Log in

Search

Latest topics

» Roger Harris revisitedby rsv1cox Today at 7:35 am

» Tee Dee .020 combat model

by GallopingGhostler Today at 7:01 am

» My latest doodle...

by batjac Yesterday at 10:05 pm

» Retail price mark-up.. how much is enough?

by gkamysz Yesterday at 9:29 pm

» Happy 77th birthday Andrew!

by roddie Yesterday at 9:22 pm

» My N-1R build log

by GallopingGhostler Yesterday at 3:04 pm

» Chocolate chip cookie dough.........

by roddie Yesterday at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Yesterday at 11:32 am

» Free Flight Radio Assist

by rdw777 Yesterday at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

Pee Wee Horseshoe back plate

Page 5 of 7

Page 5 of 7 •  1, 2, 3, 4, 5, 6, 7

1, 2, 3, 4, 5, 6, 7

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

They look really good Jason , Looks like a bit of cleanup after the print but is nice and smooth product .

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

1/2A Nut wrote:How much does that assembly weigh with engine?

Both the horseshoe and the venturi mount weigh 24g with black prop, screw, and starter spring. The tanked Pee Wee weighed 27g. So about 3 grams less than a standard Pee Wee.

Not much weight savings.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

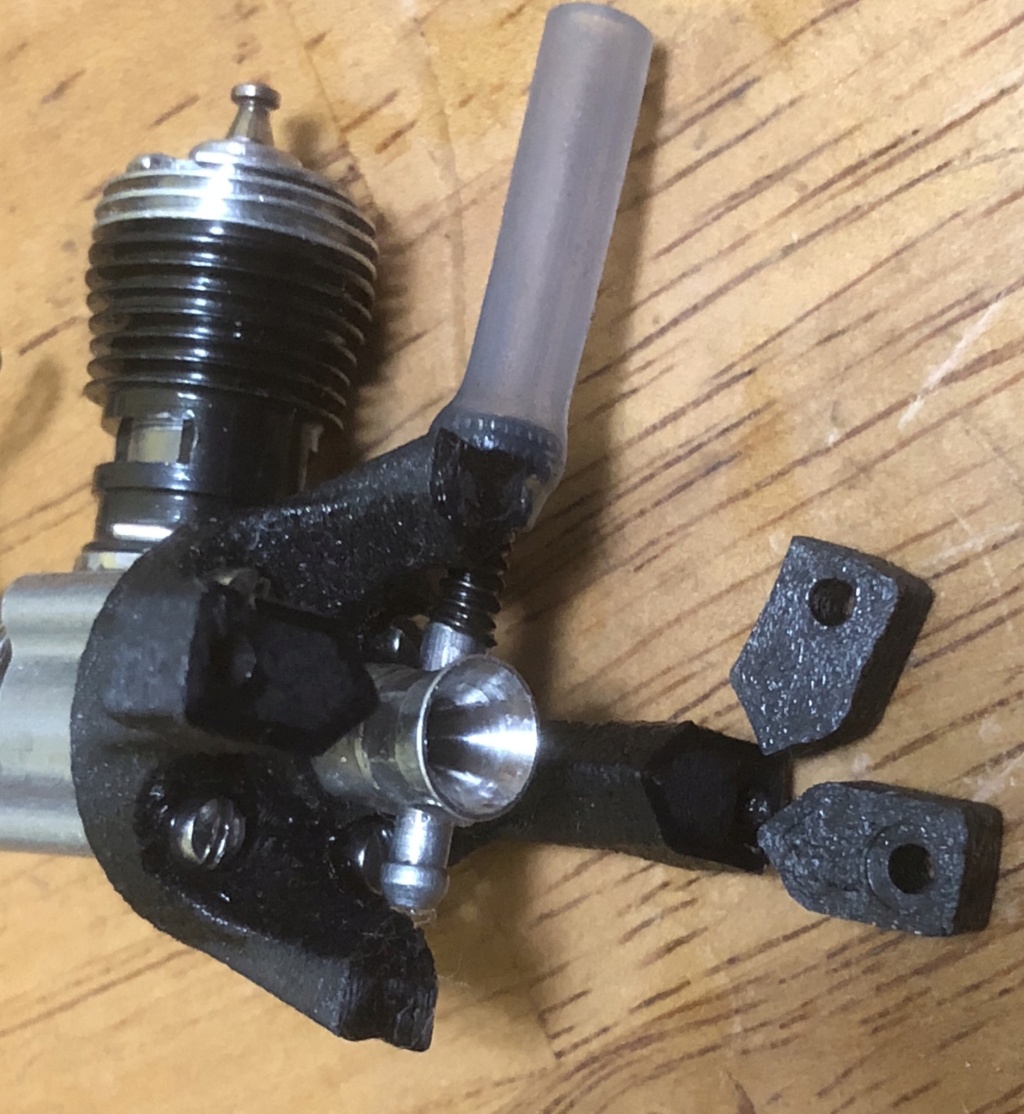

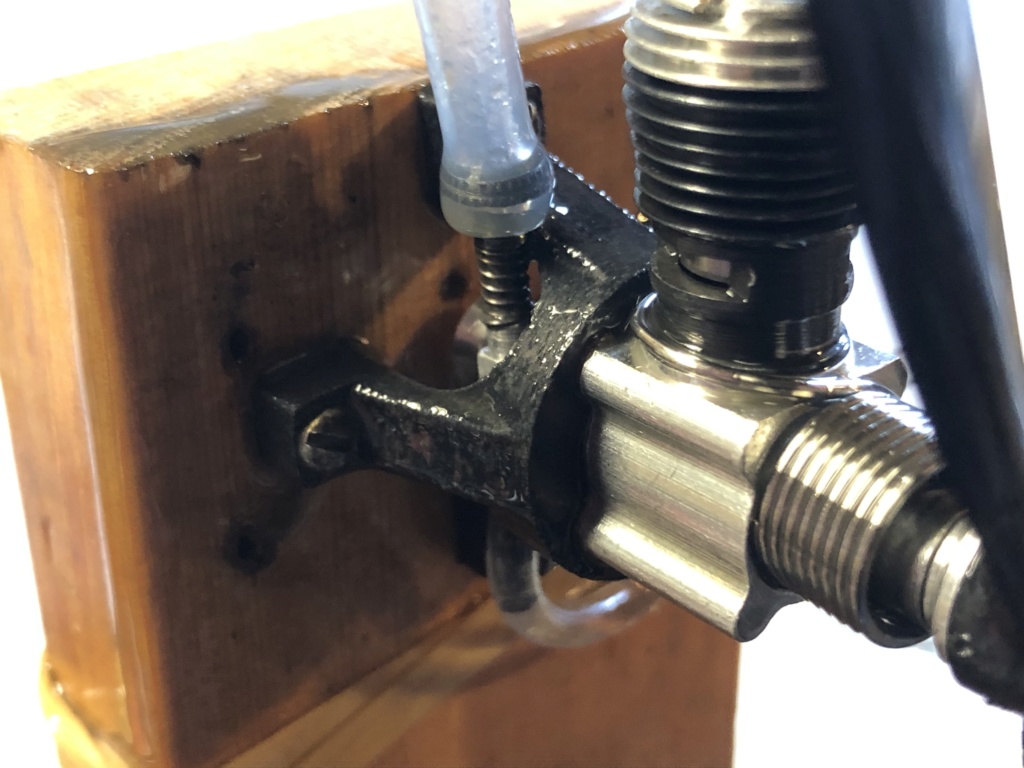

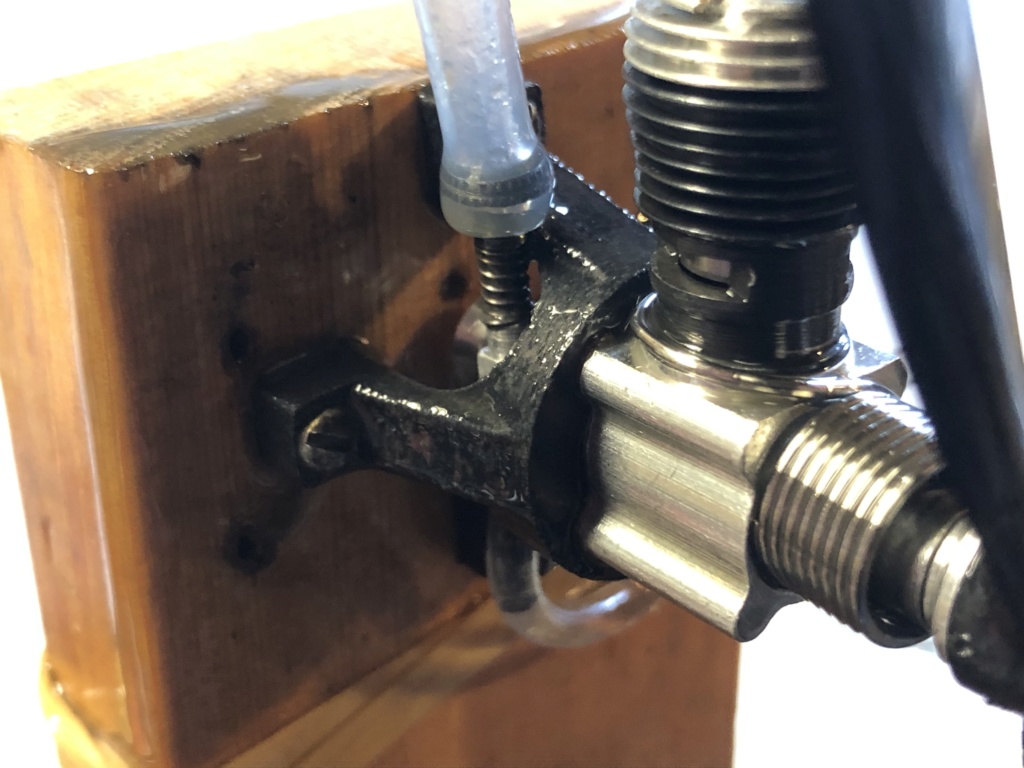

Shortened the tube in the back to allow more clearance for the needle valve from the firewall. Filed in some notches in the mounting legs to allow clearance for the needle and the fuel tube. I’m going to add that feature and beef up the other side of the notch to add strength.

This is a 7 minute run. The syringe sucks as a tank since the fuel height affects the draw. I’ll have to mount a decent tank so I don’t have to mess with the needle during testing. Nothing melted on this longer run. Too bad the TD .020 fine thread needle valve assemblies from Ace RC are hard to find. That would be an awesome addition to this setup. I have one I can try.

Cox 25% super power fuel and a black 4.5x2 flexible prop.

A pic after the run.

Set off the smoke alarm this time.

This is a 7 minute run. The syringe sucks as a tank since the fuel height affects the draw. I’ll have to mount a decent tank so I don’t have to mess with the needle during testing. Nothing melted on this longer run. Too bad the TD .020 fine thread needle valve assemblies from Ace RC are hard to find. That would be an awesome addition to this setup. I have one I can try.

Cox 25% super power fuel and a black 4.5x2 flexible prop.

A pic after the run.

Set off the smoke alarm this time.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

3:23am? Man, that’s well after last call and you’re doing test runs of a 020 in the house! I mean, there’s nothing wrong with that, I am impressed with your work and willingness to work into the wee hours to accomplish amazing projects! Keep it up!

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 72

Location : Grand Rapids, MI

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

I wanted to see if it would run with an 80 TPI NVA from a sure start backplate. It runs but the needle setting is very touchy which is expected. Same prop and fuel as previous runs.

Video posted earlier today than well......... today.

Video posted earlier today than well......... today.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

Need to back off with the cell phone camera the static noise is messing up the audio app readings for rpm.

Back away and use the camera's software zoom feature so the mic is not so close need some clean audio

for future reference.

Back away and use the camera's software zoom feature so the mic is not so close need some clean audio

for future reference.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

what app R U using again Brad , Thanks

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

Has presets for 2 stroke / 4 stroke and multi cylinders / low rpm and high rpm set to

what you expect to get out of the engine most times 30k is enough for TD engines.

what you expect to get out of the engine most times 30k is enough for TD engines.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

Suggestion for next Pee Wee printer project:

Do a scaled down copy of a Kavan Baby Bee tank extender for the Pee Wee.

Do a scaled down copy of a Kavan Baby Bee tank extender for the Pee Wee.

ticomareado- Account Under Review

- Posts : 1089

Join date : 2013-10-03

Location : NC

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

ticomareado wrote:Suggestion for next Pee Wee printer project:

Do a scaled down copy of a Kavan Baby Bee tank extender for the Pee Wee.

That would be like the SR-71......leaks fuel on the ground till takeoff.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

18,087 rpm much better =)

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

Thanks Brad , will get it . Jason i guess that material is too tight ,ridged , stiff too early but you get it has no flex lol1/2A Nut wrote:'RPM Gauge" for android phones.

Last edited by getback on Sat Mar 09, 2019 6:36 am; edited 1 time in total (Reason for editing : add on)

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

I don't want to be the one to say it, but a machined mount from aluminum would be the way to go. Somewhat like the Surestart. Maybe some kind of air intake coming out the side for a throttle? Maybe not. It would be more solid and stronger IMHO. As a speed guy, an aluminum pan would always be good for a few revs too. Having said that, maybe a fillet on the back tabs could be designed in on the next one.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

Nice going Jason, your experimental proof of concept

indicates great potential with a few minor changes, IMO.

indicates great potential with a few minor changes, IMO.

It shattered because of concentrated stress point being the near 90 degree angle of the mounting foot. This is why the British Comet jets were discovered to burst and lose cabin pressurization after so many hours of flight. The passenger compartment windows were rectangular. The window vertices at a sharp 90 degree angle in the aluminium frame and aircraft skin provided a high stress concentration point. The constant high frequency vibrations combined with expanding and contracting by cabin pressurization and depressurization coupled with fuselage bending by flight loads lead to material fatigue and weakness. After a couple blew apart in mid-air killing all, the aircraft were grounded.

The entire industry was benefited by the retrofits required to mitigate. This is why all subsequent airliners by all manufacturers now have oval shaped windows.

I remember the DC-9 cabin pressurization depressurization test when I worked at Douglas Aircraft in the 1980's. It had already passed one life time (20 years flying), when the after test bulkhead blew out. They repaired it, went another life time. Then the retired the test.

It's why you don't see DC-9's and derivatives (MD-80's, MD-90's) becoming convertibles in the air. Douglas prided themselves on their structural designs. (Not saying there were not other weaknesses; 1999, an Alaska Air MD-80 crashed when its elevator screw jack fatigued and failed.) It's why you still see an occasional DC-8 flying, now re-engined with turbo fans (basically ducted fan turbine engines). That aircraft was considered to have an unlimited lifetime. You don't see any old Boeing 707's flying.

As is, I gather that you had a very small cross sectional area to carry the weight of the engine (shear) and its bending moment (engine CG times distance to engine bulkhead, in in.-oz. or its metric equivalent). I'm thinking that if you were to move the mount legs inward slightly to a straighter position, provide a radius in lieu of the sharp inner corner near where engine bulkhead screw mounts, and may be even a triangular web outboard of the screw to strengthen the 90 degree at the foot, might be enough to mitigate point fatigue. This will increase the amount of material at the foot to carry the vibration load.

YMMV (Your Mileage May Vary).

GallopingGhostler- Top Poster

Posts : 5724

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

Worth the weight penalty if the engine makes 800 rpm + more over a stock Pee Wizzer.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

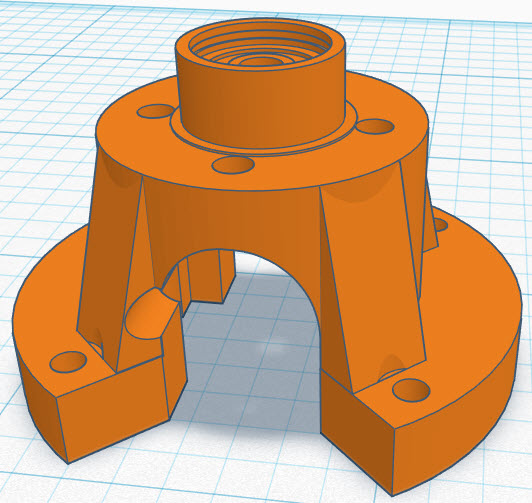

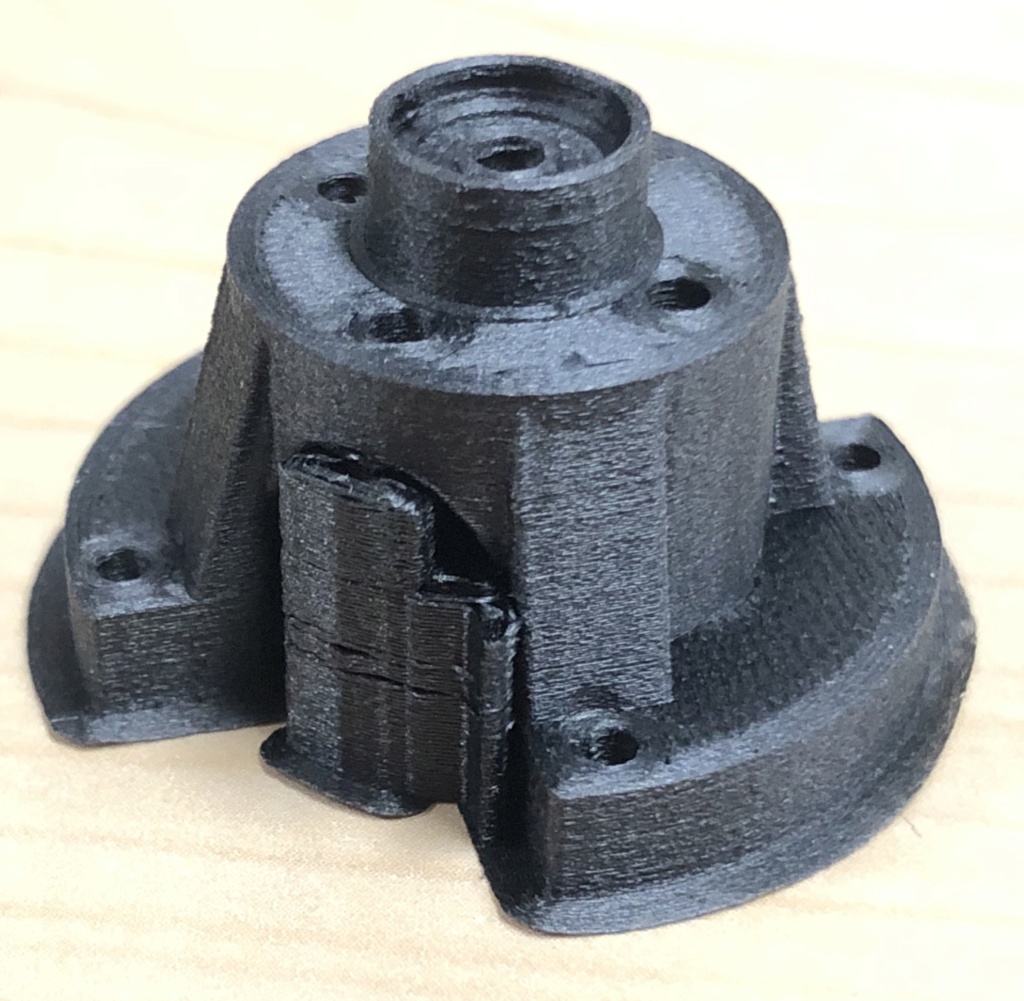

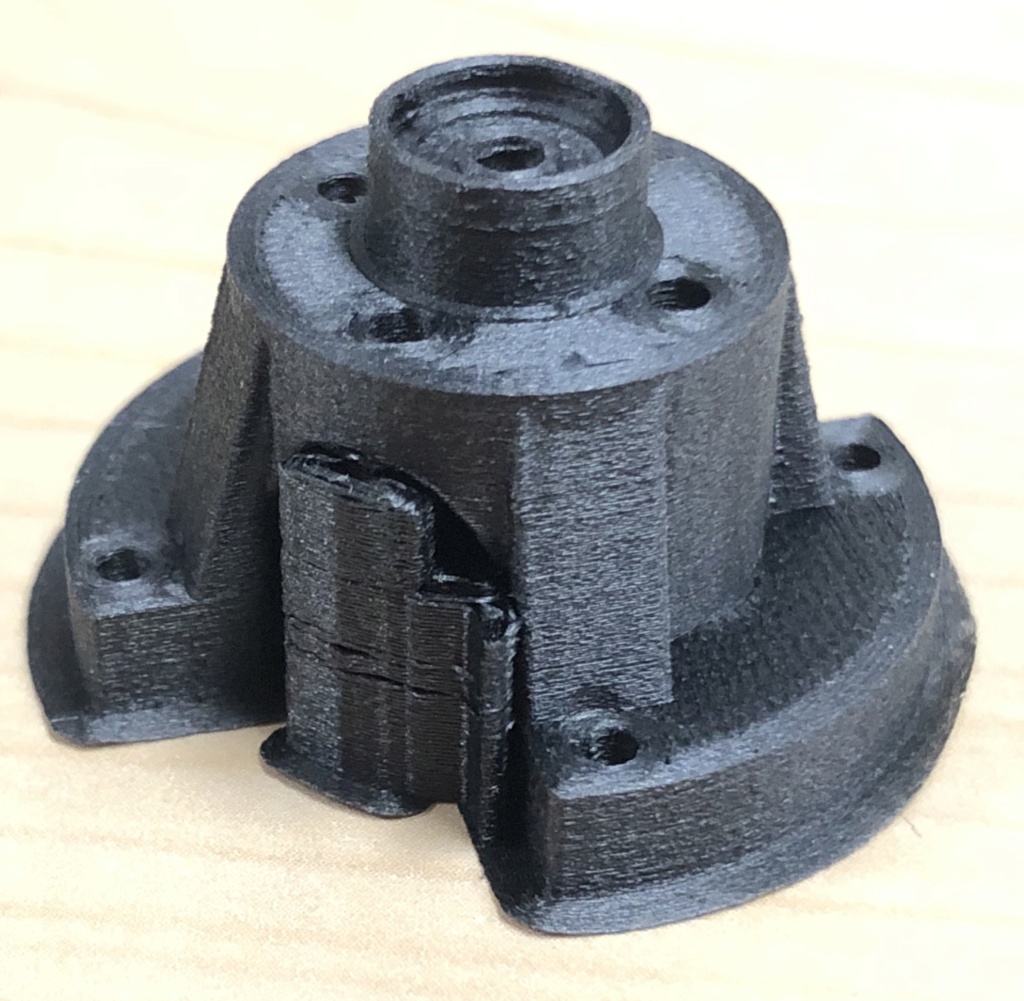

Here it is printed with a .25mm nozzle at .1mm layer height. This is after the upgrade to my printer using .9 degree/step vs 1.8 degree/step stepper motors on the x and y axis.

You can see the difference in print quality in the #3 text on the side of the part. Left is .9 degree and right is 1.8 degree.

You can see the difference in print quality in the #3 text on the side of the part. Left is .9 degree and right is 1.8 degree.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

The difference is indeed noticable. Either way, those that would like one, I am sure would be happy with either. Have you yet had a chance to test the new one to see if it is better in any aspects of running?

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

RE: Aspeed's aluminum suggestion. Also the reed valve "check action" would be much better on a smoothly machined aluminum surface

ticomareado- Account Under Review

- Posts : 1089

Join date : 2013-10-03

Location : NC

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

ticomareado wrote:RE: Aspeed's aluminum suggestion. Also the reed valve "check action" would be much better on a smoothly machined aluminum surface

The reed seal surface is polished with 400 then 1000 then 2000 grit. This pic is hot off the printer without any prep work done to it. Aluminum probably is better but I don't have a 5 axis CNC mill.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

A regular 3 axis mill would be fine. Even a standard lathe and mill. The time involved would have a high price. I have an old Hardinge turret lathe that could rough out one half and then the rest could be milled on a standard mill. I would guess a couple hours a piece with all the holes etc. Minimum wage would even be expensive for this method.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

I have a lathe and mill also and I would not want to make these in any quantities manually.

I press print, come back 6 hours later and 4 backplates are done. I spend 30 minutes removing the support material and polish up the reed seal surface and they are ready to run. The only two critical smooth surfaces are the reed seal area and the gasket area which is already smooth. Yes the external surface is not as smooth as a injected molded or machined part but it works. I did have failure with the mounting legs. I believe I have that fixed now with the venturi backplate design.

I press print, come back 6 hours later and 4 backplates are done. I spend 30 minutes removing the support material and polish up the reed seal surface and they are ready to run. The only two critical smooth surfaces are the reed seal area and the gasket area which is already smooth. Yes the external surface is not as smooth as a injected molded or machined part but it works. I did have failure with the mounting legs. I believe I have that fixed now with the venturi backplate design.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: Pee Wee Horseshoe back plate

Re: Pee Wee Horseshoe back plate

Relative roughness of the 0.9 degree backs is no rougher than some of the bead blasted aluminium crankcases on some engines. I'd say you did well, Jason.

We now see the reasoning why Cox moulded backs initially out of Delrin. The machining was invested in making the mould. The injection process was quick, adequate, low cost, reasonably accurate, and sufficiently durable.

We now see the reasoning why Cox moulded backs initially out of Delrin. The machining was invested in making the mould. The injection process was quick, adequate, low cost, reasonably accurate, and sufficiently durable.

GallopingGhostler- Top Poster

Posts : 5724

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Page 5 of 7 •  1, 2, 3, 4, 5, 6, 7

1, 2, 3, 4, 5, 6, 7

Similar topics

Similar topics» cox pee wee .020 back plate or fuel tank with back plate

» Guilow edge g-540 rc

» Cox PT-19 part

» Baby Bee back plate

» Wanted: Metal backplate for Black Widow or Golden bee. Ventless

» Guilow edge g-540 rc

» Cox PT-19 part

» Baby Bee back plate

» Wanted: Metal backplate for Black Widow or Golden bee. Ventless

Page 5 of 7

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules