Log in

Search

Latest topics

» Roger Harris revisitedby TD ABUSER Today at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Today at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Today at 1:37 pm

» Happy 77th birthday Andrew!

by getback Today at 11:52 am

» My latest doodle...

by roddie Today at 10:43 am

» My N-1R build log

by GallopingGhostler Yesterday at 3:04 pm

» Chocolate chip cookie dough.........

by roddie Yesterday at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Yesterday at 11:32 am

» Free Flight Radio Assist

by rdw777 Yesterday at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

Best prop for 020 engine

Page 1 of 1

sailjas- Moderate Poster

- Posts : 10

Join date : 2023-11-11

Age : 72

Location : Lake Kiowa, Texas

Re: Best prop for 020 engine

Re: Best prop for 020 engine

Sailjas, The Cox black nylon 4.5 x 2 is a good all around prop for .020….Balance it if possible…..The video of the Ace Stick I recently posted used that prop…

rdw777- Diamond Member

Posts : 1718

Join date : 2021-03-11

Location : West Texas

Re: Best prop for 020 engine

Re: Best prop for 020 engine

I used a nylon 5 x 3 for years on my 0.020's. Not maximum power but perhaps better thrust for free flight.

706jim- Gold Member

- Posts : 472

Join date : 2013-11-29

Levent Suberk- Diamond Member

- Posts : 2265

Join date : 2017-12-24

Location : Türkiye

sailjas- Moderate Poster

- Posts : 10

Join date : 2023-11-11

Age : 72

Location : Lake Kiowa, Texas

Re: Best prop for 020 engine

Re: Best prop for 020 engine

The Cox 4.5x2 factory prop mentioned by Robert is an optimal prop, puts the Pee Wee at its max HP when unloaded in the air as noted by Peter Chinn in his infamous engine reviews. Also, I believe the Cox factory 3.125x2.5 is also in the same category.

https://coxengines.ca/propellers/cox--020-propeller-3-125-x-2-5-3-blade-3.html

Optimal fuel for performance is 25% nitro, Pee Wee's love nitro and this will also keep the plugs from wearing out prematurely.

Jim mentioned the 5x3. 40 years ago, I used a similar 5.25x3 Top Flite white nylon back in the 1970's. The reed valves are torque engines. It dropped the Pee Wee's RPM a little, but my 1/4-A R/C planes flew at the same forward air speed but with reduced RPM's that extended my flight times by another minute. But since you are flying free flight, tank duration is not an issue.

Am interested in hearing about your experiences with your unusual but promising creation. We don't see much of these, and it is good to know that someone is breaking barriers here in CEF.

Your copter has some really good workmanship and an excellent finish on it.

https://coxengines.ca/propellers/cox--020-propeller-3-125-x-2-5-3-blade-3.html

Optimal fuel for performance is 25% nitro, Pee Wee's love nitro and this will also keep the plugs from wearing out prematurely.

Jim mentioned the 5x3. 40 years ago, I used a similar 5.25x3 Top Flite white nylon back in the 1970's. The reed valves are torque engines. It dropped the Pee Wee's RPM a little, but my 1/4-A R/C planes flew at the same forward air speed but with reduced RPM's that extended my flight times by another minute. But since you are flying free flight, tank duration is not an issue.

Am interested in hearing about your experiences with your unusual but promising creation. We don't see much of these, and it is good to know that someone is breaking barriers here in CEF.

Your copter has some really good workmanship and an excellent finish on it.

GallopingGhostler- Top Poster

Posts : 5724

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Best prop for 020 engine

Re: Best prop for 020 engine

Your heli looks really nice sailjas…. Kudos to you for taking that project on…. I always liked Roy Clough Jr.’s unorthodox designs…. In his build articles he always took the time to explain what he took advantage of to make them fly so well….Please let us know how your heli works out for you…

Robert

Robert

rdw777- Diamond Member

Posts : 1718

Join date : 2021-03-11

Location : West Texas

Re: Best prop for 020 engine

Re: Best prop for 020 engine

Avoid the 3-bladed 3-1/8 x 2-1/4 prop-they are HORRIBLY out of balance as supplied-and take a lot of work to get them in balance. Two more props not previously mentioned-the APC 4.2x2, and the Graupner 115x50 (nominally 4.5 x 2)-there are two variants of this latter-a narrow blade and a wider blade version-the thin one really turns up on a TD.

ChrisM

'ffkiwi'

ChrisM

'ffkiwi'

ffkiwi- Gold Member

- Posts : 398

Join date : 2018-07-10

Location : Wellington, NZ

Re: Best prop for 020 engine

Re: Best prop for 020 engine

good point about the 3 bladed prop Chris @ffkiwi .  I had never considered the possible extra hassle to balance a 3 bladed prop. even a good one let alone ones that start off badly balanced

I had never considered the possible extra hassle to balance a 3 bladed prop. even a good one let alone ones that start off badly balanced

I had never considered the possible extra hassle to balance a 3 bladed prop. even a good one let alone ones that start off badly balanced

I had never considered the possible extra hassle to balance a 3 bladed prop. even a good one let alone ones that start off badly balanced

Yabby- Platinum Member

Posts : 712

Join date : 2021-06-08

Location : Yorke Peninsula South Australia

Re: Best prop for 020 engine

Re: Best prop for 020 engine

ffkiwi wrote:Avoid the 3-bladed 3-1/8 x 2-1/4 prop-they are HORRIBLY out of balance as supplied-and take a lot of work to get them in balance. Two more props not previously mentioned-the APC 4.2x2, and the Graupner 115x50 (nominally 4.5 x 2)-there are two variants of this latter-a narrow blade and a wider blade version-the thin one really turns up on a TD.

ChrisM

'ffkiwi'

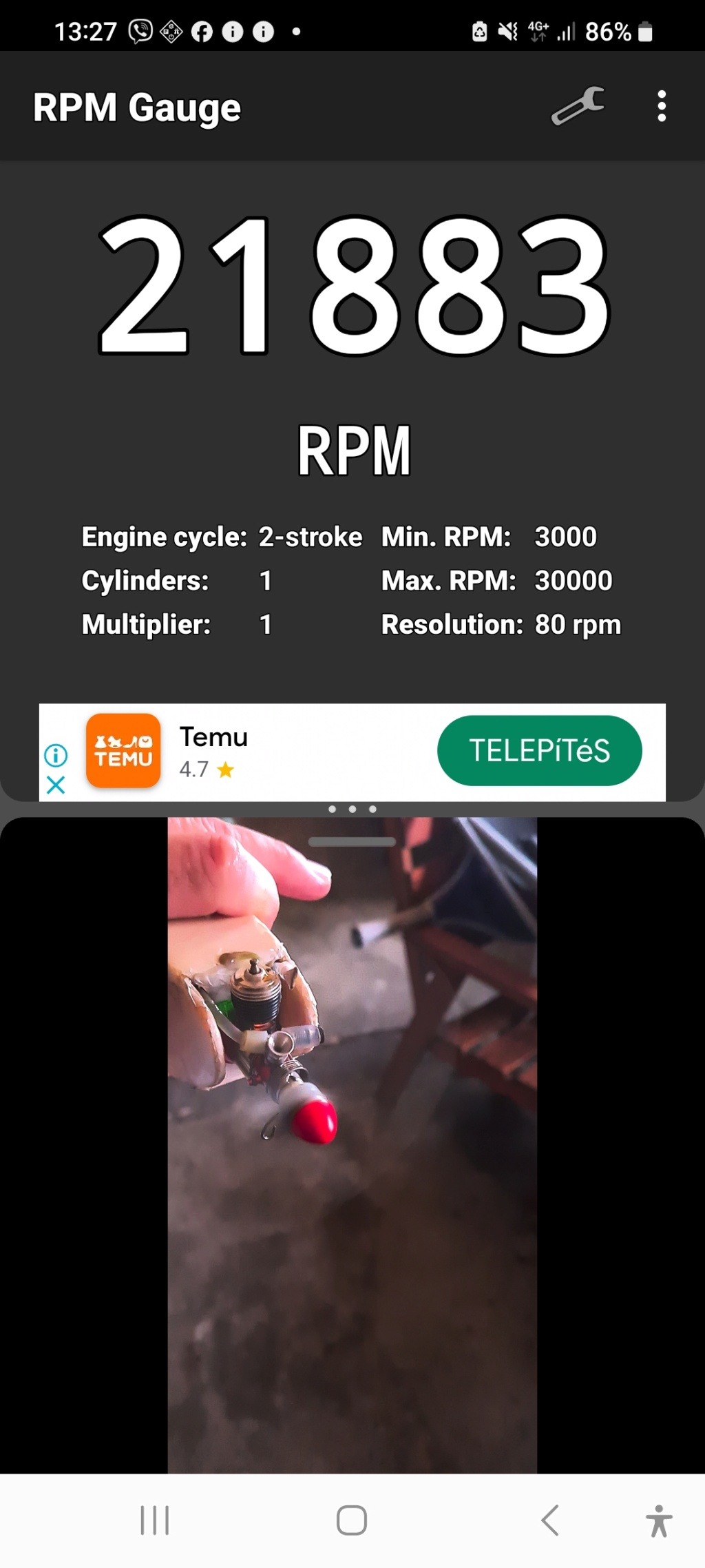

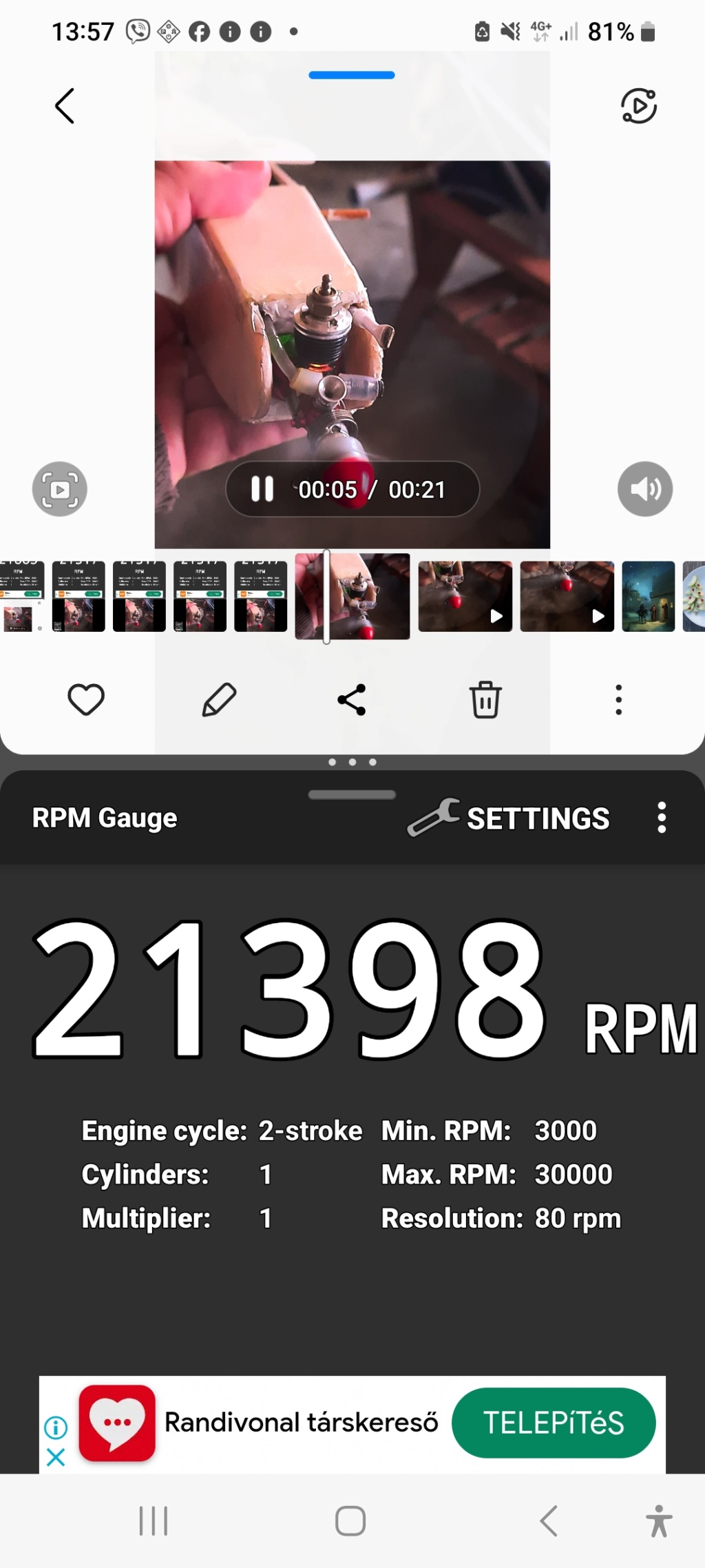

Hello Chris, just got an APC 4.2×2 as an extra gift in a hobbyshop and want to try that on my TeeDee020 that so far worked well with a well balanced COX 3 bladed one. Smaller in pitch and number of blades than the 3 bladed, can I reasonable expect the TeeDee020 to swing it at near the 22k or so rpm sweet spot of the the engine where its output peaks? The 3 bladed runs at 24k on my TeeDee020 which may be a bit beyond its peak output on the performance curve.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Best prop for 020 engine

Re: Best prop for 020 engine

Unable to resist the call for a bench test in my garage at 44F or around 7oC temperature, I tried my TeeDee020 with the APC 4.2x2 and found it smack on the peak of the engine performance curve, at near 21k rpm...with summertime air temperatures becoming thinner by 10% after a 27oC temp rise to near 32-34oC, I expect this critter to run even faster. In fact the 4.2x2 prop sees less drag and "shading" by the relatively wide firewall of my Roaring 20 than the 3-bladed COX 3.125 x 2.25, so I expect higher speeds with this prop..cannot wait to try..

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Best prop for 020 engine

Re: Best prop for 020 engine

Cox Pee Wee / 3.8x3 prop / Peak 20,833 rpm with throttle

4oz thrust / 59 mph pitch speed / .040hp - 29w

1 head shim / turbo plug adapter / 25% nitro

Sep 27, 2019

- Carbon blend horse shoe backplate

- Large bore intake

- 128 TPI Needle valve

- Tee Dee Cylinder / Piston set

- Mylar performance reed valve

- Valentine bullet spinner

- Kamtechnik Turbo Plug adapter

- OS P4 plug

4oz thrust / 59 mph pitch speed / .040hp - 29w

1 head shim / turbo plug adapter / 25% nitro

Sep 27, 2019

- Carbon blend horse shoe backplate

- Large bore intake

- 128 TPI Needle valve

- Tee Dee Cylinder / Piston set

- Mylar performance reed valve

- Valentine bullet spinner

- Kamtechnik Turbo Plug adapter

- OS P4 plug

1/2A Nut- Top Poster

- Posts : 3538

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Best prop for 020 engine

Re: Best prop for 020 engine

Yes, that observation of yours I can understand. In this case with a very small area to blanket, the thin rotor blades, really don't know 'cause I have not tried. But in this heli application, perhaps the Cox special 3.125x2.5 may really shine?

ChrisM, regarding the Cox 3 blade being notoriously out of balance, so were the Top Flite 2 blade white nylon props. I gather that both used the same molding technology of the day.

50 years ago, I spent an afternoon sanding the back side of those blades, until I achieved perfect balance. In this case, it is a requirement before use. Perhaps it was a practice that has fallen out of disuse over time? I look now at the crude hollow log kits we dealt with, amazing how we made those look like pure modelling gold after careful sanding, spot putty to fill gouges and several coats of sanding sealer and sanding between before color coat to get that solid no grain look.

And Brad, love the special spinner nut and printed horseshoe back on that Pee Wee, looks awesome. You really cooked up a performance special there, that Pee Wee is really turnin' and burnin' on 3.

You really cooked up a performance special there, that Pee Wee is really turnin' and burnin' on 3.

ChrisM, regarding the Cox 3 blade being notoriously out of balance, so were the Top Flite 2 blade white nylon props. I gather that both used the same molding technology of the day.

50 years ago, I spent an afternoon sanding the back side of those blades, until I achieved perfect balance. In this case, it is a requirement before use. Perhaps it was a practice that has fallen out of disuse over time? I look now at the crude hollow log kits we dealt with, amazing how we made those look like pure modelling gold after careful sanding, spot putty to fill gouges and several coats of sanding sealer and sanding between before color coat to get that solid no grain look.

And Brad, love the special spinner nut and printed horseshoe back on that Pee Wee, looks awesome.

You really cooked up a performance special there, that Pee Wee is really turnin' and burnin' on 3.

You really cooked up a performance special there, that Pee Wee is really turnin' and burnin' on 3.

GallopingGhostler- Top Poster

Posts : 5724

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Best prop for 020 engine

Re: Best prop for 020 engine

George -I remember reading decades-like perhaps 40 years back that the Cox 3-bladed props were to be avoided-and eventually by chance got my hands on a couple and found out the warning was well founded-I had to clip quite a significant amount off one blade to achieve balance-to the extent that when mounted it looked a bit odd....so put them away.

Given the figures that balogh has posted, his one must be bang on balance to get that sort of rpm out of it. Now as you note it may be moulding practices back then...or it may simply be a case of a 'bad run'...I mean how many would they manufacture at a time-1000? 10,000? so it is entirely possible that subsequent production (or earlier runs) were better. But it doesn't take long-even in those pre internet days-for bad news to get around!

And I recall that not too long ago, Cox International were 'caught' by a production run of props -yellow 5x4? that were all faulty-and warped. So there are plenty of reasons why things can go wrong with moulded props...not to mention sometimes they get it completely wrong-as Frog did in the UK-when they ended up with a couple of their nylon prop line with completely incorrect pitch-and to make things worse the mould had the incorrect pitch engraved in it, so customers bought a 7x 'X' prop in good faith that turned to be a 7x 'Y', but was marked as a 7x 'X' moulded on the blade.

Personally I only use 3-bladed props on scale models...or in a few rare cases where there is limited prop clearance-such as an 'over wing' power pod. As for balancing I tend to be fairly scrupulous about this-and discovered early on-that often its the hub as well as the blades that can be unbalanced. My solution for the former is clever stuff called 'tungsten putty'-apparently beloved of the RC car people who use it to fine tune suspensions...but we modellers are nothing if not magpies and adapters of other people's tricks....

ChrisM

Given the figures that balogh has posted, his one must be bang on balance to get that sort of rpm out of it. Now as you note it may be moulding practices back then...or it may simply be a case of a 'bad run'...I mean how many would they manufacture at a time-1000? 10,000? so it is entirely possible that subsequent production (or earlier runs) were better. But it doesn't take long-even in those pre internet days-for bad news to get around!

And I recall that not too long ago, Cox International were 'caught' by a production run of props -yellow 5x4? that were all faulty-and warped. So there are plenty of reasons why things can go wrong with moulded props...not to mention sometimes they get it completely wrong-as Frog did in the UK-when they ended up with a couple of their nylon prop line with completely incorrect pitch-and to make things worse the mould had the incorrect pitch engraved in it, so customers bought a 7x 'X' prop in good faith that turned to be a 7x 'Y', but was marked as a 7x 'X' moulded on the blade.

Personally I only use 3-bladed props on scale models...or in a few rare cases where there is limited prop clearance-such as an 'over wing' power pod. As for balancing I tend to be fairly scrupulous about this-and discovered early on-that often its the hub as well as the blades that can be unbalanced. My solution for the former is clever stuff called 'tungsten putty'-apparently beloved of the RC car people who use it to fine tune suspensions...but we modellers are nothing if not magpies and adapters of other people's tricks....

ChrisM

ffkiwi- Gold Member

- Posts : 398

Join date : 2018-07-10

Location : Wellington, NZ

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Thanks

Thanks

Thanks for all the help from this forum in getting my 020 running.

I am amazed that rdw777 recognized the source for this heli design as being by Roy Clough Jr. It was in the May 1962 Popular Science magazine which I first tried to build then when I was 10 years old. I quickly found that building the rotor was way beyond my capabilities at that time. I tried to make it from flattened tin cans and coat hanger wires. Of course this didn't work and I knew nothing about soldering. Jump ahead 50 years when I learned that all of the old PS magazine issues are archive on google.books.com. I didn't remember which issue (or even that this was in PS and not Popular Mechanics) but a diligent searching found it. I decided I would try to build it again. The hub was the biggest challenge as it is not only a work of art but also high precision. I now used sheet metal and piano wire and attached the rotor brackets to the wire with a wire welder. The is a very fine line between getting a good weld and burning it up with metal this thin. I found I needed a couple of mods to Roy's design in spacers between the spider and the hub plate and I incorporated the stop bracket into the hub plate for better control of blade pitch. Fabricating the rotors and an initial attempt to get the engine running was as far as I got before we packed up to move in anticipation of retirement

Jump ahead another 9 years. I a family gathering this fall I related this story and decided to get the parts out of the attic and see if I could complete it. I completed the body and reworked the hub. It acts like a cyclic and tilts all three rotors up when the engine is running and tilts all three down (theoretically) from the engine weight when the it quits allowing the copter to auto rotate and land. The up and down pitch is very critical not only for the amount but also that it is equal for all 3 rotors. I think I have it correct now but will have to wait and see when (if) it flies.

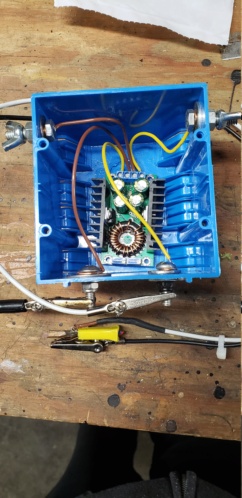

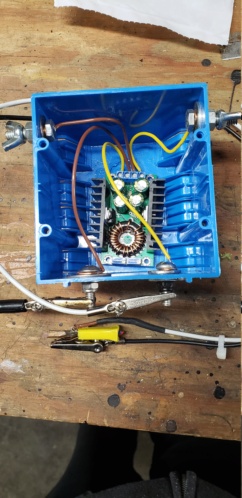

Help from the forum has really come in getting the 020 engine to run. I had thought it was an 010 but was corrected that it is an 020 when I first posted asking for a source for the reed valve spring which I had lost (and later found). I couldn't get the engine to even fire and found out I wasn't getting the glow head to glow using 2 D size batteries and an original Cox glow head connector. Finding post on Cox glow head voltage requirements I measured the set up an was only getting 1.3V. Changing to fresh batteries and 18ga wire the coil would glow nicely at 1.55V. I decided I didn't want to be dependent on the batteries so I found a very in depth post by Oz and built the power supply pictured below from the power converted he recommended. Works great. I still had a problem with a major fuel tank leak and the engine failing to run more than a few seconds. Ken Cook helped with this in recommending a sanding to flatten the back of the engine block and this worked beautifully not only stopping the leak but also sealing the tank to crankcase so the fuel draws correctly.

My first and only test run with the copter tried down to test the rotor balance and hub ended in throwing out the weight I had placed between the engine mount and rotor for balance but also breaking the only prop I had (a nylon Topflite 5.25x4). From the initial responses to this post I ordered a 5x3 prop from EXModels. I have no way of measuring the engines rpms but am not sure this is as important as the torque in getting the rotors to spin faster. It should arrive today (after almost 2 weeks, bad time of year for things in the mail) and will see how it works.

I am only able to static balance the rotors and had to add the 10g weight to the engine to get it pretty close. This was not called for in Roy's design and I am not sure why it is needed. The non powered blade tip weights are critical to the rotor pitch according to the article and I don't want to reduce them any further.

I am amazed that rdw777 recognized the source for this heli design as being by Roy Clough Jr. It was in the May 1962 Popular Science magazine which I first tried to build then when I was 10 years old. I quickly found that building the rotor was way beyond my capabilities at that time. I tried to make it from flattened tin cans and coat hanger wires. Of course this didn't work and I knew nothing about soldering. Jump ahead 50 years when I learned that all of the old PS magazine issues are archive on google.books.com. I didn't remember which issue (or even that this was in PS and not Popular Mechanics) but a diligent searching found it. I decided I would try to build it again. The hub was the biggest challenge as it is not only a work of art but also high precision. I now used sheet metal and piano wire and attached the rotor brackets to the wire with a wire welder. The is a very fine line between getting a good weld and burning it up with metal this thin. I found I needed a couple of mods to Roy's design in spacers between the spider and the hub plate and I incorporated the stop bracket into the hub plate for better control of blade pitch. Fabricating the rotors and an initial attempt to get the engine running was as far as I got before we packed up to move in anticipation of retirement

Jump ahead another 9 years. I a family gathering this fall I related this story and decided to get the parts out of the attic and see if I could complete it. I completed the body and reworked the hub. It acts like a cyclic and tilts all three rotors up when the engine is running and tilts all three down (theoretically) from the engine weight when the it quits allowing the copter to auto rotate and land. The up and down pitch is very critical not only for the amount but also that it is equal for all 3 rotors. I think I have it correct now but will have to wait and see when (if) it flies.

Help from the forum has really come in getting the 020 engine to run. I had thought it was an 010 but was corrected that it is an 020 when I first posted asking for a source for the reed valve spring which I had lost (and later found). I couldn't get the engine to even fire and found out I wasn't getting the glow head to glow using 2 D size batteries and an original Cox glow head connector. Finding post on Cox glow head voltage requirements I measured the set up an was only getting 1.3V. Changing to fresh batteries and 18ga wire the coil would glow nicely at 1.55V. I decided I didn't want to be dependent on the batteries so I found a very in depth post by Oz and built the power supply pictured below from the power converted he recommended. Works great. I still had a problem with a major fuel tank leak and the engine failing to run more than a few seconds. Ken Cook helped with this in recommending a sanding to flatten the back of the engine block and this worked beautifully not only stopping the leak but also sealing the tank to crankcase so the fuel draws correctly.

My first and only test run with the copter tried down to test the rotor balance and hub ended in throwing out the weight I had placed between the engine mount and rotor for balance but also breaking the only prop I had (a nylon Topflite 5.25x4). From the initial responses to this post I ordered a 5x3 prop from EXModels. I have no way of measuring the engines rpms but am not sure this is as important as the torque in getting the rotors to spin faster. It should arrive today (after almost 2 weeks, bad time of year for things in the mail) and will see how it works.

I am only able to static balance the rotors and had to add the 10g weight to the engine to get it pretty close. This was not called for in Roy's design and I am not sure why it is needed. The non powered blade tip weights are critical to the rotor pitch according to the article and I don't want to reduce them any further.

sailjas- Moderate Poster

- Posts : 10

Join date : 2023-11-11

Age : 72

Location : Lake Kiowa, Texas

Re: Best prop for 020 engine

Re: Best prop for 020 engine

Sailjas, Sounds like you have put a lot of thought and best effort into that rotor head, Which as you mentioned will be key for a good chance to fly….The rotor on that heli is pretty large so your thinking on the 5” prop may be OK that in it may need more torque than speed…. If you find you need more speed I still would suggest the 4.5 x 2…It will get closer to the PeeWee’s peak power band in rpm as well….Clough designed quite a few “soaring “ heli’s but yours is the only one I know of with the engine on one of the rotor blades, Very unique!…. All others are centrally located…. I’ve built a couple of flying things of his and a steam engine that was for his Naclio boat (also in google books) and all worked as described…. Brilliant man with many interesting ideas…

rdw777- Diamond Member

Posts : 1718

Join date : 2021-03-11

Location : West Texas

Re: Best prop for 020 engine

Re: Best prop for 020 engine

Got the 5x3 prop today and did my first test run with the helicopter tied down. My rotor balance is no way good enough. Too much wobble to get up enough speed for lift off. Have to rethink the static balancing method. Not an easy problem with the drastically different centrifugal dynamics between the powered and non powered rotors.The 5x3 prop is obviously designed for an 049 engine with a larger shaft screw. Is there an adapter available?

sailjas- Moderate Poster

- Posts : 10

Join date : 2023-11-11

Age : 72

Location : Lake Kiowa, Texas

Re: Best prop for 020 engine

Re: Best prop for 020 engine

Just use a short section of fuel line around the propeller retaining screw to center the prop.

706jim- Gold Member

- Posts : 472

Join date : 2013-11-29

Re: Best prop for 020 engine

Re: Best prop for 020 engine

At least a good start sailjas…. Not sure about how you are trying to balance…. My knee jerk reaction would be to hang the heli so the rotor shaft is level to horizontal…. Then like a big model airplane prop, The heavy blade(s) should roll down to the bottom if the bearing in the head is free enough….Then you can mess with blade weight as necessary…. That’s only accounting for equalizing weight though ….If it’s still wobbly when running after that you may consider to video… Maybe even in slow motion to help analyze any problem with lift dynamics …. could help with watching tip tracking too…..That rotor is a little complex and may take a bit of tweaking here and there to get it to run smooth….I bet it works though

rdw777- Diamond Member

Posts : 1718

Join date : 2021-03-11

Location : West Texas

Re: Best prop for 020 engine

Re: Best prop for 020 engine

I found that the brass tubing I used on the rotor is the perfect size for the prop shim.

The rotor balancing so far has been as suggested (what I call static balancing) but it is still pretty far off. I will try and do a slow motion video. I wonder if the running engine adds another factor to the balance.

The rotor balancing so far has been as suggested (what I call static balancing) but it is still pretty far off. I will try and do a slow motion video. I wonder if the running engine adds another factor to the balance.

sailjas- Moderate Poster

- Posts : 10

Join date : 2023-11-11

Age : 72

Location : Lake Kiowa, Texas

Re: Best prop for 020 engine

Re: Best prop for 020 engine

That is some very nice workmanship on the rotor bearing and blade holder assembly, very professional looking, @sailjas , the best I have seen.

Nice to see someone bringing Roy Clough's earlier work back to life again. Regarding an oversized prop hub hole, I've used varying sizes of fuel line, nylon pushrod material, costume jewelry beads, even electrical wire insulation. Somewhere, you'll find something that does the job.

Nice to see someone bringing Roy Clough's earlier work back to life again. Regarding an oversized prop hub hole, I've used varying sizes of fuel line, nylon pushrod material, costume jewelry beads, even electrical wire insulation. Somewhere, you'll find something that does the job.

GallopingGhostler- Top Poster

Posts : 5724

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Similar topics

Similar topics» My Cox twin collection

» 3 Blade Prop For Cox Engine

» The troublesome Corsair engine, the gruesome twosome, another Hero Testors McCoy .049 and the yellow prop returns.

» MY FIRST PROP ROD !!! AT age 57

» [The Traveling Prop] Who wants to be the one to send the prop overseas?

» 3 Blade Prop For Cox Engine

» The troublesome Corsair engine, the gruesome twosome, another Hero Testors McCoy .049 and the yellow prop returns.

» MY FIRST PROP ROD !!! AT age 57

» [The Traveling Prop] Who wants to be the one to send the prop overseas?

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules