Log in

Search

Latest topics

» Roger Harris revisitedby rsv1cox Today at 7:35 am

» Tee Dee .020 combat model

by GallopingGhostler Today at 7:01 am

» My latest doodle...

by batjac Yesterday at 10:05 pm

» Retail price mark-up.. how much is enough?

by gkamysz Yesterday at 9:29 pm

» Happy 77th birthday Andrew!

by roddie Yesterday at 9:22 pm

» My N-1R build log

by GallopingGhostler Yesterday at 3:04 pm

» Chocolate chip cookie dough.........

by roddie Yesterday at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Yesterday at 11:32 am

» Free Flight Radio Assist

by rdw777 Yesterday at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Page 26 of 30

Page 26 of 30 •  1 ... 14 ... 25, 26, 27, 28, 29, 30

1 ... 14 ... 25, 26, 27, 28, 29, 30

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Wild run, Brad! You mean it was a stock SPI TD 051? Then the only thing I still miss is a good manifold between the cylinder and the tuned pipe..suppose gkamysz will soon sell that?

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Thank you Gents !!

Yes stock .051 with SPI

Yes it is fast for a simple TD engine this is fantastic!

Yes the manifold / headers will end up in a production run for sure hard to pass up this part should sell well.

Key reasons it works so well is good seal no leaks / maximum flow in and out of the engine.

I need more of them one for bench runs testing engines / props more for flying projects and boats.

I plan to do some more flight tests this weekend now the intentions will be for actual speed runs

meant to out perform the Nano III.

See here modified props just for the Nano X engine and pipe use.

4.3 x 5.5 est. 29.6k rpm / 154 mph pitch speed

4.2 x 6.5 est. 28.8k rpm / 177 mph pitch speed

I am about to blow away the Nano III best doppler pass of 138 mph.

Note the bar cut version is a trick to relieve torque requirements adding more rpm.

The 6.5P prop by nature was made more beefy at the hub in my case I don't need the beef.

Another trick is using TD .020 bullet spinners does add top end rpm and less vibrations to the engine.

These inset into the prop hub keeping the mass as close to the prop plate as possible.

Best pass thus far in run two 33,672 / 143 mph pitch speed.

Yes stock .051 with SPI

Yes it is fast for a simple TD engine this is fantastic!

Yes the manifold / headers will end up in a production run for sure hard to pass up this part should sell well.

Key reasons it works so well is good seal no leaks / maximum flow in and out of the engine.

I need more of them one for bench runs testing engines / props more for flying projects and boats.

I plan to do some more flight tests this weekend now the intentions will be for actual speed runs

meant to out perform the Nano III.

See here modified props just for the Nano X engine and pipe use.

4.3 x 5.5 est. 29.6k rpm / 154 mph pitch speed

4.2 x 6.5 est. 28.8k rpm / 177 mph pitch speed

I am about to blow away the Nano III best doppler pass of 138 mph.

Note the bar cut version is a trick to relieve torque requirements adding more rpm.

The 6.5P prop by nature was made more beefy at the hub in my case I don't need the beef.

Another trick is using TD .020 bullet spinners does add top end rpm and less vibrations to the engine.

These inset into the prop hub keeping the mass as close to the prop plate as possible.

Best pass thus far in run two 33,672 / 143 mph pitch speed.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

I thought it was finally on the pipe when you mentioned the prop fluttering. I could be wrong. You could have launched earlier and picked off that pesky dog.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

RE: Cox.01/.02/.05/.09/.15 speed planes

RE: Cox.01/.02/.05/.09/.15 speed planes

That is one big league impressive run on the .05 !!!!

You must have an ultra secret method of keeping the rod/piston ball joint alive !!!!

Your R&D work always intrigues me and would probably really warp my brain if I understood all you do for those results !!!

Great Job !!!!!!

Steve...………..

You must have an ultra secret method of keeping the rod/piston ball joint alive !!!!

Your R&D work always intrigues me and would probably really warp my brain if I understood all you do for those results !!!

Great Job !!!!!!

Steve...………..

66 Malibu- Gold Member

- Posts : 477

Join date : 2012-02-28

Location : Georgia

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

1/2A Nut wrote:Best pass thus far in run two 33,672 / 143 mph pitch speed.

Awesome! Where at in that run (time) was the best pass?

I think I fly quite a bit closer to myself than you do (your smarter

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Thank you Oz & Steve

Yes tricks many tricks that add up to no engine damage.

I will list a run down of methods after my results this weekend.

Yes it was on the pipe a lot this second run, what I should have said in the vid

is it is not steady continuously on the pipe. The NV was close enough to cause

it to jump on the pipe with any amount of diving but once level it was hit or

miss on staying there. I imagine the NV was about 2 clicks off. I am not

running pressure. So first run was set to inure no leaning 2nd run was then

tuned closer to peak, in fact i purposely leaned it till it quit as shown on start

up to know where the stopping point is. The engine idles great and transitions

without dying on launch so happy there.

Pressure may help to nail a solid NV setting. The pipe cools in the air what has

been learned is set it to peak on the ground to compensate. The cooler pipe in

the air extends the timing. What math's out at 30.8k rpm based on the estimated

sweet spot best MRP point is less in the air with a cooler pipe was kicking in at 28k +

The non bearing engine does not suit well with flexible prop tips hence the flutter.

The Fuji with bearings has got to 37k with no flutter but did flutter at time mainly

into the wind. So the simple fix is just use more ridge blades at the tips which the

APC props can provide. Note my custom mod props eliminate flutter by the nature

of their shape. To compare the look like small APC pylon props now.

Example of a APC pylon prop.

Oz I fly much closer too this was a maiden flight day I have only flown the plane twice.

Here is how I like to line them up when I have some stick time / gives good solid sound files.

The camera makes things look a bit further away most of this was 8 to 12ft on the close ones.

I have to line up far out and try not to move the surfaces much as it scrubs off speed.

Yes tricks many tricks that add up to no engine damage.

I will list a run down of methods after my results this weekend.

Yes it was on the pipe a lot this second run, what I should have said in the vid

is it is not steady continuously on the pipe. The NV was close enough to cause

it to jump on the pipe with any amount of diving but once level it was hit or

miss on staying there. I imagine the NV was about 2 clicks off. I am not

running pressure. So first run was set to inure no leaning 2nd run was then

tuned closer to peak, in fact i purposely leaned it till it quit as shown on start

up to know where the stopping point is. The engine idles great and transitions

without dying on launch so happy there.

Pressure may help to nail a solid NV setting. The pipe cools in the air what has

been learned is set it to peak on the ground to compensate. The cooler pipe in

the air extends the timing. What math's out at 30.8k rpm based on the estimated

sweet spot best MRP point is less in the air with a cooler pipe was kicking in at 28k +

The non bearing engine does not suit well with flexible prop tips hence the flutter.

The Fuji with bearings has got to 37k with no flutter but did flutter at time mainly

into the wind. So the simple fix is just use more ridge blades at the tips which the

APC props can provide. Note my custom mod props eliminate flutter by the nature

of their shape. To compare the look like small APC pylon props now.

Example of a APC pylon prop.

Oz I fly much closer too this was a maiden flight day I have only flown the plane twice.

Here is how I like to line them up when I have some stick time / gives good solid sound files.

The camera makes things look a bit further away most of this was 8 to 12ft on the close ones.

I have to line up far out and try not to move the surfaces much as it scrubs off speed.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

--Oz-- wrote:1/2A Nut wrote:Best pass thus far in run two 33,672 / 143 mph pitch speed.

Awesome! Where at in that run (time) was the best pass?

I think I fly quite a bit closer to myself than you do (your smarter), you might be getting lower numbers than your really going.

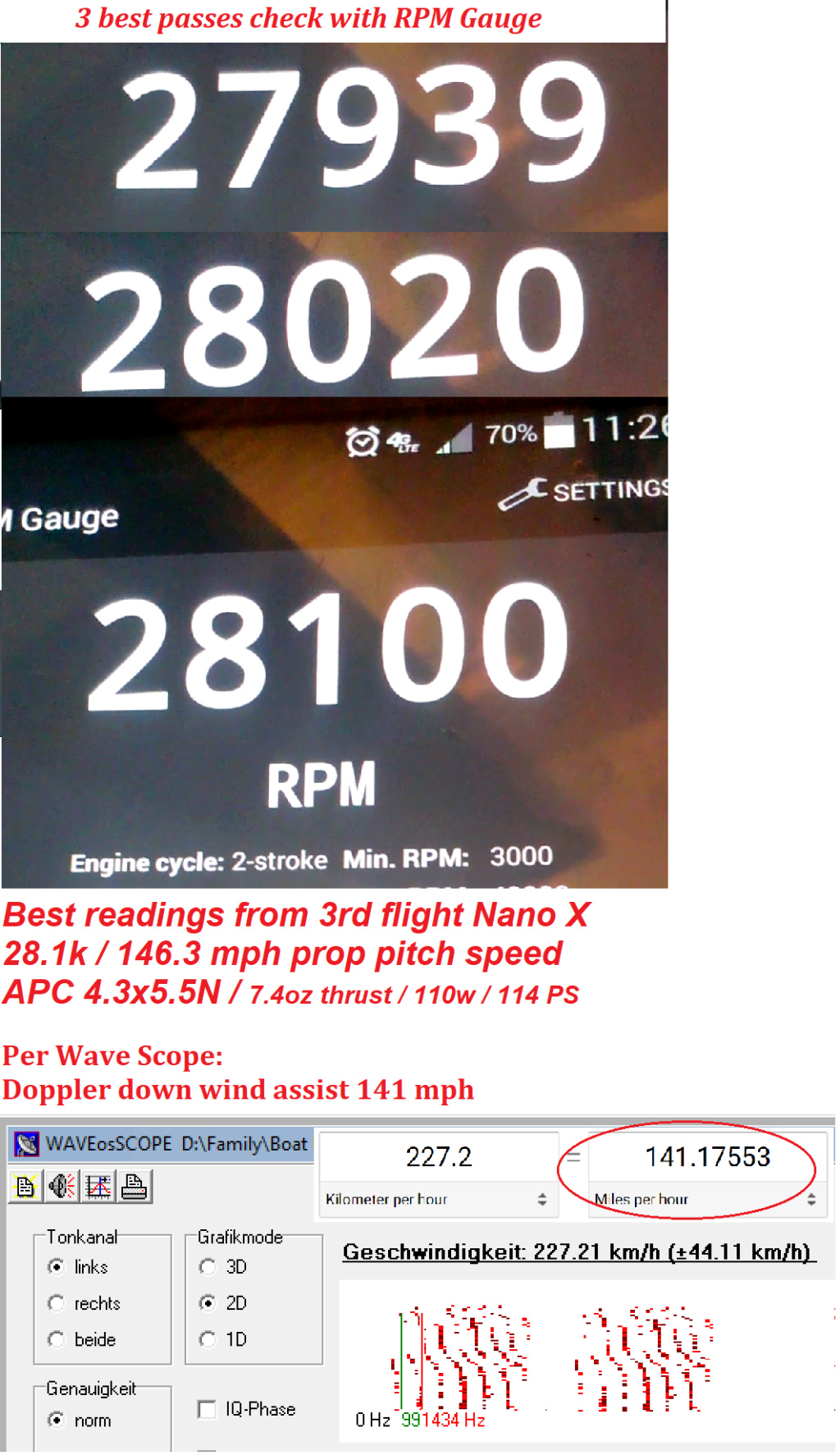

"RPM Gauge" for android phones.

I use this tool to get rpm it has been proven with my laser tach and photo cell types. You can also use

a youtube vid with someone using a tach and verify straight off the vid.

You just need to make sure the resolution is set correctly for low end and high end readings.

Observations to tell when the pipe kicks in with the 4x4.5 prop and the given NV setting and temp on the day of testing.

Another pass / reading showed it kicked in at 28.3k rpm and peaked at 32.9k

i use all the same tools to have constancy when gathering data, this will allow good choices when making changes.

The speed props will get a good review getting down to the nut cutting, once I find the best prop per software I will

take my tripod and radar gun and get results with that more to haul and set up but worth it if the best prop has been found.

Note I posted the best pass on the other page a vid of it that pass was reviewed over and over until the peak reading

showed up 4 times I then recorded vid of the RPM Gauge and review the numbers as they popped up as it happens fast.

Hence the photo above. I have a GPS unit 14.6g but just no where to put it the fuselage is full no wasted space.

Flying close is fun but risky I use aluminum bullet spinners if the mass of the plane hits me at 130 mph it will impact

with the force of 81 lbs. per dry weight of the plane not fun lol. That's 81 lbs at the tip of the bullet spinner.

https://www.smartconversion.com/unit_calculation/Force_calculator.aspx

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Published on Aug 11, 2019

Nano X - TD .051 / 3rd Flight / Tuned Pipe APC 4.3 x 5.5

Best Pass 28,100 rpm / 146.3 Prop Pitch Speed

Now the fastest TD .051 3ch Plane bested Nano III

Best static 21,962 rpm / 114 mph pitch speed'

.147 hp - 110w / 7.3oz thrust

25" span 75 sq. in. wing / 8.2oz RTF

25% nitro / 20% oil / SPI engine / no pressure tap

Kamtechnik turbo plug adapter

Kamtechnik prototype manifold and header

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

141mph

On rcg there was a guy that modified the wave0scope program to output mph, however I could not find a copy, I even tried using the waybackmachine.com

I found this bit of good info on these model motors:

https://www.mh-aerotools.de/airfoils/cox_techinfo.htm

On rcg there was a guy that modified the wave0scope program to output mph, however I could not find a copy, I even tried using the waybackmachine.com

I found this bit of good info on these model motors:

https://www.mh-aerotools.de/airfoils/cox_techinfo.htm

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Thank you Oz!

I use to have the MPH version on another comp was nice to not have to convert.

Another thing that was added down at the bottom was est. rpm. I wish there was

a sport camera with built in radar that would give continuous readings while filming.

As miniaturization continues to progress it is possible. There is a small radar gun out

right now that is the size of a cell phone in shape for ball sport use for baseball etc.

This is very good but only up to 130 mph.

https://www.pocketradar.com/products/introducing-smart-coach-radar-model-sr1100-with-free-shipping?gclid=EAIaIQobChMI8aCXv-P94wIVfv7jBx0RzAwmEAYYASABEgIhzPD_BwE

The radar gun I use now is this system:

https://shop.opticsplanet.com/bushnell-speedscreen-radar-speed-display-101922-wireless-radar-gun-screen-w-tripod-ca.html?_iv_code=BU-GA-101922-KIT1&utm_source=google&utm_medium=cpc&utm_campaign=plusbox-beta&gclsrc=aw.ds&&gclid=EAIaIQobChMI6_fy9uT94wIV0P_jBx0UCAayEAQYBCABEgLBzPD_BwE

This plane has been quite exciting for 1/2A flying. Down wind is blistering. Up wind

is better than the Nano III which is a very good plane as is. I do a reduction build

to squeak out more speed, the .049 - .051 class engine deserves max effort to find out

what's possible with today modern gear. More folks fly this displacement than any other.

Really happy with the prop mods they are the key to tap into the nominal static power,

shape selection is everything. Yep seen that site thank you.

I use to have the MPH version on another comp was nice to not have to convert.

Another thing that was added down at the bottom was est. rpm. I wish there was

a sport camera with built in radar that would give continuous readings while filming.

As miniaturization continues to progress it is possible. There is a small radar gun out

right now that is the size of a cell phone in shape for ball sport use for baseball etc.

This is very good but only up to 130 mph.

https://www.pocketradar.com/products/introducing-smart-coach-radar-model-sr1100-with-free-shipping?gclid=EAIaIQobChMI8aCXv-P94wIVfv7jBx0RzAwmEAYYASABEgIhzPD_BwE

The radar gun I use now is this system:

https://shop.opticsplanet.com/bushnell-speedscreen-radar-speed-display-101922-wireless-radar-gun-screen-w-tripod-ca.html?_iv_code=BU-GA-101922-KIT1&utm_source=google&utm_medium=cpc&utm_campaign=plusbox-beta&gclsrc=aw.ds&&gclid=EAIaIQobChMI6_fy9uT94wIV0P_jBx0UCAayEAQYBCABEgLBzPD_BwE

This plane has been quite exciting for 1/2A flying. Down wind is blistering. Up wind

is better than the Nano III which is a very good plane as is. I do a reduction build

to squeak out more speed, the .049 - .051 class engine deserves max effort to find out

what's possible with today modern gear. More folks fly this displacement than any other.

Really happy with the prop mods they are the key to tap into the nominal static power,

shape selection is everything. Yep seen that site thank you.

Last edited by 1/2A Nut on Tue Dec 20, 2022 11:47 am; edited 5 times in total

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Watched the video, seems to have been a video of clear blue sky, didn't notice any model.

Maybe I need to watch it again, but without blinking?

Maybe I need to watch it again, but without blinking?

dirk gently- Gold Member

- Posts : 430

Join date : 2012-02-03

Age : 42

Location : Poznań

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Lol Dirk  yes just a Sunday morning vid with some sunshine poking through the clouds.

yes just a Sunday morning vid with some sunshine poking through the clouds.

yes just a Sunday morning vid with some sunshine poking through the clouds.

yes just a Sunday morning vid with some sunshine poking through the clouds.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Somewhere I saw 0.140HP = 104W, being electrical engineer and flying electric planes/quads, I am guessing this wattage number is just taking 1HP=742W / HP, is this correct?

So where does this HP number come from?

What is input wattage to make this output wattage?

As we know electric power is so inefficient (specially storage density). My quad burns 1800Wpeak on 4S (2100W on 5S), but does 0 to 84mph in 1.2 sec at 9g acceleration and weighs 430g (this is old school quad, they are now up to 14:1 thrust to weight).

I am just thinking if trying to do 130-140mph with 104W electrical watts is very impressive and not really easily possible with electric, to be fair, it might be possible and a great challenge. But I am really thinking the 2 stroke nitro burning is using a lot more equivalent wattage, I could be wrong.

But I am really thinking the 2 stroke nitro burning is using a lot more equivalent wattage, I could be wrong.

Considering our gas cars are horribly inefficient (way less than 50% converting fuel to motion), nitro is probably worse (I could be wrong), and 2-stroke cant be any more efficient, thoughts?

EDIT: Here is where I saw the MPH version of waveoscope (link is dead now) https://www.rcgroups.com/forums/showthread.php?867528-WAVEoSCOPE-English-Translation

So where does this HP number come from?

What is input wattage to make this output wattage?

As we know electric power is so inefficient (specially storage density). My quad burns 1800Wpeak on 4S (2100W on 5S), but does 0 to 84mph in 1.2 sec at 9g acceleration and weighs 430g (this is old school quad, they are now up to 14:1 thrust to weight).

I am just thinking if trying to do 130-140mph with 104W electrical watts is very impressive and not really easily possible with electric, to be fair, it might be possible and a great challenge.

Considering our gas cars are horribly inefficient (way less than 50% converting fuel to motion), nitro is probably worse (I could be wrong), and 2-stroke cant be any more efficient, thoughts?

EDIT: Here is where I saw the MPH version of waveoscope (link is dead now) https://www.rcgroups.com/forums/showthread.php?867528-WAVEoSCOPE-English-Translation

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Hey Oz,

1 HP equals 745.7w / I round up to 746w

I use the same calc software for each engine on the bench and at the field so the

data stays consistent. I use watts as most who fly have done electric and the value

stands out more to easy remember. Standard Cox Tee Dee should at least make

80w with 15% nitro and stock props. The larger dia. props generally calc out to

more watts, it takes quite a bit of rpm to get the power numbers up with speed props.

- Again here is the link to the calc software:

http://www.godolloairport.hu/calc/strc_eng/index.htm

- Example:

Best static 21,962 rpm / 114 mph pitch speed'

.147 hp - 110w / 7.3oz thrust

GOOD Question how do I fly so fast on 110w.

- engine rpm unloads in the air must know what the engine can handle

- props are not stock I modify them quite a bit. (they are small)

- high pitch / just enough dia. / speed tip props

- the planes are smaller than they look simple clean low drag

- wing cord is just 4" wing tips 2" span 25" only 75 sq. in.

- nitro adds oxygen into the fuel also helps cool the engine

- methanol burns hotter than nitro

Many speed efforts made in this thread from .010 thru .09 thus far with vids.

I walk folks through the designs, parts and props.

Example:

Check out this out impressive speed for a mere 21w

A challenge you could do is: 1S 3.7v nominal charged to 4.2v

Loaded volts 3.85v x 5.45A / 21w

Published on Dec 4, 2017

NANO - TD .010 / 130.4 MPH - Best Pass Per Doppler

Prop 2.56 x 4N / 30% Nitro:

Static 28,858 rpm / 109.3 mph / .028hp / 21w / 1.5oz thrust

Unloaded best pass per prop calc 133mph audio tach / 130.4 mph per Doppler reading

and best pass on this vid 35,184 rpm / 3oz RTF / 2ch RC micro race plane.

1 HP equals 745.7w / I round up to 746w

I use the same calc software for each engine on the bench and at the field so the

data stays consistent. I use watts as most who fly have done electric and the value

stands out more to easy remember. Standard Cox Tee Dee should at least make

80w with 15% nitro and stock props. The larger dia. props generally calc out to

more watts, it takes quite a bit of rpm to get the power numbers up with speed props.

- Again here is the link to the calc software:

http://www.godolloairport.hu/calc/strc_eng/index.htm

- Example:

Best static 21,962 rpm / 114 mph pitch speed'

.147 hp - 110w / 7.3oz thrust

GOOD Question how do I fly so fast on 110w.

- engine rpm unloads in the air must know what the engine can handle

- props are not stock I modify them quite a bit. (they are small)

- high pitch / just enough dia. / speed tip props

- the planes are smaller than they look simple clean low drag

- wing cord is just 4" wing tips 2" span 25" only 75 sq. in.

- nitro adds oxygen into the fuel also helps cool the engine

- methanol burns hotter than nitro

Many speed efforts made in this thread from .010 thru .09 thus far with vids.

I walk folks through the designs, parts and props.

Example:

Check out this out impressive speed for a mere 21w

A challenge you could do is: 1S 3.7v nominal charged to 4.2v

Loaded volts 3.85v x 5.45A / 21w

Published on Dec 4, 2017

NANO - TD .010 / 130.4 MPH - Best Pass Per Doppler

Prop 2.56 x 4N / 30% Nitro:

Static 28,858 rpm / 109.3 mph / .028hp / 21w / 1.5oz thrust

Unloaded best pass per prop calc 133mph audio tach / 130.4 mph per Doppler reading

and best pass on this vid 35,184 rpm / 3oz RTF / 2ch RC micro race plane.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Electric airplanes are fast due to low drag. No cylinders, no pipes or anything else hanging out of the airframe. I think Brad could pick up significant speed simply by cleaning up the airframe. Bring the aileron linkages inside the fuse, the elevator linkage through the tail, some fairings around the engine, etc. I was flew some F5D electric pylon around 2000 when brushless became standard, but we were still running NiCd. 600-700W from the battery and 150+MPH.

When drag is low the plane can fly closer to pitch speed. It's also why CL speed is so hard. Line drag is huge. Line drag is about half of total drag for a 1/2A mouse racer.

Calculating power from prop RPM is not always very accurate. it all depends on the "prop constant" applied for a given prop. We all know and APC of a given size needs less power than a Master Airscrew. And even within a product line there are variations. Some things are just overlooked like the Graupner Super Nylon are actually metric and the inch sizes are rounded, so lead to bad numbers if used for calculation.

When drag is low the plane can fly closer to pitch speed. It's also why CL speed is so hard. Line drag is huge. Line drag is about half of total drag for a 1/2A mouse racer.

Calculating power from prop RPM is not always very accurate. it all depends on the "prop constant" applied for a given prop. We all know and APC of a given size needs less power than a Master Airscrew. And even within a product line there are variations. Some things are just overlooked like the Graupner Super Nylon are actually metric and the inch sizes are rounded, so lead to bad numbers if used for calculation.

gkamysz- Gold Member

- Posts : 415

Join date : 2018-02-22

Location : Chicagoland

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

When I was looking at and talking about the wattage numbers in my post, I was thinking this:

1 HP equals 745.7w

1hp = work being done over time

the 746W is the electrical equivalent.

These numbers states nothing about system efficiency, only output power (work) being done,

I am going to take a wide guess, a 2 stroke nitro motor is 10% efficient. That roughly means it takes 7,460W of fuel energy (input) to produce 746W of output energy.

The best brushless motors are upto 90% efficient (maybe not hobby motors), but lets go with 50%. I am sure you see where I am going with this.

In your example you mentioned 0.147 hp - 110w, in this example, input energy would be 1,100W.

In this example: "Check out this out impressive speed for a mere 21w (this is output energy, input energy would be 210W)

A challenge you could do is: 1S 3.7v nominal charged to 4.2v

Loaded volts 3.85v x 5.45A / 21w"

This is input energy, apples and oranges.

By no way am I taking anything away from the impressive speeds your getting with tiny motors, excellent work!

1 HP equals 745.7w

1hp = work being done over time

the 746W is the electrical equivalent.

These numbers states nothing about system efficiency, only output power (work) being done,

I am going to take a wide guess, a 2 stroke nitro motor is 10% efficient. That roughly means it takes 7,460W of fuel energy (input) to produce 746W of output energy.

The best brushless motors are upto 90% efficient (maybe not hobby motors), but lets go with 50%. I am sure you see where I am going with this.

In your example you mentioned 0.147 hp - 110w, in this example, input energy would be 1,100W.

In this example: "Check out this out impressive speed for a mere 21w (this is output energy, input energy would be 210W)

A challenge you could do is: 1S 3.7v nominal charged to 4.2v

Loaded volts 3.85v x 5.45A / 21w"

This is input energy, apples and oranges.

By no way am I taking anything away from the impressive speeds your getting with tiny motors, excellent work!

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Thank you Oz,

As a test you could set up a brushless motor to produce same static rpm of a given prop and IC engine.

Using a amp meter find out how much amp draw and voltage was needed to do the same work providing the

motor size is equal in weight or near too. Fuel tank weight vs Battery weight to estimate a 2 stroke

power equivalent. I have many engines / props bench tested on youtube to choose from. The goal would be

equal system weight: ESC / Motor / Battery vs Fuel / Tank / Engine and Throttle Servo for the RC carb.

Without a dyno the calc program keeps it's constancy with all my tests so I am able to see improvements and

comparisons. I will always state the results as my threads are for data storage and online sharing. The only facts

are in the build components physical measurements and the vids showing what the outcome of the total effort can do.

I would like to build a TD .15 plane next I need a manifold header yet to sort out the power and pipe length to fit with

a plane design. I have a small gps unit that will fit in a .15 size speed plane. Looking forward to taking ground speed

measurements with it and comparing to the software results.

I have wound 3 phase motors wye and delta terminations with 9 and 12 pole motors.

Back then 76 to 83% was about as good as it gets providing you don't over prop and the room

temps are cool. Some Go Brushless kits one, two stator and 3 stators / cd rom frames. Would be nice

to see more folks striving for small IC speed their approaches to the problems and displacements would be

entertaining and interesting.

E planes have more torque on the nose and can make anything fly fast. Prop blast from the IC engine

helps to keep the engine cool as I push the rpm up 30% more than what most folks fly at. Fiberglass

or carbon cowling could be used but typically increases the size of the frontal area in order to fasten

them, refueling and cleaning in the field would be a pain, as these belly lander's slide through patches

of dirt and rock. The summer heat is brutal on the grass by Sept. it's all burnt and brown thinned out

with exposed dirt so dry it shrinks up with open cracks some as wide as 2" The simple TD engine with

no bearings is not going to fare well covered up the heat will increase requiring a richer NV setting

loosing rpm and run time. The world needs a CNC crank case with bearings for the TD!

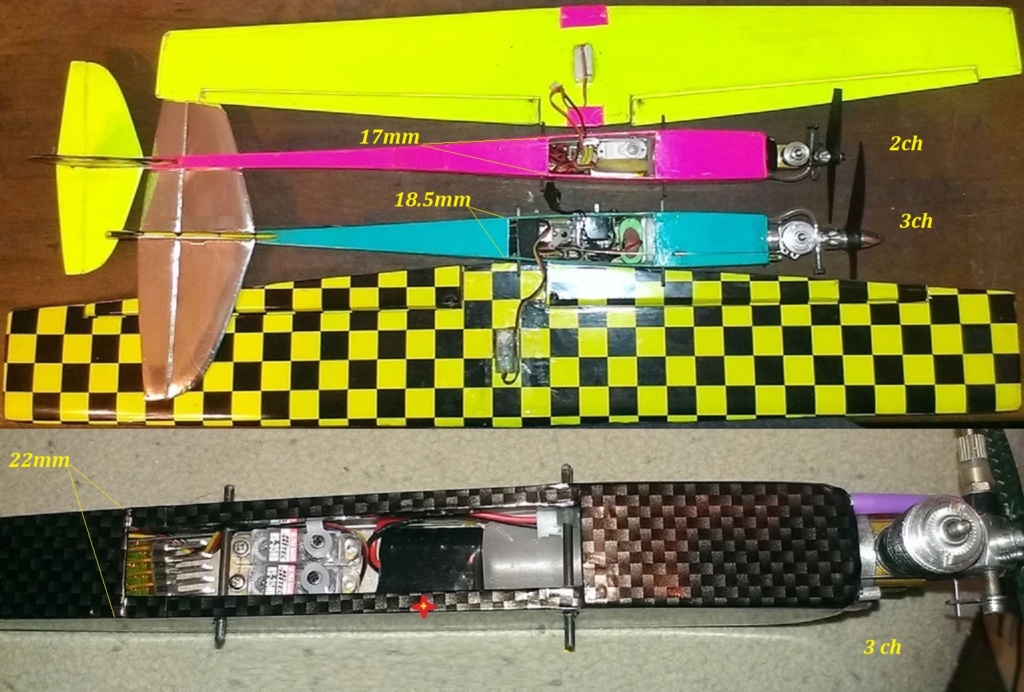

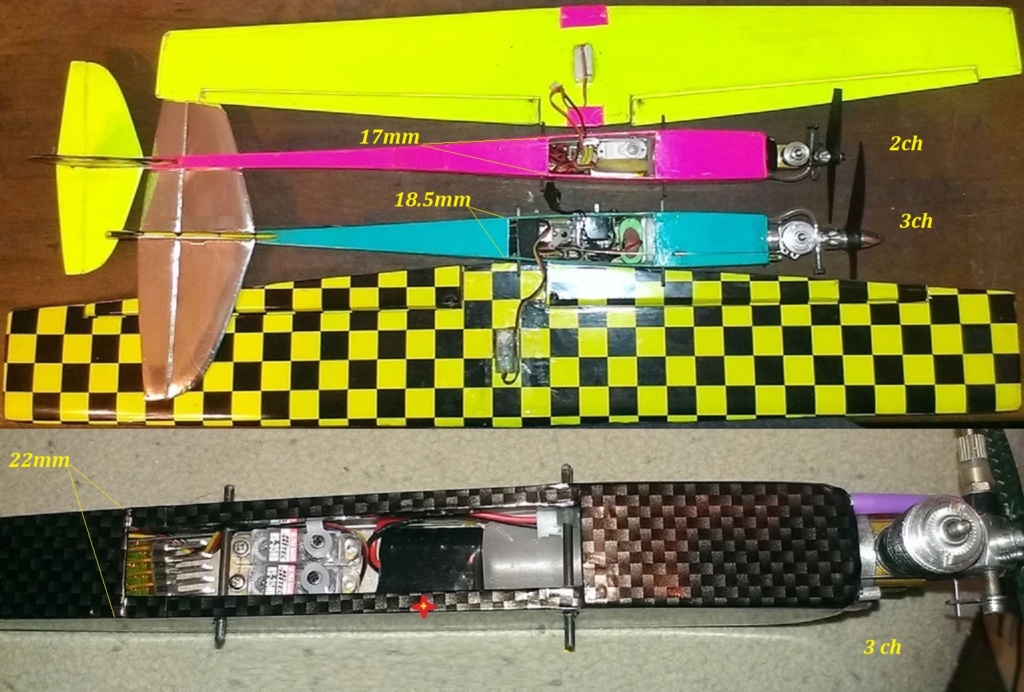

The elevator linkage is through the tail with the Nano II, Nano IV and Nano III and Nano X.

There is no room inside the fuselage for torque rods, these are very small planes the wings are held by rubber bands

to avoid wood and hardware damage on rough landings. If you crashed with torque rods sticking inside the fuselage

and the wing pops off there would be no clearance for separation. May rip up the gear, side of the fuselage, wing where

the rods would be inset into the wing. Note the width of the fuselage for size reference.

17mm / 18.5mm and 22 mm wide as shown in the photo, the Nano X is 26mm wide at the same referenced location.

Did you watch the 3rd test flight Greg?

I can handle about another 15% increase in speed, as is blinking is limited to

keep up with it as a 25" span. The field is plenty big but the plane is a dot in

seconds if not careful and orientation is fuzzy when turning it around if I let

it get out too far.

As a test you could set up a brushless motor to produce same static rpm of a given prop and IC engine.

Using a amp meter find out how much amp draw and voltage was needed to do the same work providing the

motor size is equal in weight or near too. Fuel tank weight vs Battery weight to estimate a 2 stroke

power equivalent. I have many engines / props bench tested on youtube to choose from. The goal would be

equal system weight: ESC / Motor / Battery vs Fuel / Tank / Engine and Throttle Servo for the RC carb.

Without a dyno the calc program keeps it's constancy with all my tests so I am able to see improvements and

comparisons. I will always state the results as my threads are for data storage and online sharing. The only facts

are in the build components physical measurements and the vids showing what the outcome of the total effort can do.

I would like to build a TD .15 plane next I need a manifold header yet to sort out the power and pipe length to fit with

a plane design. I have a small gps unit that will fit in a .15 size speed plane. Looking forward to taking ground speed

measurements with it and comparing to the software results.

I have wound 3 phase motors wye and delta terminations with 9 and 12 pole motors.

Back then 76 to 83% was about as good as it gets providing you don't over prop and the room

temps are cool. Some Go Brushless kits one, two stator and 3 stators / cd rom frames. Would be nice

to see more folks striving for small IC speed their approaches to the problems and displacements would be

entertaining and interesting.

E planes have more torque on the nose and can make anything fly fast. Prop blast from the IC engine

helps to keep the engine cool as I push the rpm up 30% more than what most folks fly at. Fiberglass

or carbon cowling could be used but typically increases the size of the frontal area in order to fasten

them, refueling and cleaning in the field would be a pain, as these belly lander's slide through patches

of dirt and rock. The summer heat is brutal on the grass by Sept. it's all burnt and brown thinned out

with exposed dirt so dry it shrinks up with open cracks some as wide as 2" The simple TD engine with

no bearings is not going to fare well covered up the heat will increase requiring a richer NV setting

loosing rpm and run time. The world needs a CNC crank case with bearings for the TD!

The elevator linkage is through the tail with the Nano II, Nano IV and Nano III and Nano X.

There is no room inside the fuselage for torque rods, these are very small planes the wings are held by rubber bands

to avoid wood and hardware damage on rough landings. If you crashed with torque rods sticking inside the fuselage

and the wing pops off there would be no clearance for separation. May rip up the gear, side of the fuselage, wing where

the rods would be inset into the wing. Note the width of the fuselage for size reference.

17mm / 18.5mm and 22 mm wide as shown in the photo, the Nano X is 26mm wide at the same referenced location.

Did you watch the 3rd test flight Greg?

I can handle about another 15% increase in speed, as is blinking is limited to

keep up with it as a 25" span. The field is plenty big but the plane is a dot in

seconds if not careful and orientation is fuzzy when turning it around if I let

it get out too far.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Here is a guy testing BLDC quad motors. Lots of good data (voltage/current/thrust/rpm/etc).

https://www.miniquadtestbench.com/motors/

https://www.miniquadtestbench.com/motors/

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

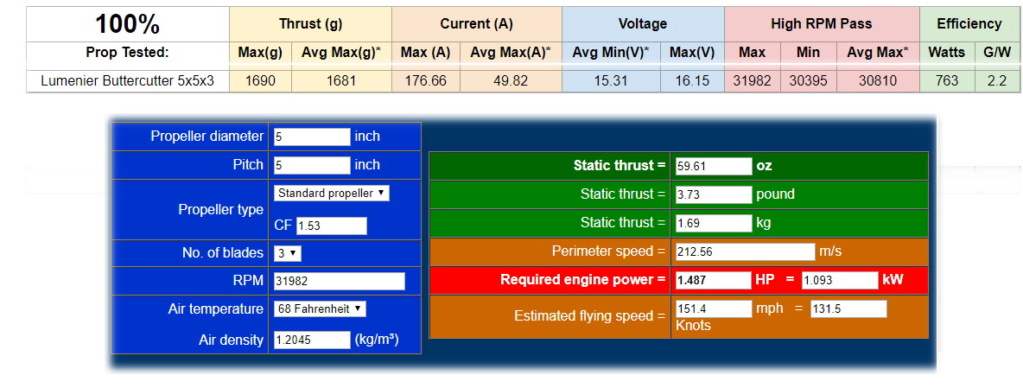

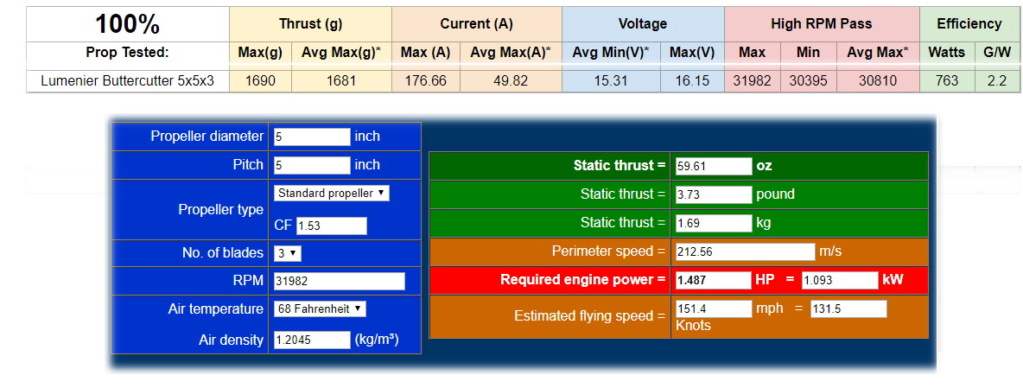

I took a common BLDC quad motor and punched in the data and hit calculate, but the thrust is only ~1Kg, should be 1.6Kg. Of course the prop that is used is not in the list (5050x3). So I adjusted the CF to get the thrust to read correctly, this is probably the mistake

31,982rpm, 15.3V, 49.8A, 763W (input)

In the output, it shows 1.093KW, i am screwing up somewhere, lol.

31,982rpm, 15.3V, 49.8A, 763W (input)

In the output, it shows 1.093KW, i am screwing up somewhere, lol.

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Yes he uses mainly 3 blade props I gave up after checking 14 write ups all with 3 blades.

I use E props and flown some stock but quickly start to modifying them to suit the engine.

I do have solid data / vid on stock HQ Drone props the carbon blend 4x4.5 and 5x4.5 two blade props.

Have you used them?

I use E props and flown some stock but quickly start to modifying them to suit the engine.

I do have solid data / vid on stock HQ Drone props the carbon blend 4x4.5 and 5x4.5 two blade props.

Have you used them?

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

1/2A Nut wrote:Yes he uses mainly 3 blade props I gave up after checking 14 write ups all with 3 blades.

I use E props and flown some stock but quickly start to modifying them to suit the engine.

I do have solid data / vid on stock HQ Drone props the carbon blend 4x4.5 and 5x4.5 two blade props.

Have you used them?

My quad is 231mm motor to motor (diag) and is designed for 6" props, but the community found out 5" tri-blades have many benefits, they can change rpm faster, this makes reaction time quicker and better stability in the worst conditions (such as flying backwards through your own dirty prop wash in a trick or u-tun), also they generally dont need balancing even after being bent (and bent back) in a crash, this is a huge time saver. E.G. a bi-blade prop, once it gets bent, it is way out of balance, with tri-blade, barely.

When i run any 5" prop under 5 pitch, they are just slow on my 2400kv motors (top end, acceleration and grip in the corners), seems guys running 2600-2700kv tend to use under 5 pitch.

I have tried HQ props, they are good in the air, but really suck in the durability department, cost and visual orientation aid. I usually fly 12-18 battery packs back-to-back in the morning before work, its a pain to change props when your time pressed and the cost, just not worth it for me when I fly a 37 cent prop that performs in the air as good, takes a beating and much lower cost and the colors really help seeing the quad. I fly the KK5050x3 (kingkong)

OT: I seen a quad do 165mph (267kph) on YT.

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Here is some serious G's (sorry its electric) at 186mph

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

That's nothing

Take a 12x24" prop and spin it up to around 27000rpm, that's good for about 280Mph:

Take a 12x24" prop and spin it up to around 27000rpm, that's good for about 280Mph:

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Page 26 of 30 •  1 ... 14 ... 25, 26, 27, 28, 29, 30

1 ... 14 ... 25, 26, 27, 28, 29, 30

Similar topics

Similar topics» CG on Speed Contest Planes

» Anyone here into Giant Scale R/C Planes? Post Pics of your Planes.

» Fellow speed freaks, help me build a pair of speed Bees.

» CL planes...

» How many cox planes do you have?

» Anyone here into Giant Scale R/C Planes? Post Pics of your Planes.

» Fellow speed freaks, help me build a pair of speed Bees.

» CL planes...

» How many cox planes do you have?

Page 26 of 30

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules