Log in

Search

Latest topics

» My latest doodle...by batjac Yesterday at 10:05 pm

» Retail price mark-up.. how much is enough?

by gkamysz Yesterday at 9:29 pm

» Happy 77th birthday Andrew!

by roddie Yesterday at 9:22 pm

» Roger Harris revisited

by rsv1cox Yesterday at 3:38 pm

» My N-1R build log

by GallopingGhostler Yesterday at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Yesterday at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Yesterday at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Yesterday at 11:32 am

» Free Flight Radio Assist

by rdw777 Yesterday at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

Sandblasting engines

Page 1 of 1

Sandblasting engines

Sandblasting engines

This is something I often do to enhance the appearance of engines that I am restoring.

Machines aluminium is easy to polish and remove marks but cast aluminium can be difficult. On PAW engines, the castings are a softer grade aluminium and marks, scratches, gouges ...... are difficult to remove.

The rounded and smooth nature of the casting makes it difficult to smooth out the rough bits with files, emery cloth...... as there is a tendency to leave flat spots that show in the light.

So I resort to blasting - it is a finish used on many engines anyway. If you already have a compressor suitable for airbrushes then the "airbrush" for use with grit is not too expensive an addition and 1kg of Aluminium Oxide lasts ages (as long as it is kept dry)

The stuff I use is

and the tool

The blasting gives the crankcase a more uniform look and "disguises" blemishes.

Here is the before

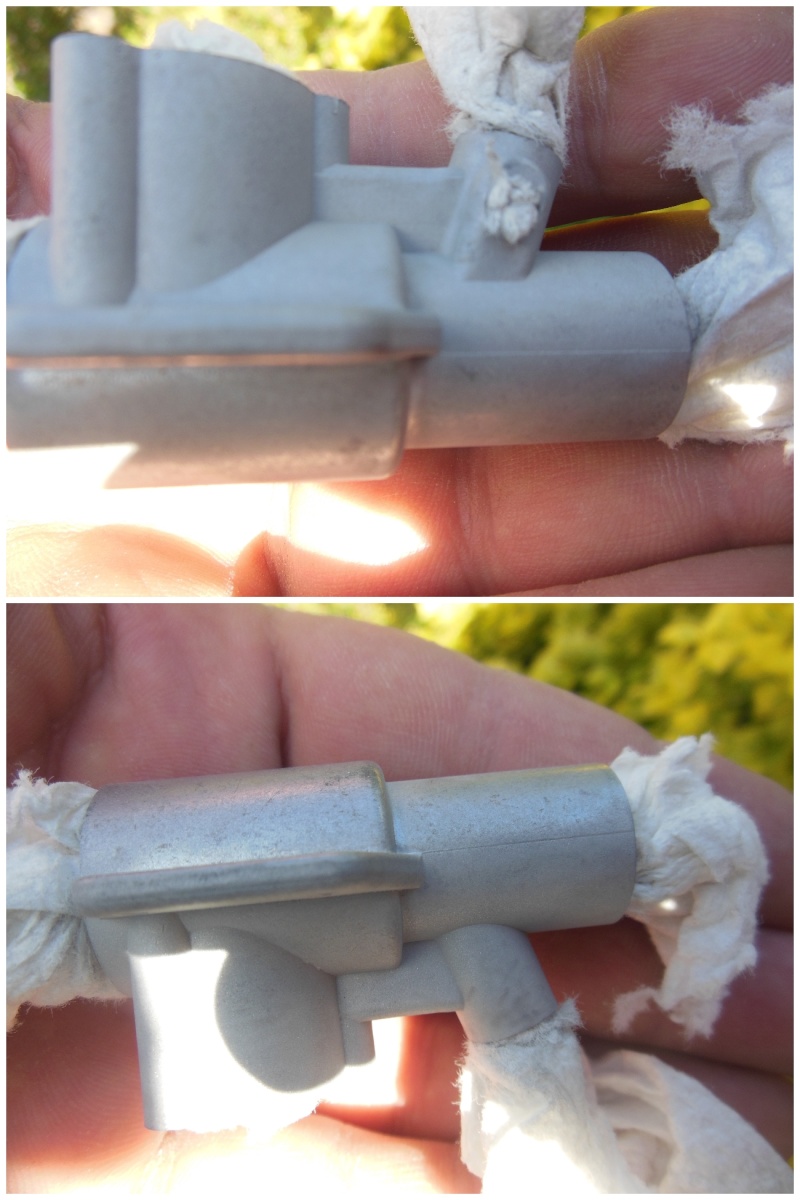

The during

and the after

The surface after this is prone to accepting fingerprints and so I "oil" it to seal it and it puts a nice and permanent sheen on the aluminium. It also repels dirt and and exhaust residue is easily cleaned off.

Dinsdale recommends ArmourAll protectant, as used on motorbikes - one of my fellow restorers uses a teflon spray that he uses for the tables on his woodworking machines. It does need sealing though and the blasted aluminium absorbs the oil.

I use

I leave it overnight before wiping off any excess.

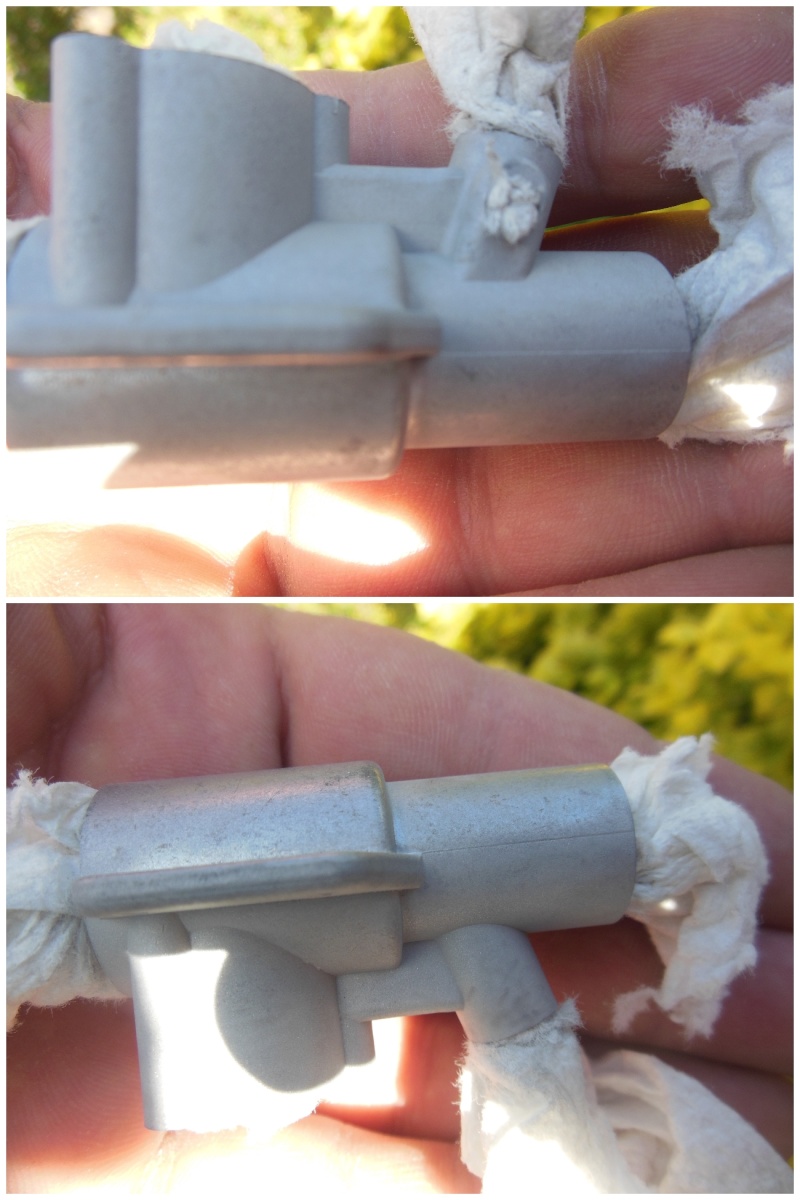

Here is a crankcase being oiled - the first picture highlights the difference.

A few words of warning. The aluminium oxide is extremely abrasive and I only do this outside. Although I seal the crankcase - some always gets in and I blow it out with a much larger air compressor before oiling. The crankcase must be dry before starting the blasting - any moisture or oil will accept the dust and make a very efficient grinding paste. The powder is very fine and blowing it out is the best option or it will end up in any crevices.

It is very hard to "wash" it out.

There is also an alternative and that is to let the blasted crankcase age naturally. It will darken and eventually and porousness will disappear as it oxidises. It must be stored dry for that and it takes months.

The sand blasting also works well on small steel parts and removes rust.

Nearly all the engines I get to restore have missing propeller washers and retaining nuts or they are rusted, butchered or deformed. It is very time consuming cleaning these up and so I just make new ones.

Buying replacements can be expensive - postage cost alone! - and these PAW 09s use a 1 BA thread. 1 BA nuts (any odd size as well) are not easy to find. 0 and 2 BA are easy to get hold of.

That is one of the reasons I restore groups of engines and then produce "extras". Once my lathe is set up - a washer rolls off every two minutes and nuts every three minutes. So 5 minutes for a new nut and washer!

Here is an old one (not in too bad a condition) with one of my spares.

Now - the trio of 09s (149s) ready to run

This process won't appeal to everybody and is involved. It changes the appearance of the engines and they are no longer original but for me they look better than the gummed up, scratched, neglected and battered things I started out with.

Machines aluminium is easy to polish and remove marks but cast aluminium can be difficult. On PAW engines, the castings are a softer grade aluminium and marks, scratches, gouges ...... are difficult to remove.

The rounded and smooth nature of the casting makes it difficult to smooth out the rough bits with files, emery cloth...... as there is a tendency to leave flat spots that show in the light.

So I resort to blasting - it is a finish used on many engines anyway. If you already have a compressor suitable for airbrushes then the "airbrush" for use with grit is not too expensive an addition and 1kg of Aluminium Oxide lasts ages (as long as it is kept dry)

The stuff I use is

and the tool

The blasting gives the crankcase a more uniform look and "disguises" blemishes.

Here is the before

The during

and the after

The surface after this is prone to accepting fingerprints and so I "oil" it to seal it and it puts a nice and permanent sheen on the aluminium. It also repels dirt and and exhaust residue is easily cleaned off.

Dinsdale recommends ArmourAll protectant, as used on motorbikes - one of my fellow restorers uses a teflon spray that he uses for the tables on his woodworking machines. It does need sealing though and the blasted aluminium absorbs the oil.

I use

I leave it overnight before wiping off any excess.

Here is a crankcase being oiled - the first picture highlights the difference.

A few words of warning. The aluminium oxide is extremely abrasive and I only do this outside. Although I seal the crankcase - some always gets in and I blow it out with a much larger air compressor before oiling. The crankcase must be dry before starting the blasting - any moisture or oil will accept the dust and make a very efficient grinding paste. The powder is very fine and blowing it out is the best option or it will end up in any crevices.

It is very hard to "wash" it out.

There is also an alternative and that is to let the blasted crankcase age naturally. It will darken and eventually and porousness will disappear as it oxidises. It must be stored dry for that and it takes months.

The sand blasting also works well on small steel parts and removes rust.

Nearly all the engines I get to restore have missing propeller washers and retaining nuts or they are rusted, butchered or deformed. It is very time consuming cleaning these up and so I just make new ones.

Buying replacements can be expensive - postage cost alone! - and these PAW 09s use a 1 BA thread. 1 BA nuts (any odd size as well) are not easy to find. 0 and 2 BA are easy to get hold of.

That is one of the reasons I restore groups of engines and then produce "extras". Once my lathe is set up - a washer rolls off every two minutes and nuts every three minutes. So 5 minutes for a new nut and washer!

Here is an old one (not in too bad a condition) with one of my spares.

Now - the trio of 09s (149s) ready to run

This process won't appeal to everybody and is involved. It changes the appearance of the engines and they are no longer original but for me they look better than the gummed up, scratched, neglected and battered things I started out with.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Sandblasting engines

Re: Sandblasting engines

I think they look excellent Ian. You really have a knack for cleaning up engines.

Thanks dor posting that info.

Ron

Thanks dor posting that info.

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Sandblasting engines

Re: Sandblasting engines

Aluminium oxide will be a bit harsh, though it does come in many different grades. As a scientific instrument maker we used to use an ultra fine grade which was called levigated alumina for polishing jewels and pivots. It was finer than jewlers' rouge. No matter what the grade, it's still a very (one of the most) abrasive product. However, I would suggest using soda (baking soda) for your aluminium castings. It's also available in many grades and it won't harm any other parts, including plastic. in fact it's eminently suitable for restoring the finish on plastic parts. It washes out easily with water, given that it's water soluble. Coconut shell and walnut shell are also excellent for non-destructive blast cleaning and they leave a rather attractive lustre on the aluminium. As you say, some sort of oily coating is necessary to maintain the finish appearance. The beauty of ArmorAll is that it doesn't burn/cook on and (on my motorbike engines) you only need to hit with a hose and all the accumulated grime and gunk just drops off. Lasts a couple of months on my bikes. I'm using a fine grade of glass beads in my blasting cabinet and they do an excellent job. If you're quick you can clean plastic parts too, but practise first, because you can ruin plastic parts easily too.

dinsdale- Account Deactivated by Owner

- Posts : 317

Join date : 2012-02-22

Re: Sandblasting engines

Re: Sandblasting engines

dinsdale wrote:Aluminium oxide will be a bit harsh, though it does come in many different grades. As a scientific instrument maker we used to use an ultra fine grade which was called levigated alumina for polishing jewels and pivots. It was finer than jewlers' rouge. No matter what the grade, it's still a very (one of the most) abrasive product. However, I would suggest using soda (baking soda) for your aluminium castings. It's also available in many grades and it won't harm any other parts, including plastic. in fact it's eminently suitable for restoring the finish on plastic parts. It washes out easily with water, given that it's water soluble. Coconut shell and walnut shell are also excellent for non-destructive blast cleaning and they leave a rather attractive lustre on the aluminium. As you say, some sort of oily coating is necessary to maintain the finish appearance. The beauty of ArmorAll is that it doesn't burn/cook on and (on my motorbike engines) you only need to hit with a hose and all the accumulated grime and gunk just drops off. Lasts a couple of months on my bikes. I'm using a fine grade of glass beads in my blasting cabinet and they do an excellent job. If you're quick you can clean plastic parts too, but practise first, because you can ruin plastic parts easily too.

I have used soda blasting for cleaning wood, removing paint and cleaning bricks. I would use it if I intended to polish aluminium afterwards but here I want to blend and texture the surface.

The airbrush I have is not happy with soda and the compressor doesn't really want to run much above 40 PSI. The soda blasting kit I use (borrow!) needs my big compressor ( min 7cfm at 80 to 100 psi) - I have used this on brass, aluminium and stainless steel. I have also made a few mistakes - I used it to "clean" what I thought was an adonised aluminium part and then found it was painted!

The material used depends on the finish you want. A fellow restorer uses pumice powder - I am not sure about the finish it produces but he is happy with it. Then again, he was given a 25kg tub of it!

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Similar topics

Similar topics» In defense of sandblasting model engines.

» Selling kits and engines. *NEW added 1/2A engines!

» Cox International Engines Flying on "The Board of Engines"

» need a bidder

» help! it wont start

» Selling kits and engines. *NEW added 1/2A engines!

» Cox International Engines Flying on "The Board of Engines"

» need a bidder

» help! it wont start

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules