Log in

Search

Latest topics

» My latest doodle...by batjac Yesterday at 10:05 pm

» Retail price mark-up.. how much is enough?

by gkamysz Yesterday at 9:29 pm

» Happy 77th birthday Andrew!

by roddie Yesterday at 9:22 pm

» Roger Harris revisited

by rsv1cox Yesterday at 3:38 pm

» My N-1R build log

by GallopingGhostler Yesterday at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Yesterday at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Yesterday at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Yesterday at 11:32 am

» Free Flight Radio Assist

by rdw777 Yesterday at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

PEE WEE help?

Page 2 of 2

Page 2 of 2 •  1, 2

1, 2

Re: PEE WEE help?

Re: PEE WEE help?

weell, if its pushing istead of pulling, the the drive plate might scrub against the crank case. no big deal.shell shock wrote:@nitroairplane:

That would explain the smaller size XP

@Cz10:

I have read that too. I just think its a cool add on

@GermanBeez

Would pinching the fuel line cause damage to the engine instead of throwing a towel on it? also, no damage can come from running the engine backwards is there?

Also, i have a .020 spring and a few other things en rout

GermanBeez- Platinum Member

- Posts : 1167

Join date : 2011-06-15

Location : Bavaria, Germany

Re: PEE WEE help?

Re: PEE WEE help?

GermanBeez wrote:weell, if its pushing istead of pulling, the the drive plate might scrub against the crank case. no big deal.shell shock wrote:@nitroairplane:

That would explain the smaller size XP

@Cz10:

I have read that too. I just think its a cool add on

@GermanBeez

Would pinching the fuel line cause damage to the engine instead of throwing a towel on it? also, no damage can come from running the engine backwards is there?

Also, i have a .020 spring and a few other things en rout

if the engine has been run clock wise it is best to keep it running that way or it will wear more on the other side.

Re: PEE WEE help?

Re: PEE WEE help?

If you are trying to stop a engine that is running without tossing a rag in it or closing the needle, just place your fingers over the backplate fuel vents and hold them there until it stops. I have been told that it could flood the engine but I have never had any issues with it before.

Re: PEE WEE help?

Re: PEE WEE help?

Admin wrote:If you are trying to stop a engine that is running without tossing a rag in it or closing the needle, just place your fingers over the backplate fuel vents and hold them there until it stops. I have been told that it could flood the engine but I have never had any issues with it before.

that wouldnt flood the engine because you create a vacuum and the fuel will not flow into the engine i have only flooded engines by restricting the airflow but event hen only when running very rich.

Re: PEE WEE help?

Re: PEE WEE help?

SuperDave wrote:If anyone is interested a have OEM .049 snap starter for CCW rotation. It was mistakenly purchased by a friend and then passed on to me.

Their most common application is in twin-engine planes where two engine running in the same direction creates torque problems.

I think I have one of those too.

Re: PEE WEE help?

Re: PEE WEE help?

Admin wrote:If you are trying to stop a engine that is running without tossing a rag in it or closing the needle, just place your fingers over the backplate fuel vents and hold them there until it stops. I have been told that it could flood the engine but I have never had any issues with it before.

At one time the Cox instruction sheets said to gasp the spinner to stop the engine. At SMALL a few years ago I did just that in the pits while prepping/tuning an .010 plane prior to flight. I pretended not to hear the comments of the old pros sitting nearby discussing how stupid and dangerous this was.

Anyone else have a copy of those early instruction sheets?

Al

Big Al- Gold Member

- Posts : 116

Join date : 2011-08-17

Age : 91

Location : Louisiana

Re: PEE WEE help?

Re: PEE WEE help?

Big Al wrote:Admin wrote:If you are trying to stop a engine that is running without tossing a rag in it or closing the needle, just place your fingers over the backplate fuel vents and hold them there until it stops. I have been told that it could flood the engine but I have never had any issues with it before.

At one time the Cox instruction sheets said to gasp the spinner to stop the engine. At SMALL a few years ago I did just that in the pits while prepping/tuning an .010 plane prior to flight. I pretended not to hear the comments of the old pros sitting nearby discussing how stupid and dangerous this was.

Anyone else have a copy of those early instruction sheets?

Al

I have 1965 set of .010 instruction sheets I can check them later.

Re: PEE WEE help?

Re: PEE WEE help?

You can check my instruction sheets page http://sites.google.com/site/coxenginecollection/ . I do remember reading that somewhere. I have tried it with a black widow and with your bare fingers, it starts to hurt (especially if the spinner screw is beaten up and has metal burrs sticking out...).

I have stopped a Babe Bee with my glow head clip wires before (not on purpose...)! I also whipped a chicken stick over the back porch with a TD .051 (not on purpose again) it did not stop the engine so I have no idea why i'm sharing this

(not on purpose...)! I also whipped a chicken stick over the back porch with a TD .051 (not on purpose again) it did not stop the engine so I have no idea why i'm sharing this  .

.

I have stopped a Babe Bee with my glow head clip wires before

(not on purpose...)! I also whipped a chicken stick over the back porch with a TD .051 (not on purpose again) it did not stop the engine so I have no idea why i'm sharing this

(not on purpose...)! I also whipped a chicken stick over the back porch with a TD .051 (not on purpose again) it did not stop the engine so I have no idea why i'm sharing this  Re: PEE WEE help?

Re: PEE WEE help?

SuperDave wrote:If used, the engine MAY have enlarged mounting lugs to accomodate more common screw sizes. Better check and see before you buy screws. DON"T ream out the holes to a larger size than you have!

IIRC, size #52 is standard for the .020.

Totally agree with Dave on NEVER EVER enlarging the mounting holes on any of these engines. I think though that #2 socket screws from these folks will work: http://www.microfasteners.com/ .

Please be extra sure that you copy the hole pattern as precisely as possible so that you're not binding the lugs against each other as you tighten the screws.

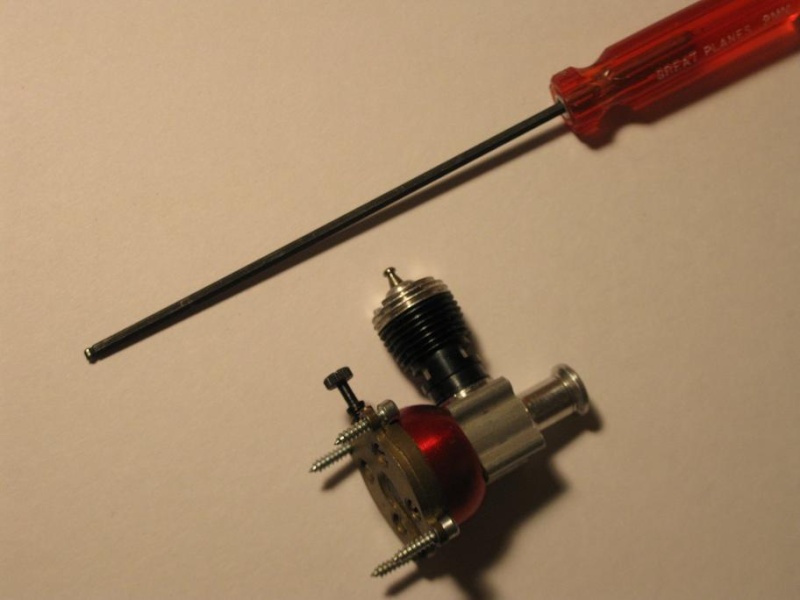

I tried some #2 self tapping socket screws in this new .020, and they seemed to work just fine...with just enough "allowance slop". Also, after a few decades of scratching tanks and stabbing airplanes with flat screwdrivers, I discovered socket screws and balldrivers, and never looked back. I now use these things on everything I bolt down. They are WELL worth the price of converting your hardware collection. Micro Fasterners has a directory table that lets you order the proper size driver to go with the socket screws you order.

Kim- Top Poster

Posts : 8625

Join date : 2011-09-06

Location : South East Missouri

Re: PEE WEE help?

Re: PEE WEE help?

yah, when i took the .049 to the local hobby shop, they all had fond memories and warm stories of these little beasts (and the scars to prove em).

shell shock- Gold Member

- Posts : 401

Join date : 2011-10-05

Age : 32

Location : Mississauga Ontario, Canada

Re: PEE WEE help?

Re: PEE WEE help?

Regarding "ball-head" drivers, be sure to NOT "torque" on them excessively as the head will snap of and leave with a hex head only.

"Over-torqing" often happens when the hole for the fastener is too small causing an over-tight fit.

"Over-torqing" often happens when the hole for the fastener is too small causing an over-tight fit.

SuperDave- Rest In Peace

- Posts : 3552

Join date : 2011-08-13

Location : Washington (state)

Re: PEE WEE help?

Re: PEE WEE help?

I THINK I remember Cox recommending putting pressure on the spinner. It was probably back in the Space Bug, Thermal Hopper, Space Bug Junior days when the prop was held on by an Acorn nut. These were smooth and would not injure your fingers.

Those instructions were probably dropped when Cox went to the screw instead of the nut.

If you prefer the Acorn nut, Cox International sells acorn nuts that will fit the old engines, and also includes a screw that makes it work with newer engines. I got a few of those for my Space Bug Juniors.

George

Those instructions were probably dropped when Cox went to the screw instead of the nut.

If you prefer the Acorn nut, Cox International sells acorn nuts that will fit the old engines, and also includes a screw that makes it work with newer engines. I got a few of those for my Space Bug Juniors.

George

gcb- Platinum Member

- Posts : 908

Join date : 2011-08-11

Location : Port Ewen, NY

Re: PEE WEE help?

Re: PEE WEE help?

Kim wrote:

I tried some #2 self tapping socket screws in this new .020, and they seemed to work just fine...with just enough "allowance slop". Also, after a few decades of scratching tanks and stabbing airplanes with flat screwdrivers, I discovered socket screws and balldrivers, and never looked back. I now use these things on everything I bolt down.

Same here. I use socket head screws in every location possible and replace slotted screws on engines with equivalent socket heads. It's so much easier to put the screw on a long allen wrench and get it started in a hard to reach place. Some of the slotted screws today are so soft or the slot is so shallow that it's easy to bugger up the head.

One screw that always get replaced immediately is the prop screw on COX .049 --- screw size is 5-40. Normally I bulk buy long fully threaded screws, then cut them to length using a Dremel cutoff wheel. That way, I don't need to keep a lot of different lengths on hand.

I generally buy from McMaster-Carr, but if they don't carry what I need, I also use Microfasteners. Two other supplies of bulk screws are Fastener Express and RTL Fasteners.

Re: PEE WEE help?

Re: PEE WEE help?

this is all good news. and with the angine arriving any day now, perfect time as well. i cant wait to finish my build tonight (minus electronics and engine) and then mount the engine to the body. my poor .049 might feel abit left out for a while ^_^

shell shock- Gold Member

- Posts : 401

Join date : 2011-10-05

Age : 32

Location : Mississauga Ontario, Canada

Re: PEE WEE help?

Re: PEE WEE help?

Although it is just a guess, I always thought Cox switched to a prop screw to replace the threaded shaft when the Babe Bee came out because so many beginners were bending the prop shaft when crashing...especially if flying their plane over concrete. I have one Space Bug Junior with a slightly bent crankshaft. Still usable though.

If that is true, switching to a stronger screw can defeat the "save the crankshaft" idea. For experienced folks it makes sense, for those who still frequently crash, perhaps not. Your choice.

I have some of each. To avoid trouble in that area, I always make sure I have only the correct size screwdriver in my flight kit. Other screwdrivers stay with the repair stuff.

George

If that is true, switching to a stronger screw can defeat the "save the crankshaft" idea. For experienced folks it makes sense, for those who still frequently crash, perhaps not. Your choice.

I have some of each. To avoid trouble in that area, I always make sure I have only the correct size screwdriver in my flight kit. Other screwdrivers stay with the repair stuff.

George

gcb- Platinum Member

- Posts : 908

Join date : 2011-08-11

Location : Port Ewen, NY

Re: PEE WEE help?

Re: PEE WEE help?

Kim wrote:SuperDave wrote:If used, the engine MAY have enlarged mounting lugs to accomodate more common screw sizes. Better check and see before you buy screws. DON"T ream out the holes to a larger size than you have!

IIRC, size #52 is standard for the .020.

Totally agree with Dave on NEVER EVER enlarging the mounting holes on any of these engines. I think though that #2 socket screws from these folks will work: http://www.microfasteners.com/ .

Please be extra sure that you copy the hole pattern as precisely as possible so that you're not binding the lugs against each other as you tighten the screws.

I tried some #2 self tapping socket screws in this new .020, and they seemed to work just fine...with just enough "allowance slop". Also, after a few decades of scratching tanks and stabbing airplanes with flat screwdrivers, I discovered socket screws and balldrivers, and never looked back. I now use these things on everything I bolt down. They are WELL worth the price of converting your hardware collection. Micro Fasterners has a directory table that lets you order the proper size driver to go with the socket screws you order.

Oh that is what you call a socket i call that an ALLEN KEY.

Re: PEE WEE help?

Re: PEE WEE help?

nitroairplane wrote:[Oh that is what you call a socket i call that an ALLEN KEY.

derp, how did i not see that?

shell shock- Gold Member

- Posts : 401

Join date : 2011-10-05

Age : 32

Location : Mississauga Ontario, Canada

Re: PEE WEE help?

Re: PEE WEE help?

well guys.. the night ended on a bitter sweet note. I finally got the lil .020! woo what a beauty of an engine. Some minor scratches and stuff, but meh. Bad news is, all the seals and tubes are dead and dried up. I have ordered the Coxinternational 3.--$ rebuild kit. hope to have her running by the time im done my p 51

shell shock- Gold Member

- Posts : 401

Join date : 2011-10-05

Age : 32

Location : Mississauga Ontario, Canada

Re: PEE WEE help?

Re: PEE WEE help?

Closely exmine the very TIP of a ball-driver and you'll find that it has a rounded end (unlike a conventional Allen wrench) allowing a fastener to be driven from an angle. Very useful in close places where a slipping screwdriver could cause engine and plane damage.

I have set of five ball-drivers and use them often enough to justifiy their cost.

I have set of five ball-drivers and use them often enough to justifiy their cost.

SuperDave- Rest In Peace

- Posts : 3552

Join date : 2011-08-13

Location : Washington (state)

Re: PEE WEE help?

Re: PEE WEE help?

Yep, they're worth every penny!

You can swap out a engine in the field or shop in 1/10th the time, and not scratch or damage anything in the process.

If your ball driver gets pretty worn out, grab the Dremel and a thin cutting disc, cut the 'ball' off and on low speed carefully cut a new groove the same height as before!

Mark

You can swap out a engine in the field or shop in 1/10th the time, and not scratch or damage anything in the process.

If your ball driver gets pretty worn out, grab the Dremel and a thin cutting disc, cut the 'ball' off and on low speed carefully cut a new groove the same height as before!

Mark

Re: PEE WEE help?

Re: PEE WEE help?

hey thats pretty smart! any website where i can pick these up? or would a hobby shop carry em?

-Edit: never mind, just read your thread on em SuperDave. Thanks for the help

-Edit: never mind, just read your thread on em SuperDave. Thanks for the help

shell shock- Gold Member

- Posts : 401

Join date : 2011-10-05

Age : 32

Location : Mississauga Ontario, Canada

Page 2 of 2 •  1, 2

1, 2

Page 2 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules