Log in

Search

Latest topics

» My latest doodle...by batjac Yesterday at 10:05 pm

» Retail price mark-up.. how much is enough?

by gkamysz Yesterday at 9:29 pm

» Happy 77th birthday Andrew!

by roddie Yesterday at 9:22 pm

» Roger Harris revisited

by rsv1cox Yesterday at 3:38 pm

» My N-1R build log

by GallopingGhostler Yesterday at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Yesterday at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Yesterday at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Yesterday at 11:32 am

» Free Flight Radio Assist

by rdw777 Yesterday at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

Turnigy thrust stand conversion

Page 1 of 1

Turnigy thrust stand conversion

Turnigy thrust stand conversion

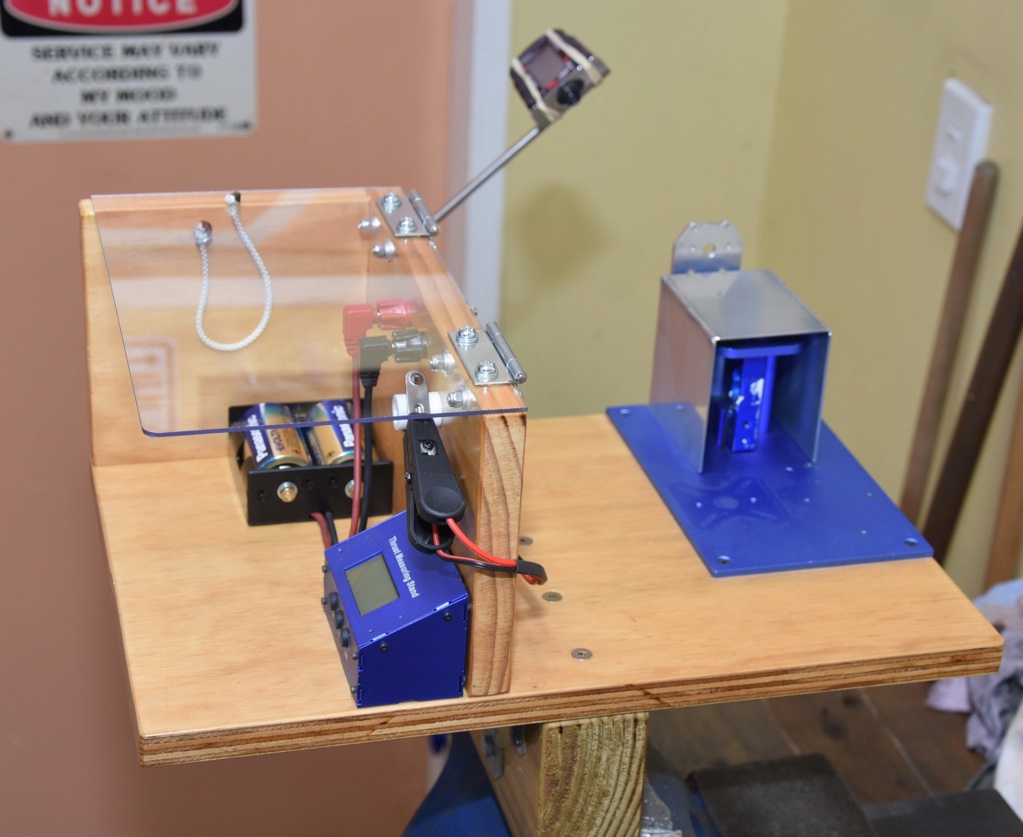

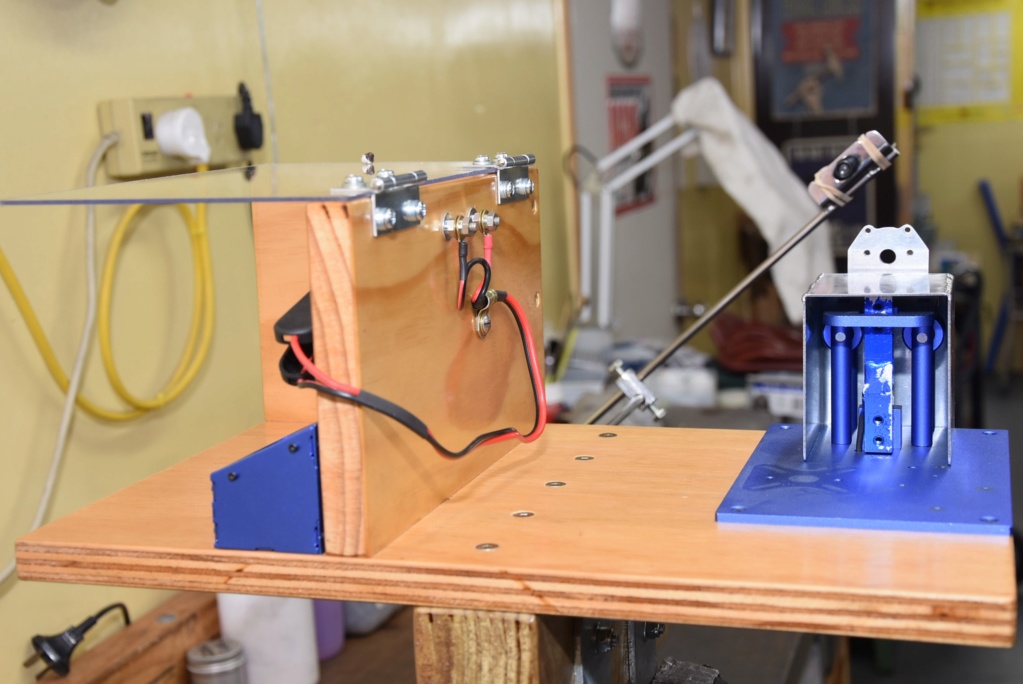

Originating from the “My Money is on the Table” thread I thought it might be better to have the stand conversion as a separate post.

The idea being to covert a Turnigy thrust measuring stand, designed for electric motors, to be able to test fuelled motors.

The main problem to me seemed to be stopping fuel residue from gumming up everything.

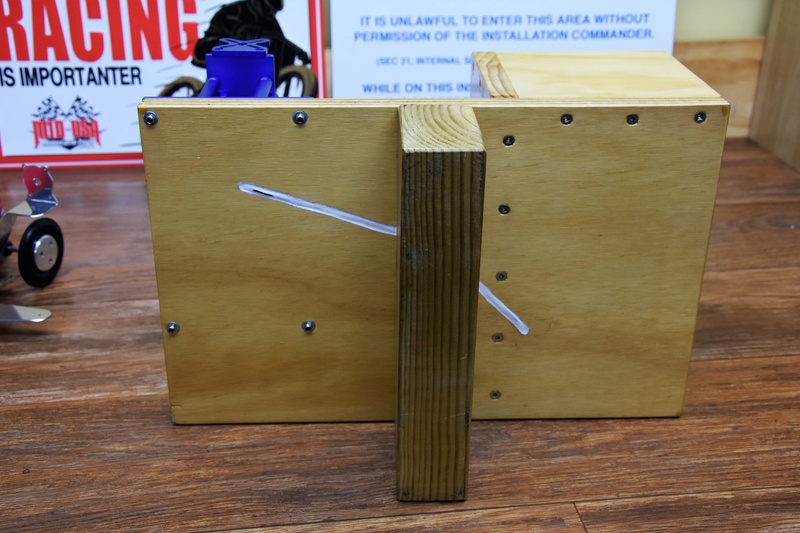

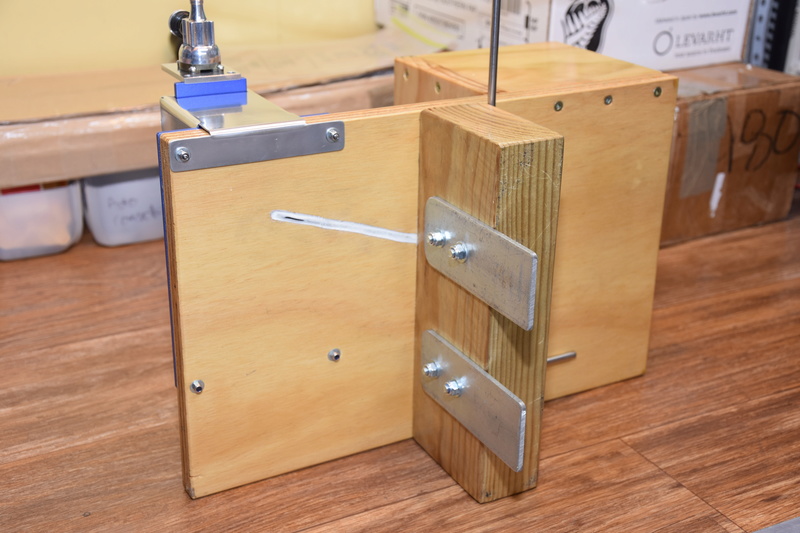

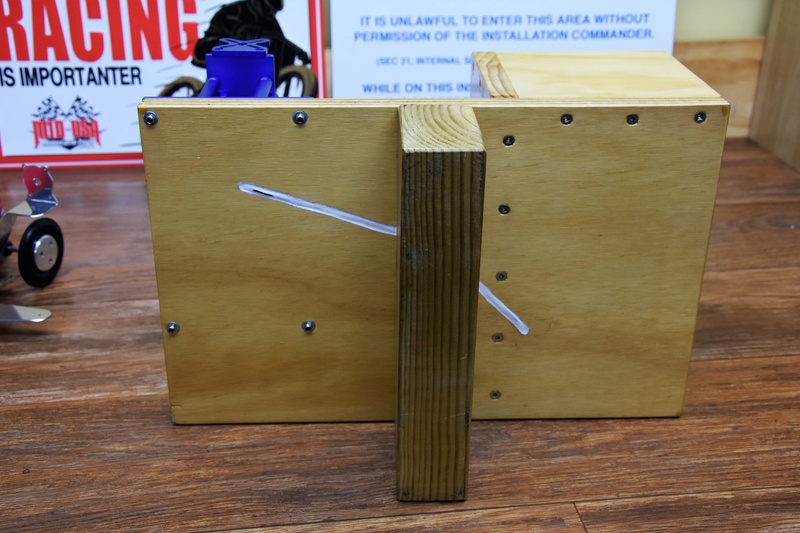

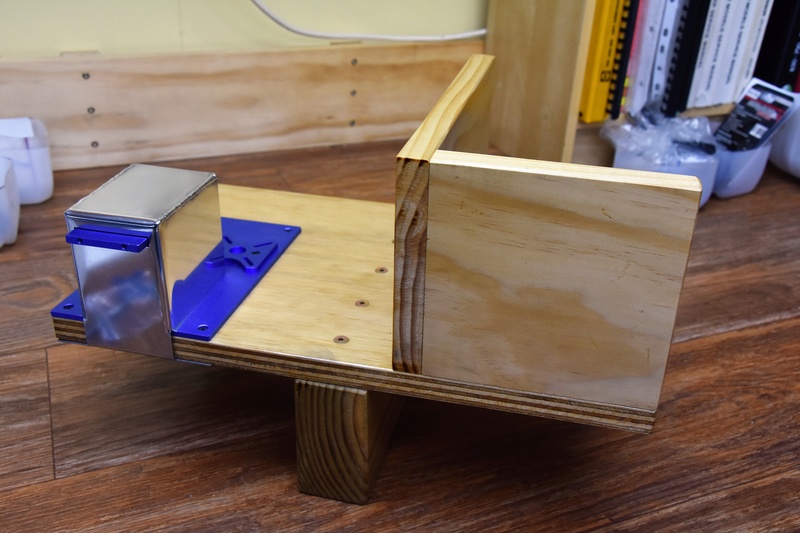

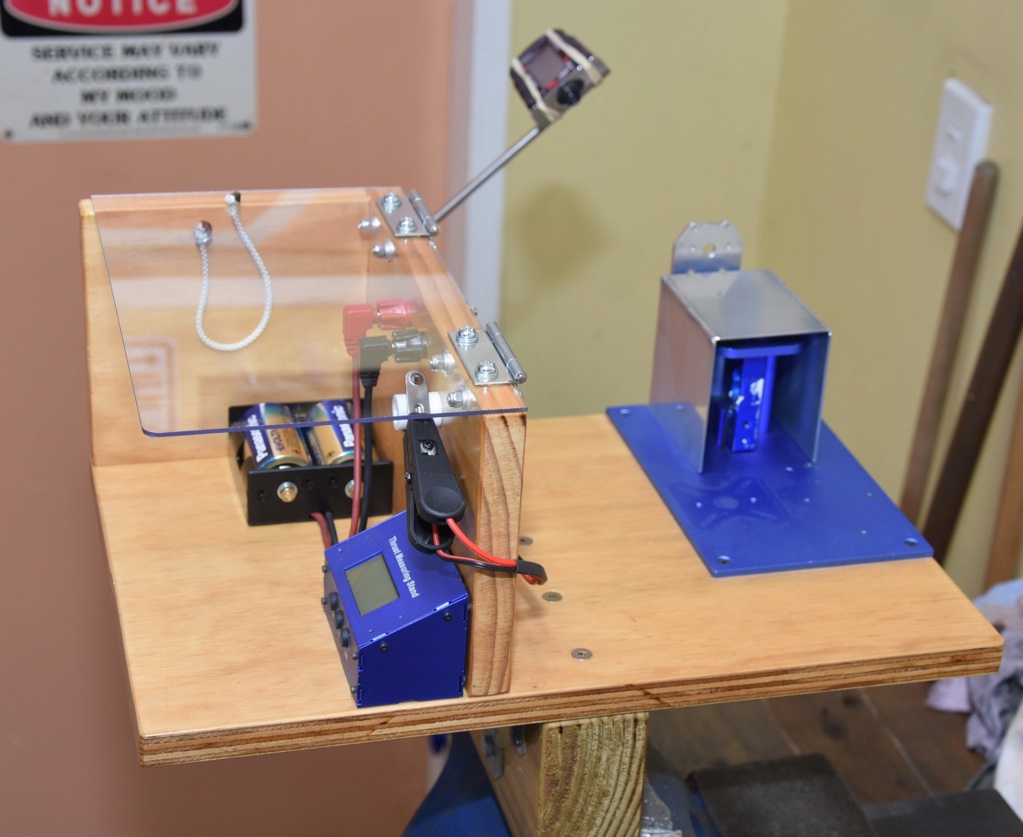

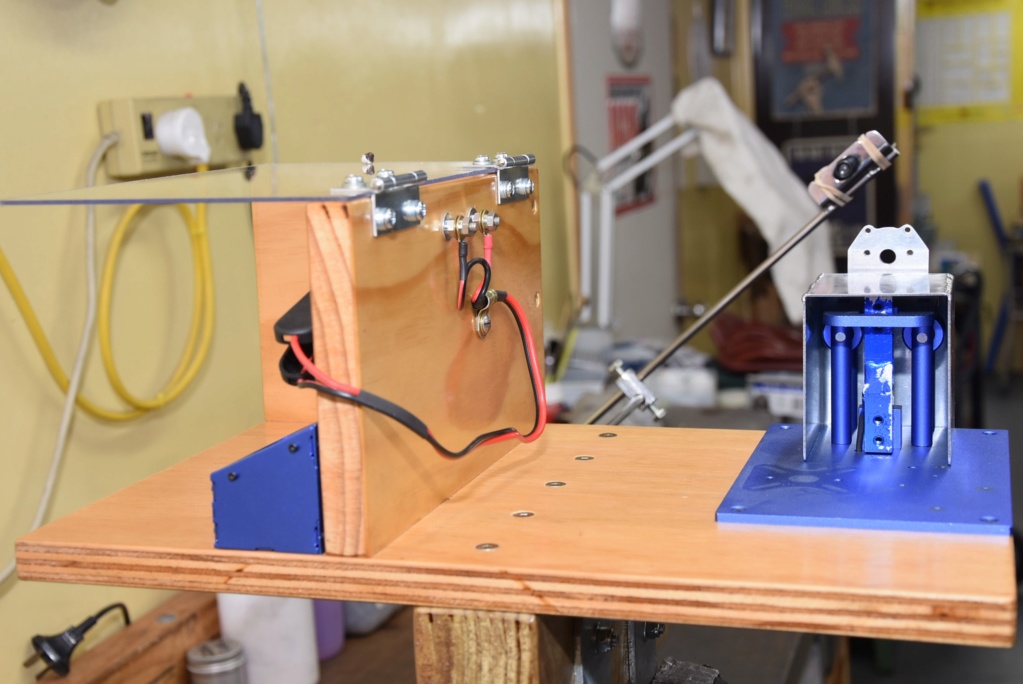

I made a platform to mount it on and removing the control panel from the base, placed it behind a piece of wood away from the engine stand, extending and running the wiring underneath the platform.

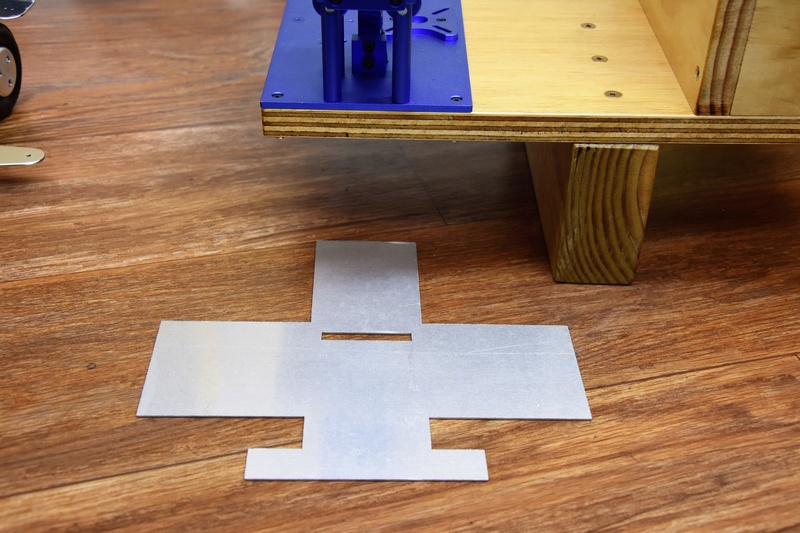

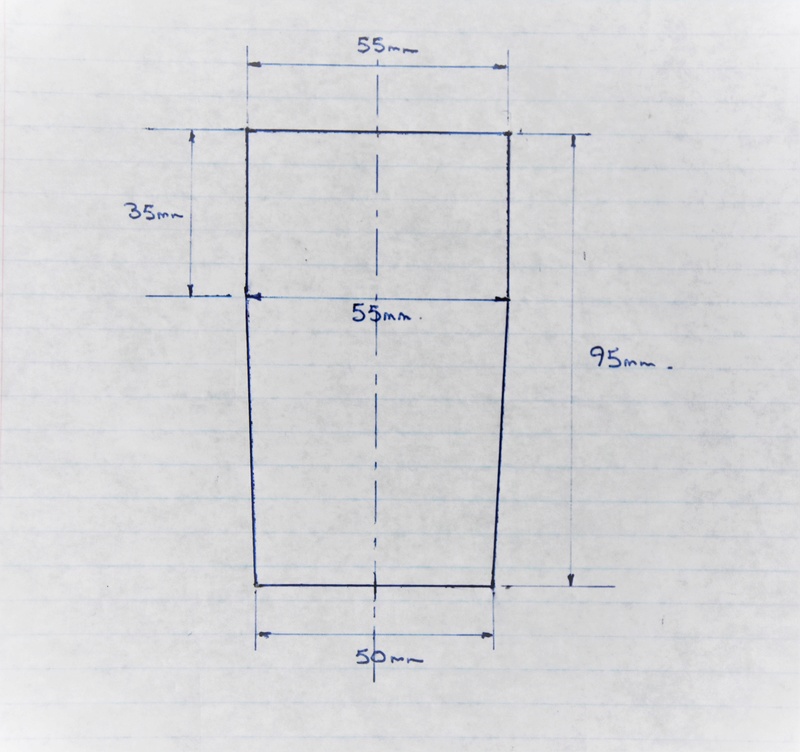

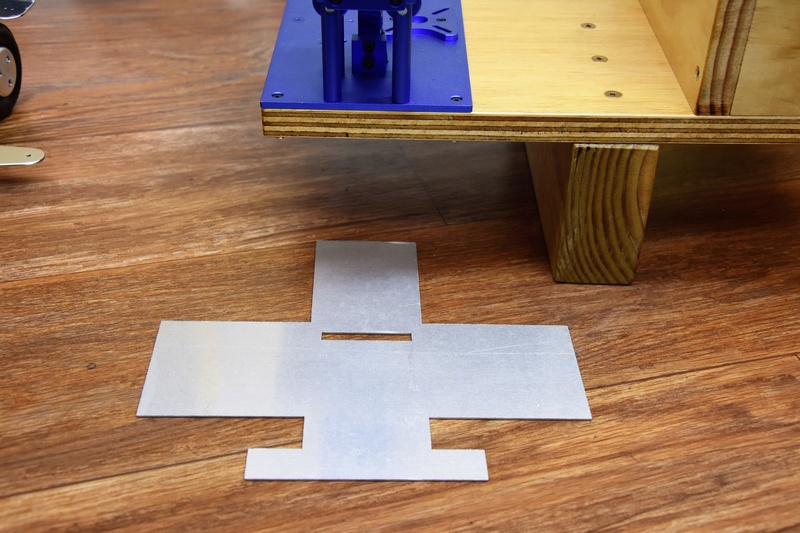

The aluminium plate (cut by a mate of mine who’s runs a water jet cutter, very handy machines) is for covering the engine stand to hopefully keep most of the fuel residue off it. The three sides, left, top and right will be folded back to form two sides and a top over the engine stand. The flat top of the engine stand will protrude through the slot (the X shaped engine mount is removed for fitting) and the area below the slot is for fixing the cover to the plywood base.

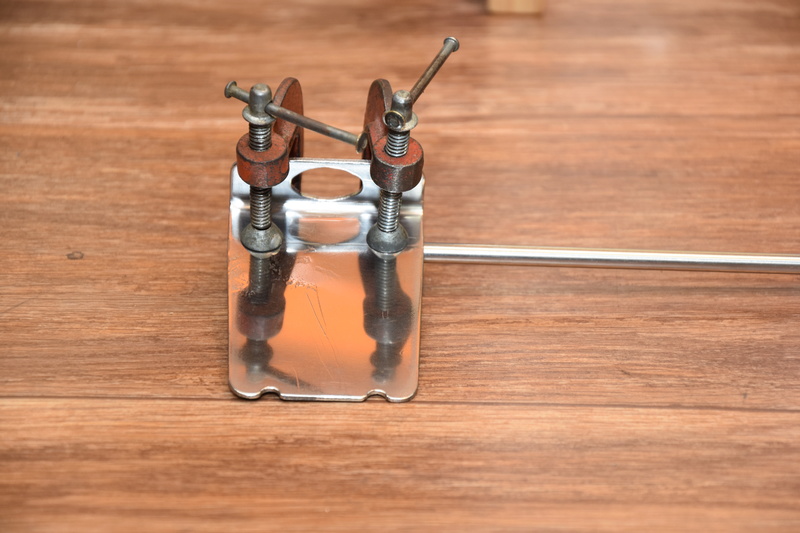

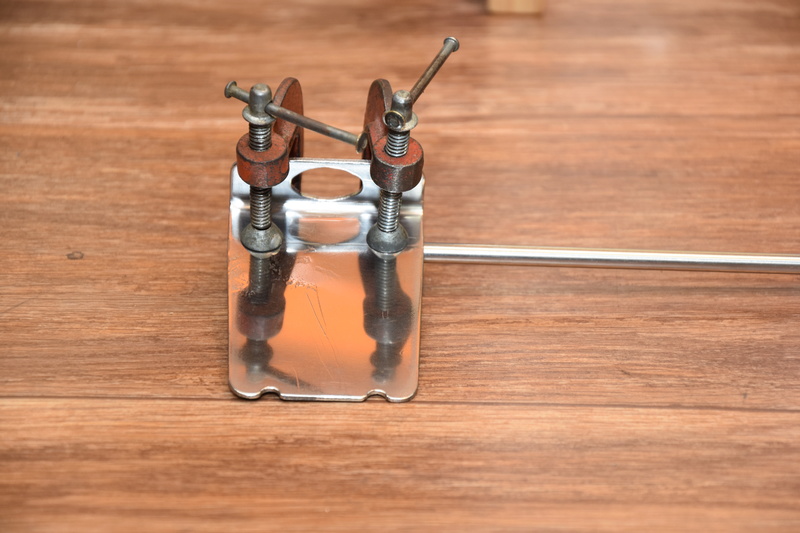

I bought a cheap science stand (ebay $7 out of China, free shipping) mainly for the clamps for mounting the tacho, and also allowing for adjustment fore and aft with different size engines.

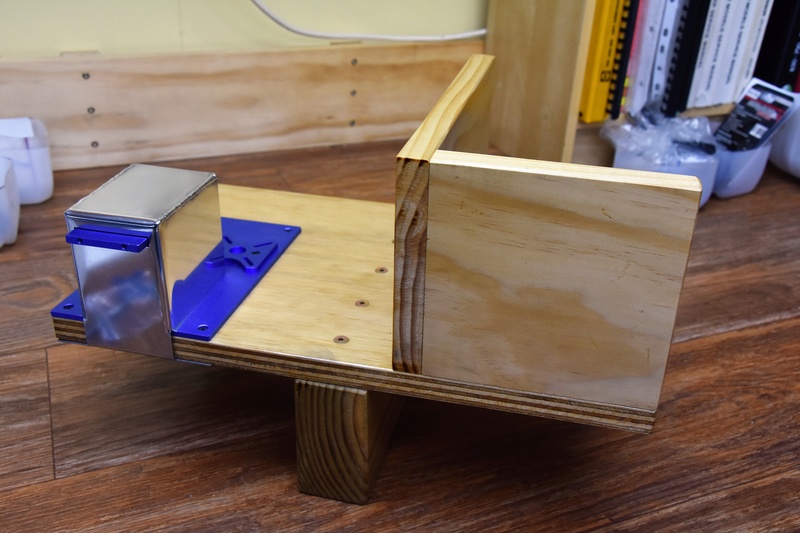

Cover folded and seams welded and mounted to base

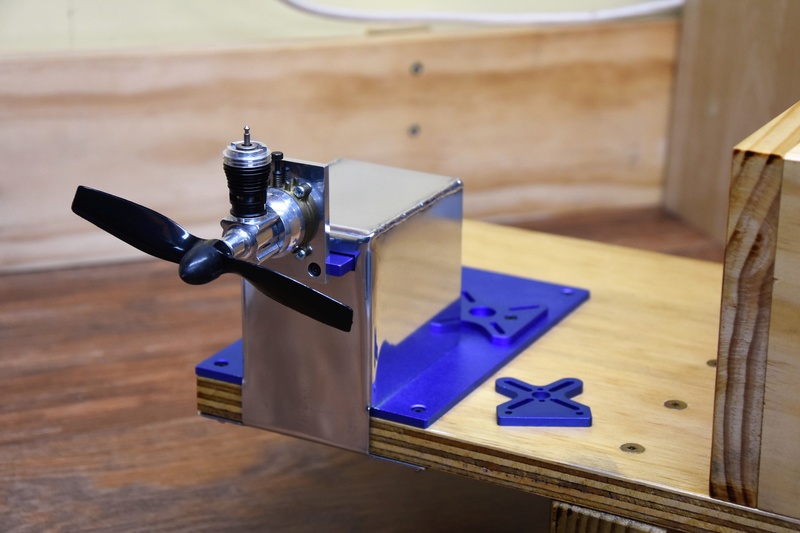

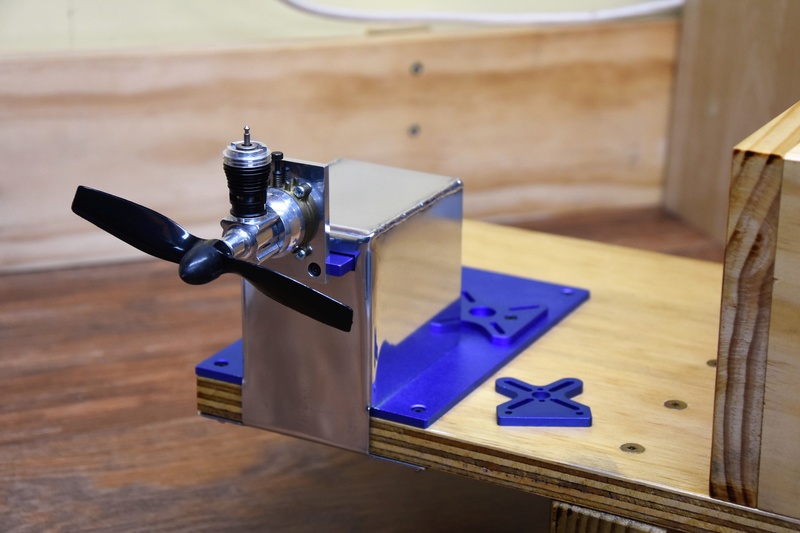

Of course the Bee’s engine mounting holes wouldn’t fit the supplied mounts so a suitable mount had to be made out of a piece of scrap alloy.

so a suitable mount had to be made out of a piece of scrap alloy.

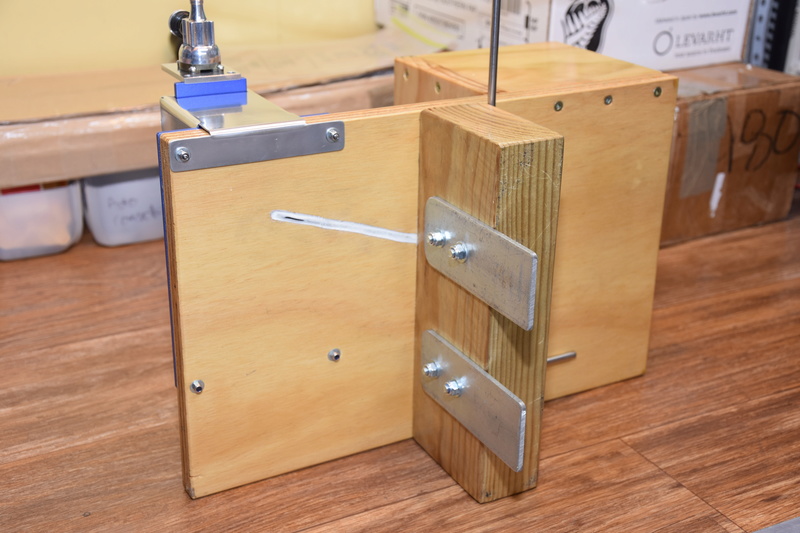

Next bend up some 6mm stainless rod for the tacho mount. Ran it through some steel cable clips to act as bushes and fabricated a backstop for the rod but leaving a gap so it can be removed if needed.

Bolted a couple of steel tabs to the base so the whole unit can be clamped in a vice.

Probably overkill but there may end up some bigger motors being tested

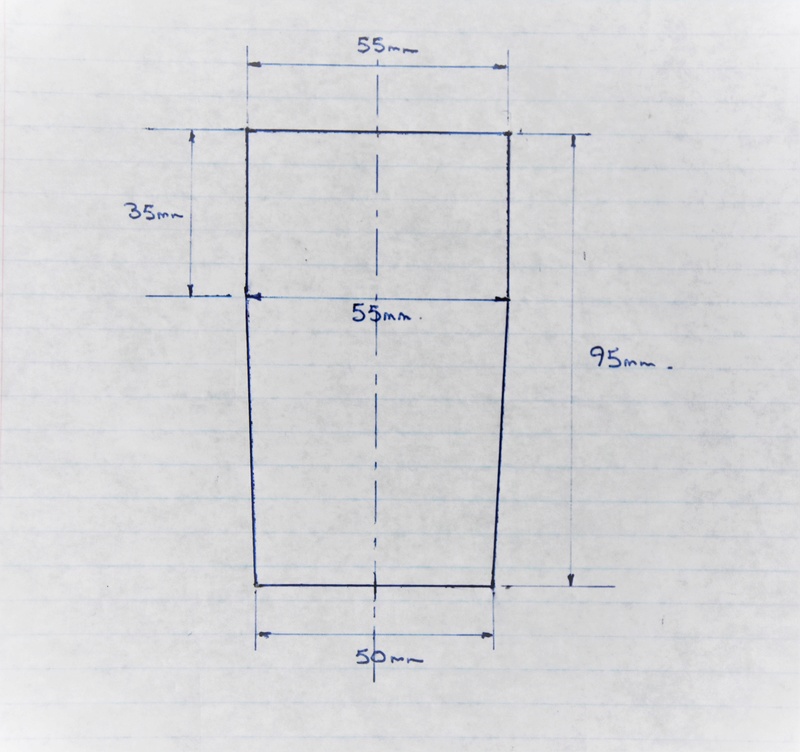

Drew a design for the tacho mount and sent it off to my mate for cutting out.

Bent it up at one end and made a hole for the tacho lens to fit through. Made some slots fore and aft (front slots hidden by clamps) for rubber bands holding the tacho unit.

All clamped up ready for welding tomorrow.

Once that’s done I think we’re good to go

The idea being to covert a Turnigy thrust measuring stand, designed for electric motors, to be able to test fuelled motors.

The main problem to me seemed to be stopping fuel residue from gumming up everything.

I made a platform to mount it on and removing the control panel from the base, placed it behind a piece of wood away from the engine stand, extending and running the wiring underneath the platform.

The aluminium plate (cut by a mate of mine who’s runs a water jet cutter, very handy machines) is for covering the engine stand to hopefully keep most of the fuel residue off it. The three sides, left, top and right will be folded back to form two sides and a top over the engine stand. The flat top of the engine stand will protrude through the slot (the X shaped engine mount is removed for fitting) and the area below the slot is for fixing the cover to the plywood base.

I bought a cheap science stand (ebay $7 out of China, free shipping) mainly for the clamps for mounting the tacho, and also allowing for adjustment fore and aft with different size engines.

Cover folded and seams welded and mounted to base

Of course the Bee’s engine mounting holes wouldn’t fit the supplied mounts

so a suitable mount had to be made out of a piece of scrap alloy.

so a suitable mount had to be made out of a piece of scrap alloy.

Next bend up some 6mm stainless rod for the tacho mount. Ran it through some steel cable clips to act as bushes and fabricated a backstop for the rod but leaving a gap so it can be removed if needed.

Bolted a couple of steel tabs to the base so the whole unit can be clamped in a vice.

Probably overkill but there may end up some bigger motors being tested

Drew a design for the tacho mount and sent it off to my mate for cutting out.

Bent it up at one end and made a hole for the tacho lens to fit through. Made some slots fore and aft (front slots hidden by clamps) for rubber bands holding the tacho unit.

All clamped up ready for welding tomorrow.

Once that’s done I think we’re good to go

Davenz13- Platinum Member

- Posts : 597

Join date : 2013-11-28

Age : 69

Location : Palmerston North, New Zealand

Re: Turnigy thrust stand conversion

Re: Turnigy thrust stand conversion

Well done Daven a Greenie for your efforts and sharing with us!!

Look forward to your tests!!

Look forward to your tests!!

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Turnigy thrust stand conversion

Re: Turnigy thrust stand conversion

Cheers for that Brad.

Gathering fuel ingredients and hope to start testing in about a week. Will try to get videos of test to post.

Gathering fuel ingredients and hope to start testing in about a week. Will try to get videos of test to post.

Davenz13- Platinum Member

- Posts : 597

Join date : 2013-11-28

Age : 69

Location : Palmerston North, New Zealand

Re: Turnigy thrust stand conversion

Re: Turnigy thrust stand conversion

Dave. While I have little understanding of the technical "nuts & bolts" of a thrust meter, I am concerned that, in my humble opinion, the centre thrust line of any engine mounted to the stand would need to align with the centre of the original mount. I'm assuming that the stand works on leverage and any deviation to the length of the "lever" will skew your results.

Rod.

Rod.

Oldenginerod- Top Poster

- Posts : 4018

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: Turnigy thrust stand conversion

Re: Turnigy thrust stand conversion

Yes, the measurement is most likely based on leverage around a rotation point.

One could easily recalibrate the scale though. With a non running engine would could use a dynometer to pull on the prop axis and read the "trust" meter in order get a conversion factor.

There is/was a nice thread on RCU on how to measure trust (some time ago now); http://www.rcuniverse.com/forum/1-2-1-8-airplanes-70/1562254-1-2a-thrust-o-meter.html

One could easily recalibrate the scale though. With a non running engine would could use a dynometer to pull on the prop axis and read the "trust" meter in order get a conversion factor.

There is/was a nice thread on RCU on how to measure trust (some time ago now); http://www.rcuniverse.com/forum/1-2-1-8-airplanes-70/1562254-1-2a-thrust-o-meter.html

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Turnigy thrust stand conversion

Re: Turnigy thrust stand conversion

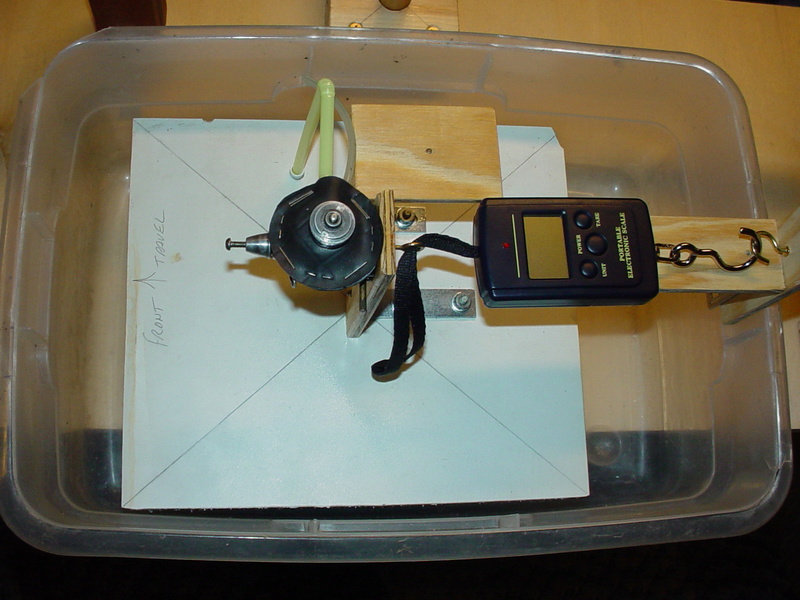

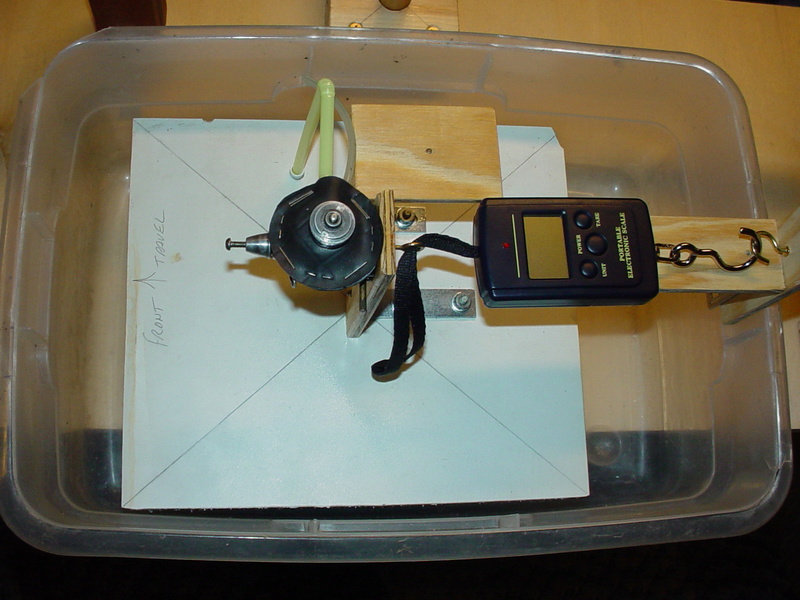

Really nice work there Dave! Does the Turnigy unit measure thrust through a conversion of torque? In other words; does the motor/engine-mount move/turn "radially"? A few years ago, I built two prototype "dyno's".. for measuring thrust on a linear-plane (pulling-force) through the use of digital hanging-style luggage-scales. I'd thought about "torque".. and how to build a mount that would turn like a dial.. but there are so many variables.. that I didn't pursue it. There's a thread here on the work I did.. and the Turnigy-unit came up in the discussion at that time. I like what you've done with it.

My first attempt was a "beam-design" that pivoted on a central-pin.. but there were variables involved that directly affected accuracy with varying-weight engines/set-ups (fuel-weight.. etc.) and balancing the beam. The design; as well as the need for it, was met with some controversy.. and I ended up abandoning the design for a "direct-pull" through the use of a floating-fixture placed in a small tub of water. The scale was attached rigidly to the tub via a horizontal tray to hold it stationary. The floating fixture has 1-2" of travel and uses a hook to engage and tension the scale-hook. A simple square block of buoyant-foam was used to float the fixture in 1-2" of water (approx. one gallon)

and I ended up abandoning the design for a "direct-pull" through the use of a floating-fixture placed in a small tub of water. The scale was attached rigidly to the tub via a horizontal tray to hold it stationary. The floating fixture has 1-2" of travel and uses a hook to engage and tension the scale-hook. A simple square block of buoyant-foam was used to float the fixture in 1-2" of water (approx. one gallon)

The prototype needs refinement.. ... but it does seem to work.

... but it does seem to work.

My first attempt was a "beam-design" that pivoted on a central-pin.. but there were variables involved that directly affected accuracy with varying-weight engines/set-ups (fuel-weight.. etc.) and balancing the beam. The design; as well as the need for it, was met with some controversy..

and I ended up abandoning the design for a "direct-pull" through the use of a floating-fixture placed in a small tub of water. The scale was attached rigidly to the tub via a horizontal tray to hold it stationary. The floating fixture has 1-2" of travel and uses a hook to engage and tension the scale-hook. A simple square block of buoyant-foam was used to float the fixture in 1-2" of water (approx. one gallon)

and I ended up abandoning the design for a "direct-pull" through the use of a floating-fixture placed in a small tub of water. The scale was attached rigidly to the tub via a horizontal tray to hold it stationary. The floating fixture has 1-2" of travel and uses a hook to engage and tension the scale-hook. A simple square block of buoyant-foam was used to float the fixture in 1-2" of water (approx. one gallon) The prototype needs refinement..

Re: Turnigy thrust stand conversion

Re: Turnigy thrust stand conversion

Very valid points being raised here.

The test stand comes with two mounts, one larger than the other and the center line of the larger mount is higher than the smaller one when mounted on the bed table. The bed table runs through bearings on two horizontal rods running fore and aft. Through a hole in the rear of the table is an upright post wired to the digital meter. When the engine pulls the table forward the table pushes on the post. Since the table slides forward and doesn’t pivot I’m not sure if it would have any gain in readings from the increased height above the table, it might even have the reverse effect by causing the bushes to bind a bit on the rods and reduce the readings.

The main reason I built it is to have a constant and hopefully reliable test bed so that any variations in prop, fuel or exhaust can be accurately measured and seen as whether they’re improvements or not in the engine being tested. With a throttled engine one should be able to plot a revs/thrust graph.

The bed is set up for Baby Bee engines (or any with the same back plate) at present and is at the same height (or very close to) the supplied small mount so there should be no problems in seeing accurate comparisons between them, apples with apples so to speak. If the actual thrust reading is slightly out it won’t really matter, it will still show variations.

If your bathrooms scales are set high or low they might not show your actual weight but they still show if you gain or lose some.

All good in theory but then, so was the Titanic

The test stand comes with two mounts, one larger than the other and the center line of the larger mount is higher than the smaller one when mounted on the bed table. The bed table runs through bearings on two horizontal rods running fore and aft. Through a hole in the rear of the table is an upright post wired to the digital meter. When the engine pulls the table forward the table pushes on the post. Since the table slides forward and doesn’t pivot I’m not sure if it would have any gain in readings from the increased height above the table, it might even have the reverse effect by causing the bushes to bind a bit on the rods and reduce the readings.

The main reason I built it is to have a constant and hopefully reliable test bed so that any variations in prop, fuel or exhaust can be accurately measured and seen as whether they’re improvements or not in the engine being tested. With a throttled engine one should be able to plot a revs/thrust graph.

The bed is set up for Baby Bee engines (or any with the same back plate) at present and is at the same height (or very close to) the supplied small mount so there should be no problems in seeing accurate comparisons between them, apples with apples so to speak. If the actual thrust reading is slightly out it won’t really matter, it will still show variations.

If your bathrooms scales are set high or low they might not show your actual weight but they still show if you gain or lose some.

All good in theory but then, so was the Titanic

Davenz13- Platinum Member

- Posts : 597

Join date : 2013-11-28

Age : 69

Location : Palmerston North, New Zealand

Re: Turnigy thrust stand conversion

Re: Turnigy thrust stand conversion

When I first notice the Turnigy test stand I though long and hard on getting one...hey they are actually pretty cheap

The the how do I keep castor OUT of the works set in....

I like this idea and exercise in the shield but I would want to see how the sensor is actuated to set in my mind if or if not fuel oil is really a problem....

Looking forward to how this turns out... I wish I had this relative device back when I was trying to see how various venturi opening sizes effected the TeeDees I was fussing with

I actually could see a tach race where top RPM and Thrust...given a set fuel and prop were in the mix for the contest...

Top RPM is not the best gage of the POWER of a particular engine

The the how do I keep castor OUT of the works set in....

I like this idea and exercise in the shield but I would want to see how the sensor is actuated to set in my mind if or if not fuel oil is really a problem....

Looking forward to how this turns out... I wish I had this relative device back when I was trying to see how various venturi opening sizes effected the TeeDees I was fussing with

I actually could see a tach race where top RPM and Thrust...given a set fuel and prop were in the mix for the contest...

Top RPM is not the best gage of the POWER of a particular engine

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: Turnigy thrust stand conversion

Re: Turnigy thrust stand conversion

I believe that a static-thrust meter is a valuable tool for model aero-engine performance-measurement.

Re: Turnigy thrust stand conversion

Re: Turnigy thrust stand conversion

I would actually be more interested in a torque reading myself.

The static thrust at a given rpm tells you something about the prop itself, but not so much about the engine really. The in-fligth thrust values are also very easy, and more fun, to test in the air.

The torque and rpm reading would instead give you the power curve of the engine, which says much more about the engine and which prop-loads that one can/should use.

Below is a power plot for a few .15 engines based on my own data. The values are very inaccurate though as they assume a prop-load based on the propsize alone, and there are no reliable source for the individual props that takes blade area and shape, true pitch and true diameter into account. With a torque reading one could bolt any wooden stick in the front, and still get an accurate power reading.

can't upload the picture.... x)

The static thrust at a given rpm tells you something about the prop itself, but not so much about the engine really. The in-fligth thrust values are also very easy, and more fun, to test in the air.

The torque and rpm reading would instead give you the power curve of the engine, which says much more about the engine and which prop-loads that one can/should use.

Below is a power plot for a few .15 engines based on my own data. The values are very inaccurate though as they assume a prop-load based on the propsize alone, and there are no reliable source for the individual props that takes blade area and shape, true pitch and true diameter into account. With a torque reading one could bolt any wooden stick in the front, and still get an accurate power reading.

can't upload the picture.... x)

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Turnigy thrust stand conversion

Re: Turnigy thrust stand conversion

Well it’s taken a while but I finally got a chance to get back into this project. I purchased all the ingredients for some fuel late last year but just couldn’t seem to get time to get at it. Anyway a break in the schedule gave me some time so I mixed some fuel up the other day and decided to give the bee’s a run. The straight case bee runs slightly better than the narrow nose case one by about 800 revs or so. Not sure why but I’ll mount the better engine on the inboard side when they go on the tether car.

They don’t seem to run for long flat out so I’ve ordered two larger 8cc tanks. Also ordered a 1oz plastic tank to fit on the test stand as well. Is the 9000 range about right for a bee or should the go higher. It did hit 10 briefly but seem to sit in the 99 range mainly. Prop is a Thimble Drome 5D 3P Fuel mix is

Methanol 55%

Nitro 25%

Klotz Castor 12%

Klotz synthetic 8%

I’ll try to get them on the test stand this week and play round with some different props and see how that goes.

If you're wondering why the tacho is upside down, I'm a lefty

They don’t seem to run for long flat out so I’ve ordered two larger 8cc tanks. Also ordered a 1oz plastic tank to fit on the test stand as well. Is the 9000 range about right for a bee or should the go higher. It did hit 10 briefly but seem to sit in the 99 range mainly. Prop is a Thimble Drome 5D 3P Fuel mix is

Methanol 55%

Nitro 25%

Klotz Castor 12%

Klotz synthetic 8%

I’ll try to get them on the test stand this week and play round with some different props and see how that goes.

If you're wondering why the tacho is upside down, I'm a lefty

Davenz13- Platinum Member

- Posts : 597

Join date : 2013-11-28

Age : 69

Location : Palmerston North, New Zealand

Re: Turnigy thrust stand conversion

Re: Turnigy thrust stand conversion

9.5K on 25% nitro w/5-3 prop?? That's one sick engine you've got there. I've got a shagged out rotten 1950 K&B Torpedo .049 that will do that.

http://www.airplanesandrockets.com/motors/torpedo-049-air-trails-november-1950.htm

http://www.airplanesandrockets.com/motors/torpedo-049-air-trails-november-1950.htm

ticomareado- Account Under Review

- Posts : 1089

Join date : 2013-10-03

Location : NC

Re: Turnigy thrust stand conversion

Re: Turnigy thrust stand conversion

Hi Dave, You should be seeing a lot more rpm's.. especially with that fuel blend. Are the engines freshly rebuilt? The integral-tanks can be a real issue if there's any leaks (air or fuel). Everything needs to seal. Don't forget to check/replace the little venturi-gasket in-between the tank-bowl and backplate. The needle-threads need to seal.. and the case-gasket needs to seal. It's fairly common that one or more of the crankcase hole-threads (2-56 size) weren't tapped all the way to the bottom of the hole. A screw could be "bottoming" in the case before tightening against the backplate. This would cause a leak in-between the screw-head and backplate.

It's a good idea to source a 2-56 bottoming-tap to properly fix this. Alternately.. you can shorten a screw by grinding a very small amount off.. but you have to note which location/screw, whenever the engine is taken apart and then reassembled.

I don't have any experience with the drop-in (insert-type) glow plugs. I see that the engine in your photo has one installed. Maybe it's not sealing tight-enough? Try swapping it with a known-good OEM style glowhead and see if there's any improvement.

It's a good idea to source a 2-56 bottoming-tap to properly fix this. Alternately.. you can shorten a screw by grinding a very small amount off.. but you have to note which location/screw, whenever the engine is taken apart and then reassembled.

I don't have any experience with the drop-in (insert-type) glow plugs. I see that the engine in your photo has one installed. Maybe it's not sealing tight-enough? Try swapping it with a known-good OEM style glowhead and see if there's any improvement.

Re: Turnigy thrust stand conversion

Re: Turnigy thrust stand conversion

Thanks Roddie, I had a feeling it should do a lot better than that hence the post. This is the first time I've ever run a cox engine so I'll keep at it. The last time I ran a model engine was an OS 40 about 40 years ago when I flew a bit of R/C. What revs should it reach.

Davenz13- Platinum Member

- Posts : 597

Join date : 2013-11-28

Age : 69

Location : Palmerston North, New Zealand

Re: Turnigy thrust stand conversion

Re: Turnigy thrust stand conversion

Davenz13 wrote:Thanks Roddie, I had a feeling it should do a lot better than that hence the post. This is the first time I've ever run a cox engine so I'll keep at it. The last time I ran a model engine was an OS 40 about 40 years ago when I flew a bit of R/C. What revs should it reach.

My pleasure Dave. Your Babe Bee should produce 13-14K rpm's on that fuel with that propeller. The 5" x 3" prop is a good choice.. and your fuel-blend is too.

I was unaware that you hadn't ran a Cox engine before. I recently (for the first time..) tore-down a few Cox .049 reed-valve engines completely. I'd never pulled a drive-plate off to remove the crankshaft before. It's a simple process.. and I would not hesitate now. There's a tiny oil-groove in the crank-journal of the case which lubricates the crankshaft. After a time.. congealed castor-oil (varnish) will accumulate. You can "see it" when removing the crankshaft. This dried-varnish tends to "sit" in there. This varnish "softens" with the heat of operation.. and acts like glue between the crankshaft and journal. Fresh-fuel doesn't wash it out because there's virtually no "blow-by" through the nose of the case due to tight clearances there. This condition is enough to "sap" significant power from an engine.. if not dealt with.

Castor-based fuel is a maintenance-concern.. BUT it's a protector of model-engines; particularly vintage/"bushed" engines.

Do you know the history of your Cox engines? If not; they could be gummed-up inside.

Re: Turnigy thrust stand conversion

Re: Turnigy thrust stand conversion

I've had the engine apart, soaked it in meths and cleaned it all up. I reset the ball and socket and reassembled with new gaskets, seals and needle and the insert type glow plug. I'll go over it for air leaks and see how I get on. Never stop learning.

Davenz13- Platinum Member

- Posts : 597

Join date : 2013-11-28

Age : 69

Location : Palmerston North, New Zealand

Re: Turnigy thrust stand conversion

Re: Turnigy thrust stand conversion

I ordered a 2-56 bottom tap and tapped the threads as far as they would go. Got an extra couple of turns on each . Even though the gasket and tank seal were new when the engines were assembled, since the engines had to be partially dismantled to fit the 8cc tanks I replaced them anyway (cheap enough) and checked the backplates where the tank rim fits.

I also removed one head gasket from each engine, had originally fitted two.

I removed the needle springs and fitted a section of silicone tube and washer as shown elsewhere in the forum.

Had to be careful that the outer rim of the washer didn’t bind on the test stand.

I also drilled a hole in the test stand opposite the intake to allow a better airflow.

Either one or all of these mods helped as the narrow nose Bee reached just over 13k (this engine has more side and end play in the crank to case fit than the straight nose Bee) and the straight nose Bee reached just over 14K (14137).

That seems in the ballpark of your figures Roddie so I’ll refit the engines to the car and give it a run.

Slowly, ever so slowly making progress

I also removed one head gasket from each engine, had originally fitted two.

I removed the needle springs and fitted a section of silicone tube and washer as shown elsewhere in the forum.

Had to be careful that the outer rim of the washer didn’t bind on the test stand.

I also drilled a hole in the test stand opposite the intake to allow a better airflow.

Either one or all of these mods helped as the narrow nose Bee reached just over 13k (this engine has more side and end play in the crank to case fit than the straight nose Bee) and the straight nose Bee reached just over 14K (14137).

That seems in the ballpark of your figures Roddie so I’ll refit the engines to the car and give it a run.

Slowly, ever so slowly making progress

Davenz13- Platinum Member

- Posts : 597

Join date : 2013-11-28

Age : 69

Location : Palmerston North, New Zealand

Re: Turnigy thrust stand conversion

Re: Turnigy thrust stand conversion

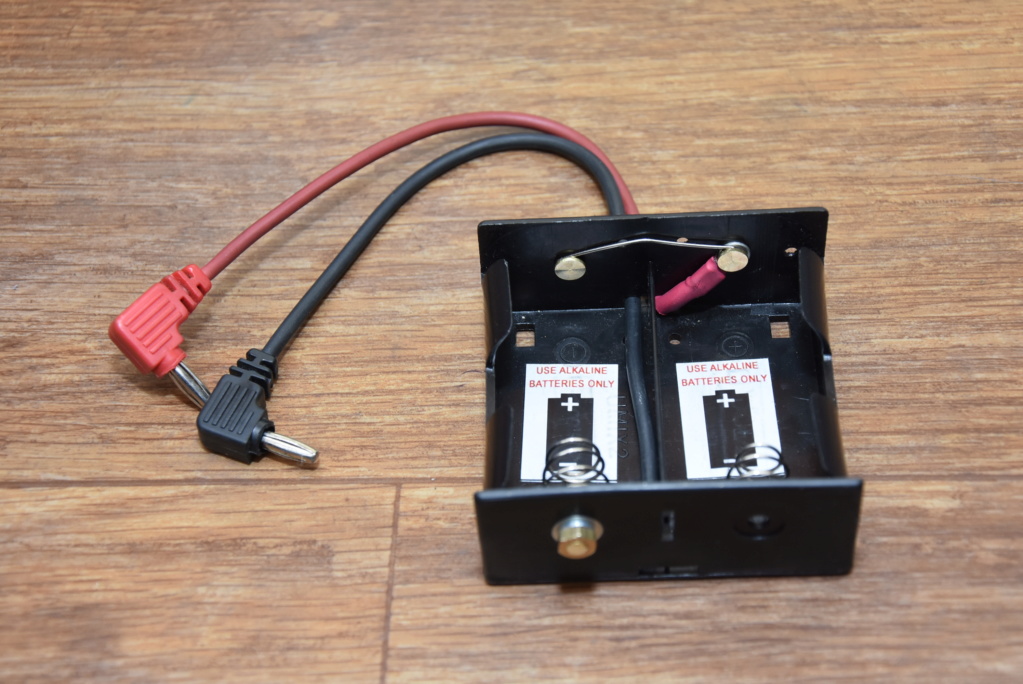

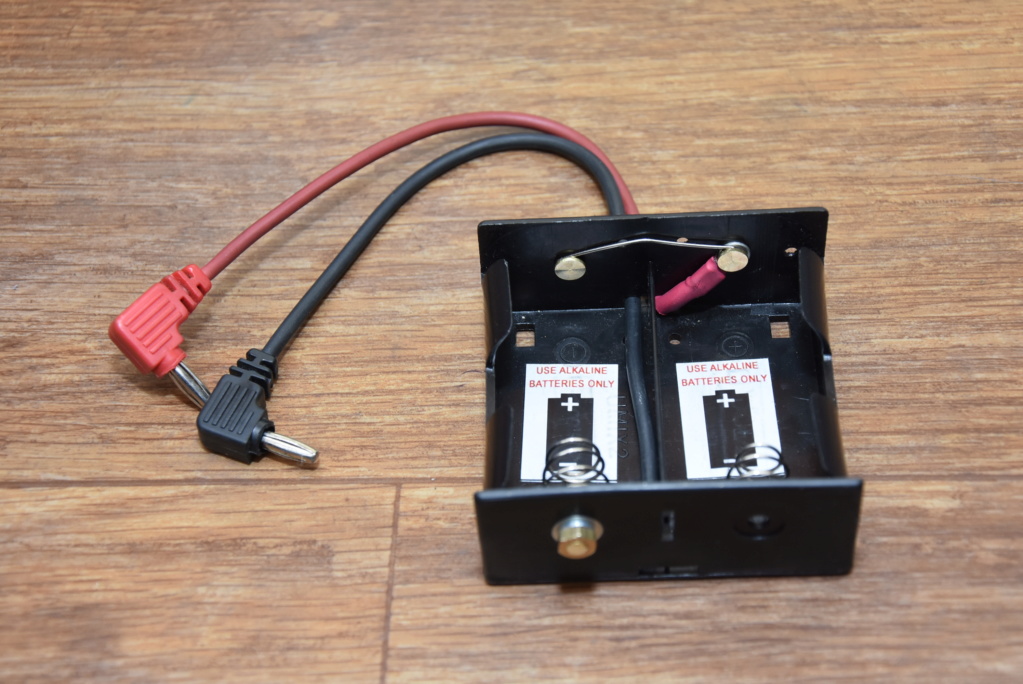

Well it’s been a year since I last did anything on the dyno build/conversion.

Since completing the tether car for the CATS competition and still being in modeling mode I thought I’d get this project completed.

Cutting up a spare set of multi-meter leads I wired these into the battery box.

I also did away with the rivet connections and turned the heads down on some brass machine screws to get a tighter more permanent connection and, hopefully, eliminate any bad connections in the future.

I fitted a Perspex cover to keep fuel residue from the readout panel and battery box area.

I fitted positive and negative terminals with the push in receptors on the inside under the cover and the glow plug wiring on the outside.

The engine mount I made was only drilled for Cox Bee motors so I added some holes so horseshoe motors can be tested as well.

I do believe it’s finally ready to use.

It’s doing a lot of raining with miserably cold days down here as we head into winter but, if I can match time with a fine day, I’ll give it a trial run.

Since completing the tether car for the CATS competition and still being in modeling mode I thought I’d get this project completed.

Cutting up a spare set of multi-meter leads I wired these into the battery box.

I also did away with the rivet connections and turned the heads down on some brass machine screws to get a tighter more permanent connection and, hopefully, eliminate any bad connections in the future.

I fitted a Perspex cover to keep fuel residue from the readout panel and battery box area.

I fitted positive and negative terminals with the push in receptors on the inside under the cover and the glow plug wiring on the outside.

The engine mount I made was only drilled for Cox Bee motors so I added some holes so horseshoe motors can be tested as well.

I do believe it’s finally ready to use.

It’s doing a lot of raining with miserably cold days down here as we head into winter but, if I can match time with a fine day, I’ll give it a trial run.

Davenz13- Platinum Member

- Posts : 597

Join date : 2013-11-28

Age : 69

Location : Palmerston North, New Zealand

depends may be a bad habit

depends may be a bad habit

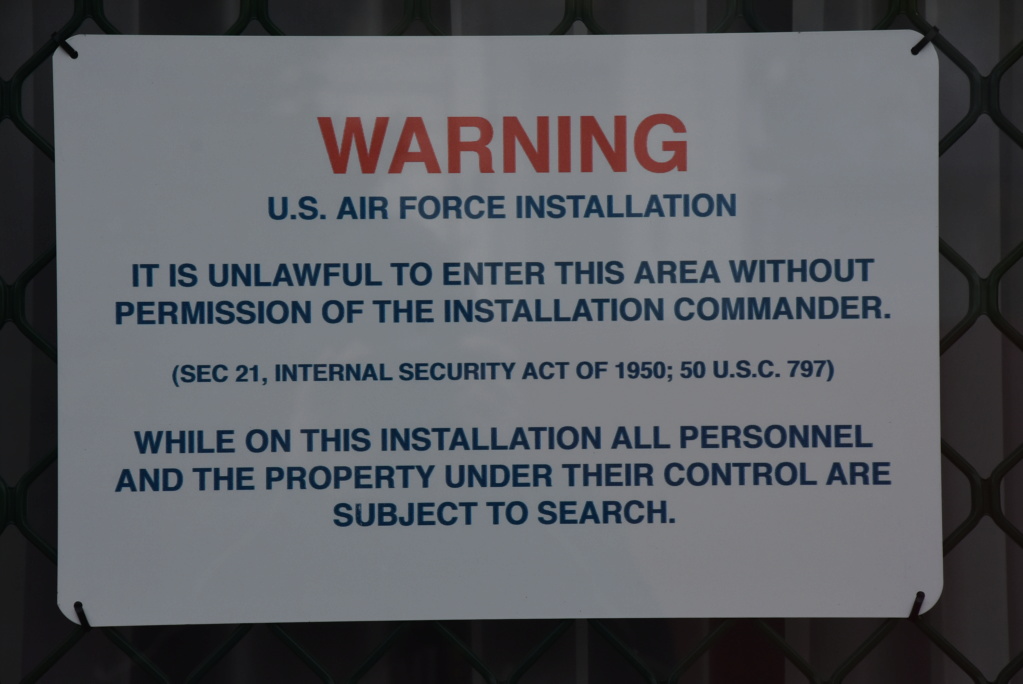

I see that our Palmerston North, New Zealand member is a security sign thief.....try as I might, I can not find a more PC term.....sorry.........it just might be that a weather event blew that sign on to Davenz13s property.....now not a thief but just removed the litter from the street/yard/driveway/roof

"Installation Commander" sounds Military to me...."---subject to search" sounds Military also

So collector of valuable and dangerous art, Davenz13

can you post a photo of the whole sign and some background?

"Installation Commander" sounds Military to me...."---subject to search" sounds Military also

So collector of valuable and dangerous art, Davenz13

can you post a photo of the whole sign and some background?

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: Turnigy thrust stand conversion

Re: Turnigy thrust stand conversion

Hi Fred

You don’t have to worry about being PC with me but as we’re on a website forum I understand where you’re coming from. World’s gone PC mad. Not allowed to say “fat” and now there’s moves afoot down here to have obese added to the list as it’s being called offensive, I guess skinny will be next on the list. Anyway, back to the sign.

In 2016 a mate and I wanted to come to the US to watch the Sacramento mile (flat-track racing) so we decided we might as well make a decent trip out it. Over an eight-week period, starting from the West coast (Seattle) and finishing on the East coast (Boston) we visited 14 aircraft bases, airports and aircraft restoration centers, 6 naval museums including the USS New Jersey, USS Wisconsin and USS Constitution, numerous motorcycle shops and wrecking yards.

While travelling through Arizona we also visited a decommissioned Titan Missile site which is where I got the sign.

Now it would be great to say I evaded vicious dogs and armed guards to grab the sign off the perimeter fence while the alarms sirens were blasting and spotlights were sweeping the mined desert floor but the only hardship I had in obtaining the sign was standing in line at the counter of the souvenir shop

I live in an industrial building (no lawns, very little garden, lots of parking and lots of room) and I have the sign attached to the door. It gets a lot of comments, one slightly tipsy lady wanted to know when were we going to be doing the searching.

Just recently I heard voices outside and turned to the door to see two males looking at the sign then at the building and generally looking a bit confused. When I opened the door, they asked me was this really a US Air Force Installation as they weren’t sure whether they should knock or not. They were Mormons doing their thing and even after assuring them this was a private address they still looked back a few times as they walked away.

I suppose the barred and grilled windows and the electronic security gate and fence added to their doubt.

I also bought a unit called a dosimeter dated August 7 1972. You just never know when that might come in handy.

You don’t have to worry about being PC with me but as we’re on a website forum I understand where you’re coming from. World’s gone PC mad. Not allowed to say “fat” and now there’s moves afoot down here to have obese added to the list as it’s being called offensive, I guess skinny will be next on the list. Anyway, back to the sign.

In 2016 a mate and I wanted to come to the US to watch the Sacramento mile (flat-track racing) so we decided we might as well make a decent trip out it. Over an eight-week period, starting from the West coast (Seattle) and finishing on the East coast (Boston) we visited 14 aircraft bases, airports and aircraft restoration centers, 6 naval museums including the USS New Jersey, USS Wisconsin and USS Constitution, numerous motorcycle shops and wrecking yards.

While travelling through Arizona we also visited a decommissioned Titan Missile site which is where I got the sign.

Now it would be great to say I evaded vicious dogs and armed guards to grab the sign off the perimeter fence while the alarms sirens were blasting and spotlights were sweeping the mined desert floor but the only hardship I had in obtaining the sign was standing in line at the counter of the souvenir shop

I live in an industrial building (no lawns, very little garden, lots of parking and lots of room) and I have the sign attached to the door. It gets a lot of comments, one slightly tipsy lady wanted to know when were we going to be doing the searching.

Just recently I heard voices outside and turned to the door to see two males looking at the sign then at the building and generally looking a bit confused. When I opened the door, they asked me was this really a US Air Force Installation as they weren’t sure whether they should knock or not. They were Mormons doing their thing and even after assuring them this was a private address they still looked back a few times as they walked away.

I suppose the barred and grilled windows and the electronic security gate and fence added to their doubt.

I also bought a unit called a dosimeter dated August 7 1972. You just never know when that might come in handy.

Davenz13- Platinum Member

- Posts : 597

Join date : 2013-11-28

Age : 69

Location : Palmerston North, New Zealand

Re: Turnigy thrust stand conversion

Re: Turnigy thrust stand conversion

his thread was too fun to leave as is from 18 months ago

so bump

curious about the Turnigy testor and military stuff

so bump

curious about the Turnigy testor and military stuff

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: Turnigy thrust stand conversion

Re: Turnigy thrust stand conversion

I have a Turnigy test stand.

All it is , is a small load cell mounted to the motor(engine) stand.

Simple enough to do if you have a loadcell to get and mount it to a table with an engine to check torque.

This from:

Former Torque wrench inspector for Caterpillar who did countless of torque wrenches every 4 months to make them certified to torque specification for precision assembly.

Worked with many load cells for many years!

From 0.5Nm to 700Nm (Newton Meters) force.

All it is , is a small load cell mounted to the motor(engine) stand.

Simple enough to do if you have a loadcell to get and mount it to a table with an engine to check torque.

This from:

Former Torque wrench inspector for Caterpillar who did countless of torque wrenches every 4 months to make them certified to torque specification for precision assembly.

Worked with many load cells for many years!

From 0.5Nm to 700Nm (Newton Meters) force.

sosam117- Diamond Member

- Posts : 1350

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: Turnigy thrust stand conversion

Re: Turnigy thrust stand conversion

not sure why this 60~70 buck item is $150+

https://www.amazon.com/Pukido-Lander-Thrust-Measuring-Tester/dp/B07HLTXGND/ref=pd_sbs_1?pd_rd_w=feI9W&pf_rd_p=ed1e2146-ecfe-435e-b3b5-d79fa072fd58&pf_rd_r=S4PFSEF89801TCKKDA24&pd_rd_r=17a9b6d0-209f-403e-b9cf-6c24628fd7c6&pd_rd_wg=TXBZB&pd_rd_i=B07HLTXGND&psc=1

https://www.amazon.com/Pukido-Lander-Thrust-Measuring-Tester/dp/B07HLTXGND/ref=pd_sbs_1?pd_rd_w=feI9W&pf_rd_p=ed1e2146-ecfe-435e-b3b5-d79fa072fd58&pf_rd_r=S4PFSEF89801TCKKDA24&pd_rd_r=17a9b6d0-209f-403e-b9cf-6c24628fd7c6&pd_rd_wg=TXBZB&pd_rd_i=B07HLTXGND&psc=1

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Similar topics

Similar topics» Turnigy .05 - .07 4wd Racing Buggy 1/16

» How Much Thrust

» Engine thrust meter

» Thrust Washer

» Who is Building

» How Much Thrust

» Engine thrust meter

» Thrust Washer

» Who is Building

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules