Log in

Search

Latest topics

» My latest doodle...by batjac Yesterday at 10:05 pm

» Retail price mark-up.. how much is enough?

by gkamysz Yesterday at 9:29 pm

» Happy 77th birthday Andrew!

by roddie Yesterday at 9:22 pm

» Roger Harris revisited

by rsv1cox Yesterday at 3:38 pm

» My N-1R build log

by GallopingGhostler Yesterday at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Yesterday at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Yesterday at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Yesterday at 11:32 am

» Free Flight Radio Assist

by rdw777 Yesterday at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

190 "Kinda Special"

Page 1 of 1

190 "Kinda Special"

190 "Kinda Special"

First I was going to post this to the "Engines" area of the forum but since this is a purpose-built engine for a certain model, and hopefully there will be a model later on, maybe this is the right place after all.

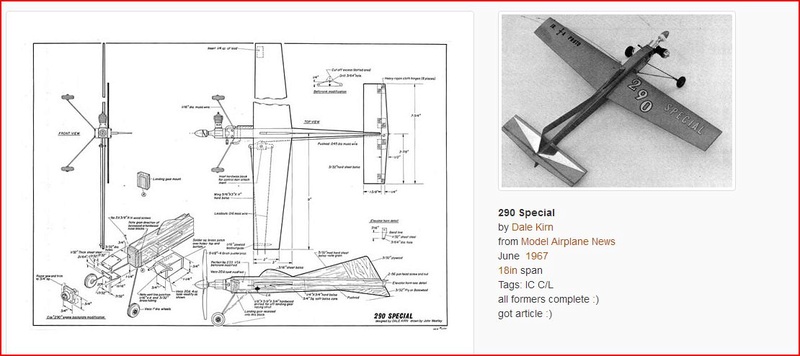

Dale Kirn's design "290 Special" has popped up a few times in different discussions, and I found the design interesting. First because it is a very slick looking model, and I am a fan of anything built for racing. The other reason is that it uses the postage stamp engine and I have a couple of them laying around. Here is a link to gwilliefox's post with parts of the original article where the plans were first published.

https://www.coxengineforum.com/t7914-dale-kirn-s-290-special?highlight=290+special

The article shows an optional modification to the engine backplate and also a way to mount it to a scratch built model.

Yesterday evening I picked up one of my later engine finds, a neglected late-model 190 (or 290) with a #1 cylinder, and decided to try out the modification on it.

Here's the poor beat-up thing as delivered:

I took it apart, of course the glow head was burnt, but what really made me wonder, was the "modification" done to the big end of the connecting rod Especially when the ball joint was nice and tight.

Especially when the ball joint was nice and tight.

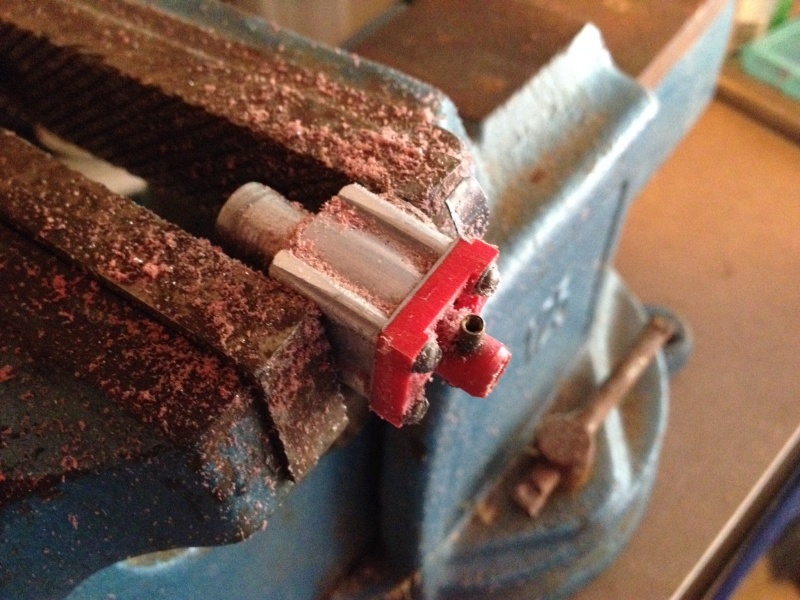

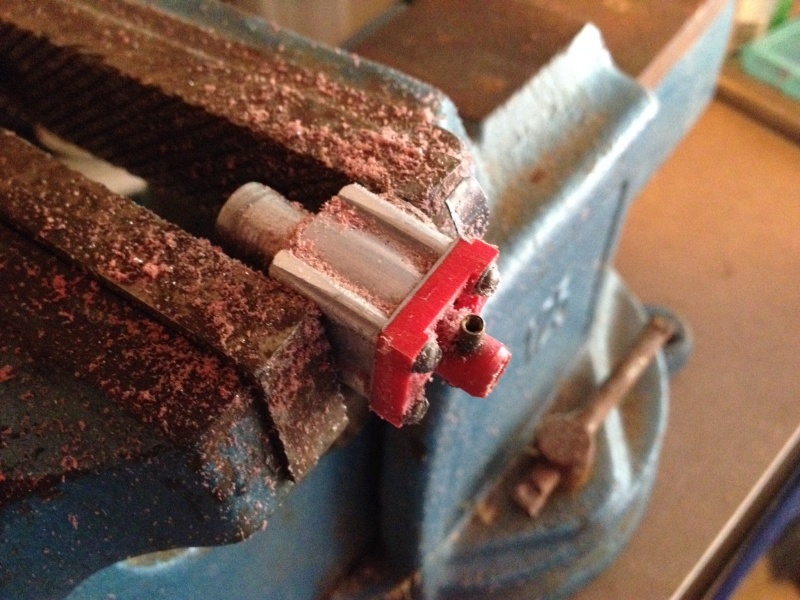

I stole a piston from another beat-up engine and honed it to match this cylinder as well as I could. Then I got to work with the backplate. I installed it to a junk crankcase so that I could mount it in a vise. I also installed an exhaust deflector so that it would work as a guide to get the backplate as square as possible.

Then I took a saw with a thin blade and cut off the wide "ears". These were cleaned up with a file, and the other two sides were field off also.

The mesh and the overall shape of the intake did not exactly yell "speed" to me so I popped the mesh off and grabbed a couple of different grinding tools to modify the intake. I used a cordless drill on low revs (the battery was almost empty ) and with the different tapered tools I managed to create a sort of a velocity stack kind of a shape on the intake. This mod was not in the article and I have no idea if it is beneficial or not. Well I do have an idea but I am not 100% certain. But it does look fast, doesn't it

) and with the different tapered tools I managed to create a sort of a velocity stack kind of a shape on the intake. This mod was not in the article and I have no idea if it is beneficial or not. Well I do have an idea but I am not 100% certain. But it does look fast, doesn't it

Here it is, all cleaned up, with a replacement needle valve and a Tee Dee head as instructed:

A #2 washer and a piece of snug fuel hose finishes the racer look Pardon the messed-up screw heads, I'll need to replace them anyway when the mounts get done and installed.

Pardon the messed-up screw heads, I'll need to replace them anyway when the mounts get done and installed.

I have some aluminum sheet set aside for the engine mounts so that's going to be the next step.

Dale Kirn's design "290 Special" has popped up a few times in different discussions, and I found the design interesting. First because it is a very slick looking model, and I am a fan of anything built for racing. The other reason is that it uses the postage stamp engine and I have a couple of them laying around. Here is a link to gwilliefox's post with parts of the original article where the plans were first published.

https://www.coxengineforum.com/t7914-dale-kirn-s-290-special?highlight=290+special

The article shows an optional modification to the engine backplate and also a way to mount it to a scratch built model.

Yesterday evening I picked up one of my later engine finds, a neglected late-model 190 (or 290) with a #1 cylinder, and decided to try out the modification on it.

Here's the poor beat-up thing as delivered:

I took it apart, of course the glow head was burnt, but what really made me wonder, was the "modification" done to the big end of the connecting rod

Especially when the ball joint was nice and tight.

Especially when the ball joint was nice and tight.

I stole a piston from another beat-up engine and honed it to match this cylinder as well as I could. Then I got to work with the backplate. I installed it to a junk crankcase so that I could mount it in a vise. I also installed an exhaust deflector so that it would work as a guide to get the backplate as square as possible.

Then I took a saw with a thin blade and cut off the wide "ears". These were cleaned up with a file, and the other two sides were field off also.

The mesh and the overall shape of the intake did not exactly yell "speed" to me so I popped the mesh off and grabbed a couple of different grinding tools to modify the intake. I used a cordless drill on low revs (the battery was almost empty

Here it is, all cleaned up, with a replacement needle valve and a Tee Dee head as instructed:

A #2 washer and a piece of snug fuel hose finishes the racer look

I have some aluminum sheet set aside for the engine mounts so that's going to be the next step.

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: 190 "Kinda Special"

Re: 190 "Kinda Special"

Nice job Kari, making something nice out of something not so nice. I like the way the funneled venturi turned out.

Bob

Bob

rsv1cox- Top Poster

Posts : 11248

Join date : 2014-08-18

Location : West Virginia

Re: 190 "Kinda Special"

Re: 190 "Kinda Special"

You have got a very nice finish on the plastic - did you use anything to "finish" it. I always end up with a very rough finish on plastic.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: 190 "Kinda Special"

Re: 190 "Kinda Special"

Looks good! You can push the spray bar out and drill the venturi out for more rpms. If you don't go to crazy it will still draw fuel on suction if your not doing loops. That's a fine thread needle on those so if you want to run a bladder you can really drill that sucker out and gain about 1000rpm.

Jim

Jim

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 57

Location : Colorado

Re: 190 "Kinda Special"

Re: 190 "Kinda Special"

Thanks Guys!

Ian, I used an ordinary rather coarse file to remove the majority of the material and then a finer one to smooth out the surface. The fine file is labeled "mill file, bastard cut". I just moved the file in a light, steady slow stroke, and at the same time just a little sideways. One direction only, not back and forth. This brought out "fresh" Delrin, so the filed areas do look pretty good.

The inside of the intake was finished with a Scotch Brite type of product after the initial grinding. It left a flat surface, and also all the surfaces of the backplate that were left intact were a little faded. I just wiped the whole thing with air tool oil, it restored the look but of course it is now "oily", so it's not perfect.

EDIT 1: in the picture where I hold the part in my hand there is no oil or anything on it, so that's what it looked like before any treatments. After that it went into the ultrasonic with warm water and hand dish detergent and then the oil.

EDIT 2: Jim, if I push out the nva, how should I re-attach it? I thought they were sort of forced into position at the factory and not meant to be removed?

Ian, I used an ordinary rather coarse file to remove the majority of the material and then a finer one to smooth out the surface. The fine file is labeled "mill file, bastard cut". I just moved the file in a light, steady slow stroke, and at the same time just a little sideways. One direction only, not back and forth. This brought out "fresh" Delrin, so the filed areas do look pretty good.

The inside of the intake was finished with a Scotch Brite type of product after the initial grinding. It left a flat surface, and also all the surfaces of the backplate that were left intact were a little faded. I just wiped the whole thing with air tool oil, it restored the look but of course it is now "oily", so it's not perfect.

EDIT 1: in the picture where I hold the part in my hand there is no oil or anything on it, so that's what it looked like before any treatments. After that it went into the ultrasonic with warm water and hand dish detergent and then the oil.

EDIT 2: Jim, if I push out the nva, how should I re-attach it? I thought they were sort of forced into position at the factory and not meant to be removed?

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: 190 "Kinda Special"

Re: 190 "Kinda Special"

Thanks. I have tried all sorts of products for restoring delrin with no success. Any that have looked promising haven't been permanent.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: 190 "Kinda Special"

Re: 190 "Kinda Special"

KariFS wrote: Jim, if I push out the nva, how should I re-attach it? I thought they were sort of forced into position at the factory and not meant to be removed?

They're not, Ha! But, if you use the back end of a screwdriver handle, a dowel, or something similar and push on the needle end of the spray bar (with the needle removed) it will come out. Force it back in needle end first. The trick is to not do it too many times or the fit gets sloppy and the spray bar will turn with the needle.

Jim

Last edited by JPvelo on Sat Jun 11, 2016 11:13 pm; edited 1 time in total

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 57

Location : Colorado

Re: 190 "Kinda Special"

Re: 190 "Kinda Special"

Jim, when you use a bladder with the fine needle plastic backplate, how many turns open do you start at?

The Student Mark

The Student Mark

batjac- Diamond Member

Posts : 2375

Join date : 2013-05-22

Age : 61

Location : Broken Arrow, OK, USA

Re: 190 "Kinda Special"

Re: 190 "Kinda Special"

JPvelo wrote:.... push on the nipple end it will come out. Force it back in nipple end first. Jim

I can't say for sure, but I was pretty certain that the spray bar needs to come out the other way, pushing out from the needle side????

Oldenginerod- Top Poster

- Posts : 4018

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: 190 "Kinda Special"

Re: 190 "Kinda Special"

Oldenginerod wrote:JPvelo wrote:.... push on the nipple end it will come out. Force it back in nipple end first. Jim

I can't say for sure, but I was pretty certain that the spray bar needs to come out the other way, pushing out from the needle side????

You are correct! Sorry, it's been a few years since I've done one. I'll go back in and edit my previous post.

The embarrassed Jim.

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 57

Location : Colorado

Re: 190 "Kinda Special"

Re: 190 "Kinda Special"

batjac wrote:Jim, when you use a bladder with the fine needle plastic backplate, how many turns open do you start at?

The Student Mark

Mark,

Here's a write up I did when I first started doing these, all the info is in there.

https://www.coxengineforum.com/t3536-cranking-up-a-reed-valve-cox-on-bladder-pressure?highlight=Bladder

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 57

Location : Colorado

Re: 190 "Kinda Special"

Re: 190 "Kinda Special"

Is that a DIY aluminum bullet spinner?

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: 190 "Kinda Special"

Re: 190 "Kinda Special"

While this may not be on topic with the subject, Mark raised the question of how many turns should the needle be out. That question is impossible to answer . This is due to many factors especially the taper of the needle. There was at least 3 style of 128 TPI needles that I own from Cox where there's a step in it. So to answer the question directly, with the bladder feed tubing pinched closed, holding this particular engine level, open the pinch off and wait a sec for the fuel to come dripping out. Adjust the needle until the drips are about 3/4"-1" apart. If the fuel is streaming out, it's obviously open too much and if you can't control the drip as I mentioned it's not going to work and their could be a problem with a clog in the spraybar or a fault in the needle. If the needle is set too lean, the engine may run, but it will surge up and down in rpm and the needle will have to be immediately opened.

Once the drip is set, starting procedures are pretty much the same. I like to run a prime through 2 times prior to opening the pinch off. I like to clear the engine and get a bit of heat into it prior to running on the bladder. Don't adjust your needle too quickly once it's running unless the setting is too lean. Trying to adjust the needle on a cold engine is going to result in a not so favorable needle setting. Stay on the ground a few seconds, I like to hold my finger on the head until I can't hold it there to get the to end heated up and the setting can now be adjust without a major change due to temperature.

For those interested in trying bladder pressure, I highly recommend using a additional head gaskets to give your plug life a bit more duration. If you don't feel the need for them, you can always remove them.

Running bladder pressure doesn't always allow for the same size prop one would run on suction, the needle sensitivity becomes too great. To counteract this, run a smaller prop and use higher nitro. This will allow for a fine adjustment and reliability. Your launch rpm is dictated by your needle setting. Quickly pinching the fuel line from the bladder should cause the engine to rise in rpm's quickly. If you pinch the line and it wants to quit, your settting is too lean. The engine is going to unload in the air and you must counteract this by launching slightly rich. The higher the nitro, the richer the setting during launch. Another tell tale sign is the end of the flight. WHen the head pressure of the bladder depletes, the engine run goes richer at the end of the flight. If your setting was on the rich side, the very last few laps of the flight will yield a lean run. This means you can go in a bit more on your needle during launch.

Once the drip is set, starting procedures are pretty much the same. I like to run a prime through 2 times prior to opening the pinch off. I like to clear the engine and get a bit of heat into it prior to running on the bladder. Don't adjust your needle too quickly once it's running unless the setting is too lean. Trying to adjust the needle on a cold engine is going to result in a not so favorable needle setting. Stay on the ground a few seconds, I like to hold my finger on the head until I can't hold it there to get the to end heated up and the setting can now be adjust without a major change due to temperature.

For those interested in trying bladder pressure, I highly recommend using a additional head gaskets to give your plug life a bit more duration. If you don't feel the need for them, you can always remove them.

Running bladder pressure doesn't always allow for the same size prop one would run on suction, the needle sensitivity becomes too great. To counteract this, run a smaller prop and use higher nitro. This will allow for a fine adjustment and reliability. Your launch rpm is dictated by your needle setting. Quickly pinching the fuel line from the bladder should cause the engine to rise in rpm's quickly. If you pinch the line and it wants to quit, your settting is too lean. The engine is going to unload in the air and you must counteract this by launching slightly rich. The higher the nitro, the richer the setting during launch. Another tell tale sign is the end of the flight. WHen the head pressure of the bladder depletes, the engine run goes richer at the end of the flight. If your setting was on the rich side, the very last few laps of the flight will yield a lean run. This means you can go in a bit more on your needle during launch.

Ken Cook- Top Poster

- Posts : 5637

Join date : 2012-03-27

Location : pennsylvania

Re: 190 "Kinda Special"

Re: 190 "Kinda Special"

1/2A Nut wrote:Is that a DIY aluminum bullet spinner?

I wish

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: 190 "Kinda Special"

Re: 190 "Kinda Special"

KariFS wrote:1/2A Nut wrote:Is that a DIY aluminum bullet spinner?

I wishIt's just a silver color Cox rubber spinner. I have two of them, not sure which model they are from.

The silver rubber spinner came from the first version (c.'68) of the Corsair and used a couple years, when it was revamped, bellcrank moved into fuselage and red spinner added.

Re: 190 "Kinda Special"

Re: 190 "Kinda Special"

Thanks Mark, it's nice to know where at least one of my p.s. engines came from

EDIT: BTW, is that a left hand prop?

EDIT: BTW, is that a left hand prop?

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: 190 "Kinda Special"

Re: 190 "Kinda Special"

KariFS wrote:Thanks Mark, it's nice to know where at least one of my p.s. engines came from

EDIT: BTW, is that a left hand prop?

I have a couple of Cox L/H 3-blade props like that. Mine are 5d x 3.5p black, square-tipped/solid-hub. Might be a good prop to try. Bernie (Cox International) currently has them in stock. I've had mine for YEARS.. not sure where they came from. Bernie's are listed as "pushers".. but on a reedie you could just run them L/H "tractor" and gain some line-tension. It would be interesting to note the difference +.5" of pitch makes. Not quite the load of a 5 x 4... but a little more edge than a 5 x 3.

Re: 190 "Kinda Special"

Re: 190 "Kinda Special"

I think a 5x3.5 three blade would have about the same load as 5x4 two blade, I do think you loose some efficiency with a three blade. The square tip LH prop was designed for the Corsair, with the thought of increasing line tension, possibly from input from Dale Kirn, who worked at Cox at the time. I think Bernie's is the same just mislabeled.

Re: 190 "Kinda Special"

Re: 190 "Kinda Special"

The complete article has now appeared on Outerzone:

http://www.outerzone.co.uk/planfile_supplement/6104/290_Special_oz6104_article.pdf

Oops, that link didn't work, let's try another one:

http://www.outerzone.co.uk/download_this_plan.asp?ID=6104

Oops, that link didn't work, let's try another one:

http://www.outerzone.co.uk/download_this_plan.asp?ID=6104

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: 190 "Kinda Special"

Re: 190 "Kinda Special"

KariFS wrote:The complete article has now appeared on Outerzone:http://www.outerzone.co.uk/planfile_supplement/6104/290_Special_oz6104_article.pdf

Oops, that link didn't work, let's try another one:

http://www.outerzone.co.uk/download_this_plan.asp?ID=6104

I couldn't access either of these Kari..

I'll be following this thread.. because the whole concept of re-using this little product engine in a more capable balsawood model, I find endearing!

I'll be following this thread.. because the whole concept of re-using this little product engine in a more capable balsawood model, I find endearing! Did you bench-run the engine yet? The backplate came out real nice!

I have to wonder about the connecting-rod that was in there when you took it apart.. That's not something that you see everyday.. and probably wasn't done by a novice. How did the crank-pin look? I assume you're using that same crank? When you replace the backplate screws (assuming you haven't yet..) it would provide the opportunity to observe if there's any "slop" in the fit of the crankpin with the replacement piston/rod by rotating the prop-driver back and forth. If there is.. I would personally replace the crank.. or crankcase assy.

On the other hand...

Did the "old" piston/rod look ok (otherwise) when you removed it from the cylinder? You might want to hang onto that piston/rod. I don't consider myself an engine-guru by any stretch of the imagination.. but by the looks of it; someone went to a lot of trouble to thin-out the pin-end of that connecting-rod. You could measure it's "web".. but I'm guessing that there might be as much as a 50% reduction in bearing-surface (friction) area.. as well as more "end-play" on the crankpin. Having a ball-socket joint design "up top".. this might equate to a hotrod engine-mod

Did the "old" piston/rod look ok (otherwise) when you removed it from the cylinder? You might want to hang onto that piston/rod. I don't consider myself an engine-guru by any stretch of the imagination.. but by the looks of it; someone went to a lot of trouble to thin-out the pin-end of that connecting-rod. You could measure it's "web".. but I'm guessing that there might be as much as a 50% reduction in bearing-surface (friction) area.. as well as more "end-play" on the crankpin. Having a ball-socket joint design "up top".. this might equate to a hotrod engine-mod

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: 190 "Kinda Special"

Re: 190 "Kinda Special"

Roddie, if the link still doesn't work, you can find the article by going to outerzone.com, then searching "290". On the 290 Special page click "downloads" button, that should get you to the page where you can either click and open the plan or the article. The article is in PDF format, I don't know how to post those or if it is possible at all. I suppose I could try to capture the pages as "images" and then post them, but I'm running a little short on round-toits...

It never occurred to me that the rod mod would be a performance thing, I figured it was maybe caused by abuse by starter or pusher prop use in another engine, or maybe a "fixed" big end meltdown or even a left-over from an attempt to make a twin engine.

The crankshaft and the crankcase both looked intact, I polished them and did not see anything out of the ordinary. This engine was thrown in to the pile when I bought 4 or 5 other engines. The other engines were "almost-NIB" except for this one and a dirty TeeDee .051. Now that I think about it, the TeeDee did have 4 or 5 head shims and a piece of fuel hose around the needle valve, so it could be that a previous owner is/was after performance

The guy I bought the lot from had got the boxed engines from "an older fellow who liked to build planes but lately had not been flying them a lot", and due to the past tense I didn't ask anything further about him, not even sure if he's still around.

I did (of course) keep the modified piston/rod, thought about using it as a part of a honing tool or something. But I will now investigate the "hot rod" aspect also

I haven't run it yet, I'll need to get the brackets done first. I did find the necessary aluminum material for the brackets and bought the balsa for the plane though. My drill press is still under a pile of junk in some corner of the garage, but I already found the vise a few weeks ago Moving in a hurry is hell, 3 years after my workshop is still a mess. I've been too busy looking for my tools to organize the shop I guess

Moving in a hurry is hell, 3 years after my workshop is still a mess. I've been too busy looking for my tools to organize the shop I guess

It never occurred to me that the rod mod would be a performance thing, I figured it was maybe caused by abuse by starter or pusher prop use in another engine, or maybe a "fixed" big end meltdown or even a left-over from an attempt to make a twin engine.

The crankshaft and the crankcase both looked intact, I polished them and did not see anything out of the ordinary. This engine was thrown in to the pile when I bought 4 or 5 other engines. The other engines were "almost-NIB" except for this one and a dirty TeeDee .051. Now that I think about it, the TeeDee did have 4 or 5 head shims and a piece of fuel hose around the needle valve, so it could be that a previous owner is/was after performance

The guy I bought the lot from had got the boxed engines from "an older fellow who liked to build planes but lately had not been flying them a lot", and due to the past tense I didn't ask anything further about him, not even sure if he's still around.

I did (of course) keep the modified piston/rod, thought about using it as a part of a honing tool or something. But I will now investigate the "hot rod" aspect also

I haven't run it yet, I'll need to get the brackets done first. I did find the necessary aluminum material for the brackets and bought the balsa for the plane though. My drill press is still under a pile of junk in some corner of the garage, but I already found the vise a few weeks ago

Moving in a hurry is hell, 3 years after my workshop is still a mess. I've been too busy looking for my tools to organize the shop I guess

Moving in a hurry is hell, 3 years after my workshop is still a mess. I've been too busy looking for my tools to organize the shop I guess

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Similar topics

Similar topics» kinda sad, kinda stupid, kinda wtf

» But kinda on topic really

» My "38 Special"

» Cox "Special .15" TD

» new 2.0 rc 1/16 049 powered bugy upgrade tee dee

» But kinda on topic really

» My "38 Special"

» Cox "Special .15" TD

» new 2.0 rc 1/16 049 powered bugy upgrade tee dee

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules