Log in

Search

Latest topics

» Roger Harris revisitedby TD ABUSER Today at 2:30 am

» My latest doodle...

by batjac Yesterday at 10:05 pm

» Retail price mark-up.. how much is enough?

by gkamysz Yesterday at 9:29 pm

» Happy 77th birthday Andrew!

by roddie Yesterday at 9:22 pm

» My N-1R build log

by GallopingGhostler Yesterday at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Yesterday at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Yesterday at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Yesterday at 11:32 am

» Free Flight Radio Assist

by rdw777 Yesterday at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

3D Printing

Page 4 of 4

Page 4 of 4 •  1, 2, 3, 4

1, 2, 3, 4

Re: 3D Printing

Re: 3D Printing

Hi Ian ,

Thanks for info. good to know its fuel proof. I'm thinking of experiment with own design horse shoe type backplate using 3d printer. Don't know if it works but I'll try to print one once I finished building my 3d printer.

ew

Thanks for info. good to know its fuel proof. I'm thinking of experiment with own design horse shoe type backplate using 3d printer. Don't know if it works but I'll try to print one once I finished building my 3d printer.

ew

tru168- Gold Member

- Posts : 277

Join date : 2012-11-03

Location : Johor, Malaysia

Re: 3D Printing

Re: 3D Printing

pkrankow wrote:The battery hanging off the bottom is not going to be helpful for stunt. It is shifting the CG low. Otherwise looks good.

Phil

If I can make one circuit without a prang - I will be pleased.

However, I have more planes lined up and perhaps I'll put more thought into the build for positioning the battery.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: 3D Printing

Re: 3D Printing

Hi Ian, Have you considered trying to print bell-cranks/bearings and/or control-horns/backing plates? Is the ABS rigid enough to handle the loads placed on these parts? Servo-trays would also be a cool part to make.

Roddie

Roddie

Re: 3D Printing

Re: 3D Printing

roddie wrote:Hi Ian, Have you considered trying to print bell-cranks/bearings and/or control-horns/backing plates? Is the ABS rigid enough to handle the loads placed on these parts? Servo-trays would also be a cool part to make.

Roddie

I have looked at this and have started the drawings. The problem I have is that small finely detailed parts do not come out too well with the 0.5mm nozzle I use.

All the models I have made recently have been kits. All the bits have been supplied , so I haven't needed to make these.

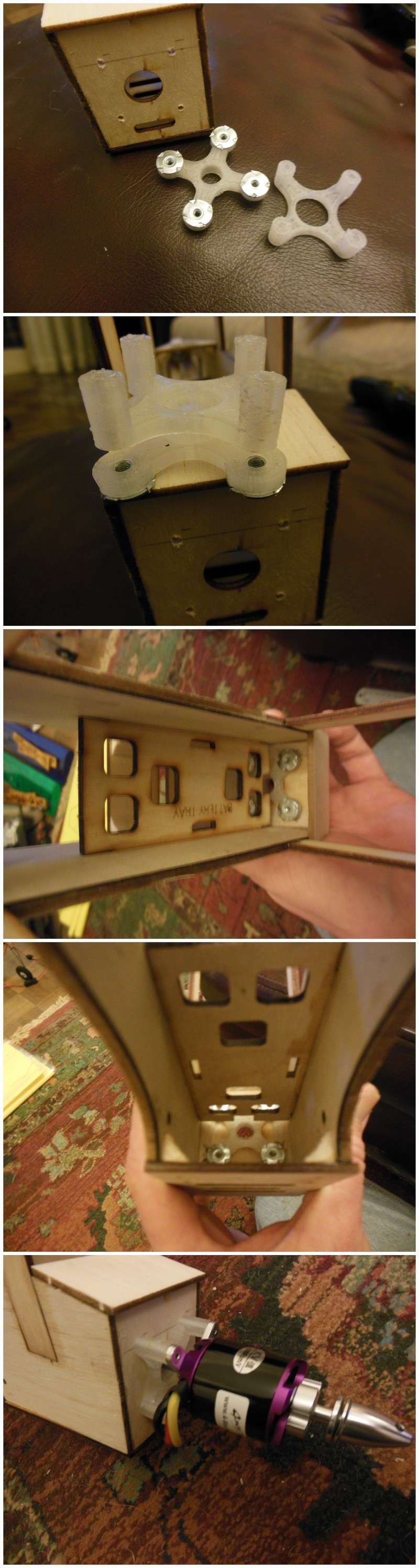

The Jive that I am just finishing off was meant for a .36 or .39 motor. That is why I designed the mount. The kit came with adjustable engine bearers so the mount was designed to use the same mountings. This is the largest model I have now - I'm hoping to use it as a slow Park Flyer ( I am have trouble with my eyes and the smaller models I have.)

That is why I am also venturing into control line again. I might not be able to see it but I will know where it is as long as I don't let go!

If you have a "special" bellcrank - unusual size or shape- send me a drawing and I will produce a 3d image for you to check and then print it.

Here is the Jive with my test mount - if you look closely you will see the wings of my mystery biplane being dwarfed by it!

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: 3D Printing

Re: 3D Printing

ian1954 wrote:roddie wrote:Hi Ian, Have you considered trying to print bell-cranks/bearings and/or control-horns/backing plates? Is the ABS rigid enough to handle the loads placed on these parts? Servo-trays would also be a cool part to make.

Roddie

I have looked at this and have started the drawings. The problem I have is that small finely detailed parts do not come out too well with the 0.5mm nozzle I use.

All the models I have made recently have been kits. All the bits have been supplied , so I haven't needed to make these.

The Jive that I am just finishing off was meant for a .36 or .39 motor. That is why I designed the mount. The kit came with adjustable engine bearers so the mount was designed to use the same mountings. This is the largest model I have now - I'm hoping to use it as a slow Park Flyer ( I am have trouble with my eyes and the smaller models I have.)

That is why I am also venturing into control line again. I might not be able to see it but I will know where it is as long as I don't let go!

If you have a "special" bellcrank - unusual size or shape- send me a drawing and I will produce a 3d image for you to check and then print it.

Here is the Jive with my test mount - if you look closely you will see the wings of my mystery biplane being dwarfed by it!

The Jive is pretty cool Ian! Everything you build is cool!

Roddie

Re: 3D Printing

Re: 3D Printing

ian1954 wrote:pkrankow wrote:The battery hanging off the bottom is not going to be helpful for stunt. It is shifting the CG low. Otherwise looks good.

Phil

If I can make one circuit without a prang - I will be pleased.

However, I have more planes lined up and perhaps I'll put more thought into the build for positioning the battery.

Should be little bother to make a new design and move the battery as your flying ability improves. Just run with it the way it is now. When you start getting into more stunt than inverted and inside loops you will need to trim better.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: 3D Printing

Re: 3D Printing

Print this RC plane : http://www.thingiverse.com/thing:56147

don't know if its suitable for a little cox engine? no further info provided, don't know its AUW.

don't know if its suitable for a little cox engine? no further info provided, don't know its AUW.

tru168- Gold Member

- Posts : 277

Join date : 2012-11-03

Location : Johor, Malaysia

Re: 3D Printing

Re: 3D Printing

tru168 wrote:Print this RC plane : http://www.thingiverse.com/thing:56147

don't know if its suitable for a little cox engine? no further info provided, don't know its AUW.

I had a good look at this and then printed a taiplane for a kit that I am building. Unfortunately, although it turned out well, it was 3 times the weight of a balsa equivalent. I think weight will be a consideration and the plastic is quite brittle when printed thinly.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: 3D Printing

Re: 3D Printing

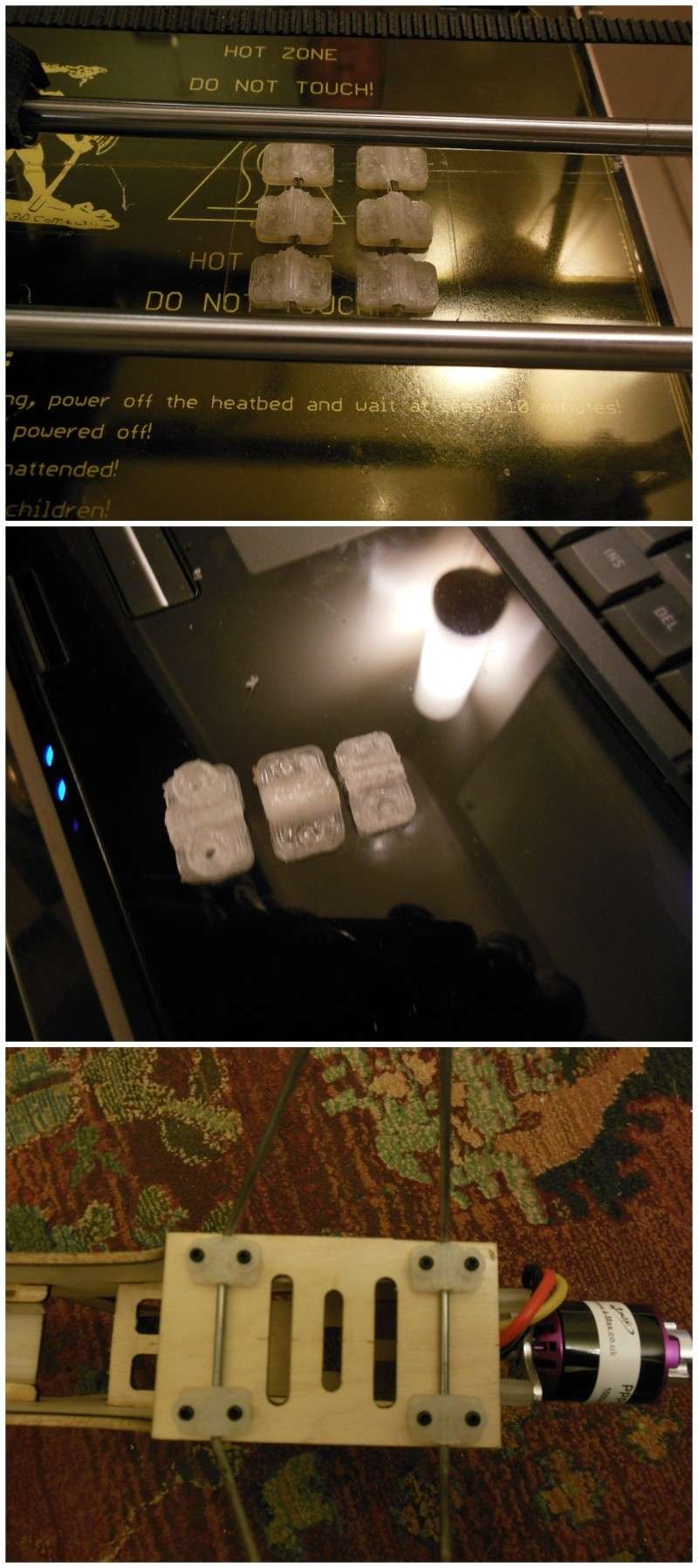

More plastic parts - this time I tried under carriage straps. Several modifications before I got the ones I wanted.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: 3D Printing

Re: 3D Printing

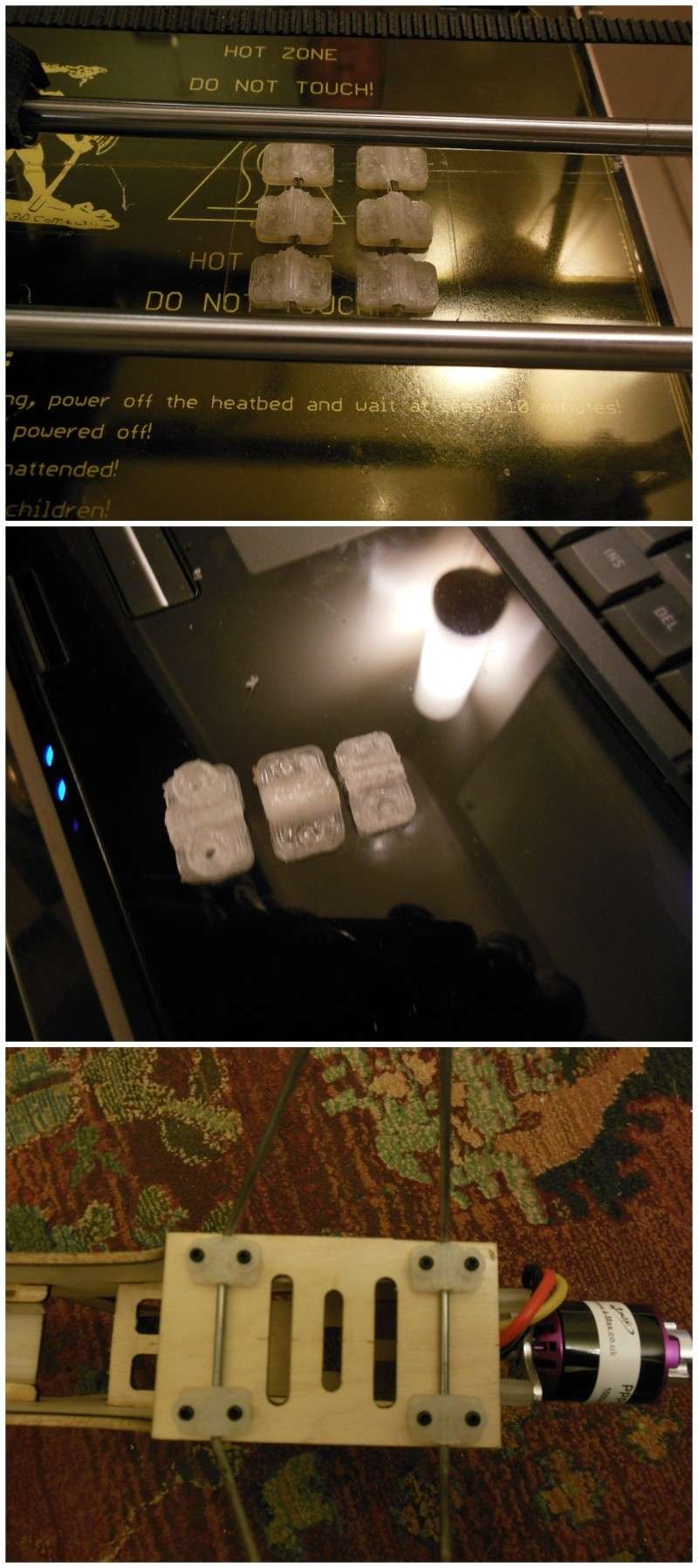

This time - a motor mount. Two part to make a sandwich around the firewall.

I will redo the outer mount when the model is finished to get the balance right.

I will redo the outer mount when the model is finished to get the balance right.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: 3D Printing

Re: 3D Printing

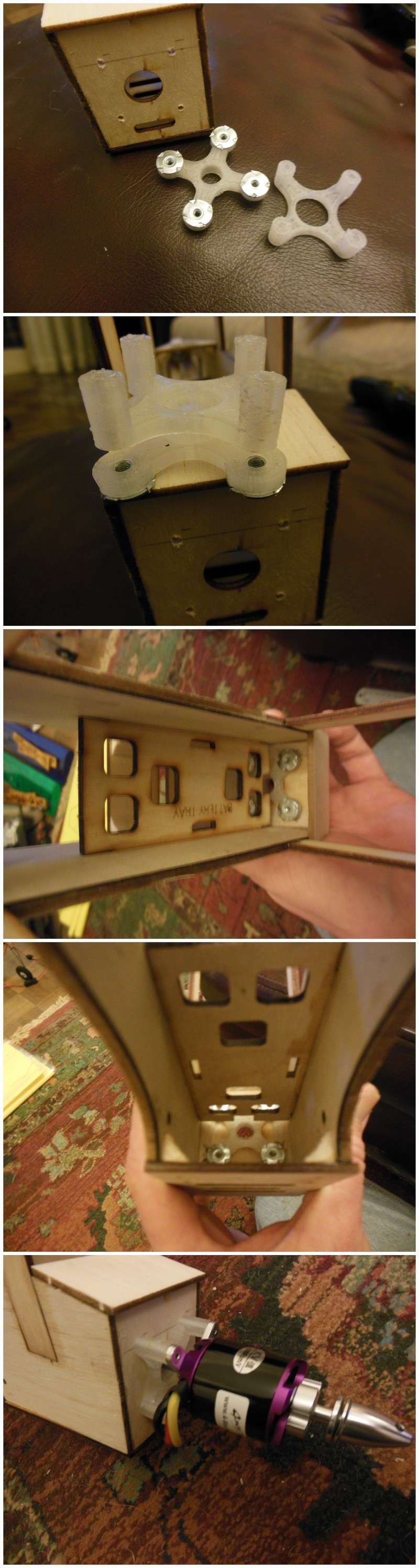

The Roddiemeter is now making good progress. I have changed a few parts and now thinking about various engine, tank, battery and ESC mounts.

This plastic printing certainly makes builds like these easy.

This plastic printing certainly makes builds like these easy.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: 3D Printing

Re: 3D Printing

[/quote]

I had a good look at this and then printed a taiplane for a kit that I am building. Unfortunately, although it turned out well, it was 3 times the weight of a balsa equivalent. I think weight will be a consideration and the plastic is quite brittle when printed thinly.[/quote]

The creator just edited info, the printed wing weights 12.7oz alone. It's not a sailplane anymore.

Anyway, some successful example in thingiverse, who create larger size trainer , and some only print out ribs and cover with traditional covering film.

tru168- Gold Member

- Posts : 277

Join date : 2012-11-03

Location : Johor, Malaysia

Re: 3D Printing

Re: 3D Printing

Ian, some questions after reading your O-ring wheels thread...

Jason asked if you had the "STL" for the wheels... I'm assuming that's a file extension similar to a .plt (plot file) i.e. "editable" shape outline... but in 3-D? When I made parts on a CNC router table, a .plt file was created (Gerber "Artpath" software) to draw/resize the design.. and an .rtp file extension contained generated male/female toolpath offsets, speeds/feeds, depths etc. for output to the machine, for actual cutting. Other than deleting, repositioning or "re-nesting" the shapes; an .rtp file's outlines could not be resized. I used to keep separate folders for both; .plt and .rtp files, saved for future use. The .rtp files were naturally larger than the .plt files.. (containing the same outlines)

I would think that 3-D "print" files may be quite large to "save" too many of them.. depending on the outlines' geometry? Do you use an external hard-drive to save your files? I have 3, which have been great for extra file storage. I have x2 320GB drives and one 1000GB drive. A 3 TB (3000 gig..) ext. hard drive is currently about $100.00 through Amazon.

I was just curious of the file size of the O-ring wheel(s)... when you output (spool?) the job to your printer?

Thanks,

Roddie

Jason asked if you had the "STL" for the wheels... I'm assuming that's a file extension similar to a .plt (plot file) i.e. "editable" shape outline... but in 3-D? When I made parts on a CNC router table, a .plt file was created (Gerber "Artpath" software) to draw/resize the design.. and an .rtp file extension contained generated male/female toolpath offsets, speeds/feeds, depths etc. for output to the machine, for actual cutting. Other than deleting, repositioning or "re-nesting" the shapes; an .rtp file's outlines could not be resized. I used to keep separate folders for both; .plt and .rtp files, saved for future use. The .rtp files were naturally larger than the .plt files.. (containing the same outlines)

I would think that 3-D "print" files may be quite large to "save" too many of them.. depending on the outlines' geometry? Do you use an external hard-drive to save your files? I have 3, which have been great for extra file storage. I have x2 320GB drives and one 1000GB drive. A 3 TB (3000 gig..) ext. hard drive is currently about $100.00 through Amazon.

I was just curious of the file size of the O-ring wheel(s)... when you output (spool?) the job to your printer?

Thanks,

Roddie

Re: 3D Printing

Re: 3D Printing

roddie wrote:Ian, some questions after reading your O-ring wheels thread...

Jason asked if you had the "STL" for the wheels... I'm assuming that's a file extension similar to a .plt (plot file) i.e. "editable" shape outline... but in 3-D? When I made parts on a CNC router table, a .plt file was created (Gerber "Artpath" software) to draw/resize the design.. and an .rtp file extension contained generated male/female toolpath offsets, speeds/feeds, depths etc. for output to the machine, for actual cutting. Other than deleting, repositioning or "re-nesting" the shapes; an .rtp file's outlines could not be resized. I used to keep separate folders for both; .plt and .rtp files, saved for future use. The .rtp files were naturally larger than the .plt files.. (containing the same outlines)

I would think that 3-D "print" files may be quite large to "save" too many of them.. depending on the outlines' geometry? Do you use an external hard-drive to save your files? I have 3, which have been great for extra file storage. I have x2 320GB drives and one 1000GB drive. A 3 TB (3000 gig..) ext. hard drive is currently about $100.00 through Amazon.

I was just curious of the file size of the O-ring wheel(s)... when you output (spool?) the job to your printer?

Thanks,

Roddie

I cannot resist this:-

STL (STereoLithography) is a file format native to the stereolithography CAD software created by 3D Systems. STL is also known as Standard Tessellation Language. This file format is supported by many other software packages; it is widely used for rapid prototyping and computer-aided manufacturing. STL files describe only the surface geometry of a three dimensional object without any representation of color, texture or other common CAD model attributes. The STL format specifies both ASCII and binary representations. Binary files are more common, since they are more compact.

An STL file describes a raw unstructured triangulated surface by the unit normal and vertices (ordered by the right-hand rule) of the triangles using a three-dimensional Cartesian coordinate system. STL coordinates must be positive numbers, there is no scale information, and the units are arbitrary.

Impressed?

None of the files produced are large.

I start using Alibre, a very nice but expensive CAD package. The part file it produces is only 438KB for this wheel. I can edit and re edit this as much as I like. When I am happy with it - I use Alibre to create the STL file. For this wheel - 1936KB.

I then load the STL file into a package called Repetier (free!). Repetier takes the STL file and allows you to place a 3D image of the part on the printing table. Move it around, duplicate it and even add other parts to be printed at the same time. I printed 4 wheels and 4 control horns together.

When you are happy with the position on the table - Repetier then executes another piece of software (also free!) called Slic3r. It takes the images and slices them into layers. My printer is set for layers of 0.2mm. It then creates the G code to move the printer head and squirt hot plastic - one layer at a time.

I do not save the G code - it is produced for that print and I may not want to print those parts in those numbers again. Slic3R creates the code in a couple of minutes anyway.

Repetier then executes the G code commands and sends them to the printer. I could also load the G code on the printer using an SD card and run it directly from the printer.

I can also create a 3D PDF file from the original - that is 224 kb. PM me your email address and I will send you a copy.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: 3D Printing

Re: 3D Printing

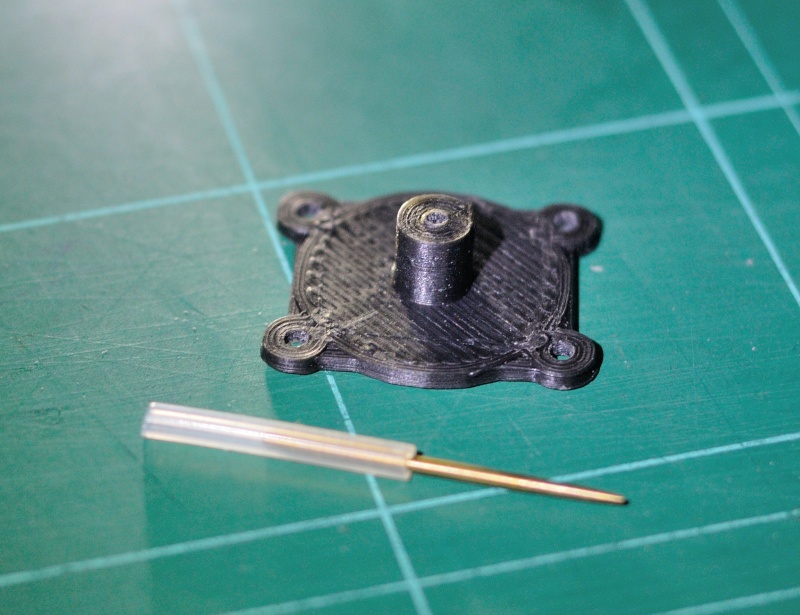

Just printed Ace style needle throttle for Babe bee . I will optimised it and make another one for my Pee Wee 020 . Don't know if PLA material can withstand the heat with metal back plate from Pee Wee, I've heard about Pee Wee fuel tank overheat problem.

tru168- Gold Member

- Posts : 277

Join date : 2012-11-03

Location : Johor, Malaysia

Re: 3D Printing

Re: 3D Printing

Insert a set of washers on the mounting lugs to provide space between the throttle and the back plate, as well as limit heat transfer. The rigidity of the system should tolerate an extra mm or so of space just fine.

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: 3D Printing

Re: 3D Printing

tru168 wrote:

Just printed Ace style needle throttle for Babe bee . I will optimised it and make another one for my Pee Wee 020 . Don't know if PLA material can withstand the heat with metal back plate from Pee Wee, I've heard about Pee Wee fuel tank overheat problem.

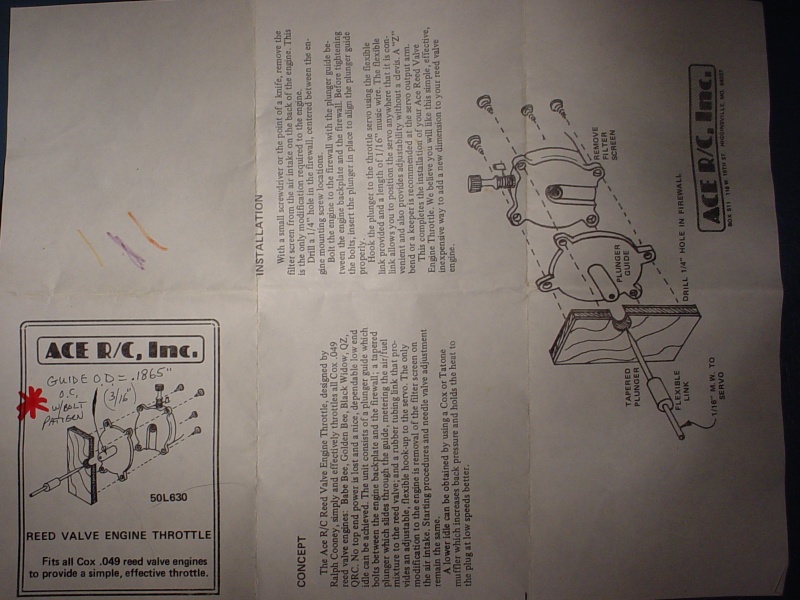

That looks great! I have experience with this "Ace" throttle on the Cox Babe Bee... and I really like it. You can make your own needles (plungers...) for the "Bee" engines, from .062" dia. music wire. I made several by cutting 1.25" lengths of wire.. then "chucking" in a drill-press and use a Dremel-tool with a "smooth-side" type cut-off wheel.. to grind a taper about 3/8" long on one end.

I have always ran this throttle design with a muffler (as recommended.. but of my own design) on my Bee's... and used 6 x 3 prop and Sig Champion "25" fuel.

Thought I'd include a photo of the instructions, for those unfamiliar with this very cool throttle design.

Roddie

Re: 3D Printing

Re: 3D Printing

That looks good.

Only thing to watch, as you seem to be aware, is that PLA softens at 60 deg C - ABS around 100 deg C.

However, PLA is harder (more rigid) than ABS.

Only thing to watch, as you seem to be aware, is that PLA softens at 60 deg C - ABS around 100 deg C.

However, PLA is harder (more rigid) than ABS.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: 3D Printing

Re: 3D Printing

Inspired by Roddie's previous test with good result, I wish my little Pee Wee can be throttle too. Yeah, good idea, a couple of washers might help to reduce heat transfer.

I will try to print one using ABS for my Pee Wee, but believe it or not, my Ormerod 3D printer can't print ABS, its more expensive than Prusa i3, but only for PLA. Supplied power unit will sag to 10.8V ( from 12.04v) when heated bed is on, it can climbed to 90 degree C max on heated bed, but never reach 110 C for ABS. Try better power supply , increase temperature and my print head assembly melted !

Need to restore my Prusa i3 for the job.

A lot of small parts for RC come in my mind now, will try to print them out and have some fun.

I will try to print one using ABS for my Pee Wee, but believe it or not, my Ormerod 3D printer can't print ABS, its more expensive than Prusa i3, but only for PLA. Supplied power unit will sag to 10.8V ( from 12.04v) when heated bed is on, it can climbed to 90 degree C max on heated bed, but never reach 110 C for ABS. Try better power supply , increase temperature and my print head assembly melted !

Need to restore my Prusa i3 for the job.

A lot of small parts for RC come in my mind now, will try to print them out and have some fun.

tru168- Gold Member

- Posts : 277

Join date : 2012-11-03

Location : Johor, Malaysia

Re: 3D Printing

Re: 3D Printing

tru168 wrote: Inspired by Roddie's previous test with good result, I wish my little Pee Wee can be throttle too. Yeah, good idea, a couple of washers might help to reduce heat transfer.

I will try to print one using ABS for my Pee Wee, but believe it or not, my Ormerod 3D printer can't print ABS, its more expensive than Prusa i3, but only for PLA. Supplied power unit will sag to 10.8V ( from 12.04v) when heated bed is on, it can climbed to 90 degree C max on heated bed, but never reach 110 C for ABS. Try better power supply , increase temperature and my print head assembly melted !

Need to restore my Prusa i3 for the job.

A lot of small parts for RC come in my mind now, will try to print them out and have some fun.

PM sent... regarding the Pee Wee .020

Re: 3D Printing

Re: 3D Printing

Hi Roddie,

Don't mind send PM again? I checked inbox but can't see any message.

Thanks

Ew

Don't mind send PM again? I checked inbox but can't see any message.

Thanks

Ew

tru168- Gold Member

- Posts : 277

Join date : 2012-11-03

Location : Johor, Malaysia

Page 4 of 4 •  1, 2, 3, 4

1, 2, 3, 4

Similar topics

Similar topics» PT-19 3D printing

» Printing on Tissue

» Printing out .pdf plans to scale

» 3D printing nonstop

» Todays Cox 3D Printing Adventures....

» Printing on Tissue

» Printing out .pdf plans to scale

» 3D printing nonstop

» Todays Cox 3D Printing Adventures....

Page 4 of 4

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules