Log in

Search

Latest topics

» Tee Dee .020 combat modelby Ken Cook Today at 5:09 am

» Roger Harris revisited

by TD ABUSER Today at 2:30 am

» My latest doodle...

by batjac Yesterday at 10:05 pm

» Retail price mark-up.. how much is enough?

by gkamysz Yesterday at 9:29 pm

» Happy 77th birthday Andrew!

by roddie Yesterday at 9:22 pm

» My N-1R build log

by GallopingGhostler Yesterday at 3:04 pm

» Chocolate chip cookie dough.........

by roddie Yesterday at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Yesterday at 11:32 am

» Free Flight Radio Assist

by rdw777 Yesterday at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

Pee Wee Horseshoe back plate

Page 2 of 7

Page 2 of 7 •  1, 2, 3, 4, 5, 6, 7

1, 2, 3, 4, 5, 6, 7

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

I'll find out tomorrow.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

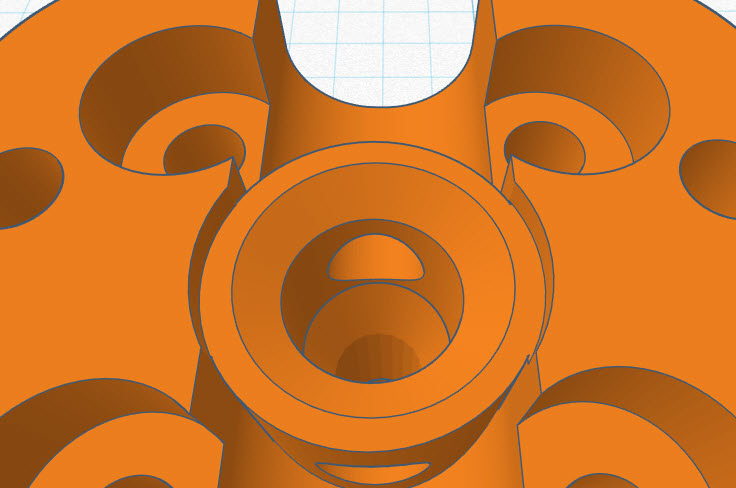

Hehe yessa all set for a run up no doubt, did you bake it in the oven at 180 degs?

I read up on this less shrink ideal for non flex applications, good for up to 220F

That should do the trick, I think you have a winner here.

I read up on this less shrink ideal for non flex applications, good for up to 220F

That should do the trick, I think you have a winner here.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

Good job Jason  can always add two caskets to seal it up if push comes to shove.

can always add two caskets to seal it up if push comes to shove.

The intake will need to be free of any possible ingestion of carbon scraps.

The stuff wears out applicator tips there is an alt. tip for this Carbon mix.

Hex head screws should do well to join the backplate to the crank case.

Post a running vid if you can.

can always add two caskets to seal it up if push comes to shove.

can always add two caskets to seal it up if push comes to shove. The intake will need to be free of any possible ingestion of carbon scraps.

The stuff wears out applicator tips there is an alt. tip for this Carbon mix.

Hex head screws should do well to join the backplate to the crank case.

Post a running vid if you can.

Last edited by 1/2A Nut on Tue Feb 19, 2019 9:38 pm; edited 1 time in total

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

That's Sweet !! I likeie the black to , Fingers crossed to hear some noise .

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

Very nice. I too like the black. Can't wait to see the test video or just hear of results.

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

Hopefully the mods you made to the original work out good. I definately like the look of it.

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

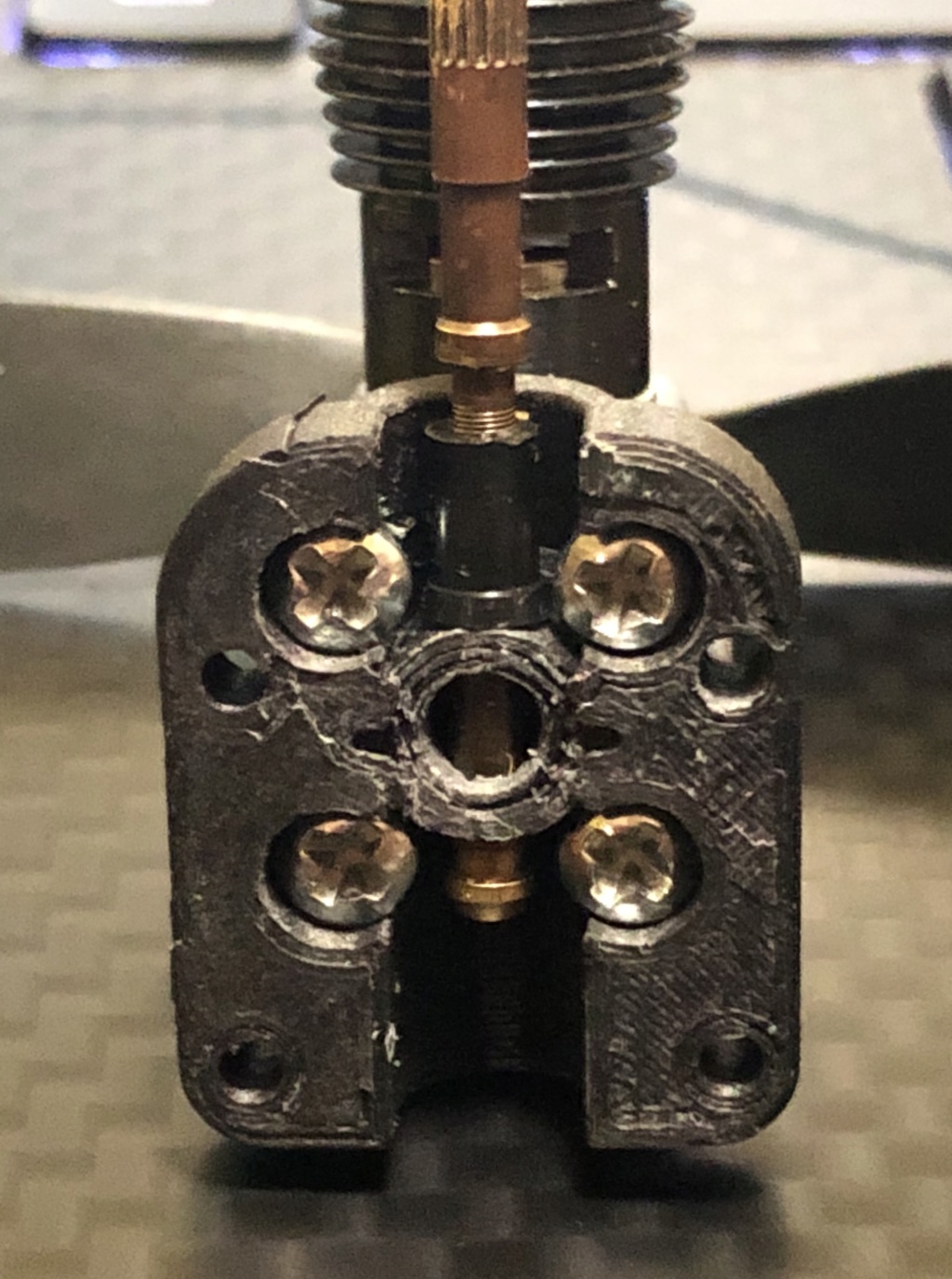

It ran until the nitro in the Cox super power fuel softened the ABS and the NVA was loose and the reed melted into the face of the reed seal area. So it shows promise just wrong material. I have carbon fiber nylon I can try. Also have POM or also called Acetal.

I only caught the last few seconds of the run but YouTube is being cranky. Here are pics of the meltage.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

Oops. But on the bright side, it did show promise and run!

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

IT Ran !!! ++++ How was the short run ? Performance wise .

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

I don’t know. By the time I got the needle set it was starting to die. Slowly melting.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

Well, now you know. How much is all this material costing you?

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

The CF ABS print above was 1.25 hours of print time and about $.30 of material. However it proved the concept worked so it wasn’t considered a failure. Just poor choice in material.

The CF nylon spool I have was a sample from a filament extruder that was free. PLA is about $.02 per gram. Standard DuPont Zytel is $.09 per gram.

The CF nylon spool I have was a sample from a filament extruder that was free. PLA is about $.02 per gram. Standard DuPont Zytel is $.09 per gram.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

Could you possibly cut off small strips and test fuel compatibility before printing? Might save you time and a little money.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

Well done Jason! Excellent work.

I should really follow this forum more closely. I did some test mills on my hobby grade CNC machine last year with the same 020 backplate in mind. I was milling them out of a solid chunk of hdpe since that is what glow fuel bottles are made of. Unfortunately HDPE either melts or chips when being milled. Chips are what you want when milling HDPE but they lead to a lightly faceted texture all over the product which caused dimensional issues in the reed seat area. I also realised I hadn’t considered the heat from the running engine in my material choice.

I should really follow this forum more closely. I did some test mills on my hobby grade CNC machine last year with the same 020 backplate in mind. I was milling them out of a solid chunk of hdpe since that is what glow fuel bottles are made of. Unfortunately HDPE either melts or chips when being milled. Chips are what you want when milling HDPE but they lead to a lightly faceted texture all over the product which caused dimensional issues in the reed seat area. I also realised I hadn’t considered the heat from the running engine in my material choice.

halfpilot- Formerly known as:

ThermalSniffer

- Posts : 96

Join date : 2011-09-06

Location : England

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

What material are the .049 back plates made from ? Jason , these .020 horse shoe back plates are going to be the new hot thing in the Cox world . I would think nylon would work for these back plates .

Mike1484

Mike1484

Mike1484- Gold Member

- Posts : 303

Join date : 2011-10-28

Age : 76

Location : Northern Ohio

ticomareado- Account Under Review

- Posts : 1089

Join date : 2013-10-03

Location : NC

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

I guess the plastic should be the same Cox used on their PT-22s and .020 helicopters.

ticomareado- Account Under Review

- Posts : 1089

Join date : 2013-10-03

Location : NC

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

ticomareado wrote:You dah man, Jason!

TRUTH !!!!

We may have to petition the Admin to create a C.E.F. Hall of Fame !!!!

Kim- Top Poster

Posts : 8625

Join date : 2011-09-06

Location : South East Missouri

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

Kim wrote:ticomareado wrote:You dah man, Jason!

TRUTH !!!!

We may have to petition the Admin to create a C.E.F. Hall of Fame !!!!

I second the motion

fit90- Diamond Member

- Posts : 1341

Join date : 2011-08-11

Location : Naples, Florida

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

Sometimes things go bad when changing nozzle sizes on the 3D printer. Almost new .4 mm plated copper nozzle twisted off in the heat block. It started to squeak when tightening it up. I stopped and tried to turn it out and this happened. Good thing I have spares on hand.

Been fighting nylon and the .25mm nozzle all day. Jamming up. I tried to slow down the print speed without luck. Back to .4mm nozzle and .2mm layer height for the backplate with nylon.

Been fighting nylon and the .25mm nozzle all day. Jamming up. I tried to slow down the print speed without luck. Back to .4mm nozzle and .2mm layer height for the backplate with nylon.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

I seen that pic and thought man that back plate had a BAD melt down , well glad you had a back up , Hope you can get the nozzle size figured out for the right layering .

I seen that pic and thought man that back plate had a BAD melt down , well glad you had a back up , Hope you can get the nozzle size figured out for the right layering .

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

That picture Jason resembles some of the engines I have been working on lately.

Bob

Bob

rsv1cox- Top Poster

Posts : 11248

Join date : 2014-08-18

Location : West Virginia

Page 2 of 7 •  1, 2, 3, 4, 5, 6, 7

1, 2, 3, 4, 5, 6, 7

Similar topics

Similar topics» cox pee wee .020 back plate or fuel tank with back plate

» Guilow edge g-540 rc

» Cox PT-19 part

» Baby Bee back plate

» Wanted: Metal backplate for Black Widow or Golden bee. Ventless

» Guilow edge g-540 rc

» Cox PT-19 part

» Baby Bee back plate

» Wanted: Metal backplate for Black Widow or Golden bee. Ventless

Page 2 of 7

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules