Log in

Search

Latest topics

» Roger Harris revisitedby TD ABUSER Today at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Today at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Today at 1:37 pm

» Happy 77th birthday Andrew!

by getback Today at 11:52 am

» My latest doodle...

by roddie Today at 10:43 am

» My N-1R build log

by GallopingGhostler Yesterday at 3:04 pm

» Chocolate chip cookie dough.........

by roddie Yesterday at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Yesterday at 11:32 am

» Free Flight Radio Assist

by rdw777 Yesterday at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

Guillow's P40 Warhawk build, photos of the finished model

Page 3 of 5

Page 3 of 5 •  1, 2, 3, 4, 5

1, 2, 3, 4, 5

Re: Guillow's P40 Warhawk build, photos of the finished model

Re: Guillow's P40 Warhawk build, photos of the finished model

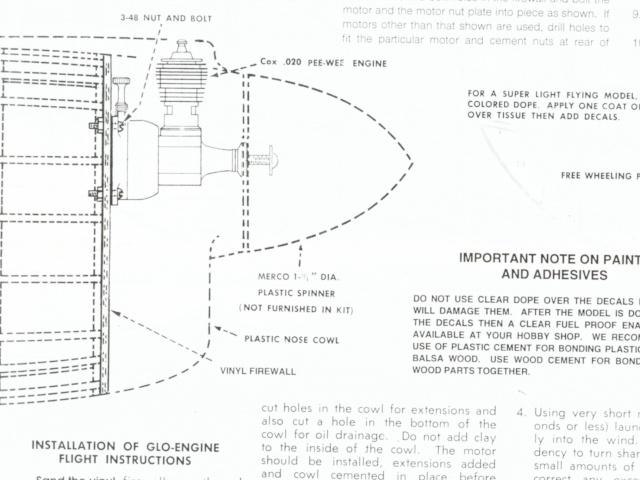

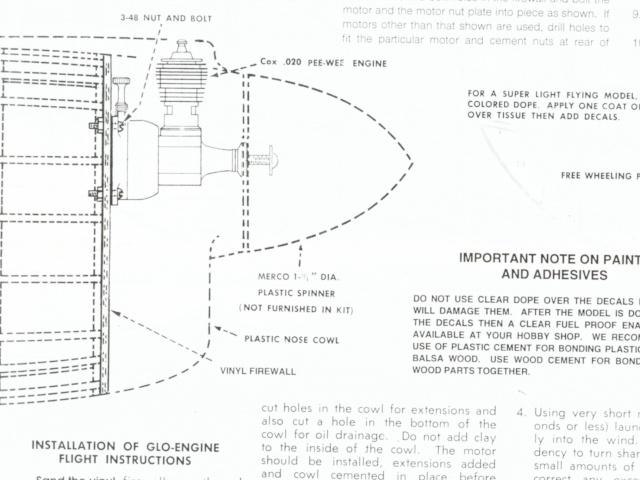

Thanks for your comments. Here's a drawing of the Warhawk's nose for free flight from the Guillow's plans:

It shows the engine and spinner but doesn't say anything about the prop.

Today, I let the Pee Wee run with the Cox 4.5x2 prop. During the first run, it went backwards but that didn't bother me much. Then happened this: the prop flew off and the engine continued running without the prop. That gave a rather screaming noise . I stopped it by pinching the drive washer with my fingers using a rag. Of course, the prop bolt is lost forever in the lawn. After putting the prop back on again with a RED PLASTIC SPINNER !!! this time, I think I found out what happened. While running backwards, drops of castor oïl fly into the propeller andwhen that happened, I heard a distinctive knock in the engine sound . Maybe the prop bolt wasn't done up enough at the same time.

. I stopped it by pinching the drive washer with my fingers using a rag. Of course, the prop bolt is lost forever in the lawn. After putting the prop back on again with a RED PLASTIC SPINNER !!! this time, I think I found out what happened. While running backwards, drops of castor oïl fly into the propeller andwhen that happened, I heard a distinctive knock in the engine sound . Maybe the prop bolt wasn't done up enough at the same time.

I put a silicon tubing on the needle but the regime was still not constant. Moving the needle with my fingers still made a difference. A video is uploading.

Would a 049 still be all right? It weights twice as much as a Pee Wee.

Lieven

It shows the engine and spinner but doesn't say anything about the prop.

Today, I let the Pee Wee run with the Cox 4.5x2 prop. During the first run, it went backwards but that didn't bother me much. Then happened this: the prop flew off and the engine continued running without the prop. That gave a rather screaming noise

. I stopped it by pinching the drive washer with my fingers using a rag. Of course, the prop bolt is lost forever in the lawn. After putting the prop back on again with a RED PLASTIC SPINNER !!! this time, I think I found out what happened. While running backwards, drops of castor oïl fly into the propeller andwhen that happened, I heard a distinctive knock in the engine sound . Maybe the prop bolt wasn't done up enough at the same time.

. I stopped it by pinching the drive washer with my fingers using a rag. Of course, the prop bolt is lost forever in the lawn. After putting the prop back on again with a RED PLASTIC SPINNER !!! this time, I think I found out what happened. While running backwards, drops of castor oïl fly into the propeller andwhen that happened, I heard a distinctive knock in the engine sound . Maybe the prop bolt wasn't done up enough at the same time.I put a silicon tubing on the needle but the regime was still not constant. Moving the needle with my fingers still made a difference. A video is uploading.

Would a 049 still be all right? It weights twice as much as a Pee Wee.

Lieven

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: Guillow's P40 Warhawk build, photos of the finished model

Re: Guillow's P40 Warhawk build, photos of the finished model

Lieven,

It's possible to make the .020 work. They are notorious air leakers so you probably need to pressurize the tank and see what happens.

That being said, it would take a bit of work to get an .049 to fit neatly under the cowl. Plus it would take some beefing up of the nose. If it were me I would do it, but it would be up to you. The horseshoe backplate .049 would be your lightest option.

Since you have so much invested in the Pee Wee maybe it's best to stick with it for now.

Ron

It's possible to make the .020 work. They are notorious air leakers so you probably need to pressurize the tank and see what happens.

That being said, it would take a bit of work to get an .049 to fit neatly under the cowl. Plus it would take some beefing up of the nose. If it were me I would do it, but it would be up to you. The horseshoe backplate .049 would be your lightest option.

Since you have so much invested in the Pee Wee maybe it's best to stick with it for now.

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Guillow's P40 Warhawk build, photos of the finished model

Re: Guillow's P40 Warhawk build, photos of the finished model

Lieven, does the Guillow's plans show a eyedropper used for a fuel tank on the plans? I'm actually quite surprised that they're using the stock tank. That's a lot of fuel for a free flight run. Running on the bench and running in the air are completely different. Seeing it run without the other prop and spinner eliminates my above theory in regards to too much prop. It however does sound better rpm wise. I don't feel though that you need a lot of rpm's here though. The spinners and cowlings look great on the plane but I've seen them cause more problematic runs than good ones due to insufficient air flow. While I do feel there's an issue here, it's hard deciphering from the video. I feel it wouldn't hurt to add an additional head gasket here and retry. Power shouldn't be an issue here as I feel the .020 will run fine even if you do decompress it with additional shims. Is the pickup pointing down to the bottom of the tank or is it currently setup for control line useage to the right?

Have you had this engine completely apart? The reason I ask, I've seen similar runs where the beginning starts out similar to your run and ends the same. Inside the case and on the shaft itself the castor develops a thick goo that when heated up starts to act somewhat like a brake and clamps down on the crank. A quick polishing of the crank and cleaning of the journal in the case can clear this up. I like to take the easy path first, I would certainly try one shim and see if any improvement is made. I'm looking forward to the video with it on the plane circling skywards. So lets get this engine going as I'm patiently waiting. Ken

Have you had this engine completely apart? The reason I ask, I've seen similar runs where the beginning starts out similar to your run and ends the same. Inside the case and on the shaft itself the castor develops a thick goo that when heated up starts to act somewhat like a brake and clamps down on the crank. A quick polishing of the crank and cleaning of the journal in the case can clear this up. I like to take the easy path first, I would certainly try one shim and see if any improvement is made. I'm looking forward to the video with it on the plane circling skywards. So lets get this engine going as I'm patiently waiting. Ken

Ken Cook- Top Poster

- Posts : 5640

Join date : 2012-03-27

Location : pennsylvania

Re: Guillow's P40 Warhawk build, photos of the finished model

Re: Guillow's P40 Warhawk build, photos of the finished model

Hey Lieven, If you disassemble the engine as per Ken's advice.. you may also want to check the "reed" and it's "seat". If you have another reed (not necessarily a new one.. just another one) try changing it before you re-assemble the engine. You might even want to try using a different "circlip" if you have one.

Like Ron said; you could have an air-leak somewhere too. May as well eliminate any variables that you can.. and Ken's question about the fuel pick-up tube should definitely be addressed.

Paul G. sent me a photo of some of his Cox Bee back-plate mods. Notice the one in the middle; particularly the way the "needle" is set up (not the feed-tube..) Notice that he uses a small steel "washer" above the fuel-line seal.. and that the seal needs to be an optimal length to be effective for the needle's range during operation. Too short; and you will have a gap exposing an air-leak.. and too long; the tubing will squash/distort.. and cause the same condition. These are .049 back-plates.. but the same modification could be made for your Pee Wee's needle. I see that you're using a seal.. but I can't see clearly from the vid; whether you're using a washer? The seal-tubing should also be cut perfectly "square" to seal properly.

Like Ron said; you could have an air-leak somewhere too. May as well eliminate any variables that you can.. and Ken's question about the fuel pick-up tube should definitely be addressed.

Paul G. sent me a photo of some of his Cox Bee back-plate mods. Notice the one in the middle; particularly the way the "needle" is set up (not the feed-tube..) Notice that he uses a small steel "washer" above the fuel-line seal.. and that the seal needs to be an optimal length to be effective for the needle's range during operation. Too short; and you will have a gap exposing an air-leak.. and too long; the tubing will squash/distort.. and cause the same condition. These are .049 back-plates.. but the same modification could be made for your Pee Wee's needle. I see that you're using a seal.. but I can't see clearly from the vid; whether you're using a washer? The seal-tubing should also be cut perfectly "square" to seal properly.

Re: Guillow's P40 Warhawk build, photos of the finished model

Re: Guillow's P40 Warhawk build, photos of the finished model

Before starting for the first time, I took the tank apart. There were no remnants of fuel or oïl in there. Also the crankcase was clean.

The fuel tube as in the control line position. There is not much space to redirect the fuel line next to the intake tube and then pointing to the bottom. After your last helpful tips, I fixed a washer above the silicon tube on the needle and removed the spring in the fuel line trying to fix in more vertically. After assembling the lot, I tried to start the engine but that became very difficult. Suddenly I noticed that the tank seriously leaked fuel. It wasn't from the tank- backplate joint but from one of the 4 crankcase bolts. I tried to rescrew the one I thought was leaking, but suddenly that went too easy: The bolt hole part of the backplate broke off

Now, before starting this kit, I got everything I thought was usefull for a Pee Wee to stay without problems, heads, gasket sets, spare bolts, reeds, spanner... but what I haven't got is a backplate!!!

Lieven

The fuel tube as in the control line position. There is not much space to redirect the fuel line next to the intake tube and then pointing to the bottom. After your last helpful tips, I fixed a washer above the silicon tube on the needle and removed the spring in the fuel line trying to fix in more vertically. After assembling the lot, I tried to start the engine but that became very difficult. Suddenly I noticed that the tank seriously leaked fuel. It wasn't from the tank- backplate joint but from one of the 4 crankcase bolts. I tried to rescrew the one I thought was leaking, but suddenly that went too easy: The bolt hole part of the backplate broke off

Now, before starting this kit, I got everything I thought was usefull for a Pee Wee to stay without problems, heads, gasket sets, spare bolts, reeds, spanner... but what I haven't got is a backplate!!!

Lieven

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: Guillow's P40 Warhawk build, photos of the finished model

Re: Guillow's P40 Warhawk build, photos of the finished model

Back in the early '70s, I flew a 27" (686mm) span Top Flite R/C Schoolboy on rudder only pulse proportional and after that a 20" (508mm) Top Flite R/C Roaring 20. I found that the Cox 4.5x2 prop only gave the plane with Cox Pee Wee about 1.5 minutes flight. A Top Flite 5.25x3 nylon prop mounted on it, gained a minute more in fflight and flight was at the same speed. Pee Wee has enough torque to spin a 5" prop. This is of course was on 15% to 25% nitro fuel.Ken Cook wrote:Lieven, one thing I might add is that the 5" prop is a bittoo much for the little Pee Wee. Combine that with that huge spinner and your really lugging it. The backplate of the spinner is as tall as the cylinder sticking up. This could really be blocking needed cooling air thus causing the engine to start overheating and sagging. For a bit the engine ran rich, then leaned up but it definitely wasn't liking it in the end. Try the prop again without the spinner and make a determination. Higher nitro will help. I'm curious myself. Ken

I'd say the the large spinner is the culprit and possibly the plastic prop too. I think the Top Flites were lighter back then. I think simply removing the spinner (except for static display) and going to a wood 5x3 prop, but I find that no one makes that small a wood prop nowadays. I'd try a Cox International 5x3 nylon prop. That I believe is lighter than the Masters or APC prop.

GallopingGhostler- Top Poster

Posts : 5724

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Guillow's P40 Warhawk build, photos of the finished model

Re: Guillow's P40 Warhawk build, photos of the finished model

Yo Lieven !!!

If you have a really tough time finding a new backplate, let me know and I'll send one your way !

Spare Parts Kim

If you have a really tough time finding a new backplate, let me know and I'll send one your way !

Spare Parts Kim

Kim- Top Poster

Posts : 8625

Join date : 2011-09-06

Location : South East Missouri

Re: Guillow's P40 Warhawk build, photos of the finished model

Re: Guillow's P40 Warhawk build, photos of the finished model

I've found the reason why the Top Flite 5-1/4x3 nylon prop worked for me in the early 1970's. I've included a link to Peter Chinn's report from March 1976 Aeromodeller from sceptreflight.net:

Cox 020 Pee Wee Model Engine Test

Peter Chinn tried a Tornado 5x3 prop and obtained 10,900 rpm on 25% nitro. He adds a statement that there is no use in trying props that diminish rpm less than 11,000. Looking at the engine power graph, engine torgue falls off at values less than 11,000. The 10,900 on a Tornado is right at the threshold. IIRC, the Top Flite prop I used has less blade area than the Tornado given its overall shape.

There is an earlier report in December 1958 Model Aircraft, which has a slightly different power graph, seen at sceptreflight.net:

MA Engine Test Cox "Pee Wee"

11,000 rpm is close to maximum torque. Between 1958 and 1976, no doubt Cox made gradual and subtle improvements to the engine's design. I obtained my engine in Fall 1972, whether it was closer to the 1958 model or 1976 one, it had the smaller tapered crankcase plain bearing shaft housing like the 1958 one.

Regardless, the Pee Wee is a little jewel, and loves high nitro fuel. (Until refomulated, don't use the Hobbico Cox Power Fuel. Even though it has 25% nitro, it has 18% oil with only a smigeon of Castor. Bernie at Cox International has recommended at least 20% oil of which half is Castor.)

I'd suggest experimentation, make sure not to run the Pee Wee overly lean but let it scream, leave off the heavy and cumbersome nose cone; and see what best results are obtained through various small props.

Cox 020 Pee Wee Model Engine Test

Peter Chinn tried a Tornado 5x3 prop and obtained 10,900 rpm on 25% nitro. He adds a statement that there is no use in trying props that diminish rpm less than 11,000. Looking at the engine power graph, engine torgue falls off at values less than 11,000. The 10,900 on a Tornado is right at the threshold. IIRC, the Top Flite prop I used has less blade area than the Tornado given its overall shape.

There is an earlier report in December 1958 Model Aircraft, which has a slightly different power graph, seen at sceptreflight.net:

MA Engine Test Cox "Pee Wee"

11,000 rpm is close to maximum torque. Between 1958 and 1976, no doubt Cox made gradual and subtle improvements to the engine's design. I obtained my engine in Fall 1972, whether it was closer to the 1958 model or 1976 one, it had the smaller tapered crankcase plain bearing shaft housing like the 1958 one.

Regardless, the Pee Wee is a little jewel, and loves high nitro fuel. (Until refomulated, don't use the Hobbico Cox Power Fuel. Even though it has 25% nitro, it has 18% oil with only a smigeon of Castor. Bernie at Cox International has recommended at least 20% oil of which half is Castor.)

I'd suggest experimentation, make sure not to run the Pee Wee overly lean but let it scream, leave off the heavy and cumbersome nose cone; and see what best results are obtained through various small props.

GallopingGhostler- Top Poster

Posts : 5724

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Guillow's P40 Warhawk build, photos of the finished model

Re: Guillow's P40 Warhawk build, photos of the finished model

Looks like you are in luck, Lieven, Kim has offered you a back plate. Leak you had may have been related to a cracked bolt hole flange, which finally separated on you. Also, if there was leakage out the rear venturi hole, it could have been due to a missing rubber washer gasket. It looks similar to a tiny O-ring, except it is flat.OVERLORD wrote:Before starting for the first time, I took the tank apart. There were no remnants of fuel or oïl in there. Also the crankcase was clean. The fuel tube as in the control line position. There is not much space to redirect the fuel line next to the intake tube and then pointing to the bottom. After your last helpful tips, I fixed a washer above the silicon tube on the needle and removed the spring in the fuel line trying to fix in more vertically. After assembling the lot, I tried to start the engine but that became very difficult. Suddenly I noticed that the tank seriously leaked fuel. It wasn't from the tank- backplate joint but from one of the 4 crankcase bolts. I tried to rescrew the one I thought was leaking, but suddenly that went too easy: The bolt hole part of the backplate broke off

Now, before starting this kit, I got everything I thought was usefull for a Pee Wee to stay without problems, heads, gasket sets, spare bolts, reeds, spanner... but what I haven't got is a backplate!!! Lieven

The vinyl fuel pickup tube nipple on the back plate is very fragile. I have already broken one. If your tube is hardened due to age, you may have to apply a little heat to it (hot water) to soften it. You can use very small silicon tubing, reuse the tubing spring and reroute to the bottom of the tank.

Cox International has an overhaul kit for US$ 3.95 (€ 2.96) that includes a new pickup tube:

http://coxengines.ca/cox-.020-pee-wee-overhaul-kit.html

GallopingGhostler- Top Poster

Posts : 5724

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Guillow's P40 Warhawk build, photos of the finished model

Re: Guillow's P40 Warhawk build, photos of the finished model

Thanks for re-iterating that, George. Warnings against that fuel are scattered about here at CEF, but it can't be stated enough. The Cox Super Power Fuel from Tower or Coxmodels.com can and will ruin a Cox engine in one short session. A couple of our members have proved it.GallopingGhostler wrote:...Regardless, the Pee Wee is a little jewel, and loves high nitro fuel. (Until reformulated, don't use the Hobbico Cox Power Fuel. Even though it has 25% nitro, it has 18% oil with only a smidgen of Castor. Bernie at Cox International has recommended at least 20% oil of which half is Castor.)...

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Guillow's P40 Warhawk build, photos of the finished model

Re: Guillow's P40 Warhawk build, photos of the finished model

Thanks, Rusty. That seems to be a Deja Vu experience with earlier modelers of the 1950's/1960's with Testors "39" fuel. (See RCU Post #139, bad engines thread)

Many a modeler ruined model aeroplane engines using that fuel.

Many a modeler ruined model aeroplane engines using that fuel.

GallopingGhostler- Top Poster

Posts : 5724

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Guillow's P40 Warhawk build, photos of the finished model

Re: Guillow's P40 Warhawk build, photos of the finished model

Thanks for your comments. Before running the engine for the first time, I had it apart but I didn't notice anything wrong so I put it back together again. I didn't look in particular for a cracked bolt boss but that could be the case indeed. When inspecting the parts again today, I noticed that when I put the tank onto the backplate, there was no springyness of the central O ring. The O ring was flat sided and hard, so I replaced that. This O ring could definitely be leaking and making the mixture uncontrollable. Also, after removing the reed - and crawling all over the floor to find the spring back - there seemed to be a kink in it, just in way of the seat edge, so I replaced the reed as well. When I get another back plate, we'll test again.

The pick up tube is still in the control line position. It doesn't bother me much. As long as the engine stops instantly when runnung out of fuel, that should be OK. What I experienced until now was that during the last 10 seconds of running time, the engine ran very irregularly, which would not give a nice flight.

As what cooling is concerned, there will be an air flow through the lower openings in the cowl that rises past the cylinder and head back out again.

Hopefully, this all will give some positive results.

Lieven

The pick up tube is still in the control line position. It doesn't bother me much. As long as the engine stops instantly when runnung out of fuel, that should be OK. What I experienced until now was that during the last 10 seconds of running time, the engine ran very irregularly, which would not give a nice flight.

As what cooling is concerned, there will be an air flow through the lower openings in the cowl that rises past the cylinder and head back out again.

Hopefully, this all will give some positive results.

Lieven

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: Guillow's P40 Warhawk build, photos of the finished model

Re: Guillow's P40 Warhawk build, photos of the finished model

Meanwhile, you might be able to salvage the tank back by JB Welding the broken screw flange. Use a piece of small nylon pushrod tubing or worn out ball pen ink cartridge tubing, cut to length so that it exerts a very slight pressure against the repaired flange when placed over the tank screw. Snug it up but don't tighten too much or you'll break the JB Weld.

Your replacing the tank venturi O-ring should improve needle response and prevent flooding. Your erratic running may have been attributed to fuel consumption going below the venturi location, starting to suck air.

Regarding needing at least 50% of the 20% oil being Castor, engine will run hot. I gather that Leroy Cox scaled the engine down from the .049, but I don't think there was science on cooling, mostly empirical (experimental). This is particularly true when using slightly larger props. The Castor will help to protect the piston ball and socket joint and piston cylinder fit. Once pickup tubing is relocated or replaced to opening at bottom of tank, expect about 1 to 1.5 minutes run time. I was getting 2.5 minutes with 5.25x3 and 5x3 Top Flite nylon props. (Although wood was superior did not use it, as they didn't stand up too well with hard landings.) Some drill a hole through the tank and use an external tank for longer run time. I did that on my Ace R/C Littlest Stick. I don't know if you want to do that to your engine.

Your replacing the tank venturi O-ring should improve needle response and prevent flooding. Your erratic running may have been attributed to fuel consumption going below the venturi location, starting to suck air.

Regarding needing at least 50% of the 20% oil being Castor, engine will run hot. I gather that Leroy Cox scaled the engine down from the .049, but I don't think there was science on cooling, mostly empirical (experimental). This is particularly true when using slightly larger props. The Castor will help to protect the piston ball and socket joint and piston cylinder fit. Once pickup tubing is relocated or replaced to opening at bottom of tank, expect about 1 to 1.5 minutes run time. I was getting 2.5 minutes with 5.25x3 and 5x3 Top Flite nylon props. (Although wood was superior did not use it, as they didn't stand up too well with hard landings.) Some drill a hole through the tank and use an external tank for longer run time. I did that on my Ace R/C Littlest Stick. I don't know if you want to do that to your engine.

GallopingGhostler- Top Poster

Posts : 5724

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Guillow's P40 Warhawk build, photos of the finished model

Re: Guillow's P40 Warhawk build, photos of the finished model

Hi Lieven! After reading your findings on disassembly.. I'm thinking that you will have better luck with that engine. You had too many conditions working against a steady run. The crease in the reed.. a brittle O-ring.. and an illusive cracked tank-screw boss in the backplate, which finally broke through.. Once you get those things taken care of and the engine running smoothly; you'll be in a better position to evaluate which prop to use.

I actually don't see that big spinner being much of a concern for this application.. It's merely a "flywheel".. and it's rotational-mass difference compared to running a smaller/lighter one.. (or no spinner at all) is really insignificant when you compare these factors to increasing propeller pitch, which "will" load the engine. If your engine were "throttled".. you might notice a dwell in throttle-response.. until reaching a steady engine speed; both throttling up or down. Consider the physics behind the "Hit and Miss" engine design, which uses a sizeable flywheel to spin the crankshaft between ignition power strokes.

I actually don't see that big spinner being much of a concern for this application.. It's merely a "flywheel".. and it's rotational-mass difference compared to running a smaller/lighter one.. (or no spinner at all) is really insignificant when you compare these factors to increasing propeller pitch, which "will" load the engine. If your engine were "throttled".. you might notice a dwell in throttle-response.. until reaching a steady engine speed; both throttling up or down. Consider the physics behind the "Hit and Miss" engine design, which uses a sizeable flywheel to spin the crankshaft between ignition power strokes.

Re: Guillow's P40 Warhawk build, photos of the finished model

Re: Guillow's P40 Warhawk build, photos of the finished model

Sometimes flywheel action works. Then on the other hand, I have had it where it didn't. I had a tough time with my Enya .09-III TV's, until I dropped the plastic prop for a wood one. Ditto with the Fuji .099S-II. Then it became a totally different engine. By process of elimination, I'd try the engine first with its recommended Cox propellor without the spinner. Then after I got it to run successfully without problem, add the spinner. Sometimes with these little engines, a little more is too much.

GallopingGhostler- Top Poster

Posts : 5724

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Guillow's P40 Warhawk build, photos of the finished model

Re: Guillow's P40 Warhawk build, photos of the finished model

Thanks guys, for thinking with me.

I considered repairing the broken bit of the backplate but it wont be easy for 2 reasons: These backplates are made of zamac, or mazac as they say in the UK, which is not a very good material to work with and once repaired, there is a lot of force acting onto that part by the crankcase bolt. I doubt that a repair would resist to all that.

Thanks to Kim, who sent me a backlate and many more spares for a proper Pee Wee overhaul, the engine is back running again. During the first tests, the engine ran with constant speed which was a big improvement due to the now non-leaking fuel tank and the replaced rubber o ring on the fuel feed. I also fixed a longer pick up tube that goes right to the bottom of the tank. The rpm was not very high though and the spinner vibrated a lot:

I found out that the vibrations of the spinner were caused by the plasting spinner base plate that flexes combined with the weight of the cone attached to it. Also, with a full tank, the engine stopped by itself half way through. Then, I could start it again and kept running till the end.

For a second test, I replaced the needle spring by a piece of silicon tubing and I removed the spinner cone. That was much better: higher rpm and no vibrations:

Now I have to find a way of determine the exact fuel quantity for a certain amount of running time. The tank should be 2 or 3 cc? With 1.5cc of fuel, the engine ran about 30 seconds but I have to do further testing for that.

I fixed the rudder to the fuse by means of a brass plate thet can be bent if needed. The plate was bolted to the fuse so it can be removed.

I'm happy that this engine is repaired and runs great. THANK YOU KIM!!!

Lieven

I considered repairing the broken bit of the backplate but it wont be easy for 2 reasons: These backplates are made of zamac, or mazac as they say in the UK, which is not a very good material to work with and once repaired, there is a lot of force acting onto that part by the crankcase bolt. I doubt that a repair would resist to all that.

Thanks to Kim, who sent me a backlate and many more spares for a proper Pee Wee overhaul, the engine is back running again. During the first tests, the engine ran with constant speed which was a big improvement due to the now non-leaking fuel tank and the replaced rubber o ring on the fuel feed. I also fixed a longer pick up tube that goes right to the bottom of the tank. The rpm was not very high though and the spinner vibrated a lot:

I found out that the vibrations of the spinner were caused by the plasting spinner base plate that flexes combined with the weight of the cone attached to it. Also, with a full tank, the engine stopped by itself half way through. Then, I could start it again and kept running till the end.

For a second test, I replaced the needle spring by a piece of silicon tubing and I removed the spinner cone. That was much better: higher rpm and no vibrations:

Now I have to find a way of determine the exact fuel quantity for a certain amount of running time. The tank should be 2 or 3 cc? With 1.5cc of fuel, the engine ran about 30 seconds but I have to do further testing for that.

I fixed the rudder to the fuse by means of a brass plate thet can be bent if needed. The plate was bolted to the fuse so it can be removed.

I'm happy that this engine is repaired and runs great. THANK YOU KIM!!!

Lieven

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: Guillow's P40 Warhawk build, photos of the finished model

Re: Guillow's P40 Warhawk build, photos of the finished model

Hi Lieven, Great that you got your engine running right! BTW.. did you replace that creased reed? (you didn't mention that)

Is it necessary to use a prop-screw that long? Also; that brass tubing spacer for the screw; is it the only thing bearing on the spinner-plate? Try cutting the screw shorter.. and use a steel washer to bear on the spinner-plate and try running the engine again with the cone.

EDIT: I just noticed that there's also a bushing that appears to be bearing on the spinner-plate. Is that part of the spinner assembly.. or something you devised in order to utilize the length of the prop-screw(s) that you had on hand? Is it a hub-reduction adapter that came with the spinner? If so; maybe retaining it with the shorter screw/steel washer would stabilize it better

I didn't "see" any vibration in the first test vid.. and if you only did the two tests.. you may find now; that the spinner runs smoother with a shortened prop-screw w/washer.. and at a higher RPM due to harmonic differences.

Is it necessary to use a prop-screw that long? Also; that brass tubing spacer for the screw; is it the only thing bearing on the spinner-plate? Try cutting the screw shorter.. and use a steel washer to bear on the spinner-plate and try running the engine again with the cone.

EDIT: I just noticed that there's also a bushing that appears to be bearing on the spinner-plate. Is that part of the spinner assembly.. or something you devised in order to utilize the length of the prop-screw(s) that you had on hand? Is it a hub-reduction adapter that came with the spinner? If so; maybe retaining it with the shorter screw/steel washer would stabilize it better

I didn't "see" any vibration in the first test vid.. and if you only did the two tests.. you may find now; that the spinner runs smoother with a shortened prop-screw w/washer.. and at a higher RPM due to harmonic differences.

Re: Guillow's P40 Warhawk build, photos of the finished model

Re: Guillow's P40 Warhawk build, photos of the finished model

Sounds good Lieven , believe you got all the problems repaired , I had a back plate on a BW that gave me a hard way to go till it broke it was plastic

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Guillow's P40 Warhawk build, photos of the finished model

Re: Guillow's P40 Warhawk build, photos of the finished model

Yes, Roddie, the reed was replaced. The reason for this longer bolt is that a standard bolt is not long enough for the spinner back plate and the prop. So I used a mounting bolt of a Dragonfly. It is impossible to find such bolts over here so I sought till I found that solution. I'm not going to cut that bolt but I found since then a proper Pee Wee prop washer so I'll put that one on. i think Bernie sells longer prop bolts but I have to check.

There is no other spacer or bushing on that spinner plate. Just the bolt and the small brass tube. I distilled a picture out of the video showing the spinner vibration. That is only caused by the bending of the spinner plate when the cone is attached. Maybe I should look out for a Kavan spinner. These are screwed on with the cone onto the prop and they have no back plate at all.

Lieven

There is no other spacer or bushing on that spinner plate. Just the bolt and the small brass tube. I distilled a picture out of the video showing the spinner vibration. That is only caused by the bending of the spinner plate when the cone is attached. Maybe I should look out for a Kavan spinner. These are screwed on with the cone onto the prop and they have no back plate at all.

Lieven

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: Guillow's P40 Warhawk build, photos of the finished model

Re: Guillow's P40 Warhawk build, photos of the finished model

You have a very small support area from the prop washer on the back side and propeller bearing area on the inside to support the large spinner. Larger engines have a larger prop washer and larger prop bearing area, which help to prevent the spinner's plastic backplate from excessively flexing. A small fender washer or two might be able to stiffen it up enough to prevent excessive vibration. Caveate is added weight. Another possible solution may be a 3/32" plywood disk on one side might dampen some of the flexing. A better solution might be an aluminum spinner, but finding adapters plus the added cost may be prohibitive.

GallopingGhostler- Top Poster

Posts : 5724

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Guillow's P40 Warhawk build, photos of the finished model

Re: Guillow's P40 Warhawk build, photos of the finished model

That's right George, the prop washer is too small to properly support that spinner plate. I think that whatever solution one thinks of to stiffen that by adding more washers or plates would not give super results but would certainly add weight. Therefore I think a Kavan spinner is the solution. The spinner is fixed with the cone and not with the back plate.

http://www.weymuller.fr/catalogue/cones/cones_nylon/cones_kavan_bipale.html

Lieven

http://www.weymuller.fr/catalogue/cones/cones_nylon/cones_kavan_bipale.html

Lieven

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: Guillow's P40 Warhawk build, photos of the finished model

Re: Guillow's P40 Warhawk build, photos of the finished model

That spinner dia. is so big it leaves less working prop for flying the plane. I wonder if a 5x2 would do some good.

1/2A Nut- Top Poster

- Posts : 3538

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Guillow's P40 Warhawk build, photos of the finished model

Re: Guillow's P40 Warhawk build, photos of the finished model

The Cox Pee Wee is a torquey little bugger. I flew them in the early 1970's in single channel RC planes. I gaine an additional minute of flight time on a Top Flite 5.25x3 nylon prop with no change in flight speed. Haven't tried a modern 5x2, but I don't see why it shouldn't work. Still have my Ace RC Littlest Stick from the late 1970's with Cox Pee Wee. Still need to install modern RC micro gear, convert to 2 channel. Then I'll be able to test the more recent props.1/2A Nut wrote:That spinner dia. is so big it leaves less working prop for flying the plane. I wonder if a 5x2 would do some good.

GallopingGhostler- Top Poster

Posts : 5724

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Guillow's P40 Warhawk build, photos of the finished model

Re: Guillow's P40 Warhawk build, photos of the finished model

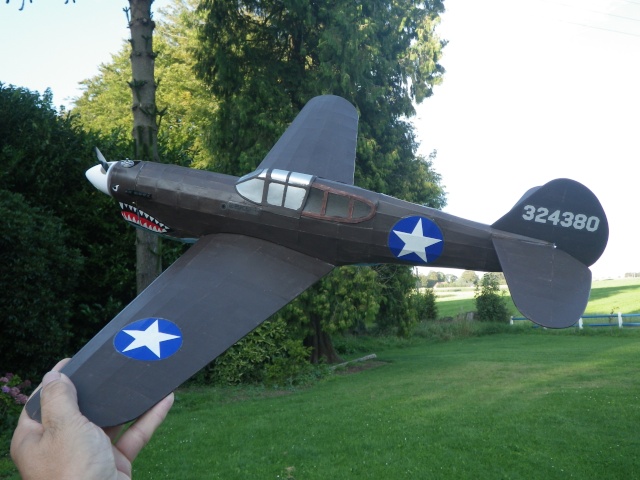

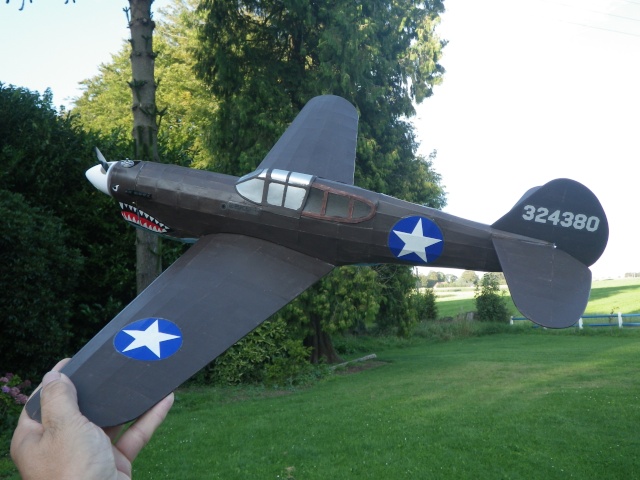

The P40 is as good as finished. I glued on the canopy, the exhaust stacks and put the decals on. I took some pics before fuel proofing.

Things that still need doing:

- add a fuel filling tube

- make a drain hole on the cowl

- reinforce the spinner's back plate to prevent wobbling. A reinforcement device, custom built by Roddie is on its way.

- fit a 5x2 prop and experimenting

- balancing

- flying

Does it look mean?

Lieven

Things that still need doing:

- add a fuel filling tube

- make a drain hole on the cowl

- reinforce the spinner's back plate to prevent wobbling. A reinforcement device, custom built by Roddie is on its way.

- fit a 5x2 prop and experimenting

- balancing

- flying

Does it look mean?

Lieven

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Page 3 of 5 •  1, 2, 3, 4, 5

1, 2, 3, 4, 5

Similar topics

Similar topics» guillows, curtiss p-40 warhawk free flight

» Guillows Cessna 150 build circa 1970 (Build Log)

» Another Li'l Satan build (Finished)

» Guillows Spitfire park flyer FINISHED!!!!!!!!!!!!

» Guillows Cessna build advice needed

» Guillows Cessna 150 build circa 1970 (Build Log)

» Another Li'l Satan build (Finished)

» Guillows Spitfire park flyer FINISHED!!!!!!!!!!!!

» Guillows Cessna build advice needed

Page 3 of 5

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules