Log in

Search

Latest topics

» My latest doodle...by batjac Yesterday at 10:05 pm

» Retail price mark-up.. how much is enough?

by gkamysz Yesterday at 9:29 pm

» Happy 77th birthday Andrew!

by roddie Yesterday at 9:22 pm

» Roger Harris revisited

by rsv1cox Yesterday at 3:38 pm

» My N-1R build log

by GallopingGhostler Yesterday at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Yesterday at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Yesterday at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Yesterday at 11:32 am

» Free Flight Radio Assist

by rdw777 Yesterday at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

Varnished Cylinder

Page 1 of 1

Varnished Cylinder

Varnished Cylinder

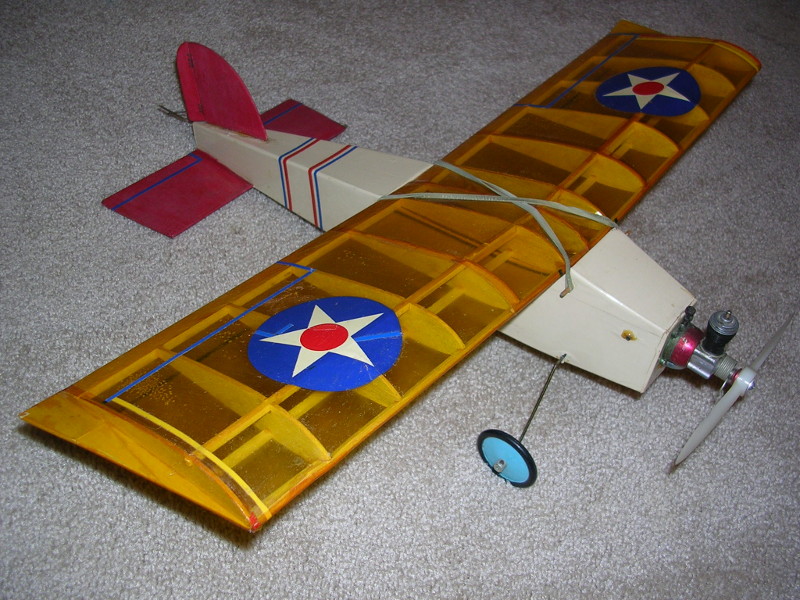

I recently won a Pee Wee .020 RC …. It was free to turn when I got it but pretty gummy from old castor …. It came apart easily and I cleaned the upper cylinder assembly with ISO alcohol then installed on a Tee Dee lower end…. Hard to start and could only get about 15K with 4.5 x 2 Cox prop…Took it apart and paid more attention and thought it may be varnished due to the dry piston/cylinder fit so I soaked it Hoppe’s #9 for about 30 min and scrubbed gently with a round nylon brush (that doesn’t fit the bore tightly)…Cleaned, reassembled, ran with about the same result…Needle adjustment seemed very narrow and acted like it was on the verge of too lean the whole time…

Maybe the photo will show the brownish tinge above the exhaust ports…

Piston goes in about this far before resistance is felt (dry)

Do I have it diagnosed right?…. I don’t see any evidence of a burr….. Maybe I need to soak longer?…. I have acetone as well… I can get other stuff as needed…. Opinions appreciated…

Maybe the photo will show the brownish tinge above the exhaust ports…

Piston goes in about this far before resistance is felt (dry)

Do I have it diagnosed right?…. I don’t see any evidence of a burr….. Maybe I need to soak longer?…. I have acetone as well… I can get other stuff as needed…. Opinions appreciated…

rdw777- Diamond Member

Posts : 1718

Join date : 2021-03-11

Location : West Texas

Re: Varnished Cylinder

Re: Varnished Cylinder

To removed baked on Castor grime, I resorted to fine steel wool. It is able to gently scrub off that, I think you'll find a different fit result when you remove the last of the Castor.

GallopingGhostler- Top Poster

Posts : 5723

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Varnished Cylinder

Re: Varnished Cylinder

I use cold degreaser spray - same as cleaing fry pans in the kitchen- to losen up the varnish, then a cotton swab to remove it.

If your piston is a bit tight near the TDC, that may be due to taper cylinder bore that was common with old stock thin wall and even some stepped wall cylinders. This will not compromise engine rpm rhough.

If the piston firmly sticks halfway up, then there may be a burr near the exhaust ports..though the flats on the top fin allows the safe use of a wrench, so a wrench inflicted burr in the exhaust port is not a probable cause of power loss.

What backplate do you use on this engine? Check that all mating surfaces should fit airtight, because the narrow needle valve range and lean run indicate there may be some unwanted air leakege somewhere.

If your piston is a bit tight near the TDC, that may be due to taper cylinder bore that was common with old stock thin wall and even some stepped wall cylinders. This will not compromise engine rpm rhough.

If the piston firmly sticks halfway up, then there may be a burr near the exhaust ports..though the flats on the top fin allows the safe use of a wrench, so a wrench inflicted burr in the exhaust port is not a probable cause of power loss.

What backplate do you use on this engine? Check that all mating surfaces should fit airtight, because the narrow needle valve range and lean run indicate there may be some unwanted air leakege somewhere.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Varnished Cylinder

Re: Varnished Cylinder

I have VERY CAREFULLY used a small round file to remove such burrs caused by wrenching a (now old, been a while  ) thin wall cylinder off that didn't have wrenching flats like the later ones. If one is VEHWY VEHWY CAREFUL (saying this in an Elmer Fudd voice after a silly wabbit

) thin wall cylinder off that didn't have wrenching flats like the later ones. If one is VEHWY VEHWY CAREFUL (saying this in an Elmer Fudd voice after a silly wabbit  ), they can save the cylinder.

), they can save the cylinder.  Since fit is measured in tens of thousands of an inch, it is also possible to damage the cylinder beyond saving.

Since fit is measured in tens of thousands of an inch, it is also possible to damage the cylinder beyond saving.

Because of the now rarity of .020 cylinder / piston assemblies, It is almost like disarming a time bomb.

It is almost like disarming a time bomb.  (Thinking of a Hogan's Heroes episode)

(Thinking of a Hogan's Heroes episode)  You have two wires, white and black. You clip one, the clock stops.

You have two wires, white and black. You clip one, the clock stops.  You clip the other, you are immediately blown up.

You clip the other, you are immediately blown up.

Nonetheless, it is not too hard to imagine that Bob @rsv1cox, Broussard Mud Dabber @Kim, and @Ken Cook, (and @Admin Jacob - the kitchen heirloom fluorescent ceiling lamp) have been down this path with tails to tell.

The thing today is, if we don't experiment with our methods to redeem a lost cause, then we serve no purpose to benefit. If we happen to ruin it, all is not lost, just another tale to tell on CEF.

Because of the now rarity of .020 cylinder / piston assemblies,

It is almost like disarming a time bomb.

It is almost like disarming a time bomb.

Nonetheless, it is not too hard to imagine that Bob @rsv1cox, Broussard Mud Dabber @Kim, and @Ken Cook, (and @Admin Jacob - the kitchen heirloom fluorescent ceiling lamp) have been down this path with tails to tell.

The thing today is, if we don't experiment with our methods to redeem a lost cause, then we serve no purpose to benefit. If we happen to ruin it, all is not lost, just another tale to tell on CEF.

GallopingGhostler- Top Poster

Posts : 5723

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Varnished Cylinder

Re: Varnished Cylinder

Thank you Balogh, George…I’ll go the chemical route first and check the feel again… I have other Pee Wee’s and Tee Dee’s that are good runners to compare fit-feel with…

Backplate was Kamtechnik with the O-ring seal… I leveled the back of the case anyway…I did not however have a fuel line seal on the needle valve… Will add that next time..

Yes, It’s too bad they are getting more scarce… I bought a few PW and TD 020 the last year or so… I think my favorite size..

I’ll report back on how well it ran ….Or asking more help!!!!

Thanks again

Backplate was Kamtechnik with the O-ring seal… I leveled the back of the case anyway…I did not however have a fuel line seal on the needle valve… Will add that next time..

Yes, It’s too bad they are getting more scarce… I bought a few PW and TD 020 the last year or so… I think my favorite size..

I’ll report back on how well it ran ….Or asking more help!!!!

Thanks again

rdw777- Diamond Member

Posts : 1718

Join date : 2021-03-11

Location : West Texas

Re: Varnished Cylinder

Re: Varnished Cylinder

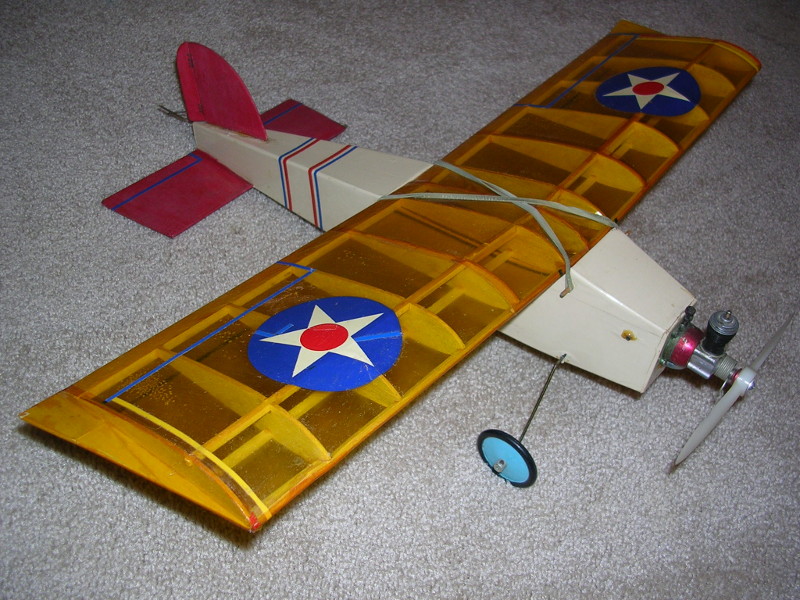

I started out with the Pee Wee for R/C, it is an excellent hard working and reliable engine, may be not as prestigious as the equivalent in power .010 Tee Dee, but a little powerhouse to its own. I still have a remnant from the 1980's, an Ace R/C Littlest Stick. Was on Ace Adams Baby Twin actuator and single channel R/C, but now that I have 6 gram servos, can make it a rudder and elevator plane.

I drilled a hole in the tank and plumbed it to a larger capacity Perfect tank. All is not lost, if need be, I could restore the tank with a non-anodized production engine tank from my parts engine.

I recently renewed my MADS R/C club membership, hope this Fall to do some flying. (Don't mind the obsolete and now unsafe Top Flite 5.25x3 white nylon prop, I will replace with a good prop prior to flights.)

(Don't mind the obsolete and now unsafe Top Flite 5.25x3 white nylon prop, I will replace with a good prop prior to flights.)

I drilled a hole in the tank and plumbed it to a larger capacity Perfect tank. All is not lost, if need be, I could restore the tank with a non-anodized production engine tank from my parts engine.

I recently renewed my MADS R/C club membership, hope this Fall to do some flying.

GallopingGhostler- Top Poster

Posts : 5723

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Varnished Cylinder

Re: Varnished Cylinder

GallopingGhostler wrote:I have VERY CAREFULLY used a small round file to remove such burrs caused by wrenching a (now old, been a while) thin wall cylinder off that didn't have wrenching flats like the later ones. If one is VEHWY VEHWY CAREFUL (saying this in an Elmer Fudd voice after a silly wabbit

), they can save the cylinder.

Since fit is measured in tens of thousands of an inch, it is also possible to damage the cylinder beyond saving.

Nonetheless, it is not too hard to imagine that Bob @rsv1cox, Broussard Mud Dabber @Kim, and @Ken Cook, (and @Admin Jacob - the kitchen heirloom fluorescent ceiling lamp) have been down this path with tails to tell.

The thing today is, if we don't experiment with our methods to redeem a lost cause, then we serve no purpose to benefit. If we happen to ruin it, all is not lost, just another tale to tell on CEF.

Yes, I have shelved all other cleaning methods. Berryman's is now my go-to forsaking alcohol, crock pot, Simple Green, and all other crazy cleaning methods that I have ever tried. I'm talking over 500 model engines cleaned and restored.

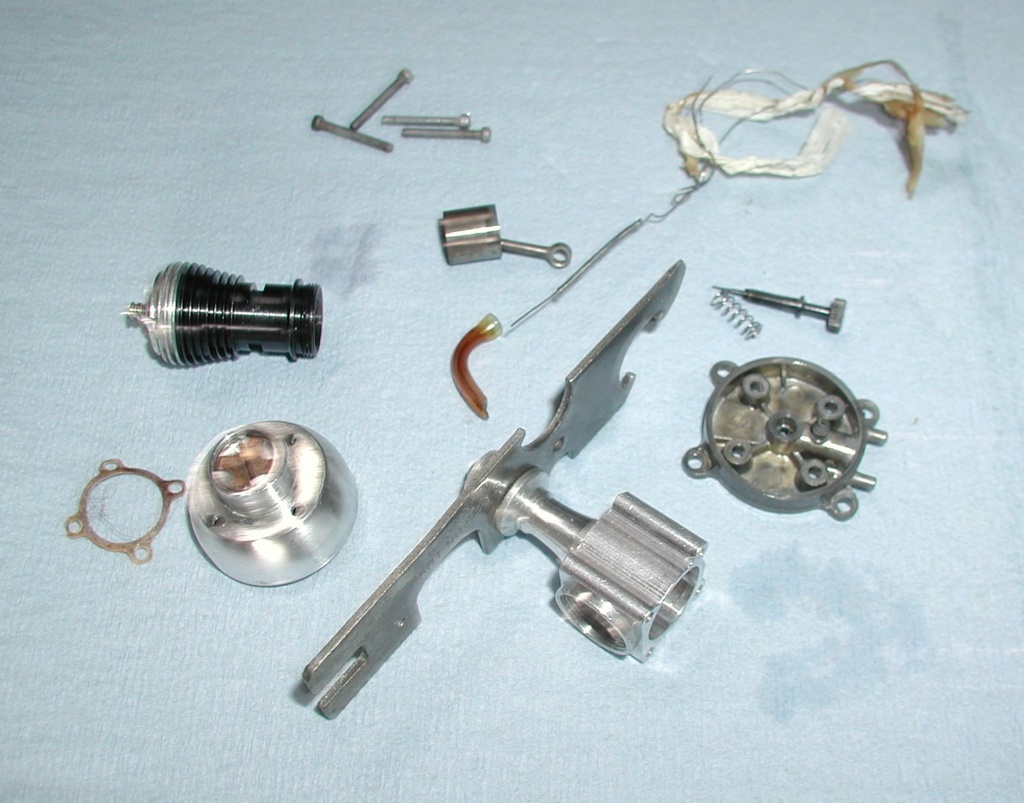

The latest, and one I reported here was this very early Babe Bee. It had a severe varnish drag when I got it. Surprised me as the exteror was quite clean. But as we all know, it's what inside that counts. A 30 minute Berryman's soak followed by a soapy warm water rinse, followed again by a clear water rinse, a compressed air blow-out and Remoil. No effort at all was made to wipe the inside of the bore. Nada. Reassembled and perfect function was restored.

I really have no idea as to why anyone would use anything else.

The fuel pick-up tube gives some indication of how gummed up the interior of this engine was. It was black when I started and full of goo as was the NVA.

The bore is the thing, the more you fool with it the worse it gets.

rsv1cox- Top Poster

Posts : 11248

Join date : 2014-08-18

Location : West Virginia

Re: Varnished Cylinder

Re: Varnished Cylinder

Thanks Bob, I’m just moving slow and cautious to minimize risk of injury to the cylinder…. Really looking forward to see if I can make it throttle …. Course then I have to build something for it

Love the Littlest Stick George… I have a survivor from the 80’s as well…. Started life with a Pee Wee and one Ace servo…I never really got that good at rudder only back then…It’s on its second set of electronics and motors as three channel now…Totally rebuilt a couple of years ago… It got a new rudder and stab at that time..I know we have talked about small planes flying in the wind from time to time… This is my go to for that…Pretty stable for a small, light plane….Hope you get some good flying in this fall…

Love the Littlest Stick George… I have a survivor from the 80’s as well…. Started life with a Pee Wee and one Ace servo…I never really got that good at rudder only back then…It’s on its second set of electronics and motors as three channel now…Totally rebuilt a couple of years ago… It got a new rudder and stab at that time..I know we have talked about small planes flying in the wind from time to time… This is my go to for that…Pretty stable for a small, light plane….Hope you get some good flying in this fall…

rdw777- Diamond Member

Posts : 1718

Join date : 2021-03-11

Location : West Texas

Re: Varnished Cylinder

Re: Varnished Cylinder

rdw777 wrote:Thanks Bob, I’m just moving slow and cautious to minimize risk of injury to the cylinder…. Really looking forward to see if I can make it throttle …. Course then I have to build something for it

]

I probably shouldn't be so forcefully opinionated about this, but seriously "500 engines" is an understatement closer to 600 engines would be more accuraate and I have learned from my mistakes. I posted many of my "worst of the worst" engines here, until it got old. But I never stopped. These two beauties should be here this weekend. Yup, Berryman's.

Think they might be varnished up.

rsv1cox- Top Poster

Posts : 11248

Join date : 2014-08-18

Location : West Virginia

Re: Varnished Cylinder

Re: Varnished Cylinder

That Bee did shine up really well….I’m enjoying to learn these new tricks of the trade…Throws a little spice back into the hobby

rdw777- Diamond Member

Posts : 1718

Join date : 2021-03-11

Location : West Texas

Re: Varnished Cylinder

Re: Varnished Cylinder

Familiarity with methods at the time, familiarity, Bob. Reason why I use fine steel wool is because that was the method described in the Cox engine instructions, IMO. Following is stated in the Cox Pee Wee instructions that came with the engine. Apparently these are the more recent instructions, as it includes the Pee Wee R/C with exhaust throttle ring.rsv1cox wrote:I really have no idea as to why anyone would use anything else.

This is why for right, wrong, or indifferentCox .020 Pee Wee Instructions wrote:Varnish - If the engine gets tight it is not frozen up. Do not send to factory. A new engine will sometimes tighten up a few times, especially after slow runs. Certain kinds of weather, especially warm, humid (sticky) weather will cause excessive shellacking in a new cylinder. The smoother the fit the more susceptible is the engine to this trouble. Do not run it tight. The tightness is caused by a shellac-like deposit on the cylinder wall. Screw the head off. Remove the cylinder and scour the inside wall very lightly with a bit of fine or medium steel wool. Wash, oil, and replace. The engine will then turn over freely and run properly. Never use sandpaper, emery cloth, or abrasives of any kind, or scrapers. Such methods will ruin the cylinder. Steel wool, will not harm the bore.

However, I do listen to the alternative methods, nothing is cast in stone. Your method of using Berryman, which I am familiar in using on car and motorcycle carburetors and small parts, has caught my attention. They changed the formulation, didn't know how well the newer stuff works.

Thanks, sharp looking Littlest Stick, Robert, and good conversion to electric. I started out on R/O and got to where I could dead stick within 10 feet of me consistently, plus learned how to kick the rudder, so I could get the plane to flair for landing. True R/O flight is a real blast of fun.rdw777 wrote:TLove the Littlest Stick George… I have a survivor from the 80’s as well…. Started life with a Pee Wee and one Ace servo…I never really got that good at rudder only back then…It’s on its second set of electronics and motors as three channel now…Totally rebuilt a couple of years ago… It got a new rudder and stab at that time..I know we have talked about small planes flying in the wind from time to time… This is my go to for that…Pretty stable for a small, light plane….Hope you get some good flying in this fall…

GallopingGhostler- Top Poster

Posts : 5723

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Varnished Cylinder

Re: Varnished Cylinder

medium steel wool. ? I hesitate to use fine steel wool or any abrasive inside the bore except in extreme cases where rust/corrison is evident. At that point your not going to lose much anyway. There are those (here on the forum) that would argue that varnish is necessary and should not be removed. There is reason on some bores that may be true.

The bottom line is that whatever works for you is best for you, and I would not change that.

The bottom line is that whatever works for you is best for you, and I would not change that.

rsv1cox- Top Poster

Posts : 11248

Join date : 2014-08-18

Location : West Virginia

Re: Varnished Cylinder

Re: Varnished Cylinder

OEM instructions stated to go "lightly". For me, it only took a couple swipes. I suppose if one can't chew gum and walk, then may be they shouldn't.rsv1cox wrote:medium steel wool. ? I hesitate to use fine steel wool or any abrasive inside the bore except in extreme cases where rust/corrosion is evident. At that point your not going to lose much anyway.

On the older engines that lost compression due to wear and tear, the Castor acted as a seal. Think of it as the J.C. Whitney "Engine Overhaul in a Can" of the 1960's and 1970's, with the wax pellets you put a handful in each cylinder through the spark plug hole and poured their pint of "Liquid Plate" oil additive into the engine oil. It was guaranteed 10,000 miles of smoke free oil less burning mileage with restored compression.rsv1cox wrote:There are those (here on the forum) that would argue that varnish is necessary and should not be removed. There is reason on some bores that may be true.

Ken showed a photo of a Fox .35 stunt that was totally engrossed in Castor stating that this is how a Fox should look.

Was searching for a photo of that on both CEF and Stunt Hangar without luck.

Was searching for a photo of that on both CEF and Stunt Hangar without luck. The larger slag iron piston on steel cylinder engines that were badly worn out, they still ran fine if one didn't dink with the baked on Castor coating. That was mostly on control line aircraft. Removing such an engine off a favored aircraft was like:

Peanuts cartoon by late Charles Shultz

If it works, don't fix it seemed to be the motto of the day.

However, I have an Enya .15-III TV with very weak compression. A shot of heavy oil to temporarily restore compression, once fired up, seemed to run well regardless. It would benefit from all Castor fuel.

GallopingGhostler- Top Poster

Posts : 5723

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Varnished Cylinder

Re: Varnished Cylinder

I use oil and a pistol nylon barrel brush for the cyl. I can find it now but there was a discussion about if a Pee Wee and TD share the same piston / cyl. . Do They ?

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Varnished Cylinder

Re: Varnished Cylinder

ANSWER: https://www.coxengineforum.com/t11396-cox-020-pee-wee-tee-dee-question#145027getback [Inquisitive Eric] wrote:I can['t] find it now but there was a discussion about if a Pee Wee and TD share the same piston / cyl. . Do They ?

I looked at the engine articles on Sceptre Flight. Peter Chinn gave the exact same description of both the Pee Wee and the Tee Dee cylinders.Jason_WI on Dec 09, 2017 wrote:Cylinders are all the same for the .020. The only difference is thin walled, stepped wall, thick walled, mesh, and slotted screen. Nothing affected the ports on these variants. Early .020 TD pistons were tapered. This was phased out in '72.

The .020 Tee Dee is a more powerful engine due to its freer flowing inlet fuel charge design and timing differences. Its power rated at 0.055 BHP at 23,000 RPM on 30% nitro according to the graphs approaches that of a Babe Bee. (H.R. Warring's earlier 1962 test used 20% nitro and as such, obtained lower power of 0.0304 BHP at 20,500 RPM. The Tee Dee is most happy on higher nitro fuels.) In comparison, Peter in his 1976 test rated the Pee Wee at 0.035 BHP at 18,500 RPM on 25% nitro fuel.

With dual intake bypass ports, the Pee Wee is more like a miniature Black Widow,

GallopingGhostler- Top Poster

Posts : 5723

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Varnished Cylinder

Re: Varnished Cylinder

Got it going… Kitchen degreaser (Formula 409) got all the brown goo …. Put it back in its native PeeWee block and tried again…. Still wasn’t there so apart again…. I think I knocked a small burr out of the way when I inserted the piston skirt first and gently pushed up the bore…. After that a dry piston would drop to the top of the cylinder and stop right at the landing for the head …. Runs and throttles good now…. Thanks for the advices!!!!

Robert

Robert

rdw777- Diamond Member

Posts : 1718

Join date : 2021-03-11

Location : West Texas

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules