Log in

Search

Latest topics

» Tee Dee .020 combat modelby rsv1cox Today at 9:00 am

» Roger Harris revisited

by rsv1cox Today at 7:35 am

» My latest doodle...

by batjac Yesterday at 10:05 pm

» Retail price mark-up.. how much is enough?

by gkamysz Yesterday at 9:29 pm

» Happy 77th birthday Andrew!

by roddie Yesterday at 9:22 pm

» My N-1R build log

by GallopingGhostler Yesterday at 3:04 pm

» Chocolate chip cookie dough.........

by roddie Yesterday at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Yesterday at 11:32 am

» Free Flight Radio Assist

by rdw777 Yesterday at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Page 12 of 30

Page 12 of 30 •  1 ... 7 ... 11, 12, 13 ... 21 ... 30

1 ... 7 ... 11, 12, 13 ... 21 ... 30

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Yes tried that with the large Skorch the vid was not so great and the sound from the prop wash

irritated the mic. Better readings doing passes right in front of the sports cam. Vibration isolation

mounting would have been the best route to make better vid and a wind shield for the mic.

All the same the sound is excellent with the sports cam I found no advantage. Really only interested

in passes in front of the cam. Perhaps one day there will be a data logger small enough for 1/2A.

irritated the mic. Better readings doing passes right in front of the sports cam. Vibration isolation

mounting would have been the best route to make better vid and a wind shield for the mic.

All the same the sound is excellent with the sports cam I found no advantage. Really only interested

in passes in front of the cam. Perhaps one day there will be a data logger small enough for 1/2A.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Previous stats: Fuji .05 / Profi .8cc Tuned Pipe

Static: HQ Prop 4x4.5 / Idle 9.3k rpm / 28,746 rpm / 122.4 mph

9.6oz thrust / .198hp / 147.71w

Sportswerk engine for the Nano it is not the original Fuji that was on the Dart.

The engines appear to be the same so I expect similar results. I did

notice less compression with the Sportwerks using the OS gold plug.

As soon as the engine fired up my ears said stop, it is loud the all metal

header with no dampening no aluminum reducer like before has made this

thing a noisy beast. I had to test fast due to noise the NV is not peaked in

the vid the low load 4x4.5 carbon prop can get away with a richer setting

and still scream. Good oil % is a safe bet for now.

AmpAbuser

Published on Feb 16, 2018

Sportswerks .05 / HQ Carbon mix 4x4.5 / 26,586 rpm static

8.15oz thrust / 113.3 mph / 116w NV set rich by 1/2 turn.

I leaned it till it hit peak then backed off to get the oil % up.

Will field tweak should do 26.9k ish prior to launch for a good

first flight to give this engine some air time.

Bought used from a car nut guy. Motor was pulled from a new car

for an upgraded engine, claimed short time on the engine.

Inspections showed no use to me very clean with oil present.

Sportswerks header pipe nice and clean but again very loud.

It's going to push me to set up the tune pipe soon, way better on

the ears and static boost is very good. Rare I try just a header so

trying to follow through will be a bit less noise outside.

Static: HQ Prop 4x4.5 / Idle 9.3k rpm / 28,746 rpm / 122.4 mph

9.6oz thrust / .198hp / 147.71w

Sportswerk engine for the Nano it is not the original Fuji that was on the Dart.

The engines appear to be the same so I expect similar results. I did

notice less compression with the Sportwerks using the OS gold plug.

As soon as the engine fired up my ears said stop, it is loud the all metal

header with no dampening no aluminum reducer like before has made this

thing a noisy beast. I had to test fast due to noise the NV is not peaked in

the vid the low load 4x4.5 carbon prop can get away with a richer setting

and still scream. Good oil % is a safe bet for now.

AmpAbuser

Published on Feb 16, 2018

Sportswerks .05 / HQ Carbon mix 4x4.5 / 26,586 rpm static

8.15oz thrust / 113.3 mph / 116w NV set rich by 1/2 turn.

I leaned it till it hit peak then backed off to get the oil % up.

Will field tweak should do 26.9k ish prior to launch for a good

first flight to give this engine some air time.

Bought used from a car nut guy. Motor was pulled from a new car

for an upgraded engine, claimed short time on the engine.

Inspections showed no use to me very clean with oil present.

Sportswerks header pipe nice and clean but again very loud.

It's going to push me to set up the tune pipe soon, way better on

the ears and static boost is very good. Rare I try just a header so

trying to follow through will be a bit less noise outside.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

It’s a shame to hear about the back plates  no worries though I’ll just make my own in the meantime.

no worries though I’ll just make my own in the meantime.

Would you be able to measure the diameter and depth of the part that slips into the crankcase and the oring?

Or better yet include a photo I’m sure I can figure the rest out.

The tracking for my .020 conversion shows it’s in New Zealand so hopefully it will be here Monday/Sunday

What do you think about a single blade 1.5x5.2? I will probably mould it from carbon and machine a brass counterbalance, I also may extend the tip in the mould to make it a 1.7x5.2

no worries though I’ll just make my own in the meantime.

no worries though I’ll just make my own in the meantime.Would you be able to measure the diameter and depth of the part that slips into the crankcase and the oring?

Or better yet include a photo I’m sure I can figure the rest out.

The tracking for my .020 conversion shows it’s in New Zealand so hopefully it will be here Monday/Sunday

What do you think about a single blade 1.5x5.2? I will probably mould it from carbon and machine a brass counterbalance, I also may extend the tip in the mould to make it a 1.7x5.2

Littlebuzz_97- Moderate Poster

- Posts : 25

Join date : 2017-07-21

Age : 27

Location : Gore

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

I would not worry about the backplates yet they may very well show up.

Lets see what will happen to them, was told a run of them was made will

see where they end up being sold from.

A single blade is tricky I noticed the 3 blade ran very smooth do to even disk load of

the three blades. It certainly is possible providing you can balance the prop to keep

the wear on the aluminum crank case to a minimum. But there is another huge factor

that can not be addressed the single load of the prop in operation will naturally pull

on the blade side as it lifts. Without bearings you can't control the adverse wear on

crank case. A 2 blade prop at least has counter acting lift from the opposing blade.

Yes typically you can up the dia. or pitch with 1 blade there is some natural reduction

in load. If you do try it monitor the wear / wobble in crank to case fit. Perhaps up the

castor content to 22% to compensate some. 2x5.2 if you make it can always trim

down to 1.7 if need be.

Any new vids would like a peek if so..

I set up the tuned pipe on the Nano III the NV was turned in to sync the pipe no tweaking.

Static: 28,262 rpm / (26.586 with no pipe) a good jump up +1,676 rpm.

9.3oz thrust / 140w / 120.4 mph prop speed.

Lets see what will happen to them, was told a run of them was made will

see where they end up being sold from.

A single blade is tricky I noticed the 3 blade ran very smooth do to even disk load of

the three blades. It certainly is possible providing you can balance the prop to keep

the wear on the aluminum crank case to a minimum. But there is another huge factor

that can not be addressed the single load of the prop in operation will naturally pull

on the blade side as it lifts. Without bearings you can't control the adverse wear on

crank case. A 2 blade prop at least has counter acting lift from the opposing blade.

Yes typically you can up the dia. or pitch with 1 blade there is some natural reduction

in load. If you do try it monitor the wear / wobble in crank to case fit. Perhaps up the

castor content to 22% to compensate some. 2x5.2 if you make it can always trim

down to 1.7 if need be.

Any new vids would like a peek if so..

I set up the tuned pipe on the Nano III the NV was turned in to sync the pipe no tweaking.

Static: 28,262 rpm / (26.586 with no pipe) a good jump up +1,676 rpm.

9.3oz thrust / 140w / 120.4 mph prop speed.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Update from the machinist!

"Well this project is finally over. I'll be setting up the lathe to run the

rest of the backplates Monday and if things go well should be able to go

public Monday night or Tuesday."

"Well this project is finally over. I'll be setting up the lathe to run the

rest of the backplates Monday and if things go well should be able to go

public Monday night or Tuesday."

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Cooooooooooooollllllll

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Yes! Excited for those backplates! Just picked up an aluminium tank mount for the TD .020, and now this! My spares inventory is getting heavy.

rhyslegge- Bronze Member

- Posts : 31

Join date : 2017-11-05

Age : 44

Location : Lake Ariel, PA

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Woooo yeah!!!

Littlebuzz_97- Moderate Poster

- Posts : 25

Join date : 2017-07-21

Age : 27

Location : Gore

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

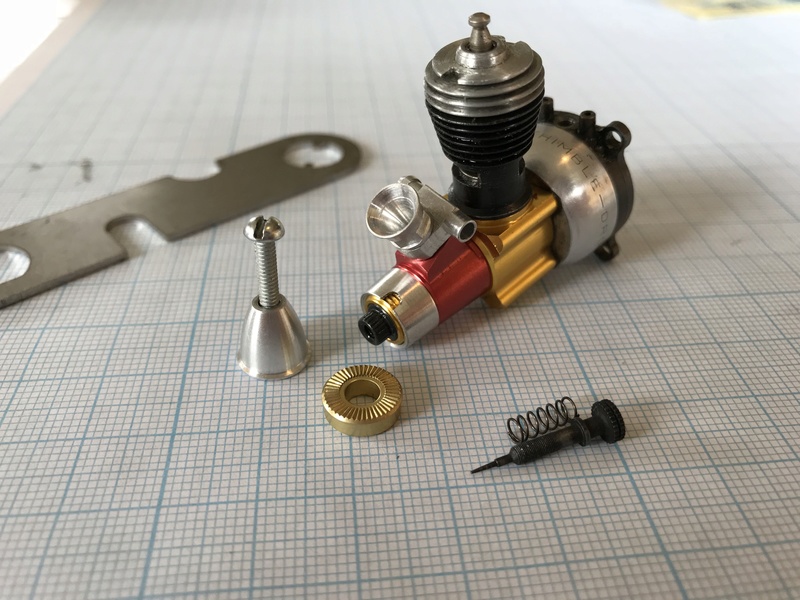

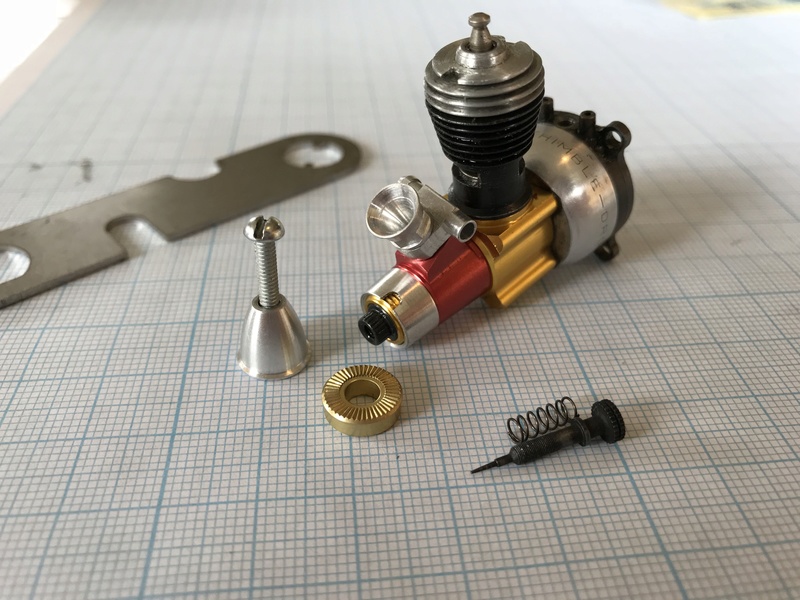

Well.. my goodies showed up this morning, every thing is so so tiny!!

So far I’ve assembled most of it, I have a pee wee back plate on there so I don’t get dust in the case for the time being.

I have a few problems though, the thrust plate doesn’t have any splines to engage with the crank?

So do I just press fit this by winding the screw down with a prop on?

It’s super tight.

Also the Venturi body where the needle screws in looks like they’ve tried to recess the first 1/16 of the thread to make it easier to start the thread except it’s gone the full depth and the needle pushes all the way to the bottom

The only thing I can think of would be to crimp around the neck and hopefully cut the thread onto the NV, and a slice of fuel tube to seal any leaks?

Anyway not sure if this will work, I may just end up getting a genuine cox one.

So far I’ve assembled most of it, I have a pee wee back plate on there so I don’t get dust in the case for the time being.

I have a few problems though, the thrust plate doesn’t have any splines to engage with the crank?

So do I just press fit this by winding the screw down with a prop on?

It’s super tight.

Also the Venturi body where the needle screws in looks like they’ve tried to recess the first 1/16 of the thread to make it easier to start the thread except it’s gone the full depth and the needle pushes all the way to the bottom

The only thing I can think of would be to crimp around the neck and hopefully cut the thread onto the NV, and a slice of fuel tube to seal any leaks?

Anyway not sure if this will work, I may just end up getting a genuine cox one.

Littlebuzz_97- Moderate Poster

- Posts : 25

Join date : 2017-07-21

Age : 27

Location : Gore

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Yay congratulations its a Wee Lil TD .020!

Yes this parts are small but the engine is mighty with it's front

induction system pumping in air and fuel at a much better rate

than the Pee Wee can.

No do not use the prop screw to set the prop plate.

If the bolt snaps your screwed.

Set prop plate down on flat surface

Take the fuel tank off to expose the back end of the crank.

Line up the crank and place a steel 3mm rod thru the back end of the crank

and with a hammer tap tap tap till the splines migrate thru the thrust plate.

The thrust plate is aluminum the splines will create the grooves easy enough

but you need to tap tap lightly insure it stays straight as it goes down may

have to angle the prop plate and tap the steel rod lightly until it's straight again.

Once seated rotate and check if it is flush. There should be a slight gap between

the thrust plate and front carb collar once completed .

Don't cut and crimp anything. Yes on fuel tubing no on the spring make sure the

tube goes over the NV body as show and over the NV as shown. Steel rod I use

to set thrust plates.

The type aluminum carb body you have has a slight issue you will need to fix.

When the venturi screws down the NV body the body does not sit flush to the carb

body they can leak air there making fuel draw less consistent. What I did with the

one that Matt sold me was carefully file a flat spot about 1mm wide ring around the

intake hole of the carb body. Now this is best to do with the front collar removed

and the carb body removed from the assembly. Any aluminum partials from the file

work can be cleaned out easy. Oil the inside of the carb body and its threads before

assembling to help seat and seal. Oil the collar threads the TD tool has a special

function for the collar be careful not to mare the square slot for the tool to fit in.

Oil all thread. NV, Glow plug, prop bolt, rear bolts anything with threads to help

seal and help when taking it apart. Make sure the collar tool is flush well seated

before turning tight or untightening. It barely catches the into the square cut out

of the collar as is and will rip as it break free screwing up that cutout.

You need a TD starter spring, I will show you how to use them with aluminum carb bodies.

http://www.exmodelengines.com/product.php?productid=18274&cat=249&page=1

Should have never been a curved surface do not attempt to get completely flat with a file you will screw it up

any offset will cause a leak just a small introduction of flat area will help the NV body seal to it. You can make

a thin gasket washer for this if you do not want to file.

I have bought 1 assembled version from Matt, I'm surprised your's was not assembled.

When I tighten down the soft metal bolts I found them shifting causing notable wobble and

the spinner too robs top rpm. the solution is a quality hard bolt that will not flex when torqued

down. Less chance of a prop flying off loosing the spinner assembly in the grass. Major power

robbing issue if not addressed. I hate spinner wobble wears out the crank case over time.

Yes this parts are small but the engine is mighty with it's front

induction system pumping in air and fuel at a much better rate

than the Pee Wee can.

No do not use the prop screw to set the prop plate.

If the bolt snaps your screwed.

Set prop plate down on flat surface

Take the fuel tank off to expose the back end of the crank.

Line up the crank and place a steel 3mm rod thru the back end of the crank

and with a hammer tap tap tap till the splines migrate thru the thrust plate.

The thrust plate is aluminum the splines will create the grooves easy enough

but you need to tap tap lightly insure it stays straight as it goes down may

have to angle the prop plate and tap the steel rod lightly until it's straight again.

Once seated rotate and check if it is flush. There should be a slight gap between

the thrust plate and front carb collar once completed .

Don't cut and crimp anything. Yes on fuel tubing no on the spring make sure the

tube goes over the NV body as show and over the NV as shown. Steel rod I use

to set thrust plates.

The type aluminum carb body you have has a slight issue you will need to fix.

When the venturi screws down the NV body the body does not sit flush to the carb

body they can leak air there making fuel draw less consistent. What I did with the

one that Matt sold me was carefully file a flat spot about 1mm wide ring around the

intake hole of the carb body. Now this is best to do with the front collar removed

and the carb body removed from the assembly. Any aluminum partials from the file

work can be cleaned out easy. Oil the inside of the carb body and its threads before

assembling to help seat and seal. Oil the collar threads the TD tool has a special

function for the collar be careful not to mare the square slot for the tool to fit in.

Oil all thread. NV, Glow plug, prop bolt, rear bolts anything with threads to help

seal and help when taking it apart. Make sure the collar tool is flush well seated

before turning tight or untightening. It barely catches the into the square cut out

of the collar as is and will rip as it break free screwing up that cutout.

You need a TD starter spring, I will show you how to use them with aluminum carb bodies.

http://www.exmodelengines.com/product.php?productid=18274&cat=249&page=1

Should have never been a curved surface do not attempt to get completely flat with a file you will screw it up

any offset will cause a leak just a small introduction of flat area will help the NV body seal to it. You can make

a thin gasket washer for this if you do not want to file.

I have bought 1 assembled version from Matt, I'm surprised your's was not assembled.

When I tighten down the soft metal bolts I found them shifting causing notable wobble and

the spinner too robs top rpm. the solution is a quality hard bolt that will not flex when torqued

down. Less chance of a prop flying off loosing the spinner assembly in the grass. Major power

robbing issue if not addressed. I hate spinner wobble wears out the crank case over time.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

I tested the NANO III today with some trouble with the clunk first toss nosed dived the

plane with a good smack breaking the prop. What I didn't know at that time was the

clunk flipped forward in the tank. I had added down thrust and right thrust with the

car engine anticipating the need as speed was going to go up quite a bit. These offsets

help from using the control surfaces to compensate which scrubs speed. With that said

I dialed in some up trim for the second flight this time it launched but rough wanted to dip

and pull to the right, the old settings with the Cox engine would not do so the struggle

to correct had me flying a tiger by it's tail. The engine was throttled down but the unloading

of the prop was causing the engine to pop on and off the tuned pipe. Quite a handful till

I had the trims set then I punched the throttle wide open up high to monitor for aircraft

potential deflection at speed. All was well it went nice and straight a good shot across the big blue

sky it tracking very well at full bore. The clunk being up front cause fuel intake starvation

as the tuned pipe acted like a pump demanding additional air / fuel mix yet all the fuel was

plastered to the back of the tank as the plane accelerated. Quite a sight to see like a turbo

charged nitro beast it freaking shot off like a rocket burned off it's fuel charge and shut down.

The abrupt stop of the engine had my ears listening to the plane whistling over head till the

speed bleed off. I started the engine back up but noticed it would not run nose up so figured

my fuel tank was to blame I thought the clunk line came loose was surprised to see if flipped

forward. So took it home to work on and called it a day as the tank is glued into place. All

fixed now, will try again next weekend. Least I was able to find out the unloaded speed potential

of the smaller Nano vs the Dart, once fully tweaked I expect to get more rpm doing passes in front

of the camera the NV was left rich as the engine has hardly any run time but also to handle the

huge fuel demand when on the pipe.

Static at launch 27,816 rpm / 119 mph prop speed

Unloaded 37,710 rpm / 161 mph prop speed (PS)

+960 rpm increase do to less drag and weight, this will also

improve the doppler reading to be closer in sync with prop calc.

Warm partly sunny 78F with the heat index. 5 to 8 mph winds.

Perfect day thwarted by a fuel tank clunk!

DART - Fuji .05 / 148 mph doppler / 156 (PS) / 4x4.5 / 36.75K

NANO- Sportswerks .05 / doppler? / 161 (PS) / 4x4.5 / 37.71K

A 4x5 will be tried after I lay down some good 4x4.5 passes in front of the camera expect about 155 per doppler.

The 4x5 should bust 160+

The rains and warm weather have the bugs out playing in the sky:

At 2 mins 10 seconds into the vid I see the plane is finally in good trim and set up to bang the throttle wide open.

The glide is still good with the extra 1.15oz of weight of the new engine pipe combo 10.15oz RTF

1440p HD

plane with a good smack breaking the prop. What I didn't know at that time was the

clunk flipped forward in the tank. I had added down thrust and right thrust with the

car engine anticipating the need as speed was going to go up quite a bit. These offsets

help from using the control surfaces to compensate which scrubs speed. With that said

I dialed in some up trim for the second flight this time it launched but rough wanted to dip

and pull to the right, the old settings with the Cox engine would not do so the struggle

to correct had me flying a tiger by it's tail. The engine was throttled down but the unloading

of the prop was causing the engine to pop on and off the tuned pipe. Quite a handful till

I had the trims set then I punched the throttle wide open up high to monitor for aircraft

potential deflection at speed. All was well it went nice and straight a good shot across the big blue

sky it tracking very well at full bore. The clunk being up front cause fuel intake starvation

as the tuned pipe acted like a pump demanding additional air / fuel mix yet all the fuel was

plastered to the back of the tank as the plane accelerated. Quite a sight to see like a turbo

charged nitro beast it freaking shot off like a rocket burned off it's fuel charge and shut down.

The abrupt stop of the engine had my ears listening to the plane whistling over head till the

speed bleed off. I started the engine back up but noticed it would not run nose up so figured

my fuel tank was to blame I thought the clunk line came loose was surprised to see if flipped

forward. So took it home to work on and called it a day as the tank is glued into place. All

fixed now, will try again next weekend. Least I was able to find out the unloaded speed potential

of the smaller Nano vs the Dart, once fully tweaked I expect to get more rpm doing passes in front

of the camera the NV was left rich as the engine has hardly any run time but also to handle the

huge fuel demand when on the pipe.

Static at launch 27,816 rpm / 119 mph prop speed

Unloaded 37,710 rpm / 161 mph prop speed (PS)

+960 rpm increase do to less drag and weight, this will also

improve the doppler reading to be closer in sync with prop calc.

Warm partly sunny 78F with the heat index. 5 to 8 mph winds.

Perfect day thwarted by a fuel tank clunk!

DART - Fuji .05 / 148 mph doppler / 156 (PS) / 4x4.5 / 36.75K

NANO- Sportswerks .05 / doppler? / 161 (PS) / 4x4.5 / 37.71K

A 4x5 will be tried after I lay down some good 4x4.5 passes in front of the camera expect about 155 per doppler.

The 4x5 should bust 160+

The rains and warm weather have the bugs out playing in the sky:

At 2 mins 10 seconds into the vid I see the plane is finally in good trim and set up to bang the throttle wide open.

The glide is still good with the extra 1.15oz of weight of the new engine pipe combo 10.15oz RTF

1440p HD

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Wow that’s some serious rpm!

Unloading an extra 10k seems like a lot

Some of those bugs look bigger than the nano lol

I’ve seen you build a header for the tee dee .049 do you think it’s possible for the .020?

I suppose the best way to make a pipe would be a wax plug on a lathe then wind on carbon tow with some high heat resin.

Also have you tried enlarging the Venturi what affect would this have?

And what about bladder tanks for the .020?

Just as well I waited for your reply, getting the drive plate on with the crank inside the case had me stumped.

I think I’ll send the carb body and NV assembly back and re order some oem parts, Coxengines looks to have the carb body already milled flat on to to accept the Venturi assembly.

I also brought a rod resetting tool as I noticed a tiny bit of play on one of my pistons.

I’ll keep that spinner for one of my pee wees I’ll probably build a vintage free flight for

.

Unloading an extra 10k seems like a lot

Some of those bugs look bigger than the nano lol

I’ve seen you build a header for the tee dee .049 do you think it’s possible for the .020?

I suppose the best way to make a pipe would be a wax plug on a lathe then wind on carbon tow with some high heat resin.

Also have you tried enlarging the Venturi what affect would this have?

And what about bladder tanks for the .020?

Just as well I waited for your reply, getting the drive plate on with the crank inside the case had me stumped.

I think I’ll send the carb body and NV assembly back and re order some oem parts, Coxengines looks to have the carb body already milled flat on to to accept the Venturi assembly.

I also brought a rod resetting tool as I noticed a tiny bit of play on one of my pistons.

I’ll keep that spinner for one of my pee wees I’ll probably build a vintage free flight for

.

Littlebuzz_97- Moderate Poster

- Posts : 25

Join date : 2017-07-21

Age : 27

Location : Gore

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

1/2A Nut wrote:...

When I tighten down the soft metal bolts I found them shifting causing notable wobble and

the spinner too robs top rpm. the solution is a quality hard bolt that will not flex when torqued

down. Less chance of a prop flying off loosing the spinner assembly in the grass. Major power

robbing issue if not addressed. I hate spinner wobble wears out the crank case over time.

For the same reason I replaced the TD020 stock prop screw with the 049 engine mount socket head screw sold by COX Int'l, and it was really worth it:

https://coxengines.ca/cox-049-engine-mounting-3-48-x-1-2-socket-head-screws-3-4.html

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

That's what i would do littlebuzz , dont like problem with new stuff !! Thanks for the info on the prop plate i have one coming from Cox and some other stuff to get some up and running , The Nano III was wanting to move out can't wait to see it up to par screaming (( That engine has what i call a rattle to it (loud)  I hate bugs in the summer and its coming !!

I hate bugs in the summer and its coming !!

I hate bugs in the summer and its coming !!

I hate bugs in the summer and its coming !!

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Yes loud and fast with just a taste at the end of the vid a quick shot across the sky

was enough data to calc out the possibilities with the next flights. The bugs are having

a party no doubt in Texas we are getting into the rainy stormy time of the year, grass

is growing and the bug count is picking up and thriving. The car engines on pipes can

really turn up and let loose in the air.

I would not bore out the venturi too much fuel draw issues, steady runs etc. If you have

a spare one opening it up a 10% and bench testing vs stock. Should be a safe bet for

a bit more rpm and even more in the air. Smooth and polished intake after drilling it out

a hair bit will help speed up influx. Pressure works till the pressure is down and

then you have a section of the run time at the end that won't be as stellar. A good latex

tube will keep the flow going 90% of the run. I would learn the TD .020 in stock form

first less trouble more flying.

Tune pipes have been made using carbon sock, wax form and high temp epoxy.

Scroll through the conversation / pics / data / articles.

https://www.rcgroups.com/forums/showthread.php?2684743-1-2A-Speed-010-to-15-Size/page5#post36993976

https://www.rcgroups.com/forums/showthread.php?2684743-1-2A-Speed-010-to-15-Size/page3#post35409217

https://www.rcgroups.com/forums/showthread.php?2684743-1-2A-Speed-010-to-15-Size/page9#post37321755

Here is the only engine I have with the arched top on the carb body a careful effort with

the flat file as previously described only a small area need be flat, was enough to get 118 mph

prop speed with the engine. You should be brave and just fix it save some time, everything you

have will work fine. If you keep using Cox engines times like these tend to happen.

I have some of the carbon sock material in rolls can stretch it over a form here is a rendering for the TD .020

was enough data to calc out the possibilities with the next flights. The bugs are having

a party no doubt in Texas we are getting into the rainy stormy time of the year, grass

is growing and the bug count is picking up and thriving. The car engines on pipes can

really turn up and let loose in the air.

I would not bore out the venturi too much fuel draw issues, steady runs etc. If you have

a spare one opening it up a 10% and bench testing vs stock. Should be a safe bet for

a bit more rpm and even more in the air. Smooth and polished intake after drilling it out

a hair bit will help speed up influx. Pressure works till the pressure is down and

then you have a section of the run time at the end that won't be as stellar. A good latex

tube will keep the flow going 90% of the run. I would learn the TD .020 in stock form

first less trouble more flying.

Tune pipes have been made using carbon sock, wax form and high temp epoxy.

Scroll through the conversation / pics / data / articles.

https://www.rcgroups.com/forums/showthread.php?2684743-1-2A-Speed-010-to-15-Size/page5#post36993976

https://www.rcgroups.com/forums/showthread.php?2684743-1-2A-Speed-010-to-15-Size/page3#post35409217

https://www.rcgroups.com/forums/showthread.php?2684743-1-2A-Speed-010-to-15-Size/page9#post37321755

Here is the only engine I have with the arched top on the carb body a careful effort with

the flat file as previously described only a small area need be flat, was enough to get 118 mph

prop speed with the engine. You should be brave and just fix it save some time, everything you

have will work fine. If you keep using Cox engines times like these tend to happen.

I have some of the carbon sock material in rolls can stretch it over a form here is a rendering for the TD .020

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

That was some good reading material there, I’ve saved the articles for later reference.

I’ll make sure I’ve got everything running reliably before I start messing around with big modifications, I’ll try enlarge my spare Venturi and polish it to see how it goes.

I have noticed when you use an exhaust collector you use a piston and cylinder that doesn’t have SPI, all of the .020s do, will that counter the gain of putting a pipe on it?

I had to get a new needle valve body because it was stripped out so I ended up throwing in a new carb body in the same order as well as a piston reset tool.

You’ll have to tell me how to use them too

I’ll make sure I’ve got everything running reliably before I start messing around with big modifications, I’ll try enlarge my spare Venturi and polish it to see how it goes.

I have noticed when you use an exhaust collector you use a piston and cylinder that doesn’t have SPI, all of the .020s do, will that counter the gain of putting a pipe on it?

I had to get a new needle valve body because it was stripped out so I ended up throwing in a new carb body in the same order as well as a piston reset tool.

You’ll have to tell me how to use them too

Littlebuzz_97- Moderate Poster

- Posts : 25

Join date : 2017-07-21

Age : 27

Location : Gore

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

There are many high performance engines that have SPI and use tuned pipes,

my take is mixed on the subject but the bottom line is the engine can function

with the pipe from 140 degs timing and up, the higher the timing the more

gate time you have to shove in more boost of course. The pipe adds enough

benefits to use them. Sound and goo control is a plus. They add to the fun

of it all and look cool on the plane. I have mentioned header pipes for the

.020 and .049 so folks can use mufflers and in my case I want to try a

tuned pipe on the .020. I hope he releases them backplates soon. Turbo

plug adapter for the .020 is another item on the menu, lastly a RC carb

for the .020, a good engine size for park flying with modern micro gear

this displacement has much to offer now. I plane on making another

.020 plane made for the new backplate motor and if all goes the additional

add on's. Yes reset tool is good to have I have one for all the cox engines

less the .15 TD. I plane on making a 21" span NANO IV a 4th generation

design with some new changes made for 3.7g metal gear servos.

my take is mixed on the subject but the bottom line is the engine can function

with the pipe from 140 degs timing and up, the higher the timing the more

gate time you have to shove in more boost of course. The pipe adds enough

benefits to use them. Sound and goo control is a plus. They add to the fun

of it all and look cool on the plane. I have mentioned header pipes for the

.020 and .049 so folks can use mufflers and in my case I want to try a

tuned pipe on the .020. I hope he releases them backplates soon. Turbo

plug adapter for the .020 is another item on the menu, lastly a RC carb

for the .020, a good engine size for park flying with modern micro gear

this displacement has much to offer now. I plane on making another

.020 plane made for the new backplate motor and if all goes the additional

add on's. Yes reset tool is good to have I have one for all the cox engines

less the .15 TD. I plane on making a 21" span NANO IV a 4th generation

design with some new changes made for 3.7g metal gear servos.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

I just bought a hands free radar gun that will wifi (150ft range) to a 20" LED screen shows the

top speed and current speed. Comes with a tripod for the radar gun nice setup.

- Bushnell Speedster III / range of 1,500 feet and an accuracy of +/- 1

- LED Radar Gun Display

- Tripod

- $247 delivered.

https://www.opticsplanet.com/bushnell-speedscreen-radar-speed-display-101922-wireless-radar-gun-screen-w-tripod-ca.html?_iv_code=BU-GA-101922-KIT1&image=a33fe854e7

Free shipping bundle deal you save some cash. I will buy a shoulder strap bag to haul the

setup out to the flying spot at my field, leaves me free to carry the plane and field box.

The radar is good for up to 200 mph with IC engines. I wanted the screen so I could glance down

at the latest speed pass. I have been eyeballing this for a while the price has gone down after

a couple of years on the market. It will hold the last reading till it picks up a new reading so

each pass can be evaluated as I glance at the screen while filming. After landing I can do a final

check of the fastest pass per the smaller display in the bottom right corner. Easy enough and

no more calculating mph. Will still want to know the rpm. This will be good for my outrigger hydro's

too big plus to have real time data flowing in for swapping / testing props.

top speed and current speed. Comes with a tripod for the radar gun nice setup.

- Bushnell Speedster III / range of 1,500 feet and an accuracy of +/- 1

- LED Radar Gun Display

- Tripod

- $247 delivered.

https://www.opticsplanet.com/bushnell-speedscreen-radar-speed-display-101922-wireless-radar-gun-screen-w-tripod-ca.html?_iv_code=BU-GA-101922-KIT1&image=a33fe854e7

Free shipping bundle deal you save some cash. I will buy a shoulder strap bag to haul the

setup out to the flying spot at my field, leaves me free to carry the plane and field box.

The radar is good for up to 200 mph with IC engines. I wanted the screen so I could glance down

at the latest speed pass. I have been eyeballing this for a while the price has gone down after

a couple of years on the market. It will hold the last reading till it picks up a new reading so

each pass can be evaluated as I glance at the screen while filming. After landing I can do a final

check of the fastest pass per the smaller display in the bottom right corner. Easy enough and

no more calculating mph. Will still want to know the rpm. This will be good for my outrigger hydro's

too big plus to have real time data flowing in for swapping / testing props.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

That’s a sweet set up with the radar gun, especially with that massive screen!

One of our members is a cop so I’ll get him to bring one out from work hahaha

Will your next nano design have internal push rods?

I’m also going to design a new fuselage for the tee dee.020, there is too much drag from the engine and fire wall and push rods for my liking, I may do something similar to this with a Cowell for the cylinder

Possibly even a wooden speed pan to give a good solid mount for the engine.

I’ll probably decrease the wing span a little too, it glides too well I thing, just a waste of area

One of our members is a cop so I’ll get him to bring one out from work hahaha

Will your next nano design have internal push rods?

I’m also going to design a new fuselage for the tee dee.020, there is too much drag from the engine and fire wall and push rods for my liking, I may do something similar to this with a Cowell for the cylinder

Possibly even a wooden speed pan to give a good solid mount for the engine.

I’ll probably decrease the wing span a little too, it glides too well I thing, just a waste of area

Littlebuzz_97- Moderate Poster

- Posts : 25

Join date : 2017-07-21

Age : 27

Location : Gore

gkamysz- Gold Member

- Posts : 415

Join date : 2018-02-22

Location : Chicagoland

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Greg,

Welcom to the forum. Thanks for designing and making these back plates for these little gems.

Jason

Welcom to the forum. Thanks for designing and making these back plates for these little gems.

Jason

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

1/2A Nut wrote:I just bought a hands free radar gun that will wifi (150ft range) to a 20" LED screen shows the

top speed and current speed. Comes with a tripod for the radar gun nice setup.

- Bushnell Speedster III / range of 1,500 feet and an accuracy of +/- 1

- LED Radar Gun Display

- Tripod

- $247 delivered.

https://www.opticsplanet.com/bushnell-speedscreen-radar-speed-display-101922-wireless-radar-gun-screen-w-tripod-ca.html?_iv_code=BU-GA-101922-KIT1&image=a33fe854e7

Free shipping bundle deal you save some cash. I will buy a shoulder strap bag to haul the

setup out to the flying spot at my field, leaves me free to carry the plane and field box.

The radar is good for up to 200 mph with IC engines. I wanted the screen so I could glance down

at the latest speed pass. I have been eyeballing this for a while the price has gone down after

a couple of years on the market. It will hold the last reading till it picks up a new reading so

each pass can be evaluated as I glance at the screen while filming. After landing I can do a final

check of the fastest pass per the smaller display in the bottom right corner. Easy enough and

no more calculating mph. Will still want to know the rpm. This will be good for my outrigger hydro's

too big plus to have real time data flowing in for swapping / testing props.

Brad, do you think the gun can take the model given its small size?

That is to say, I do not know the capacity of that team, I was wondering if the model is not very small so that the gun can read it ...?! ?!

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

I already own the Bushnell Velocity radar gun is good to 200 mph it has had no problems

reading airplanes and boats.

The new tech is the Bushnell Speedster III

I will have the radar gun in front of me to insure I get accurate readings and when the plane

passes in front of me going down wind the gun will be to safe by my right side out of the way.

As the plane accelerates towards the radar gun the mph readings will increase to it's maximum

for that pass. The 20" LED wifi monitor will be positioned as shown in the foreground as shown

in the photo to capture on video the speed of each pass with the current top speed in the

bottom left hand corner.

This will save me time calculating speeds at home and from defending the reported speeds.

Beyond that it just makes for a better video when you can have real time speed results.

The Speedster III is on K band 18 to 24 ghz. so the radio frequency will be sent out up to

24 billion hrz as far as 1,500 ft with accuracy and bounce back off the plane to the radar gun

which will receive the difference in the compressed frequency wave and calculate the speed.

As you know my passion has been to maximize for speed without going exotic with materials

to achieve good results with the Cox engines.

Jordan, I like your approach to improve on the simple design look forward to your next build!

Internal torque rods for the ailerons requires a bit bigger fuselage and more weight but

would be nice to run a clean setup. A cowled engine would be cool, it gets very hot here in

Texas in the summer, I would have to have a intake vent for the crank case and for the cylinder

with good size exits to keep airflow positive. I like the open firewall to make engine changing

easy the Sportswerks engine was fast to set up.

reading airplanes and boats.

The new tech is the Bushnell Speedster III

I will have the radar gun in front of me to insure I get accurate readings and when the plane

passes in front of me going down wind the gun will be to safe by my right side out of the way.

As the plane accelerates towards the radar gun the mph readings will increase to it's maximum

for that pass. The 20" LED wifi monitor will be positioned as shown in the foreground as shown

in the photo to capture on video the speed of each pass with the current top speed in the

bottom left hand corner.

This will save me time calculating speeds at home and from defending the reported speeds.

Beyond that it just makes for a better video when you can have real time speed results.

The Speedster III is on K band 18 to 24 ghz. so the radio frequency will be sent out up to

24 billion hrz as far as 1,500 ft with accuracy and bounce back off the plane to the radar gun

which will receive the difference in the compressed frequency wave and calculate the speed.

As you know my passion has been to maximize for speed without going exotic with materials

to achieve good results with the Cox engines.

Jordan, I like your approach to improve on the simple design look forward to your next build!

Internal torque rods for the ailerons requires a bit bigger fuselage and more weight but

would be nice to run a clean setup. A cowled engine would be cool, it gets very hot here in

Texas in the summer, I would have to have a intake vent for the crank case and for the cylinder

with good size exits to keep airflow positive. I like the open firewall to make engine changing

easy the Sportswerks engine was fast to set up.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Page 12 of 30 •  1 ... 7 ... 11, 12, 13 ... 21 ... 30

1 ... 7 ... 11, 12, 13 ... 21 ... 30

Similar topics

Similar topics» CG on Speed Contest Planes

» Anyone here into Giant Scale R/C Planes? Post Pics of your Planes.

» Fellow speed freaks, help me build a pair of speed Bees.

» CL planes...

» How many cox planes do you have?

» Anyone here into Giant Scale R/C Planes? Post Pics of your Planes.

» Fellow speed freaks, help me build a pair of speed Bees.

» CL planes...

» How many cox planes do you have?

Page 12 of 30

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules