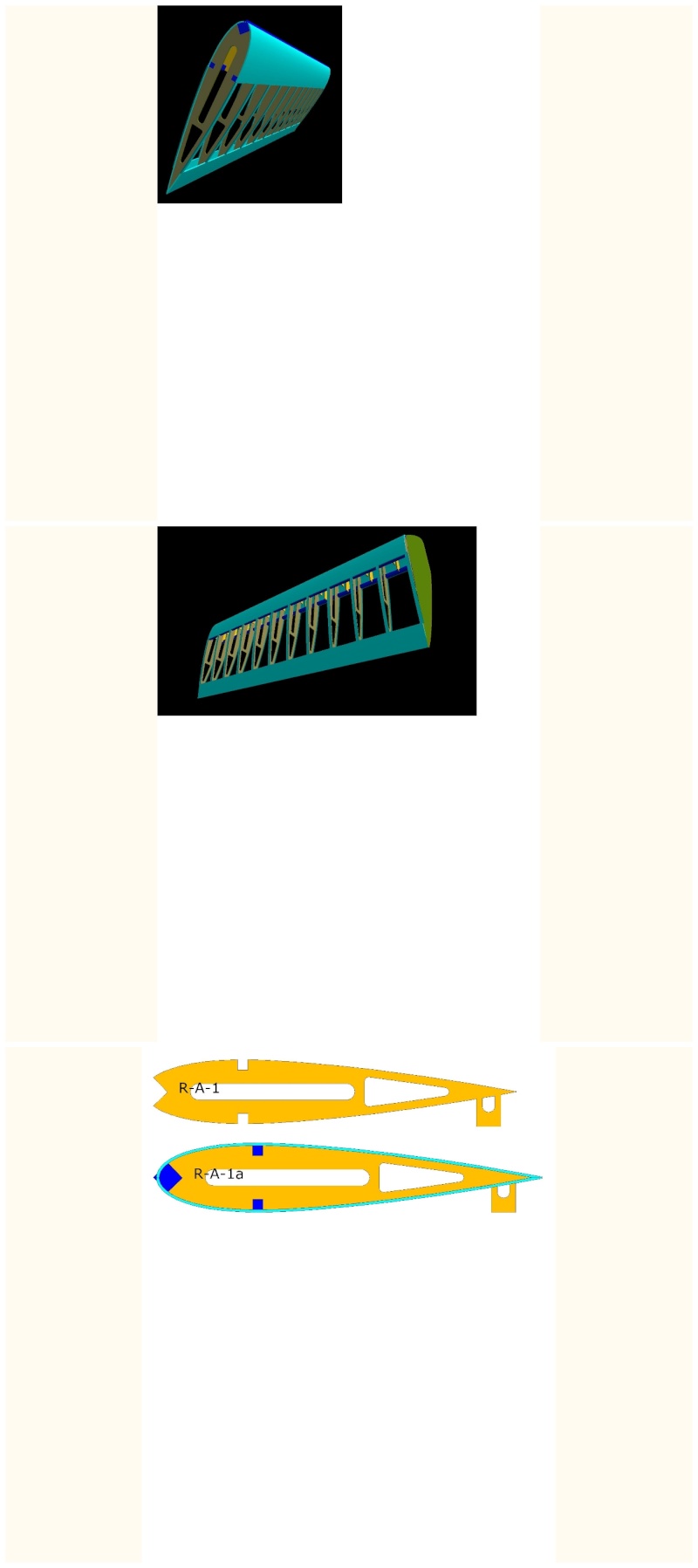

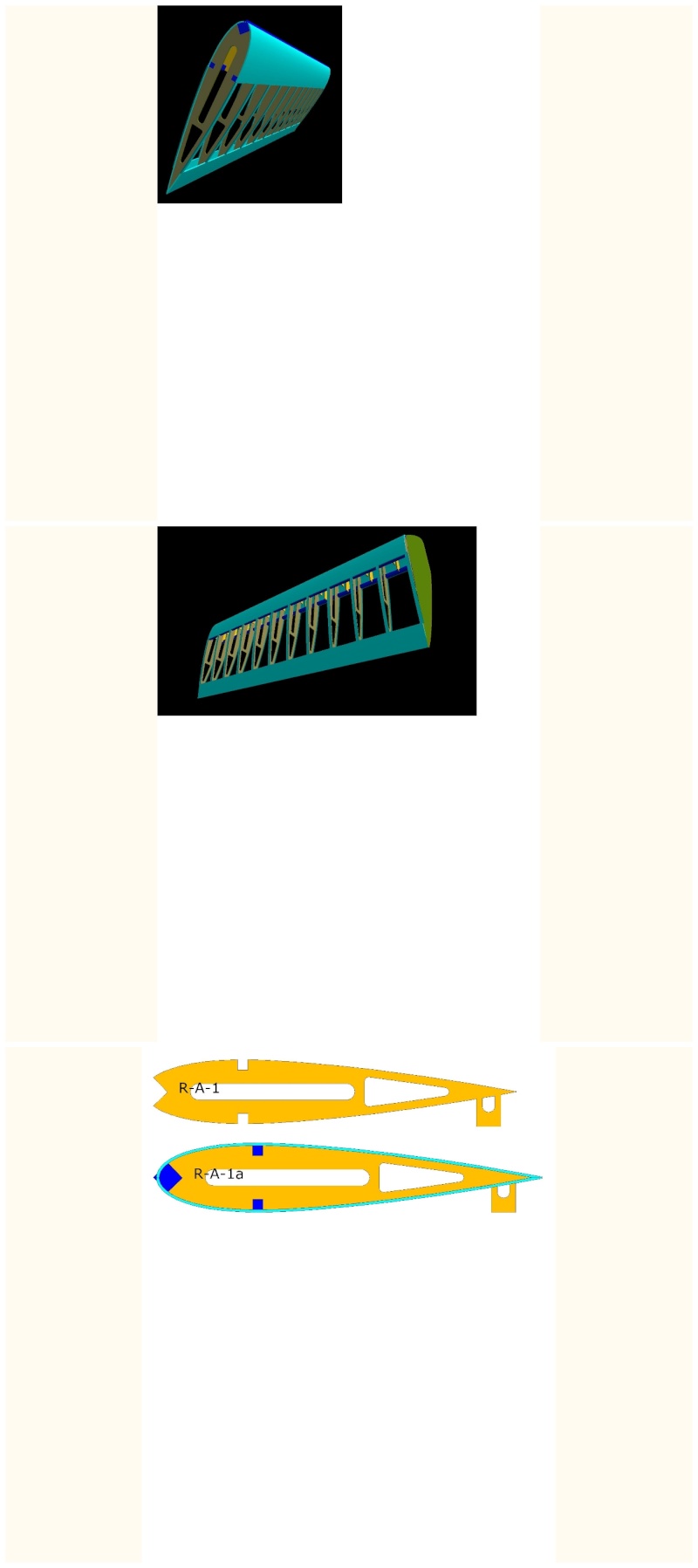

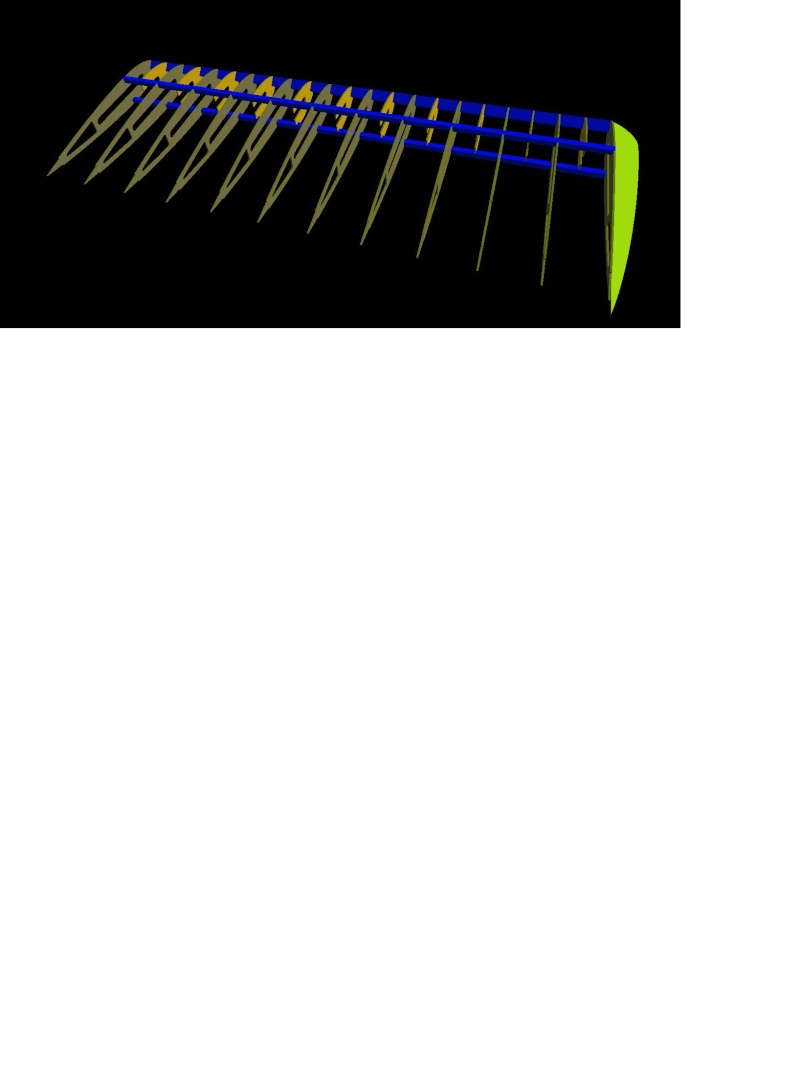

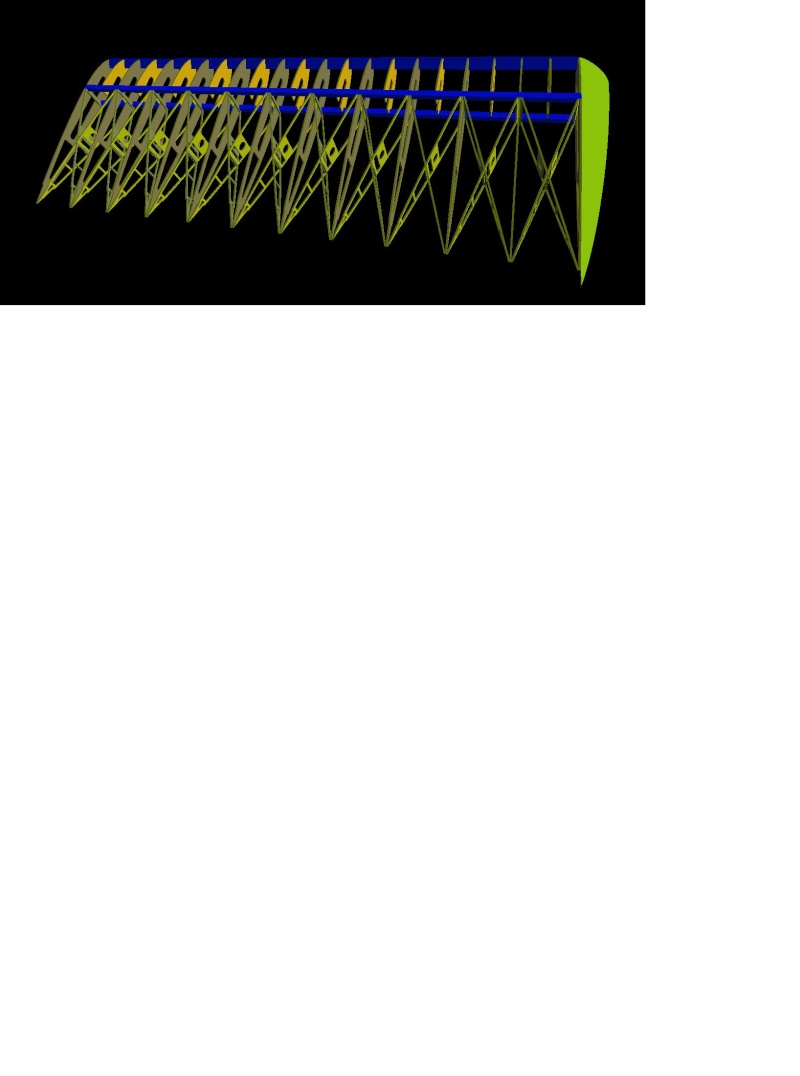

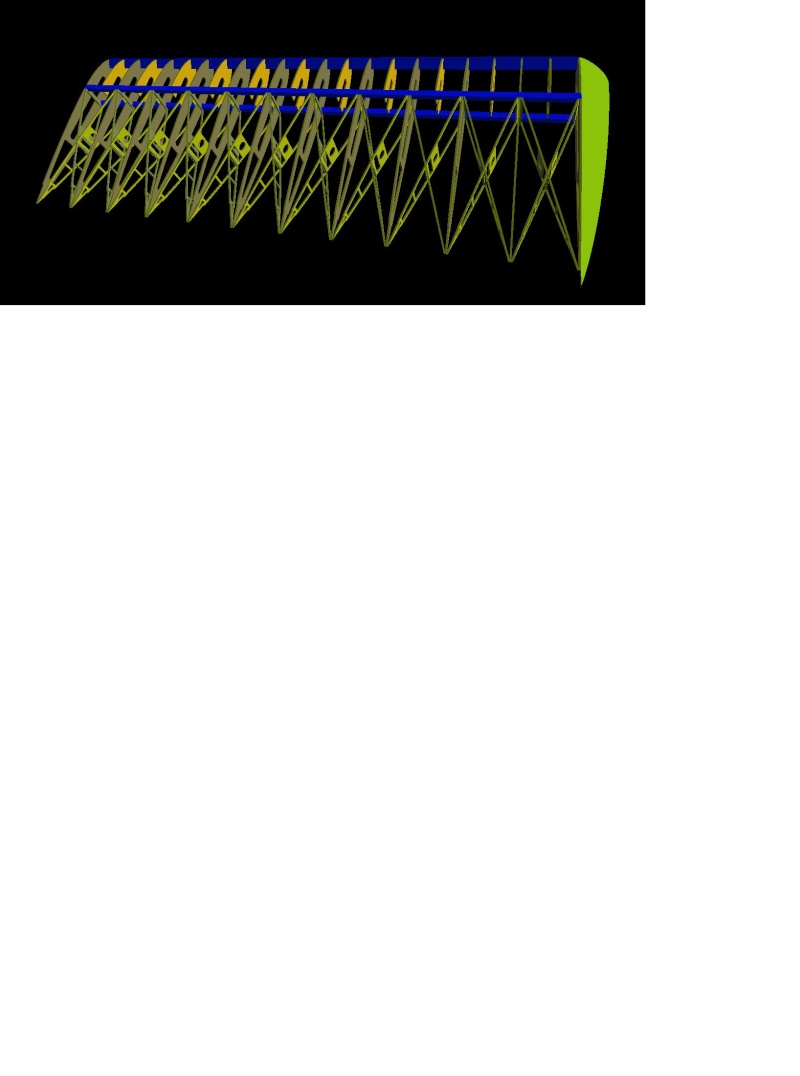

This is the same wing with identical profile. Sheeting and capping strips have been applied.

Many options are possible but what is the best approach?

More ribs? Thick or thin? Ply or balsa?

Apply sheeting and capping strips with thinner wood?

The Sky(ray) is the limit!

It would appear that, contra to my initials thoughts, the plywood wing ribs, make the wing more liable to breaking.

Also quite a few builders increase the wing area to lower the wing loading.

I have several options open to me now following the application of a little "technology".

Any thickness balsa, plywood, number of ribs, half ribs, rib lightening, tapering ...............

This is the wing with half ribs following standard build and a little lightening.

This is the same wing with identical profile. Sheeting and capping strips have been applied.

Many options are possible but what is the best approach?

More ribs? Thick or thin? Ply or balsa?

Apply sheeting and capping strips with thinner wood?

The Sky(ray) is the limit!

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Skyray 35 Wings

Re: Skyray 35 Wings

I'm not sure how much less prone to breaking balsa is in a crash, than lite ply. Very possibly less because of reduced inertia. But more importantly, lite ply splinters so badly that it's much more difficult to repair than balsa. Which brings me one of your questions;

Many options are possible but what is the best approach?

More ribs? Thick or thin? Ply or balsa?

Apply sheeting and capping strips with thinner wood?

My answer and recommendation is, since you're an inexperienced CL pilot, use the quickest simplest method. They will all likely fly equally well since the wing loading, especially if slightly increased, is plenty to support this plane in the air. So you may want to consider how much blood, sweat, and tears to put into this stunt trainer plane. And above that, how much of your heart and love is in it as it flies its entire life, 1/100th of a second from the ground.

Rusty

Many options are possible but what is the best approach?

More ribs? Thick or thin? Ply or balsa?

Apply sheeting and capping strips with thinner wood?

My answer and recommendation is, since you're an inexperienced CL pilot, use the quickest simplest method. They will all likely fly equally well since the wing loading, especially if slightly increased, is plenty to support this plane in the air. So you may want to consider how much blood, sweat, and tears to put into this stunt trainer plane. And above that, how much of your heart and love is in it as it flies its entire life, 1/100th of a second from the ground.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Skyray 35 Wings

Re: Skyray 35 Wings

Hi Rusty,

You mistake my motivation. Breaking models is something I do on a regular basis. Particularly getting over ambitious close to the ground.

Why? Because I like to see the model close up as it flies by. Most of the damage I do is light and quickly repairable - the majority of the planes (RC) that I regularly fly are foamies and very tough. Also because they are quick to build and easy to repair - I often throw caution to the wind and have little discipline by making snap decisions. ( I snapped a wing recently doing a barrel roll close to the ground and too fast - However, this was a 15 minute repair and the "battle scarred parkflyer was back in the air again)

You are quite correct to point out the effect that a balsa bashing build has. I am exceeding cautious with my balsa builds and always maintain a safe height and any damage has been a result of a wobbly landing (easy repair but time consuming)

I have only smashed one of these and this was through experimenting with AS3X stabilisation. Took it out on a windy day to test it - lost control immediately after launch - treed it - the resulting plummet from the tree totaled it. Post mortem established that I had set it up in reverse. So it didn't fight the wind, it rolled even further with it. This one had been repaired a few times due to my experimentation and carelessness (checking CG after a battery upgrade!)

However, I digress.

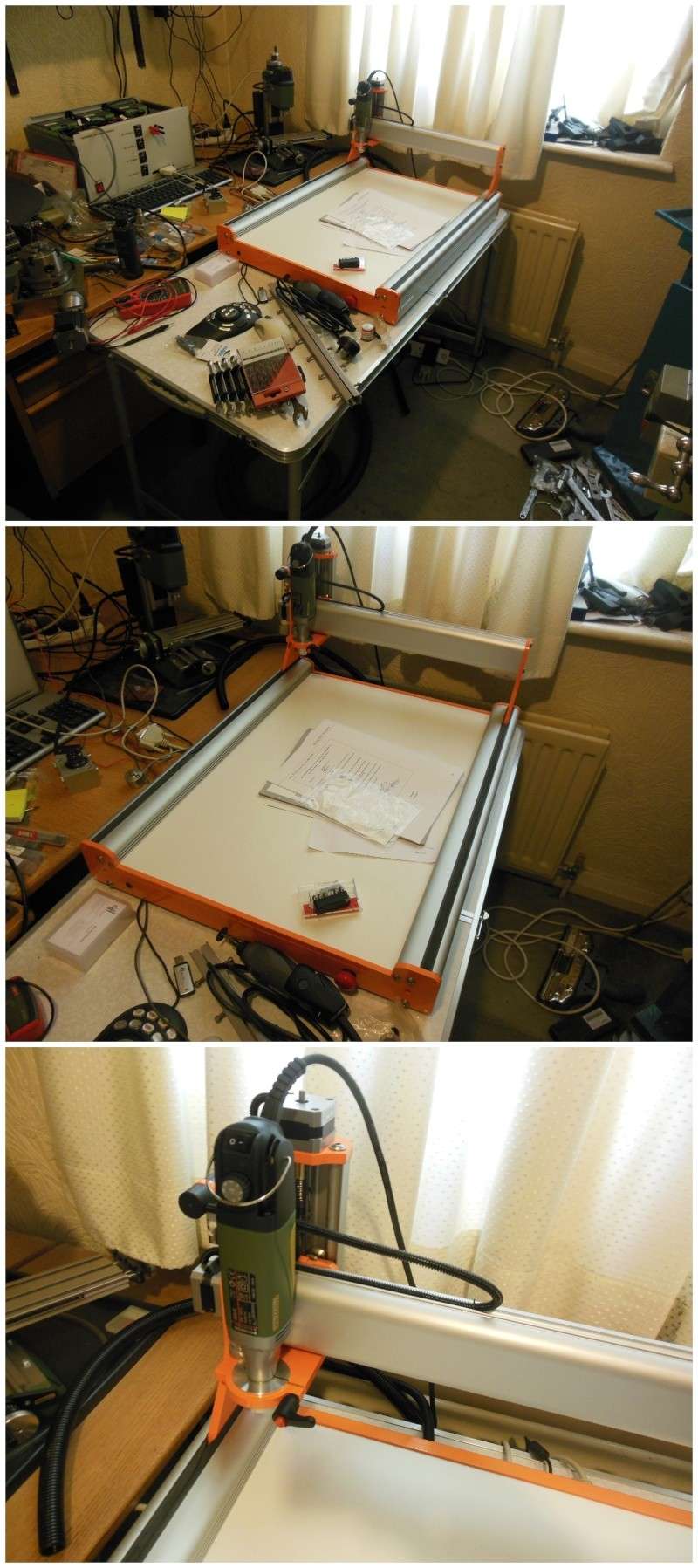

What I haven't made clear is that the pictures are screen snapshots from one of my CAD/CAM systems. It took one hour to prepare the first set per the original Skyray design and 5 minutes to clone this and modify it for the sheeting.

The pictures of the ribs can be printed and used as templates for cutting and following the procedure you adopted for sandwich sanding.

The material thickness can be altered in seconds and the ribs individualised.

When I have finalized everything - it takes about 20 seconds to produced the G code for my machine and around 3 minutes per rib to cut. 20 ribs in an hour while I drink coffee and smoke cigarettes!

What I am really after is - if you had the opportunity - with no time restriction - to build a wing for the Skyray with the same profile - what would you change to make it lighter, stronger and more flexible?

You mistake my motivation. Breaking models is something I do on a regular basis. Particularly getting over ambitious close to the ground.

Why? Because I like to see the model close up as it flies by. Most of the damage I do is light and quickly repairable - the majority of the planes (RC) that I regularly fly are foamies and very tough. Also because they are quick to build and easy to repair - I often throw caution to the wind and have little discipline by making snap decisions. ( I snapped a wing recently doing a barrel roll close to the ground and too fast - However, this was a 15 minute repair and the "battle scarred parkflyer was back in the air again)

You are quite correct to point out the effect that a balsa bashing build has. I am exceeding cautious with my balsa builds and always maintain a safe height and any damage has been a result of a wobbly landing (easy repair but time consuming)

I have only smashed one of these and this was through experimenting with AS3X stabilisation. Took it out on a windy day to test it - lost control immediately after launch - treed it - the resulting plummet from the tree totaled it. Post mortem established that I had set it up in reverse. So it didn't fight the wind, it rolled even further with it. This one had been repaired a few times due to my experimentation and carelessness (checking CG after a battery upgrade!)

However, I digress.

What I haven't made clear is that the pictures are screen snapshots from one of my CAD/CAM systems. It took one hour to prepare the first set per the original Skyray design and 5 minutes to clone this and modify it for the sheeting.

The pictures of the ribs can be printed and used as templates for cutting and following the procedure you adopted for sandwich sanding.

The material thickness can be altered in seconds and the ribs individualised.

When I have finalized everything - it takes about 20 seconds to produced the G code for my machine and around 3 minutes per rib to cut. 20 ribs in an hour while I drink coffee and smoke cigarettes!

What I am really after is - if you had the opportunity - with no time restriction - to build a wing for the Skyray with the same profile - what would you change to make it lighter, stronger and more flexible?

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Skyray 35 Wings

Re: Skyray 35 Wings

Replace the wing with a foam core and make it a plug in. Use 1/64th play as a saddle around the cutout in the fuse. The saddle being a 1 1/4" wide and core out holes in the foam. Cover with laminating film or equivalent. Foam wings are far stronger in terms of flex and ground pounding. They also can be repaired easier. Certain profiles actually fly better with a little weight behind them. They have a lot of side area and can be bounced in the wind pretty hard. Think of it as a tractor trailer going down the highway with a side wind. While you don't want the plane to be a brick, you won't be penalized too badly if the plane misses the kit's target weight by an ounce or two. While the framed wing may be lighter than a foam wing, it depends on the foam used and the construction and covering used on the foam. In terms of strength, I've driven planes straight in from over the top of the circle full bore and flew the foamy 5 min later with a bit of clear packing tape or epoxy. Your not doing that with a built up woody.

My profiles with foam wings have electrical tape holding the wing to the fuse or just a few dots of Gorilla glue. This allows the wing to cleanly break away from the fuse. The plane would also have external bellcrank with the platform doweled and pinned to the fuse. The techniques I described are similar to the Ukey .35 which was a terrific success some years ago. A simple design with about 500 squares for a .35. It could take punishment like no other model available and flew extremely well.

One major problem with control line models is the difficulty accessing the bellcrank without major surgery. Years back most would think that more elevator in terms of size and fast moving controls were the key to success. Look at a Flite Streak for instance. The Skyray .35 is essentially the same squares as a Streak and has very similar characteristics. A very small elevator and slow controls are the key to success. Having the ability to change your bellcrank settings on external controls is really a nice feature. Ken

My profiles with foam wings have electrical tape holding the wing to the fuse or just a few dots of Gorilla glue. This allows the wing to cleanly break away from the fuse. The plane would also have external bellcrank with the platform doweled and pinned to the fuse. The techniques I described are similar to the Ukey .35 which was a terrific success some years ago. A simple design with about 500 squares for a .35. It could take punishment like no other model available and flew extremely well.

One major problem with control line models is the difficulty accessing the bellcrank without major surgery. Years back most would think that more elevator in terms of size and fast moving controls were the key to success. Look at a Flite Streak for instance. The Skyray .35 is essentially the same squares as a Streak and has very similar characteristics. A very small elevator and slow controls are the key to success. Having the ability to change your bellcrank settings on external controls is really a nice feature. Ken

Ken Cook- Top Poster

- Posts : 5644

Join date : 2012-03-27

Location : pennsylvania

Re: Skyray 35 Wings

Re: Skyray 35 Wings

The Ukey 35

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Skyray 35 Wings

Re: Skyray 35 Wings

After looking at Ken's post re foam core wings - I had a scout around and found this

http://winshiprc.tripod.com/building_techniques.htm

A combination of the best of both worlds.

I also find the concept of an accessible bell crank appealing. I have just got myself into a right mess buidling the Frog Aerobat. That will be the subject of another post when I have resolved the issue(s).

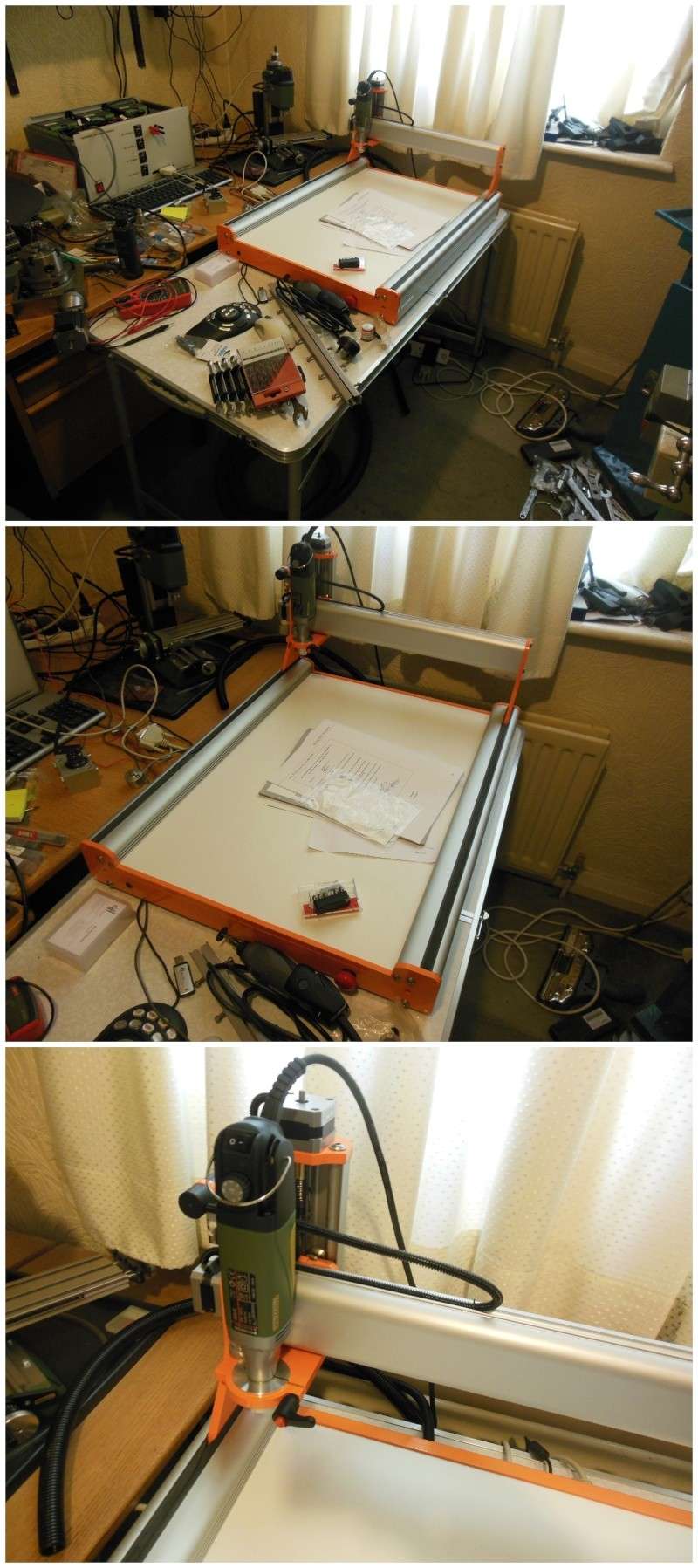

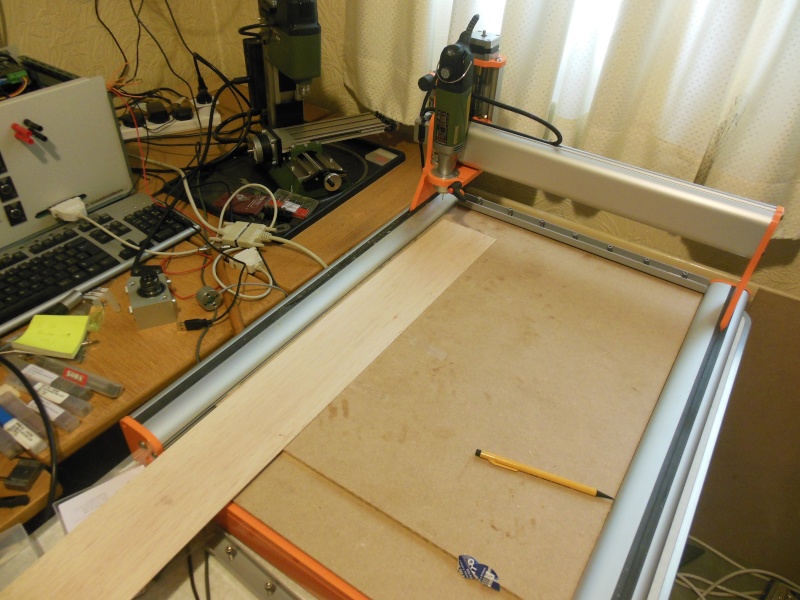

Now that I have "mastered" the software - I am well on the way to finishing my "wing rib cutter" (amongst other things). I am now fine tuning the axes for accuracy.

http://winshiprc.tripod.com/building_techniques.htm

A combination of the best of both worlds.

I also find the concept of an accessible bell crank appealing. I have just got myself into a right mess buidling the Frog Aerobat. That will be the subject of another post when I have resolved the issue(s).

Now that I have "mastered" the software - I am well on the way to finishing my "wing rib cutter" (amongst other things). I am now fine tuning the axes for accuracy.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Skyray 35 Wings

Re: Skyray 35 Wings

Poor curtains! cutting wood will make a mess!

Phil

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Skyray 35 Wings

Re: Skyray 35 Wings

pkrankow wrote:Poor curtains! cutting wood will make a mess!

Phil

Wood vacuums off - the cutting fluids and metal swarf from the milling machines either side doesn't!

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Skyray 35 Wings

Re: Skyray 35 Wings

I forgot to mention.

Curtains make very good towel substitutes.

Curtains make very good towel substitutes.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Skyray 35 Wings

Re: Skyray 35 Wings

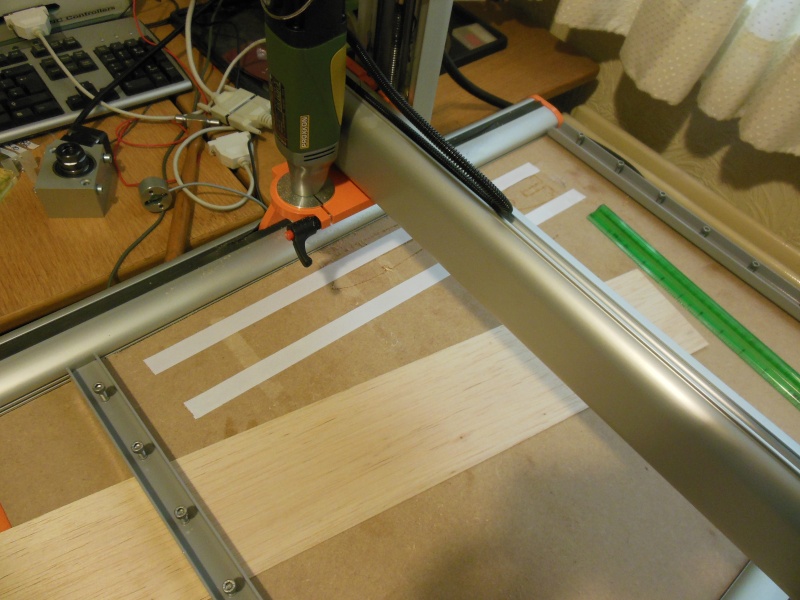

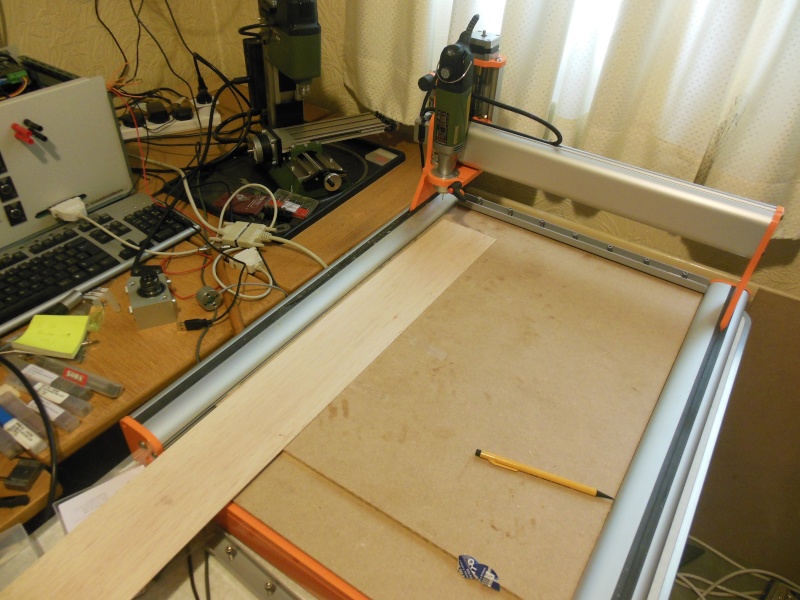

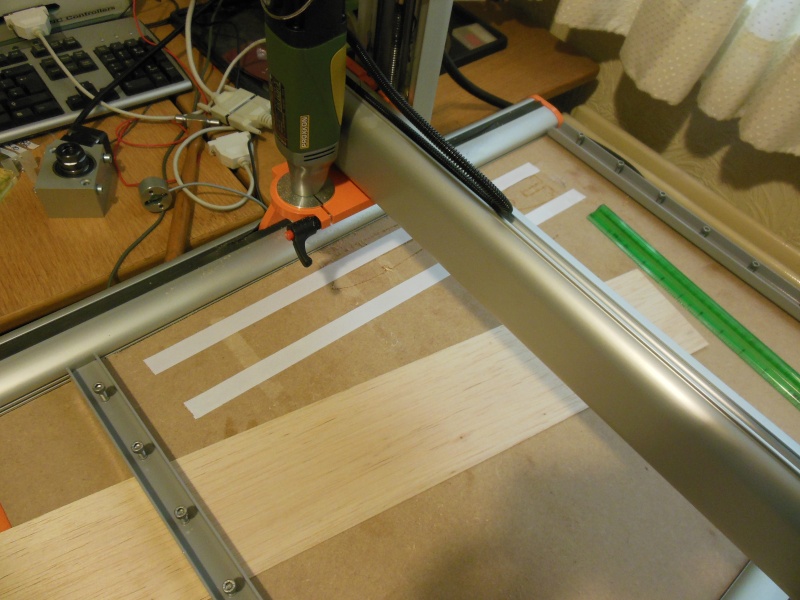

I have been playing close attention to Rusty's build and this weekend I finally stoked up my CNC router. Not a patch on the one Roddie uses to create his little masterpieces but a handy size for DIY use.

I put down a couple of strips of double sided tape.

Apply some wood

Fire up the machine

and

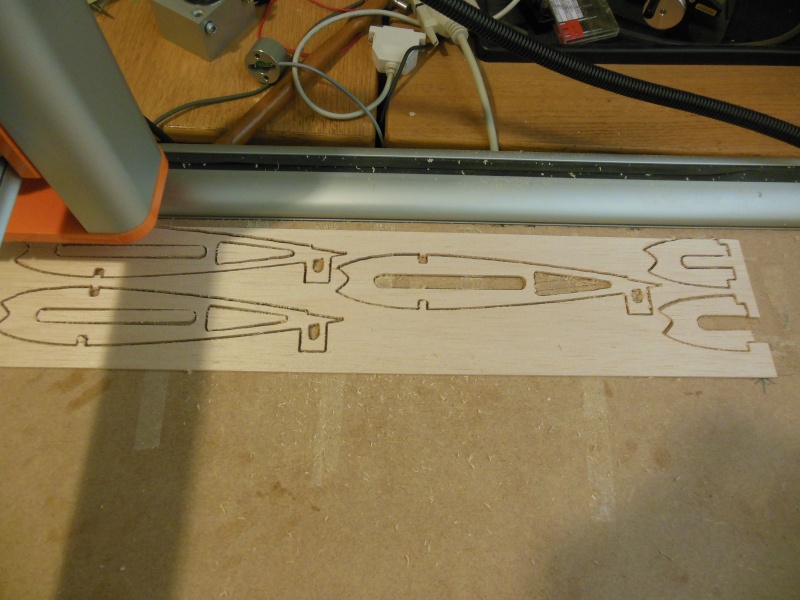

It didn't take long to do these

This is part of the structure for half of the wing (still subject to modification)

I keep trying to resist taking it too far!

I put down a couple of strips of double sided tape.

Apply some wood

Fire up the machine

and

It didn't take long to do these

This is part of the structure for half of the wing (still subject to modification)

I keep trying to resist taking it too far!

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Similar topics

Similar topics» Great video on building and flying the 1/2A Skyray and Skyray 35

» Sig Skyray

» Got me a SkyRay !

» Sig Skyray

» Believe it or not, the Copeland Skyray will fly again.

» Sig Skyray

» Got me a SkyRay !

» Sig Skyray

» Believe it or not, the Copeland Skyray will fly again.

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules