Log in

Search

Latest topics

» coreflute helpby Ken Cook Today at 10:35 am

» *Cox Engine of The Month* Submit your pictures! -June 2024-

by Levent Suberk Today at 9:54 am

» Kofuku Maru Fishing Boat Model

by Levent Suberk Today at 8:54 am

» Hawk had breakfast and then took a bath

by HalfaDave Today at 7:15 am

» Jim Walker Firebaby

by rdw777 Yesterday at 5:08 pm

» music vids.. some of your favorites

by Levent Suberk Yesterday at 4:04 pm

» S.M.A.L.L. 2024

by balogh Yesterday at 12:21 am

» Jim Walkers FireBee - This is going to be fun

by rdw777 Fri May 31, 2024 4:24 pm

» Feed Station Zebra.. Spring 2024

by roddie Fri May 31, 2024 4:10 pm

» Cox .049 Tee Dee engines back in stock (limited availablility)

by Cox International Fri May 31, 2024 1:08 pm

» Cox Mustang repair

by getback Fri May 31, 2024 7:29 am

» You know you’re in Branson, Missouri when

by batjac Thu May 30, 2024 10:52 am

Engine A/F boil

Page 1 of 1

Engine A/F boil

Engine A/F boil

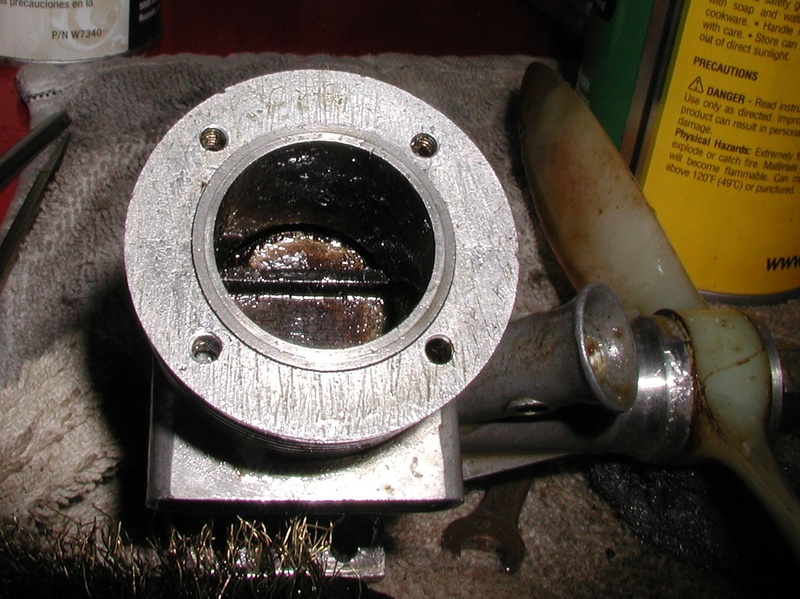

Got up at 6am "O dark December hundred," temperature in the 20's = Dark and Cold..Brrr to start a six hour anti freeze boil of this:

Really nasty, perhaps the most castor locked engine that I have ever come across. The propeller and it washer was so fouled up with the stuff that it took aggressive heat gun action to free them. I finally had to use a thin blade between the prop and drive washer to back it off the splines so I could remove it and drop it into the pot.

This engine is significant because it is one of the rarest Enya's. From Bob Allan's "Compendium."

The decision by Enya to make a 36 size engine probably the result of rival OS releasing their 36 in

1953 (apparently, around this time, Fuji had a 36 as well), specifically for distribution in the US by

the (Bill) Atwood Company. One theory on why the 36 was so short lived is – during 1955, it was

discovered that quite a few 35 size engines in the States actually displaced more than the 0.350

cu. in. limit set by the AMA. As an example (when discussing this anomaly) Chinn revealed (in

MAN April 1956) that both the FOX 35 and Sabre 35 were actually 0.3519 cu. in., the K&B Torpedo

35 was 0.3529 cu. in., and the OS Max 1 35 was at 0.3555 cu. in. Possibly these discrepancies in

“pushing the boundaries” were small enough to overlook initially, but eventually perhaps it was

thought wise to curb this trend of ever increasing illegal capacity, thus Enya had to more or less

scrap their 36 immediately. One other theory is, the capacity was reduced to comply with a 0.35 cu.

in. limit on C/L Combat engines, yet another that maybe OS were confused in the first place by the

0.349 cu. in. McCoy 36.

An ebay find with serious bidders. Coincidentally it was found within 20 miles of my old home town in NH.

Gwillie has an excellent example.

Bob

Really nasty, perhaps the most castor locked engine that I have ever come across. The propeller and it washer was so fouled up with the stuff that it took aggressive heat gun action to free them. I finally had to use a thin blade between the prop and drive washer to back it off the splines so I could remove it and drop it into the pot.

This engine is significant because it is one of the rarest Enya's. From Bob Allan's "Compendium."

The decision by Enya to make a 36 size engine probably the result of rival OS releasing their 36 in

1953 (apparently, around this time, Fuji had a 36 as well), specifically for distribution in the US by

the (Bill) Atwood Company. One theory on why the 36 was so short lived is – during 1955, it was

discovered that quite a few 35 size engines in the States actually displaced more than the 0.350

cu. in. limit set by the AMA. As an example (when discussing this anomaly) Chinn revealed (in

MAN April 1956) that both the FOX 35 and Sabre 35 were actually 0.3519 cu. in., the K&B Torpedo

35 was 0.3529 cu. in., and the OS Max 1 35 was at 0.3555 cu. in. Possibly these discrepancies in

“pushing the boundaries” were small enough to overlook initially, but eventually perhaps it was

thought wise to curb this trend of ever increasing illegal capacity, thus Enya had to more or less

scrap their 36 immediately. One other theory is, the capacity was reduced to comply with a 0.35 cu.

in. limit on C/L Combat engines, yet another that maybe OS were confused in the first place by the

0.349 cu. in. McCoy 36.

An ebay find with serious bidders. Coincidentally it was found within 20 miles of my old home town in NH.

Gwillie has an excellent example.

Bob

rsv1cox- Top Poster

Posts : 10685

Join date : 2014-08-18

Location : West Virginia

Re: Engine A/F boil

Re: Engine A/F boil

That is Nasty Looking but i am sure if anyone can make it prestige you can // 20*

getback- Top Poster

Posts : 10186

Join date : 2013-01-18

Age : 66

Location : julian , NC

Re: Engine A/F boil

Re: Engine A/F boil

My friend and Rusty's flying partner Bob Zambelli had a few of the .36's. I recall him stating they were only made for about a year. Ken

Ken Cook- Top Poster

- Posts : 5496

Join date : 2012-03-27

Location : pennsylvania

Re: Engine A/F boil

Re: Engine A/F boil

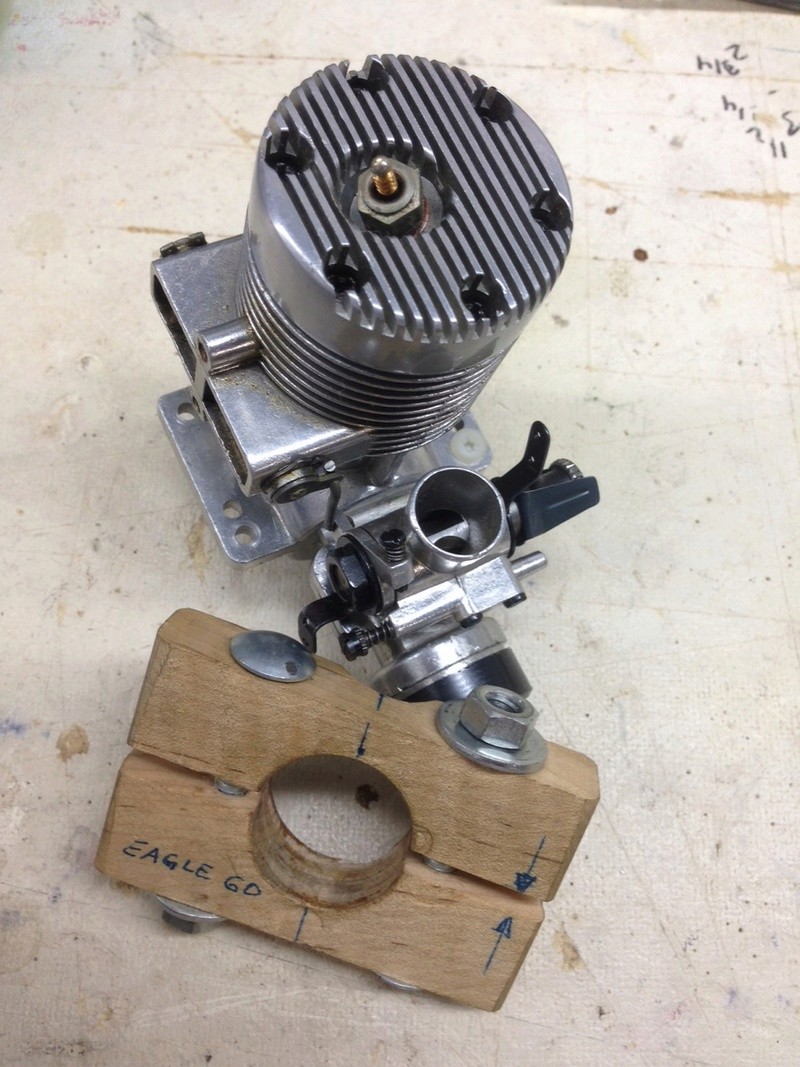

Wow, this was a near disaster. I knew that this engine was severely locked up with congealed castor, but I was not ready for this.

After a six hour boil I thought it would just fall apart, boy was I wrong. I got the NVA out and the forward assembly off then tried to move the piston up using a wood dowel capturing the cylinders taper and ridge of burned carbon forcing the cylinder up and out of the case. My standard procedure. Heck, the piston wouldn't even move.

Heated up the already hot engine with a heat gun and got it to move just a bit when it stopped. No amount of coxing would move it. More heat, nothing. Using a 5/8" wood dowel I tried tapping the piston down from the top gently at first. Nothing. More heat on the case and a cooling spray of Remoil on the piston finally got it down to a point when I could get the prop drive shaft and case back on, affixed the prop as a lever, more heat and Remoil and I could finally move the prop back and forth a bit but never a full cycle. There was just so much castor goo within the pistons skirt and case. More boil. I finally was able to get most of the goo out of the cylinder using Remoil and fine steel wool and pop the piston and the liner out. What a mess.

Bobby Brooks keeps telling me that the early Enya's used no case gaskets, but I keep scraping them off.

Of all the Enya's that I have done this one was the hardest. A rare engine I did not want to damage it, but seems no harm done, the piston and liner are not scored in any way and the rest is ok. However a PO sure mess up the mounting holes and there is some rash on the head fins.

First layer off, two more to go then maybe a bit in the sandblaster to even the finish out and regain that original Enya matte finish. I protect the shiny surfaces with electrical tape.

Bob

After a six hour boil I thought it would just fall apart, boy was I wrong. I got the NVA out and the forward assembly off then tried to move the piston up using a wood dowel capturing the cylinders taper and ridge of burned carbon forcing the cylinder up and out of the case. My standard procedure. Heck, the piston wouldn't even move.

Heated up the already hot engine with a heat gun and got it to move just a bit when it stopped. No amount of coxing would move it. More heat, nothing. Using a 5/8" wood dowel I tried tapping the piston down from the top gently at first. Nothing. More heat on the case and a cooling spray of Remoil on the piston finally got it down to a point when I could get the prop drive shaft and case back on, affixed the prop as a lever, more heat and Remoil and I could finally move the prop back and forth a bit but never a full cycle. There was just so much castor goo within the pistons skirt and case. More boil. I finally was able to get most of the goo out of the cylinder using Remoil and fine steel wool and pop the piston and the liner out. What a mess.

Bobby Brooks keeps telling me that the early Enya's used no case gaskets, but I keep scraping them off.

Of all the Enya's that I have done this one was the hardest. A rare engine I did not want to damage it, but seems no harm done, the piston and liner are not scored in any way and the rest is ok. However a PO sure mess up the mounting holes and there is some rash on the head fins.

First layer off, two more to go then maybe a bit in the sandblaster to even the finish out and regain that original Enya matte finish. I protect the shiny surfaces with electrical tape.

Bob

rsv1cox- Top Poster

Posts : 10685

Join date : 2014-08-18

Location : West Virginia

Re: Engine A/F boil

Re: Engine A/F boil

It's amazing how so much castor can stay in there to stiffing up like that , looks like the PO was running it on 30W. You got her looking good Bob the Enya man , are you using tooth brush or brass/steel brushes or both on the outer cases ? I got some larger engines i need to clean up and would like to get them to look as good as yours

getback- Top Poster

Posts : 10186

Join date : 2013-01-18

Age : 66

Location : julian , NC

Re: Engine A/F boil

Re: Engine A/F boil

Eric, you should see some of my engines . That's nothing on there. When the engine gets 500+ flights on it they more or less look black. That's the way you want them because they run the best.

Ken Cook- Top Poster

- Posts : 5496

Join date : 2012-03-27

Location : pennsylvania

Re: Engine A/F boil

Re: Engine A/F boil

Ken Cook wrote: Eric, you should see some of my engines . That's nothing on there. When the engine gets 500+ flights on it they more or less look black. That's the way you want them because they run the best.

Great advice! Run them often enough.. that you don't want.. and there's no need for a tear-down. Models in queue for your engines..

That would be the good-life for a good-running engine. Just bolt-it-on to the next candidate.

That would be the good-life for a good-running engine. Just bolt-it-on to the next candidate.  Re: Engine A/F boil

Re: Engine A/F boil

I have to disagree a bit here, a clean engine will run cooler if the cooling fins are clean of caked on castor residue, same goes for the intake and exhaust ports and may hold true for the heads combustion chamber. Where it makes a difference is the thin "varnish" buildup on cylinder walls which aids in sealing.

In the case of this Enya .36 there was no way this puppy was ever going to run without a complete tear-down and cleaning. Heck as discussed it would not even turn over even after extreme heat was applied. Where the previous owner erred is that he failed to clean it properly after running it leaving it mired internally in unburned fuel and castor.

I have got in the habit of flushing my engines after a run with Remoil then applying some after-run. Seems to work fine for me.

But, I must admit...I enjoy tearing down and cleaning model engines and don't see the harm in it.

Bob

In the case of this Enya .36 there was no way this puppy was ever going to run without a complete tear-down and cleaning. Heck as discussed it would not even turn over even after extreme heat was applied. Where the previous owner erred is that he failed to clean it properly after running it leaving it mired internally in unburned fuel and castor.

I have got in the habit of flushing my engines after a run with Remoil then applying some after-run. Seems to work fine for me.

But, I must admit...I enjoy tearing down and cleaning model engines and don't see the harm in it.

Bob

rsv1cox- Top Poster

Posts : 10685

Join date : 2014-08-18

Location : West Virginia

Re: Engine A/F boil

Re: Engine A/F boil

Bob. How did you go about removing the cylinder liner? That's the one item I seem to have the most trouble with in a gunked up Enya. I actually used a bolt & washer rigged up as a puller to pull the liner from a Torpedo .40. I think they must be an interference fit. Had to heat the case & cool the liner to get it installed.

Rod.

Rod.

Oldenginerod- Top Poster

- Posts : 3978

Join date : 2012-06-15

Age : 61

Location : Drouin, Victoria

Re: Engine A/F boil

Re: Engine A/F boil

It's amazing how much gunk can build up between the case and the liner, most come out an amber colored brown.

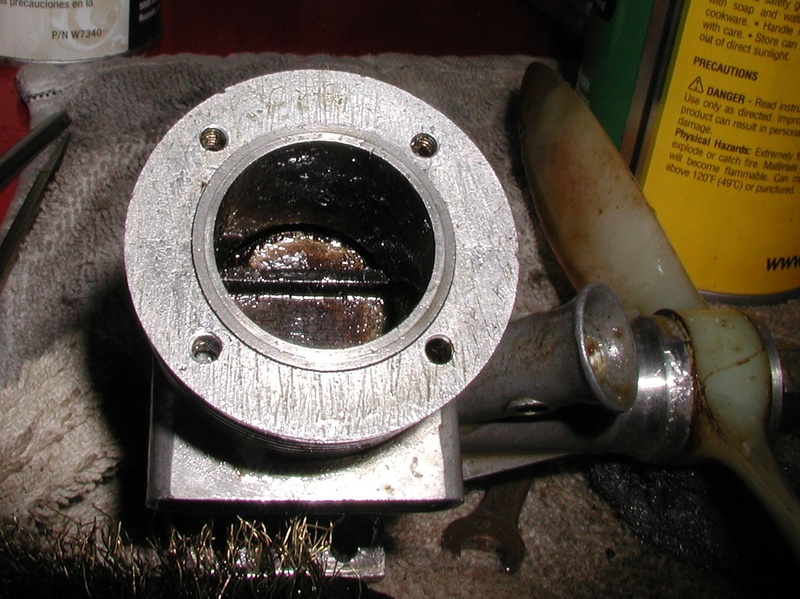

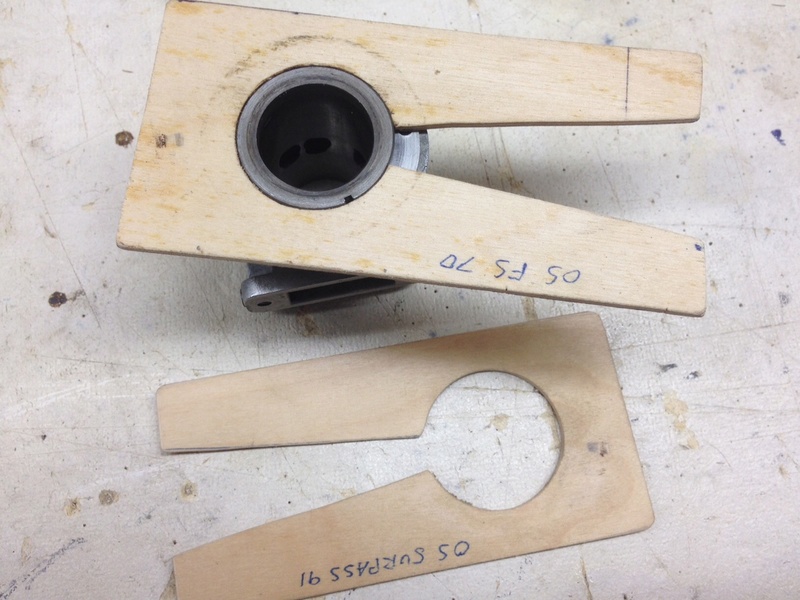

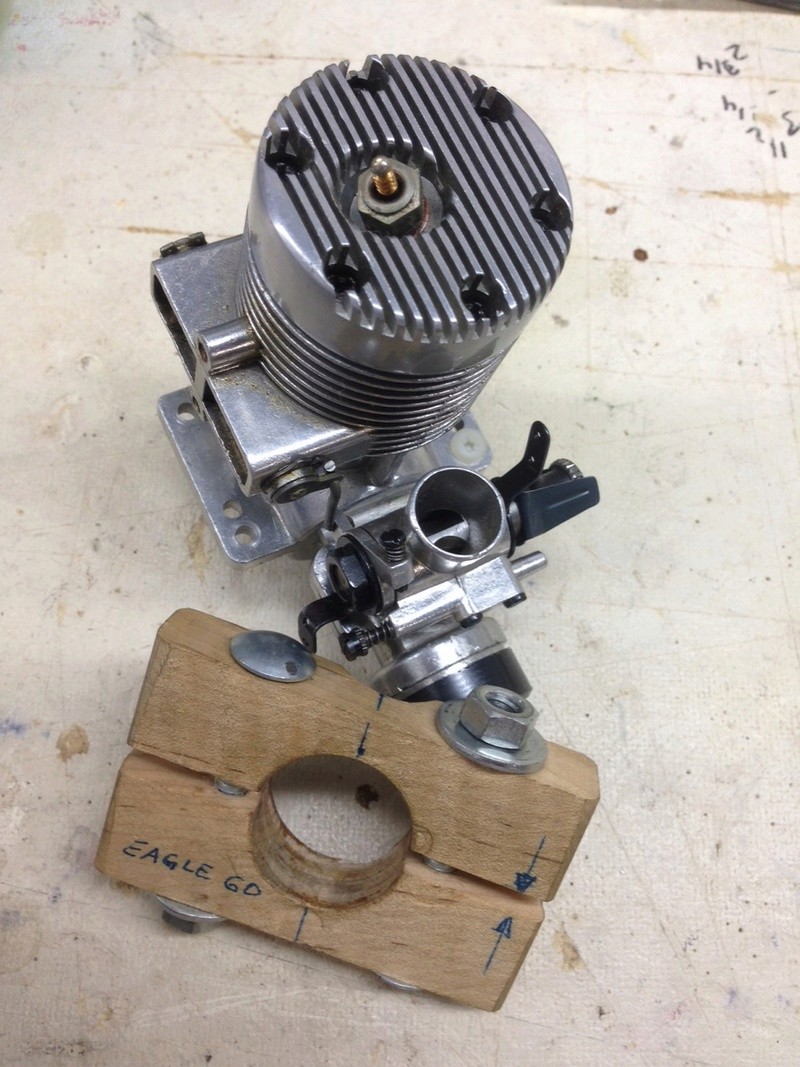

With the head off and the case well heated I turn the case upside down on a wooden block with a hole cut the diameter of the liner and using a wooden dowel (3/8" dowel in the picture above) push the connecting rod (oldenginerod ) down as far as it will go (which isn't enough to expel the liner) then angling the dowel on the end of the connecting rod I tap the piston/liner assembly out of the case using a small tapping hammer.

) down as far as it will go (which isn't enough to expel the liner) then angling the dowel on the end of the connecting rod I tap the piston/liner assembly out of the case using a small tapping hammer.

Usually the taper of the cylinder coupled with the caked on buildup of carbon at the top of the pistons stroke is enough to prevent the piston from coming up out of the liner helping to force the liner up and out of the case. I then use another larger wooden dowel to tap the piston back down through the liner and out the bottom end. Except for this .36 it has always been an easy job for me.

Bob

With the head off and the case well heated I turn the case upside down on a wooden block with a hole cut the diameter of the liner and using a wooden dowel (3/8" dowel in the picture above) push the connecting rod (oldenginerod

Usually the taper of the cylinder coupled with the caked on buildup of carbon at the top of the pistons stroke is enough to prevent the piston from coming up out of the liner helping to force the liner up and out of the case. I then use another larger wooden dowel to tap the piston back down through the liner and out the bottom end. Except for this .36 it has always been an easy job for me.

Bob

rsv1cox- Top Poster

Posts : 10685

Join date : 2014-08-18

Location : West Virginia

Re: Engine A/F boil

Re: Engine A/F boil

I think it is safer to use the piston in order to push out the liner. Heat everything up then put a wooden dowel in the exhaust port from the top and turn the crank over gently, thus pushing the liner up. If the resistance is too high you need more heat.

I would never boil the piston and liner in antifreeze though, that is just asking for trouble as you will loose the protective, and sealing, varnish of the piston. On a well used engine you risk cleaning it beyond recovery of the varnish layer...

I would never boil the piston and liner in antifreeze though, that is just asking for trouble as you will loose the protective, and sealing, varnish of the piston. On a well used engine you risk cleaning it beyond recovery of the varnish layer...

Surfer_kris- Diamond Member

- Posts : 1906

Join date : 2010-11-20

Location : Sweden

Re: Engine A/F boil

Re: Engine A/F boil

Recently I have been doing a test of my new to me used engines. I start them as received and note how they run, then clean them in A/F my normal way including complete disassembly then run them again. So far in a small sample of six or seven engines I have noticed no difference in ease of starting or performance although I didn't tach them, something that I will do in the future.

"I think it is safer to use the piston in order to push out the liner. Heat everything up then put a wooden dowel in the exhaust port from the top and turn the crank over gently, thus pushing the liner up. If the resistance is too high you need more heat."

I would like to try your method, but I don't quite understand it. "Put a wooden dowel in the exhaust port?" I'm pretty dense and sometimes need a picture. I have destroyed many engines, (thankfully dime a dozen .049 Wen's etc.) trying to clean them before learning the AF method. On most if not all engines I use fine steel wool and a light oil to clean the piston and cylinder liner. Some may cringe at this but it works for me. But I would share your concern that some engines may be so worn that a sealing film on the interior of the cylinder may not build up again during subsequent running's.

I have destroyed many engines, (thankfully dime a dozen .049 Wen's etc.) trying to clean them before learning the AF method. On most if not all engines I use fine steel wool and a light oil to clean the piston and cylinder liner. Some may cringe at this but it works for me. But I would share your concern that some engines may be so worn that a sealing film on the interior of the cylinder may not build up again during subsequent running's.

I just use a 3" 3/8" diameter wood dowel angled from the bottom of the case and placed squarely on the end of the connecting rod to push the piston/cylinder liner assembly up and out of the case. Conservatively, I have probably done well in excess of 75 engines this way.

I have a few engines Enya's and otherwise that will just not run, clapped out and abused beyond belief. I'm afraid to "part them out" for fear that the worn parts would make it into one of my other engines. I just clean them note the problem, and mount or bag them.

Bob

"I think it is safer to use the piston in order to push out the liner. Heat everything up then put a wooden dowel in the exhaust port from the top and turn the crank over gently, thus pushing the liner up. If the resistance is too high you need more heat."

I would like to try your method, but I don't quite understand it. "Put a wooden dowel in the exhaust port?" I'm pretty dense and sometimes need a picture.

I just use a 3" 3/8" diameter wood dowel angled from the bottom of the case and placed squarely on the end of the connecting rod to push the piston/cylinder liner assembly up and out of the case. Conservatively, I have probably done well in excess of 75 engines this way.

I have a few engines Enya's and otherwise that will just not run, clapped out and abused beyond belief. I'm afraid to "part them out" for fear that the worn parts would make it into one of my other engines. I just clean them note the problem, and mount or bag them.

Bob

rsv1cox- Top Poster

Posts : 10685

Join date : 2014-08-18

Location : West Virginia

Re: Engine A/F boil

Re: Engine A/F boil

Halfway through the last century Duke Fox said to put a glow plug washer on top of the piston, just sticking through the exhaust port. Then pulling the prop through thus raising the cylinder. This, along with heat works very well. But never ever try it on a ringed engine; the piston will deform, trapping the ring. Instant spare parts engine.

Lots has been written on after boiling. I never kept track of how many engines I'very done with it, but it is a big number. I learned Oxford it from George Aldrich.

Lots has been written on after boiling. I never kept track of how many engines I'very done with it, but it is a big number. I learned Oxford it from George Aldrich.

GWILLIEFOX- Rest In Peace

- Posts : 304

Join date : 2014-12-23

Age : 80

Location : Beaver Falls, PA

Re: Engine A/F boil

Re: Engine A/F boil

GWILLIEFOX wrote:Halfway through the last century Duke Fox said to put a glow plug washer on top of the piston, just sticking through the exhaust port. Then pulling the prop through thus raising the cylinder. This, along with heat works very well. But never ever try it on a ringed engine; the piston will deform, trapping the ring. Instant spare parts engine.

Lots has been written on after boiling. I never kept track of how many engines I'very done with it, but it is a big number. I learned Oxford it from George Aldrich.

Thanks, Got it!!!

But, that would only raise the cylinder liner a sixteenth or so not nearly enough to grasp it and pull it out, especially with sticky castor cooling by the moment. I guess a 3 armed gear puller could be employed, catch the rim and pulling. A dowel from the bottom of the case pushes it all the way out. But I usually grasp it then twist and pull the last half inch or so. A cloth holding the hot case eases the pain.

Bob

BTW, I'm going to try it. But I think I'm going to wind up with a badly bent glow plug washer and a stuck liner.

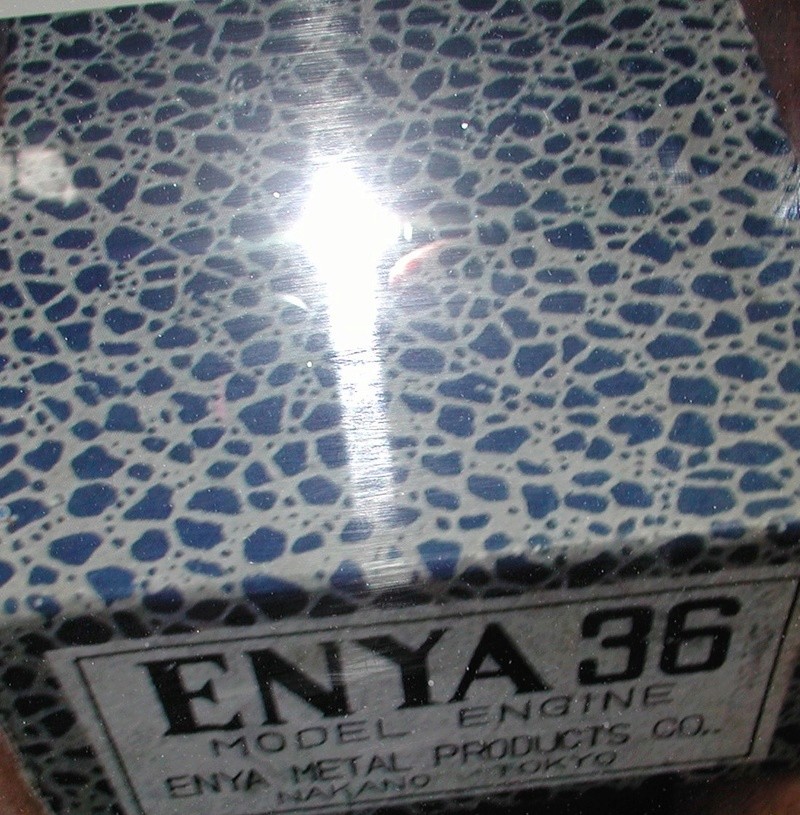

BTW again. Bobby Brooks finally agrees with me that the .09II's and .36's had case gaskets. He finally took apart both and found them. Perhaps not on the 3001 early .09's though. He says the SS40 gasket fits perfectly on the .36 and is send me a couple. Ever see the box on the .36?

rsv1cox- Top Poster

Posts : 10685

Join date : 2014-08-18

Location : West Virginia

Re: Engine A/F boil

Re: Engine A/F boil

I've never seen the 36 box Bob. If you place the gasket so it old sticks out the thickness of the liner, you can push it way up.

Here's some info I had in the MECA Bulletin last year:

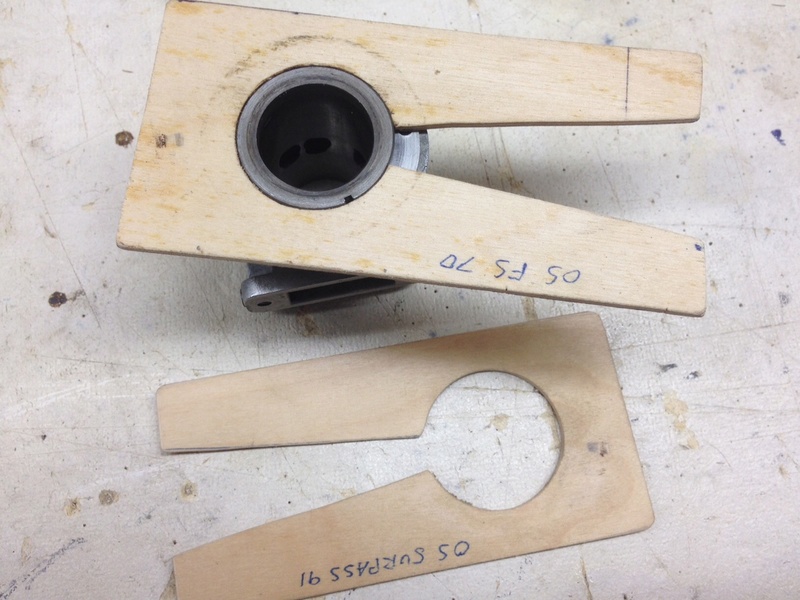

During Russ Gardner’s engine restoration discussion, I realized most of us have pet methods to accomplish our tasks. Heat is very often our most useful tool, but how do you hold onto things? Cylinder liners are usually stuck in place in the cylinder; pliers are a no-no; using the piston with a piece of soft metal in the exhaust works on steel pistons, but will most often collapse an aluminum piston, trapping the rings and ruining the piston. I make a simple tool from 1/8” or so plywood. It has a circle that just fits around the top of the liner and has a notch cut from it. Quick and easy to make. To use it, heat the cylinder, hold it with a glove, put the tool over the liner, squeeze it and try and rotate it. Once it rotates just a little, the cylinder can be wiggled out. You may have to try reheating things on a stubborn

engine; always remember patience is our most valuable tool!

Collet style prop drivers are easy to remove once you can get a grip on them. I use 2 pieces of hard maple engine mounts. Bolt them together with a piece of 1/8 ply between them. Drill/file, saw, bore out a hole just the size of the driver, then remove the 1/8” spacer. You now have a tool that can be tightened securely around the driver. Bolt tightly in place, hang the engine from the tool with the ends of the tool resting on something solid like scrap 2x4. Give the propshaft a sharp blow with a brass or plastic hammer; don’t even think about a regular one. The driver will pop off. You can heat the driver if it is stubborn. The support must all be solid to get the blow to the collet.

To spin a liner or cylinder for shining, I make an expanding mandrel from a piece of hardwood and a concrete anchor. The anchors come in many sizes and have a bolt with a tapered head. Get one the size you need, drill a hole the size of the bolt thru a dowel. Turn sand carve the dowel for a snug fit into the liner, then cut 4 slots in one end of it. Put the dowel into the liner, drop the bolt into it with the tapered end at the slots, tighten the nut on the other end, and spin to your heart’s content!

Here's some info I had in the MECA Bulletin last year:

During Russ Gardner’s engine restoration discussion, I realized most of us have pet methods to accomplish our tasks. Heat is very often our most useful tool, but how do you hold onto things? Cylinder liners are usually stuck in place in the cylinder; pliers are a no-no; using the piston with a piece of soft metal in the exhaust works on steel pistons, but will most often collapse an aluminum piston, trapping the rings and ruining the piston. I make a simple tool from 1/8” or so plywood. It has a circle that just fits around the top of the liner and has a notch cut from it. Quick and easy to make. To use it, heat the cylinder, hold it with a glove, put the tool over the liner, squeeze it and try and rotate it. Once it rotates just a little, the cylinder can be wiggled out. You may have to try reheating things on a stubborn

engine; always remember patience is our most valuable tool!

Collet style prop drivers are easy to remove once you can get a grip on them. I use 2 pieces of hard maple engine mounts. Bolt them together with a piece of 1/8 ply between them. Drill/file, saw, bore out a hole just the size of the driver, then remove the 1/8” spacer. You now have a tool that can be tightened securely around the driver. Bolt tightly in place, hang the engine from the tool with the ends of the tool resting on something solid like scrap 2x4. Give the propshaft a sharp blow with a brass or plastic hammer; don’t even think about a regular one. The driver will pop off. You can heat the driver if it is stubborn. The support must all be solid to get the blow to the collet.

To spin a liner or cylinder for shining, I make an expanding mandrel from a piece of hardwood and a concrete anchor. The anchors come in many sizes and have a bolt with a tapered head. Get one the size you need, drill a hole the size of the bolt thru a dowel. Turn sand carve the dowel for a snug fit into the liner, then cut 4 slots in one end of it. Put the dowel into the liner, drop the bolt into it with the tapered end at the slots, tighten the nut on the other end, and spin to your heart’s content!

GWILLIEFOX- Rest In Peace

- Posts : 304

Join date : 2014-12-23

Age : 80

Location : Beaver Falls, PA

Re: Engine A/F boil

Re: Engine A/F boil

Great tutorial Bill. I have never thought to much "outside the box" on this as my method has always been successful, but if it's easier and works I'm all in. I should break down and get a hobby lathe, right now I just use a drill press to accomplish the same thing.

Plier marks on the prop drive washer is my grievance, so unnecessary.

An Enya .36 box thanks to Bobby Brooks.

I asked him if he would sell the box and contents. His one word answer was "NO"!!!

Plier marks on the prop drive washer is my grievance, so unnecessary.

An Enya .36 box thanks to Bobby Brooks.

I asked him if he would sell the box and contents. His one word answer was "NO"!!!

rsv1cox- Top Poster

Posts : 10685

Join date : 2014-08-18

Location : West Virginia

Similar topics

Similar topics» Cox P-40 engine boil

» *Cox Engine of The Month* Submit your pictures! -December 2013- *ENGINE GIVEAWAY*

» *Cox Engine of The Month* Submit your pictures! -December 2017- *ENGINE GIVEAWAY*

» *Cox Engine of The Month* Submit your pictures! -June 2015- *ENGINE GIVEAWAY*

» *Cox Engine of The Month* Submit your pictures! -June 2017- *ENGINE GIVEAWAY*

» *Cox Engine of The Month* Submit your pictures! -December 2013- *ENGINE GIVEAWAY*

» *Cox Engine of The Month* Submit your pictures! -December 2017- *ENGINE GIVEAWAY*

» *Cox Engine of The Month* Submit your pictures! -June 2015- *ENGINE GIVEAWAY*

» *Cox Engine of The Month* Submit your pictures! -June 2017- *ENGINE GIVEAWAY*

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules