Log in

Search

Latest topics

» My latest doodle...by batjac Yesterday at 10:05 pm

» Retail price mark-up.. how much is enough?

by gkamysz Yesterday at 9:29 pm

» Happy 77th birthday Andrew!

by roddie Yesterday at 9:22 pm

» Roger Harris revisited

by rsv1cox Yesterday at 3:38 pm

» My N-1R build log

by GallopingGhostler Yesterday at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Yesterday at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Yesterday at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Yesterday at 11:32 am

» Free Flight Radio Assist

by rdw777 Yesterday at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

Prop Rod engine screws and restoration

Page 1 of 4

Page 1 of 4 • 1, 2, 3, 4

Prop Rod engine screws and restoration

Prop Rod engine screws and restoration

Been a real long time since I've been on here. I have a small number of Cox planes and cars that I have restored and posted on here in the past. I am starting a resto project on my fourth Prop Rod and have a question. It's missing a couple of the small slot head screws that attach the babe bee motor to the plastic nacelle at the rear. Does anyone know the size of these screws? It's for an aluminum chassis version from about 1959, although they would be the same for the prop rods and shrikes alnost clear up to the end production models.

Last edited by bottomgun on Fri Apr 15, 2022 6:41 pm; edited 1 time in total

bottomgun- Gold Member

- Posts : 138

Join date : 2012-12-27

Age : 67

Location : Southern California

Re: Prop Rod engine screws and restoration

Re: Prop Rod engine screws and restoration

May be someone here may post photos of their screw sets used by such a model of such vintage.

Back then, all was standard western threads, (ANSI, etc.). 3-48 machine screws are normally used that fit the Cox .049 tank back mount lugs, so would be most likely a #3 sheet metal screw, probably pan head slot, about 1/4" longer than the mount lug thickness, so may be 3/8" long but could be 1/2".

As a kid, I liked to remove the engines, put them back on, probably strip the plastic mounting thread then have to find an oversized screw like a #4 to refasten. (When 10, stuck my finger in a powered lamp socket that shocked the out of myself, I gained a life long interest in electricity.)

out of myself, I gained a life long interest in electricity.)

But, please don't mind me. I don't collect these, but enjoy reading about these historic restorations.

Back then, all was standard western threads, (ANSI, etc.). 3-48 machine screws are normally used that fit the Cox .049 tank back mount lugs, so would be most likely a #3 sheet metal screw, probably pan head slot, about 1/4" longer than the mount lug thickness, so may be 3/8" long but could be 1/2".

As a kid, I liked to remove the engines, put them back on, probably strip the plastic mounting thread then have to find an oversized screw like a #4 to refasten. (When 10, stuck my finger in a powered lamp socket that shocked the

out of myself, I gained a life long interest in electricity.)

out of myself, I gained a life long interest in electricity.)But, please don't mind me. I don't collect these, but enjoy reading about these historic restorations.

GallopingGhostler- Top Poster

Posts : 5723

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Prop Rod engine screws and restoration

Re: Prop Rod engine screws and restoration

Strangely enough there is no prop rod that i can find in the Instruction sheets the one Shrike i found says screw pack  I have a PR but has a bad nautical on it and don't think the screws are original .. It is most likely a PLASTITE type screw made for plastic , hardware stores and Lowes usually have them . Since you have more than the one PR why not take a screw out and go to a store for comparison? https://stockscrews.com/products/plastite-48-2-screw-pan-head-phillips-recess Finding the slot hd. will bee a problem .

I have a PR but has a bad nautical on it and don't think the screws are original .. It is most likely a PLASTITE type screw made for plastic , hardware stores and Lowes usually have them . Since you have more than the one PR why not take a screw out and go to a store for comparison? https://stockscrews.com/products/plastite-48-2-screw-pan-head-phillips-recess Finding the slot hd. will bee a problem .

I have a PR but has a bad nautical on it and don't think the screws are original .. It is most likely a PLASTITE type screw made for plastic , hardware stores and Lowes usually have them . Since you have more than the one PR why not take a screw out and go to a store for comparison? https://stockscrews.com/products/plastite-48-2-screw-pan-head-phillips-recess Finding the slot hd. will bee a problem .

I have a PR but has a bad nautical on it and don't think the screws are original .. It is most likely a PLASTITE type screw made for plastic , hardware stores and Lowes usually have them . Since you have more than the one PR why not take a screw out and go to a store for comparison? https://stockscrews.com/products/plastite-48-2-screw-pan-head-phillips-recess Finding the slot hd. will bee a problem .

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Prop Rod engine screws and restoration

Re: Prop Rod engine screws and restoration

those are special screws, course thread and tapered for plastic. Using a normal sized screw will likely crack the plastic.

crankbndr- Top Poster

- Posts : 3109

Join date : 2011-12-10

Location : Homestead FL

Re: Prop Rod engine screws and restoration

Re: Prop Rod engine screws and restoration

Thanks for the replies. We have a specialty hardware warehouse in Riverside that deals with all kinds of fasteners great and small that I remembered about. I'll see if they're still around first and take one of my samples with me.

bottomgun- Gold Member

- Posts : 138

Join date : 2012-12-27

Age : 67

Location : Southern California

Re: Prop Rod engine screws and restoration

Re: Prop Rod engine screws and restoration

You might consider old junk plastic gadgets that are fastened together with screws…Toys, Electronics, etc….

rdw777- Diamond Member

Posts : 1718

Join date : 2021-03-11

Location : West Texas

Re: Prop Rod engine screws and restoration

Re: Prop Rod engine screws and restoration

getback wrote:It is most likely a PLASTITE type screw made for plastic , hardware stores and Lowes usually have them . Since you have more than the one PR why not take a screw out and go to a store for comparison? https://stockscrews.com/products/plastite-48-2-screw-pan-head-phillips-recess Finding the slot hd. will bee a problem .

Excellent deduction, Eric! I have seen those screws being used to even today. Salvaging from electronics to be discarded, sometimes come in odd "tamper-proof" screw heads for triangle or square shanked tool tips. Lemme see, all we need to do now is convince Matt at Ex Model Engines or Bernie at Cox International to buy those screws at $354.48 US per 5,000 plus shipping and tax, say $390.00.

In packs of 12 would make 416 packs. So far that is $0.94 per pack. It will take someone at least a half day to assemble those packs by counting 12, putting in a small plastic bag & label/staple, $15 minimum wage with fringes x 4 = $60, bags and labels say $15, plus 25% small stuff overhead amortization (rent, utilities, insurance, upkeep, taxes, storage, vehicles, administration) and 15% profit.

That gives us a total of $668.44 / 416 = $1.61 US each package of 12. Now, all they need to do is find 416 buyers that need Cox Prop Rod engine mounting screws!

Amazing how a small screw can hold up a project for the most discerning in historic detail! (Now I understand how classic cars get away with modern clear coat finishes and Toyo tires!

I have purchased those same type screws online in plastic cased universal sets but they were metric, usually in black with Phillips or socket heads and for R/C cars.

rdw777 wrote:You might consider old junk plastic gadgets that are fastened together with screws…Toys, Electronics, etc….

That is probably the best way to go about getting an authentic replacement.

GallopingGhostler- Top Poster

Posts : 5723

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Prop Rod engine screws and restoration

Re: Prop Rod engine screws and restoration

Last edited by bottomgun on Wed Apr 20, 2022 12:20 pm; edited 1 time in total

bottomgun- Gold Member

- Posts : 138

Join date : 2012-12-27

Age : 67

Location : Southern California

Re: Prop Rod engine screws and restoration

Re: Prop Rod engine screws and restoration

It would be interesting/informative to see a pic of one of those screws removed from the nacelle. Round Slot head fastener, what type of thread? Tapered shank or full sized? Curious minds want to know!!

BTW: the Screw Co that Getback referenced in his response is here in my hometown. The address rang a bell, Ding, Ding Ding. It's in a big industrial complex that has a computer re-cycling center where I've dropped off my old Computers. As soon as they obsolete my Windows7 OS, I'll stop by and see if the sell any small screws..in small quantities!

BTW: the Screw Co that Getback referenced in his response is here in my hometown. The address rang a bell, Ding, Ding Ding. It's in a big industrial complex that has a computer re-cycling center where I've dropped off my old Computers. As soon as they obsolete my Windows7 OS, I'll stop by and see if the sell any small screws..in small quantities!

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 72

Location : Grand Rapids, MI

Re: Prop Rod engine screws and restoration

Re: Prop Rod engine screws and restoration

bottomgun wrote:Problem solved. I found an old nacelle with the screws still attached in my cox parts box.

That is interesting, bottomgun, round slotted heads, but makes sense. I've seen a lot of engines from the same era put together with round headed screws of fairly soft steel, easy to mar the heads. They were the least expensive at the time. However, when costs need to be cut to be able to undersell the competition, that is what it takes. Anything new looks good. A lot of earlier kits containing hardware had the same cheap screws, engine bolt sets, etc.

GallopingGhostler- Top Poster

Posts : 5723

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Prop Rod engine screws and restoration

Re: Prop Rod engine screws and restoration

I'll pull the screws out tomorrow and post pics. They look just like the original screws from my other prop rod and two Shrikes.

bottomgun- Gold Member

- Posts : 138

Join date : 2012-12-27

Age : 67

Location : Southern California

Re: Prop Rod engine screws and restoration

Re: Prop Rod engine screws and restoration

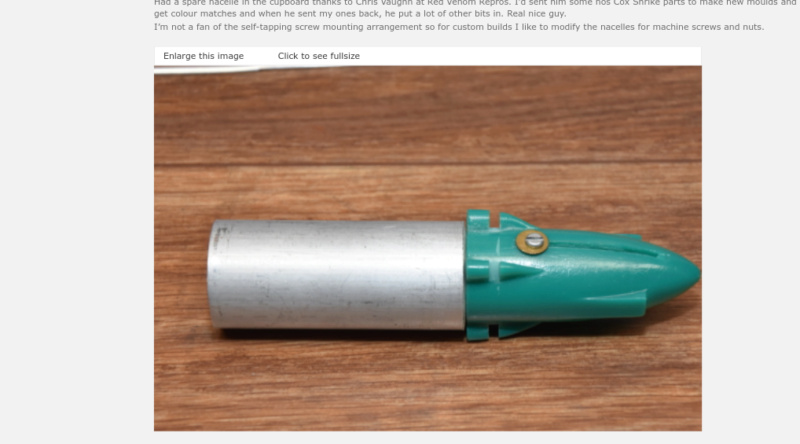

Some pics of this taken apart. One of the photos shows at some time that four threaded nuts were taped to the inside front of the chassis to add weight for whatever reason. I thumbnail linked these so we'll see how this looks. Doesn't seem to be a preview option so I'm just trying things out.

bottomgun- Gold Member

- Posts : 138

Join date : 2012-12-27

Age : 67

Location : Southern California

Re: Prop Rod engine screws and restoration

Re: Prop Rod engine screws and restoration

Wow, nice, you've got one of the original prop rods with a metal bottom pan, which is die cast magnesium? That is definitely a show stopper.

GallopingGhostler- Top Poster

Posts : 5723

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 72

Location : Grand Rapids, MI

Re: Prop Rod engine screws and restoration

Re: Prop Rod engine screws and restoration

Is the bottom pic to be used with an Estes rocket engine, like D sized? Pretty interesting. Anyway I got a pic of the original screw. I also included a pic of one of the bits I use when restoring these old models. Mine is an old Chapman set used for gunsmithing. They prevent the buggering up of these and any other small screws. Measurements as I can best describe would be .432 total length. In milimeters using my small measuring rule I get 11mm total length and 9mm from tip to inside base of the screw head.

bottomgun- Gold Member

- Posts : 138

Join date : 2012-12-27

Age : 67

Location : Southern California

Re: Prop Rod engine screws and restoration

Re: Prop Rod engine screws and restoration

Started working on the wheel units yesterday. Two of the wheels on both front and rear were so "welded" on by old dried castor oil that I had to soak the ends in alcohol for an hour to get them to free up, and even then I had to tap on them gently with a rubber mallet to do so. I boiled all wheels for a short time in water to remove the tires. Fronts were fine. Rear knobbys were so dry rotted they broke off in chunks easily. I have spares so I"ll use those. I have a comparison pic of one completed tire and wheel. I used Mothers aluminum polish for the aluminum pieces on all of the car. I treated the tires with Ballistol and wiped off the excess. It's a non petrolium lubricant invented by the Germans in 1906 to be used for firearms, leather, rubber, machinery, etc. Still being produced today. I had two pics of my front wheel but my photo host site is only showing four of my original downloaded pics so I don't know whats up with that.

bottomgun- Gold Member

- Posts : 138

Join date : 2012-12-27

Age : 67

Location : Southern California

Re: Prop Rod engine screws and restoration

Re: Prop Rod engine screws and restoration

bottomgun, I cropped and reposted your photo in servimg native to this forum, as imgbb for some reason isn't displaying in Firefox (although works in Chromium). Yup, it is just as Eric pointed out, a Plastite type screw with standard round slotted head, thread length 3/8 inch.

Marlesky, was that Prop Rod you show, one that already you bought with the "free"

ugly JB Weld glue repairs on the engine mount nodes?

ugly JB Weld glue repairs on the engine mount nodes?

GallopingGhostler- Top Poster

Posts : 5723

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

bottomgun- Gold Member

- Posts : 138

Join date : 2012-12-27

Age : 67

Location : Southern California

Re: Prop Rod engine screws and restoration

Re: Prop Rod engine screws and restoration

I have hunted for the same engine mounting screws for the plastic nacelle on Prop Rod/ Shrikes before.

I found many that had a suitable thread section but the heads are too big and won't fit in between the webs on the engine backplate. Got round it by turning down the head. Drilled a suitable size hole in the end of a piece of wooden dowel or metal bar in the lathe. Then screwed to screw into it and machined the head down.

Dave

I found many that had a suitable thread section but the heads are too big and won't fit in between the webs on the engine backplate. Got round it by turning down the head. Drilled a suitable size hole in the end of a piece of wooden dowel or metal bar in the lathe. Then screwed to screw into it and machined the head down.

Dave

Davenz13- Platinum Member

- Posts : 597

Join date : 2013-11-28

Age : 69

Location : Palmerston North, New Zealand

Re: Prop Rod engine screws and restoration

Re: Prop Rod engine screws and restoration

Davenz13 wrote:I have hunted for the same engine mounting screws for the plastic nacelle on Prop Rod/ Shrikes before. I found many that had a suitable thread section but the heads are too big and won't fit in between the webs on the engine backplate. Got round it by turning down the head. Drilled a suitable size hole in the end of a piece of wooden dowel or metal bar in the lathe. Then screwed to screw into it and machined the head down.

I found a similar problem with model engine screws, the heads on today's screws are larger in diameter than in the past. Fortunately, unless one is attempting to maintain museum quality for display only, that hex socket head screws have the right diameter, and make engine tear down easier.

For those who have their Prop Rods as runners versus historic display only, a Plastite or sheet metal socket head screw would be easier to remove. Plus, if the threads are stripped, going from inch to metric sometimes provides one that still works but slightly larger in diameter for better grip in the plastic.

I have at times though, "JB Welded" shut a plastic screw hole, then redrilled so a screw will properly grip again. Goes ditto with sheet metal screw holes in plywood.

GallopingGhostler- Top Poster

Posts : 5723

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Prop Rod engine screws and restoration

Re: Prop Rod engine screws and restoration

I was fortunate that the four cars I have came with the original screws. A hobby shop close to me that has since shut down used to carry all manner of micro screws for sheet metal and plastic specifically for model use. They probably would have had a very close replacement. Really do miss the old school hobby shops.

bottomgun- Gold Member

- Posts : 138

Join date : 2012-12-27

Age : 67

Location : Southern California

Re: Prop Rod engine screws and restoration

Re: Prop Rod engine screws and restoration

Marleysky wrote:BTW: the Screw Co that Getback referenced in his response is here in my hometown. The address rang a bell, Ding, Ding Ding. It's in a big industrial complex that has a computer re-cycling center where I've dropped off my old Computers. As soon as they obsolete my Windows7 OS, I'll stop by and see if the sell any small screws..in small quantities!

Support for Windows 7 was discontinued by Microsoft Fall 2019. I still have a Windows 7 laptop, dual boot with a version of Ubuntu Linux. Got it in 2011, then around 2016, it was offering me a free upgrade to Windows 8 or 10, can't remember which. I kept turning it down for at least a year, because I wanted to retain Windows 7 Home for software compatibility purposes. I needed Win7 for a scanner that there is no Linux driver for.

Then one day, it declared I was no longer genuine, would not download patches any more. Since I bought it from Gateway, MS tells me that it is an OEM problem, not theirs. Now I am a software thief.

Regarding hardware suppliers, 7 years ago I bought an Enya .35-III TV. Seller provided an ANSI nut with diameter just large enough to slip over the prop shaft M7x1 threads, looked good in the photos. (Now I understand why I was the only bidder for this seller.)

Since I got it cheap enough, I went to the local Fastenal hardware store. They are a wholesaler, although any can buy, usually have to buy in bulk. I asked the salesman if they had any nuts that would fit my Enya, showed him the engine. He went to the metric nut bins. Recognizing that he's had no sales at all for a while on the M7x1 nuts, opened the package and handed me 4 of them for free.

We still have decent folk in this small town.

GallopingGhostler- Top Poster

Posts : 5723

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

bottomgun- Gold Member

- Posts : 138

Join date : 2012-12-27

Age : 67

Location : Southern California

Re: Prop Rod engine screws and restoration

Re: Prop Rod engine screws and restoration

Nice and Shiny ! Good Fun !

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Prop Rod engine screws and restoration

Re: Prop Rod engine screws and restoration

Worked on the body today. Rear number sticker came off with a little difficulty. The front gold arrow is the original water transfer decal. I was able to scrape that off with my thumbnail. The plastic is in good shape as it sits and was not hard to polish out to a nice luster. I used Meguires plastic polish and it worked fine. Just waiting for my repro stickers to come in now.

bottomgun- Gold Member

- Posts : 138

Join date : 2012-12-27

Age : 67

Location : Southern California

Page 1 of 4 • 1, 2, 3, 4

Similar topics

Similar topics» Screws For Engines

» Engine Restoration

» Cox TD-3 Instructions.

» COX QRC restoration (was: Help with identifying an engine)

» restoration PT-19 .049 engine advice needed

» Engine Restoration

» Cox TD-3 Instructions.

» COX QRC restoration (was: Help with identifying an engine)

» restoration PT-19 .049 engine advice needed

Page 1 of 4

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules